Description

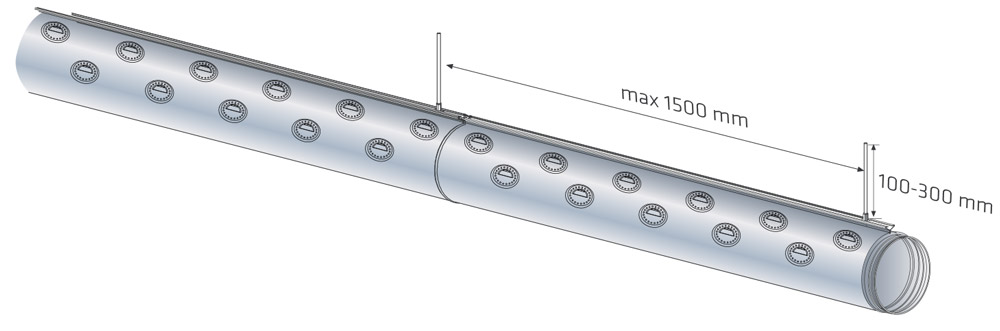

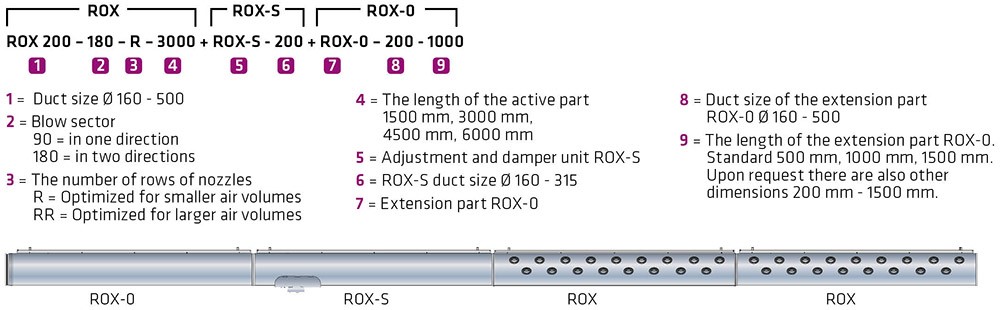

The set includes an active and adaptable supply air unit (ROX), accurate and easy-to-use control part (ROX-S) and non-perforated extension part (ROX-0).

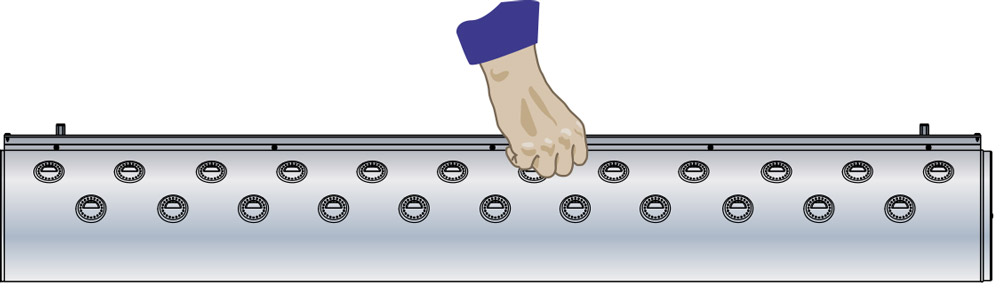

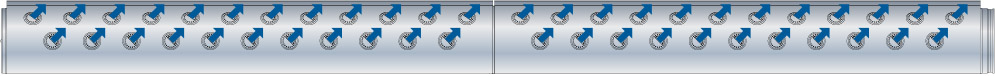

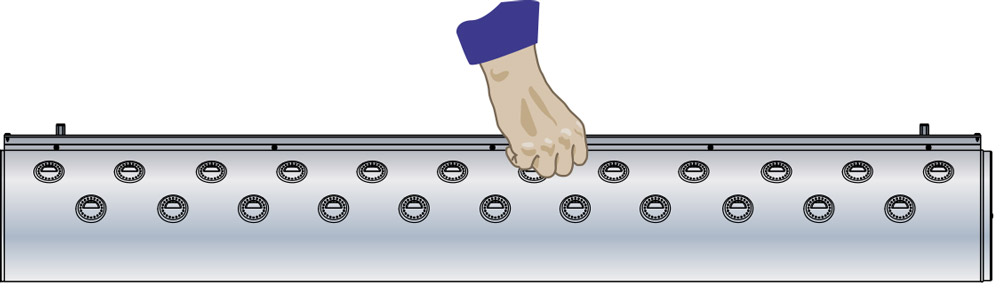

ROX is equipped with unique directable CliMix® nozzles, which combine 100% adaptable throw pattern and a high mixing ratio. Changing the throw pattern of ROX is easy in connection with rearrangement of space by directing nozzles to the desired direction with the help of the adjustment tool supplied with the product. Thanks to an ingenious structure of CliMix® nozzles the surface of the nozzles will also stay completely clean.

ROX is a part of the new OptiFlow® product family!

OptiFlow® products adapt to changes in the life cycle of the space due to an optimized and adaptable throw pattern.

A stylish package

The nozzles embedded in the surface of ROX provide a uniformly stylish and easy to clean package. In addition to the standard white color RAL 9016, ROX is available in edgy black RAL 9005 or an impressively stainless steel color RAL 9007/9023.

