Adjustment accuracy classes are given for terminal devices and plenum boxes, depending on the margin of error in their adjustment. Class 1 allows a maximum variance of 5% between the designed and actual airflows, for class 2 up to one tenth difference is allowed. These differences must remain at the same level even after the control section has been removed, for example during maintenance. The range of the devices’ adjustment is also considered when testing the devices. Precise adjustment and a wide adjustment range are therefore prerequisites for achieving measurement accuracy of class 1.

FLO combines precise adjustment and reliable locking

The high dimensional accuracy of FLO plenum boxes is ensured by a unique control section that measures the pressure difference across the control section instead of pressure difference between the room and the device. In this way a very high accuracy is achieved. Additionally, the adjustment position remains in place with a reliable SlideFix locking mechanism.

FLO is suitable for both OLO and HALO diffusers for suspended ceiling systems. With FLO’s proven precision in adjustment and the directed throw pattern of the terminal devices, draft-free and controlled indoor climate can be designed at offices, business premises and school sites.

Accurate equipment for controlled ventilation system

If inaccurate devices are used in the ventilation system, a device-specific error will affect the operation of all devices throughout the entire channel system. Especially at low air volumes and duct velocities, supply air left in the duct may be significantly less than planned for the last devices.

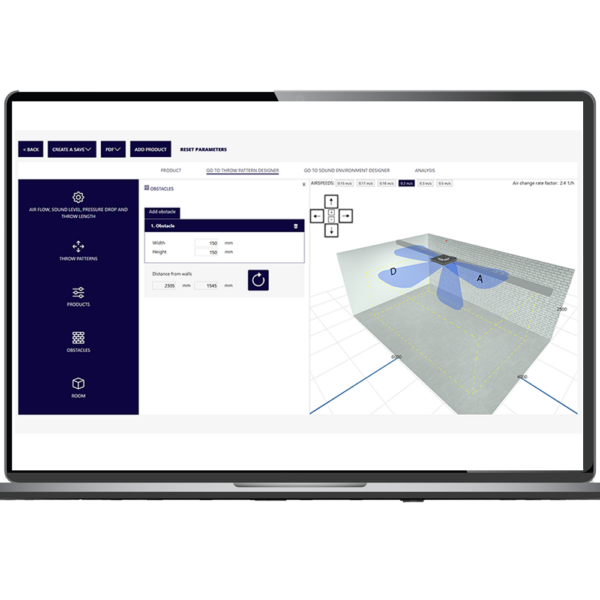

Using the precise and pre-adjusted FLO also significantly speeds up simplifying the adjustment process and ensuring accurate air volumes and sound levels. Preset values are obtained directly from the designs, from MagiCAD, and Revit, and ventilation designers can rest assured that the devices operate within the desired airflow and sound range.