Easy product search using various criteria

When choosing a product, you can define which criteria are used and find the one you like from the options using the highlighted criteria. There are several criteria to choose from in the basic view, and even rarer criteria can be found in the plus icon.

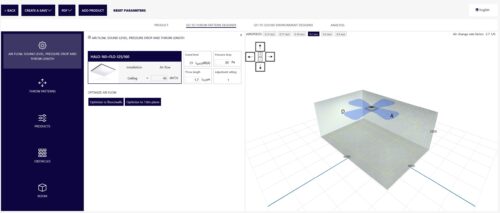

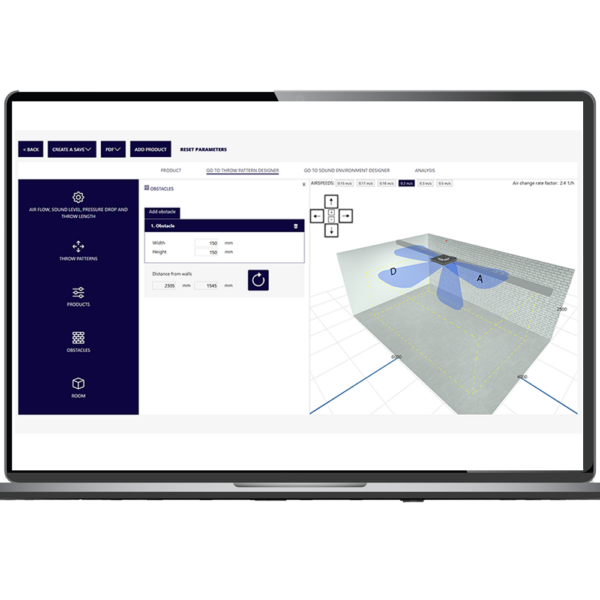

Many dimensioning and modeling functions are arranged logically

Once the product has been selected, you can model and dimension its distribution pattern and design the sound environment. Also, see the quality analysis from the tab at the top of the screen in the Analysis tab. On the left side of the simulation screen, the choices related to the product and the space are divided under a few intuitive selections. Changing the product and room specifics laterally opens the fields for filling.

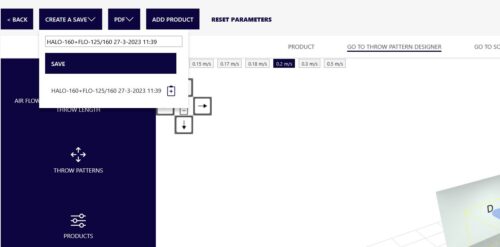

Add devices and finally save your plan

Several pieces of the same device or more different devices can be brought into the design using the blue buttons at the top of the view. Among the same buttons, there is also a save function, which can be used to save the plan for later continuation, sharing, or adding to the project plan.

Do you or your team need training in using Vent.X renewed selection program in the design of ventilation terminals? Our ventilation design expert Marko will show the basic functions and power-user tips for accurate and reliable design process.