Advanced adjustment and damper unit

ROX-S-adjustment and damper unit has a very high immunity to interference. The adjustment unit allows a precise adjustment of airflow (± 5%) even at low airflows and duct speeds. The design of ROX-S fits perfectly with ROX so that they together form a stylish and polished package.

Watch a video of ROX nozzle duct

Applications

Particularly suitable for rooms in which large draftless and quiet amounts of air are required, such as:

- Schools and kindergartens

- Canteens and restaurants

- Museums and lecture halls

- Laboratories

- Industrial premises

- Also the premises where the intended use or the space arrangements may change during the product’s lifecycle

Quick guide

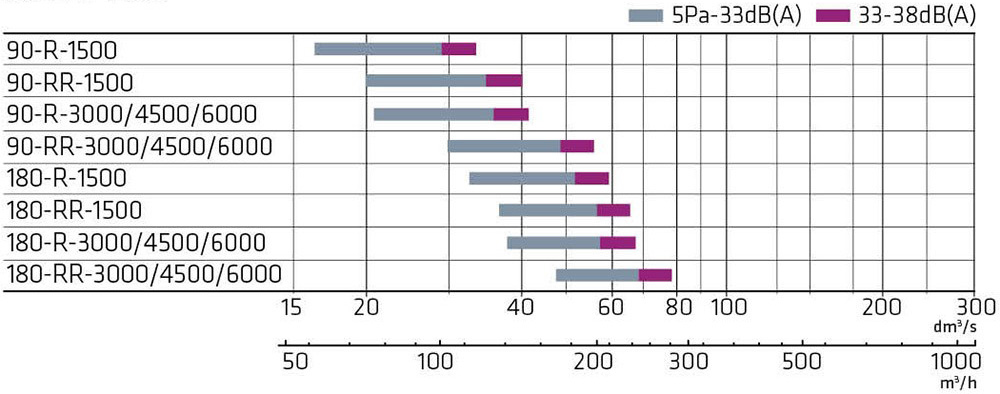

