Time after time we receive extremely positive feedback while presenting our diverse selection tools. Our aim is to provide precise and reliable ventilation solutions for HVAC designers to add to their design plans – also for the most unusual projects.

1. Composition obstacles

Composition obstacles affect the throw pattern of the terminal but not always in an obstructing way. By examining the throw pattern when also the obstacles of the room have been modeled you can ensure that both your chosen terminal is suitable and its location is correct.

This feature is especially useful in renovation projects where the location of the ventilation terminals is often set with little room for changes. To avoid draught it is particularly important to examine composition obstacles’ impact on ventilation.

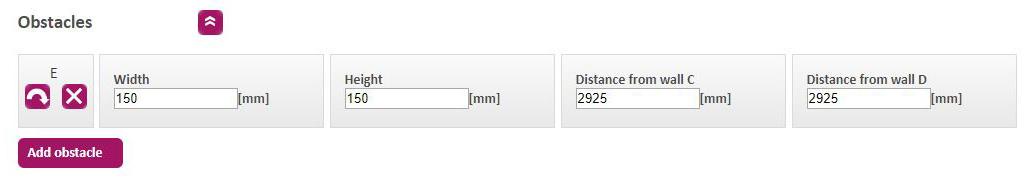

You can model obstacles in Vent.X Throw pattern designer in “Obstacles” section. After adding an obstacle, you can modify its width, height and location. Also, multiple obstacles can be added by using the “Add obstacle” button.

2. Diffuser positioning buttons

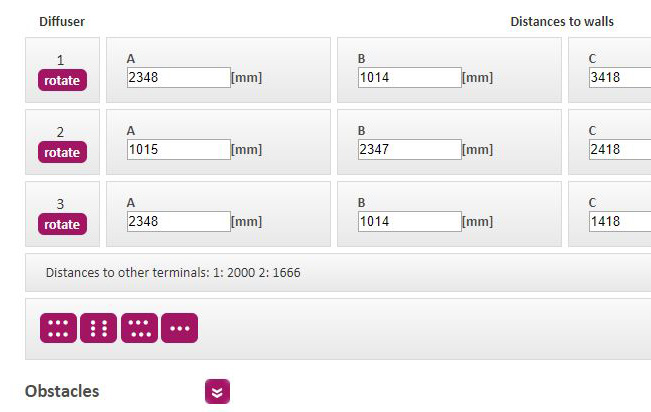

To speed up the design process, Vent.X provides buttons for positioning the terminals. Examining the center points and relationships is usually slow in design softwares, whereas our diffuser positioning function places the terminals symmetrically in relation to each other and to the room. This way the designer can automatically locate the chosen terminals in a room extremely fast and precisely.

When you insert a number bigger than 1 in ”Pcs” box in Vent.X throw patter design, the diffuser positioning buttons appear in the bottom of the “Diffuser” section with which you can automatically center or locate the terminals.

3. Optimizing the throw pattern

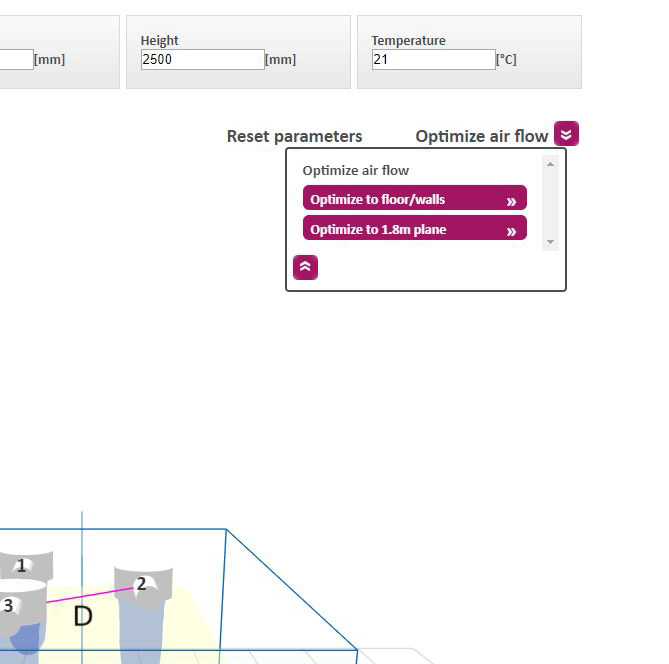

The throw pattern optimization feature enables you to adjust the air flow according to your preferences. This supports the design process because modeling air flows to a specific room area in desired temperatures is often difficult and requires complex calculations.

In some cases, it is important to make sure that the throw pattern reaches an exact point of the area. After this the number of terminals is adjusted to reach the needed air flow in the room.

For HVAC designers this means that there is no need for making tricky calculations. Also, parameters of the devices can be modified and the impacts of these changes can be examined in Vent.X.

The function can be used by inserting the wanted parameters, such as the room height, supply air flow, room temperature and the location of the terminal in the room. After this, press the ”Optimize air flow” button on top of the simulation view. You can optimize the air flow to reach the floor, the walls or to remain at 1,8 meter height from the floor plane.