Ventilation design as part of building information modeling

The aim of building information modelling (BIM) is to bring the diverse parties involved in various phases of a building life-cycle closer to one another ramping up efficiency and streamlining work-flow in large-scale, international building and infrastructure projects. Integrated ventilation design and data-based air-flow modelling play an important role in creating buildings of the future.

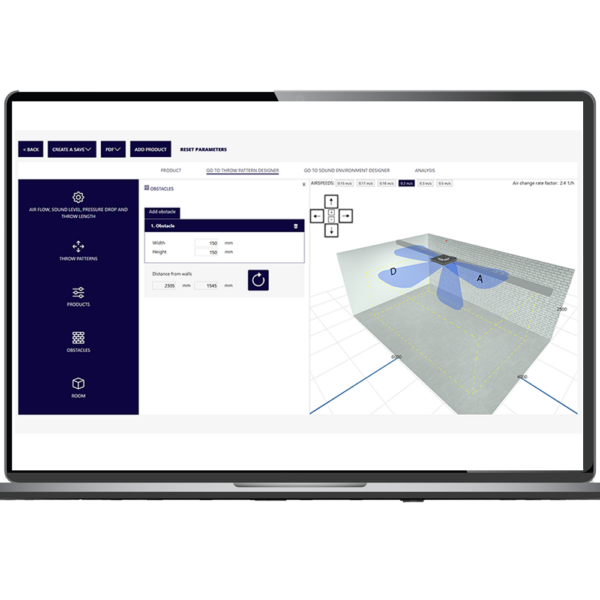

Reliable ventilation design brings efficiency to the planning and installation phases of building and construction projects not to mention have an impeccable influence on the comfort and health factors of the end-users. Widely used design software’s and accurate CFD modelling tools are an integral part of designing healthy indoor atmosphere.

Design accuracy and reliable performance values are also heavily linked to reoccurring costs throughout the building lifecycle. Due to the vastness of ventilation systems, the data quality and accurate objects at the design stage become increasingly important factors on the path towards energy efficient buildings and sustainable living.

This sets high demands for selection tools of air terminal devices and ventilation solutions to comply precise air flows, sound levels and throw patterns.

The speakers at the Progman conderence are prestigious experts in the field and Rytivaara makes no exception. In addition to selection tool training, Antti has been highly involved in developing Climecon’s selection tools and plugins to better serve the needs of HVAC designers as well as containing the evolving requirements in cooperation with Progman.

Designing quiet work places with accurate tools

“Possibly the greatest distinctive factor of Climecon selection tools’ is that they involve sound properties”, states Rytivaara. From BIM perspective, this represents a major step towards utilization of smart objects in MEP design. Comprehensive, accurate designs that cover sound environment design, are keys to well-functioning indoor environments and healthy buildings. “No wonder our selection tools have been acquired as everyday tools in leading designing companies.”

Rytivaara began his career in HVAC design and states customer-centric approach to the development of the Climecon selection tools as the greatest factor behind their vast success. “How the devices function within the tools bases on actual, tested values. Accurate modelling on top of ease of use have been at the core of development. With these tools a designer gets exactly what they bargain for, no more or less – which is ideal in HVAC designing.”

Climecon selection tools and their plugins for Revit and MagiCAD offer reliable tools for professional use build on our knowledge of our devices, expertise on sound technique and ventilation. Accurate dimensioning within the tools is based on performance values verified by a sovereign third party testing institution.

If you’re interested in a free tutorial on Climecon selection tools, don’t hesitate to contact us:

Antti Rytivaara

[email protected]

+358 50 406 6071