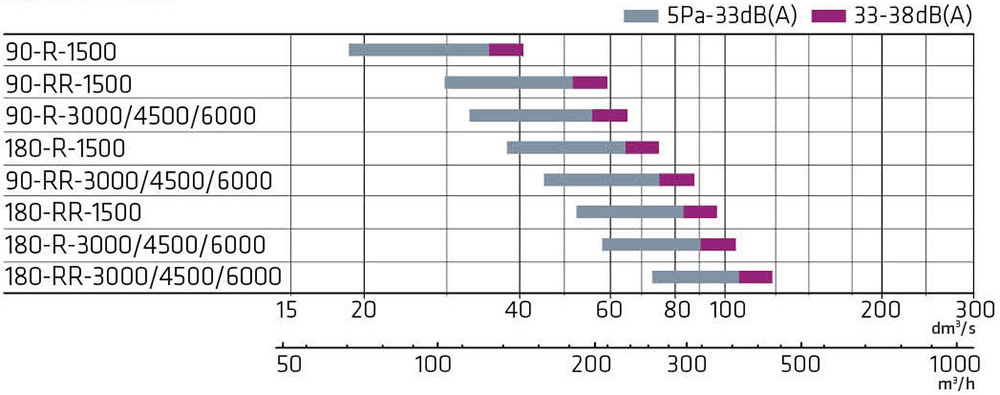

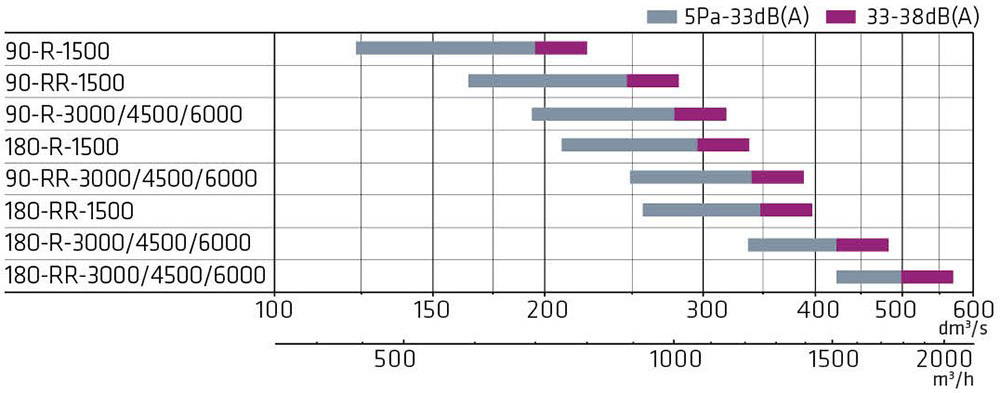

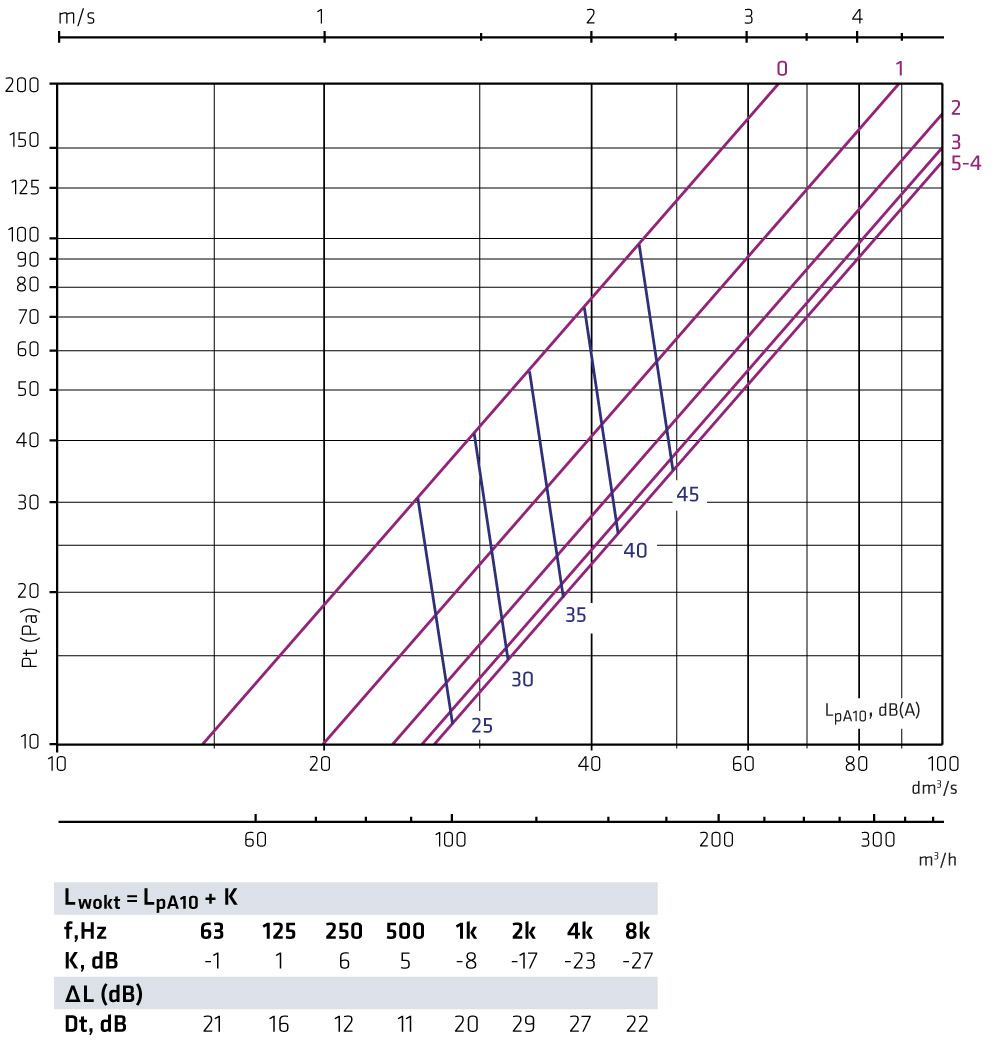

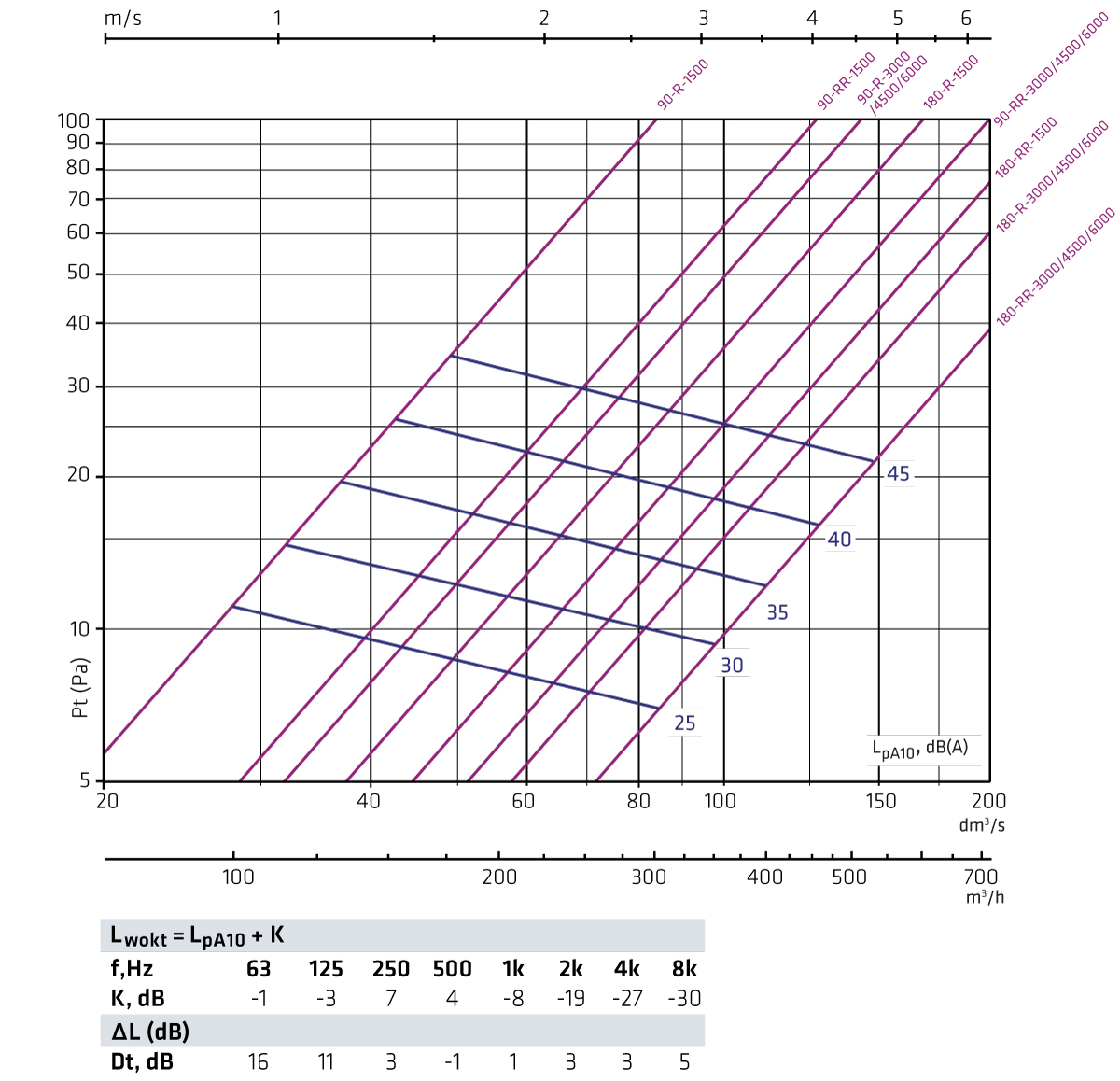

