A 100% maintenance-free professional kitchen hood or ceiling ventilation solution does not exist. Even the most advanced systems require up-keeping – similarly to any other kitchen device. What makes the difference is just how much maintenance is required?

As an answer to that, Climecon’s CleanMaster® hoods do not require regular maintenance, thanks to their highly effective cleaning technology. We recommend a brief look-up every now and then. In case the device detects an error, it sends an automated notification to the user which is also available for the building automation system. The savings from the generally low maintenance costs combined with the resource-saving notification system of CleanMaster® devices result in significantly low life-cycle costs.

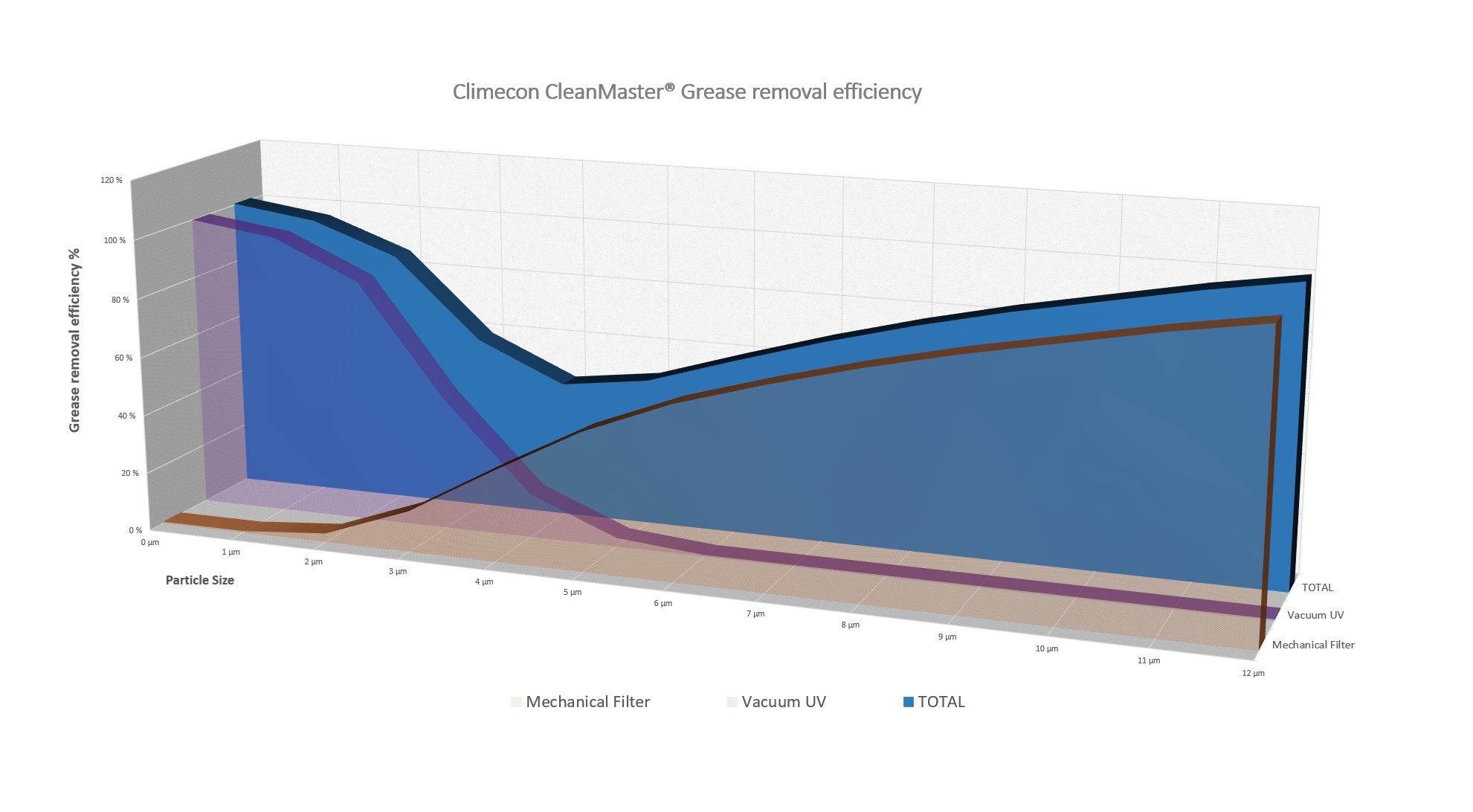

Cleaning power with effective UV technology

The CleanMaster® system uses a special-made UV-tube with the longest lifespan on the markets. The UV tube is designed specifically for professional kitchen use granting flawless performance also in temperatures over 90 C, which is impressive compared to the traditional UV tubes significantly losing their effectiveness when the temperatures exceed 40 C.

The most advanced cleaning system combining 4 separate cleaning techniques guarantees clean crease chambers. The UV technologies of two different wave lengths clean the air flowing through the chambers. Additionally, ozone finishes grease degradation eliminating odors.

Safety and user-friendliness

Safety is always the top priority for us. The CleanMaster® system is equipped with a patented SlideSafe safety mechanism shutting down the device in case of an error.

Safety and usability have been taken to the next level with a special lighting, OptiLumo specifically designed for professional kitchen use. The pioneering optics provide advanced luminous intensity distribution minimizing the dazzling effect at the work station. Kitchen professionals praise the ideal color temperature of the feature as well. Thanks to the dazzle-free design, the long shifts at the kitchen don’t come at the expense of accuracy to detailed visual tasks.

Our professional kitchen ventilation solutions have been designed to stand time technically as well as visually. The high-quality Climecon kitchen devices provide an economic and long-term solution for any kitchen where high-functioning and user-friendly ventilation solutions as well as fire-safety are highly valued.