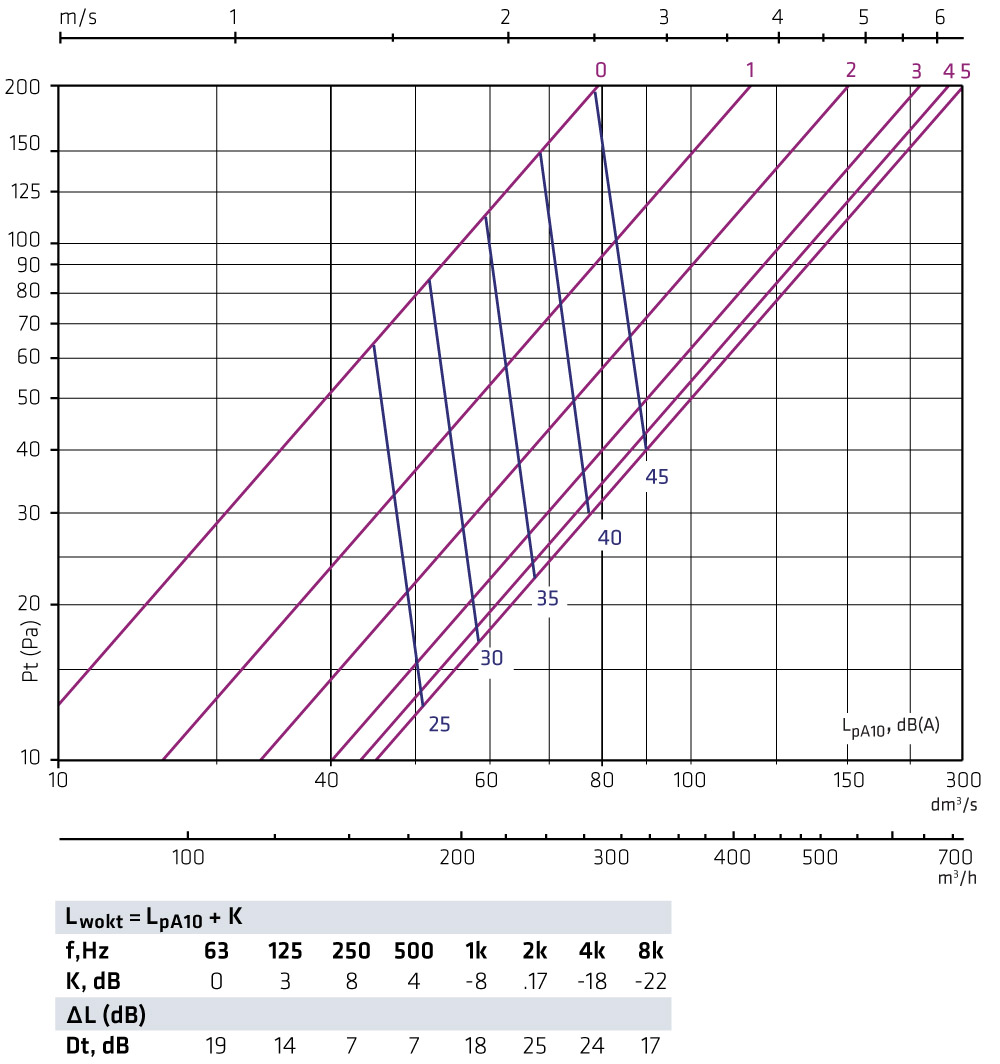

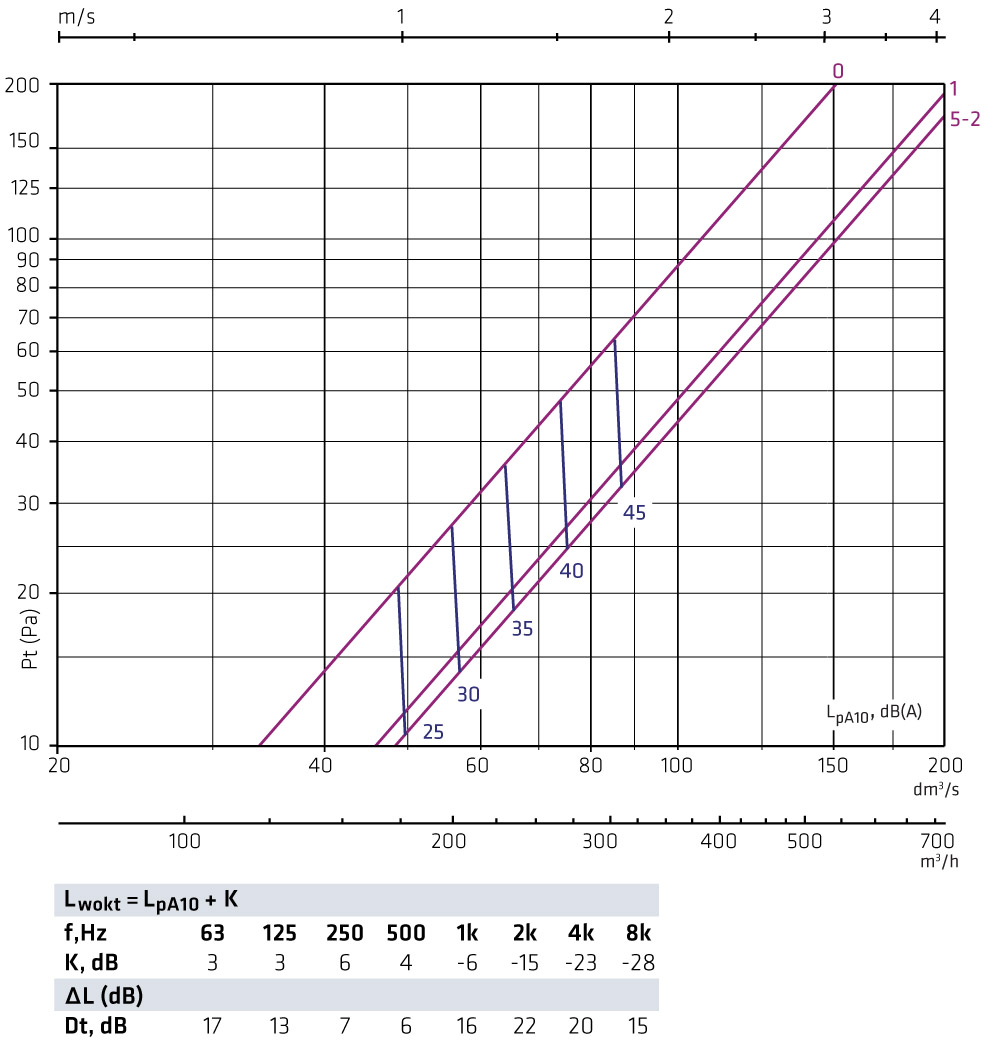

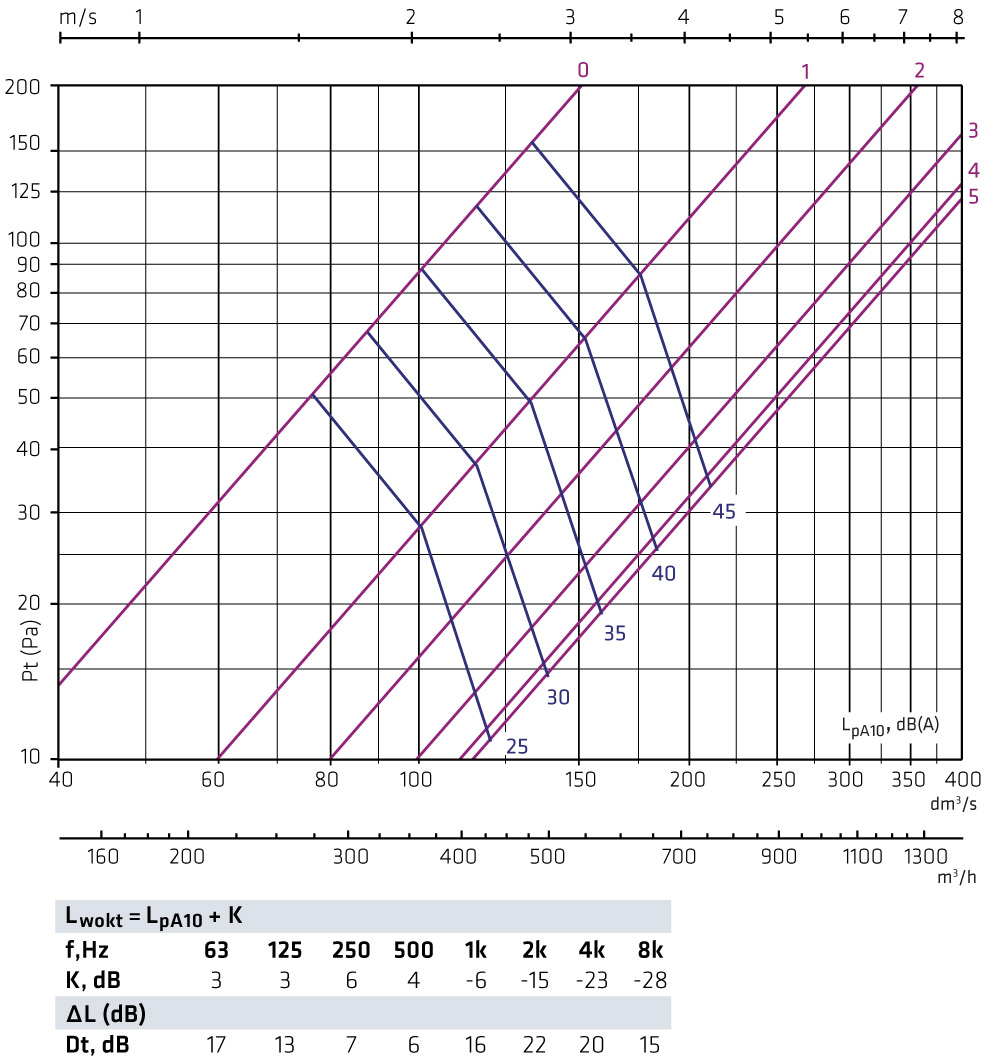

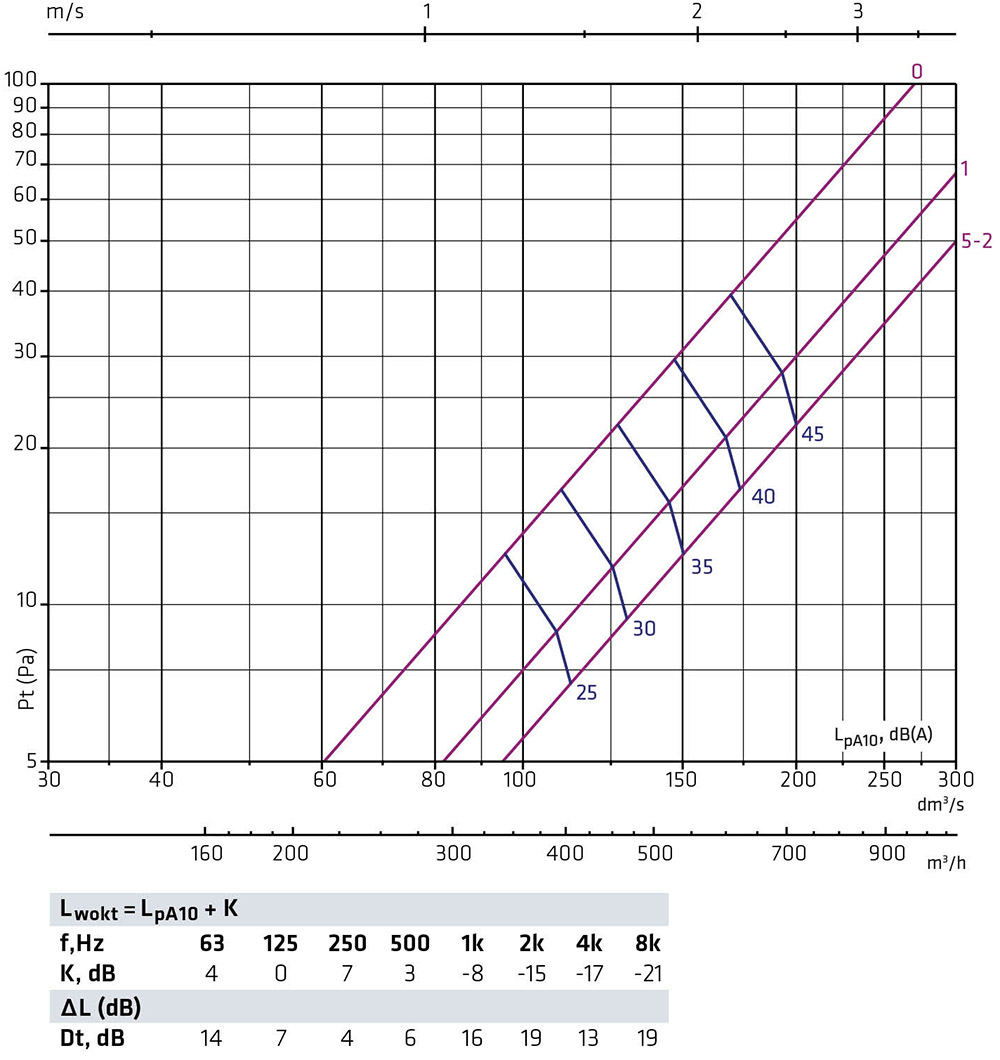

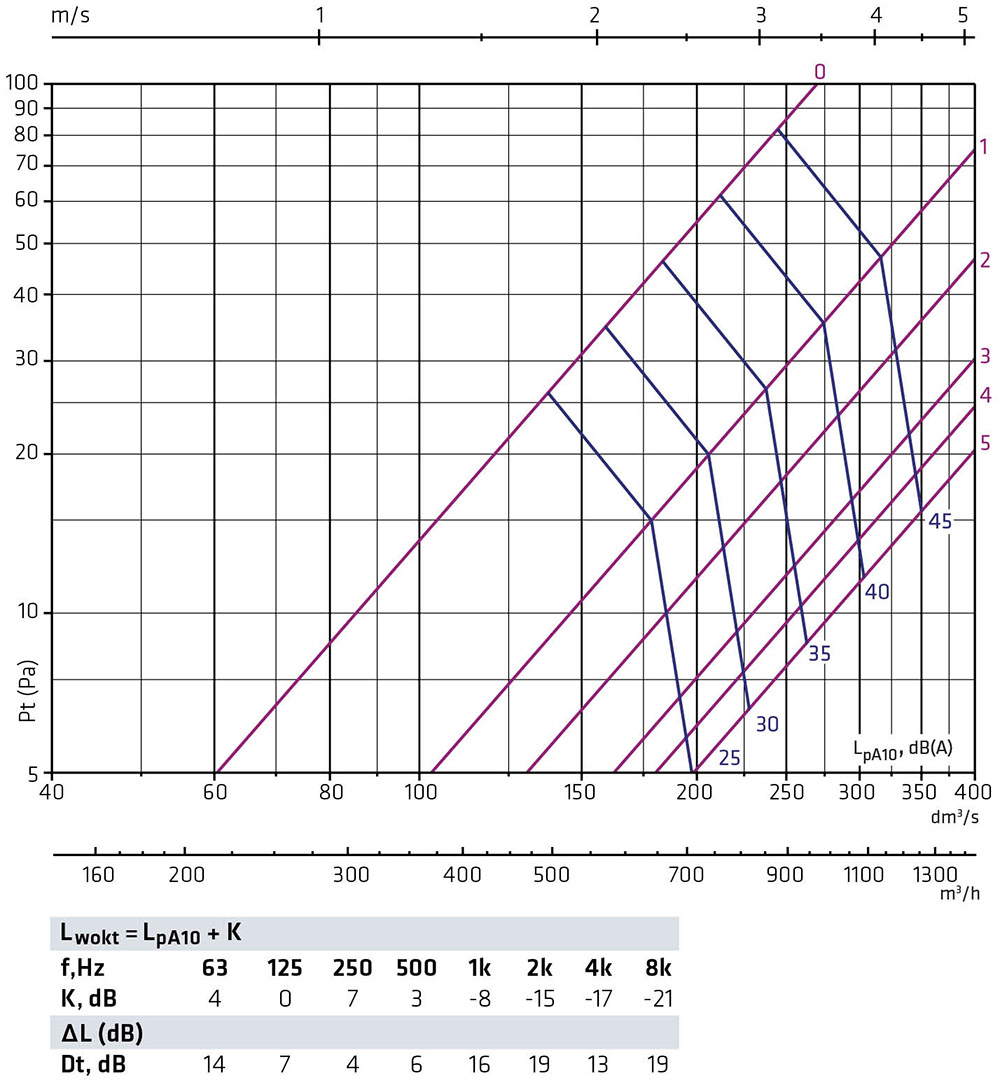

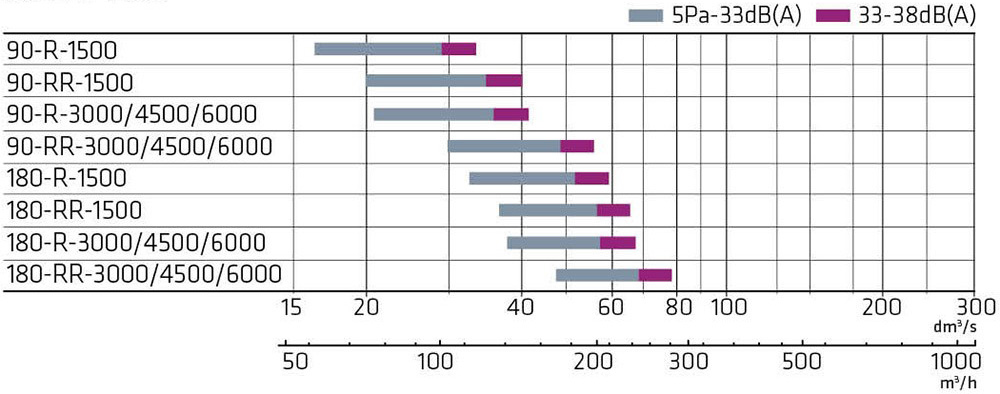

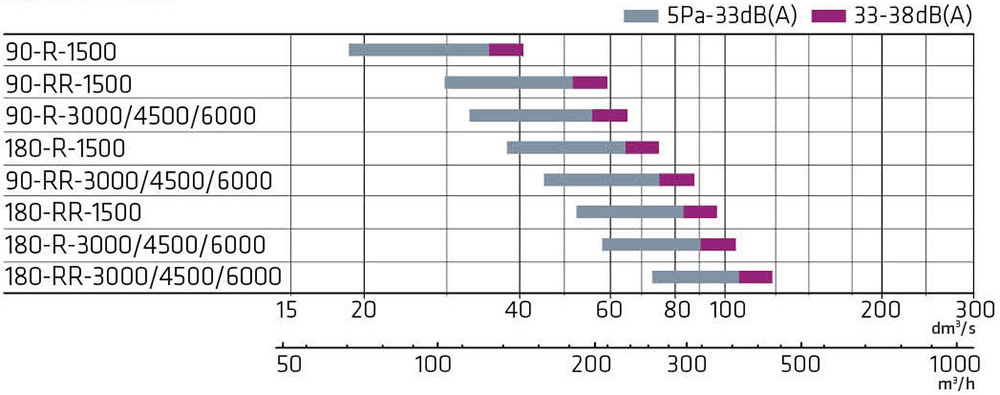

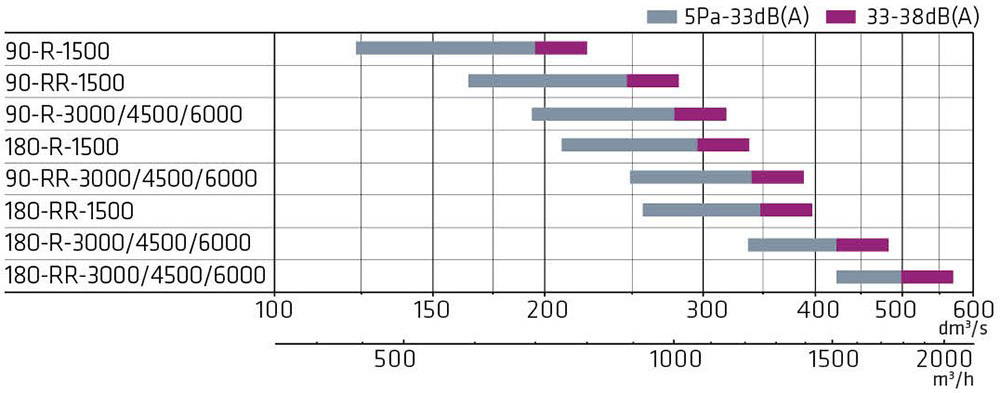

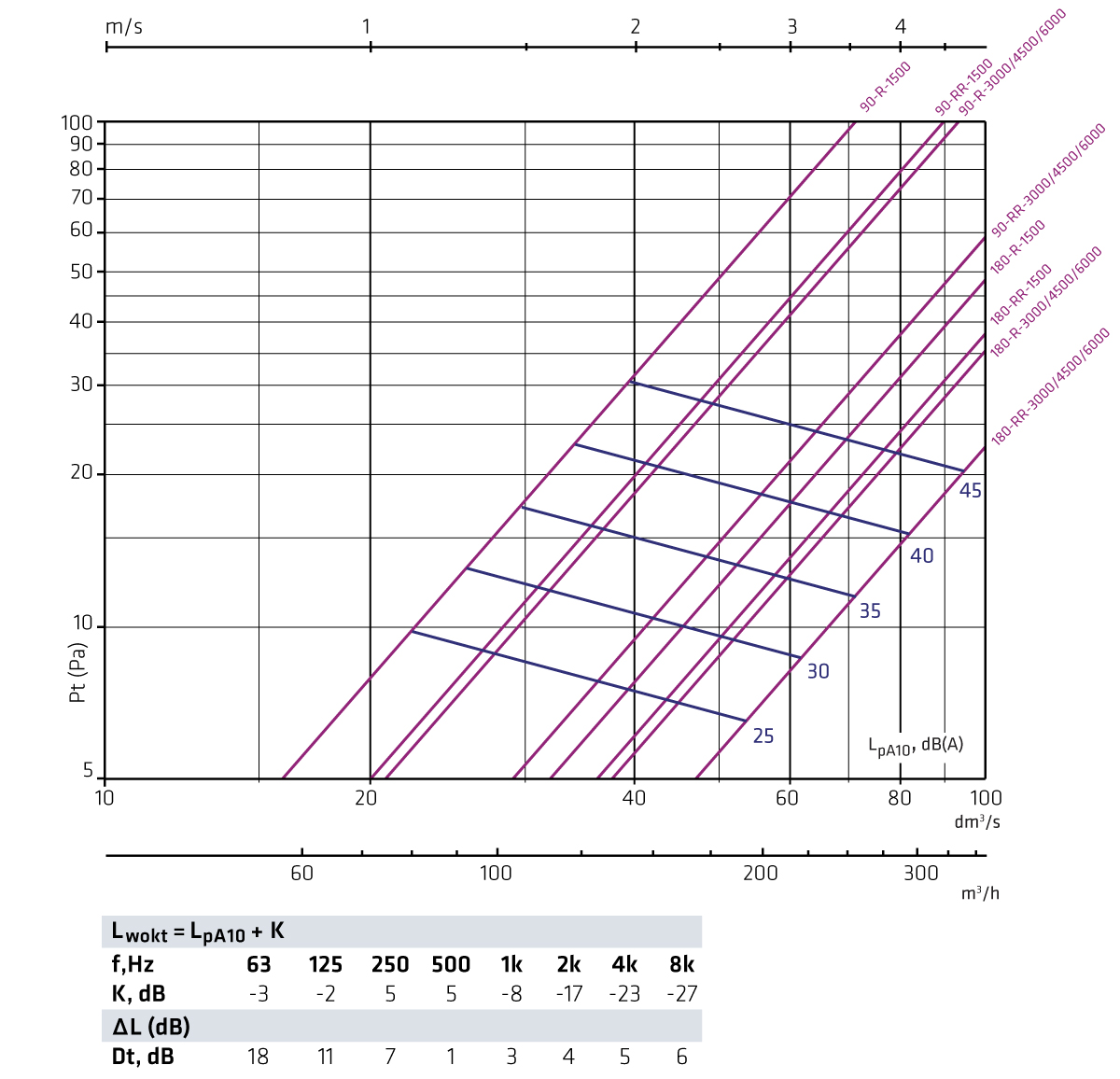

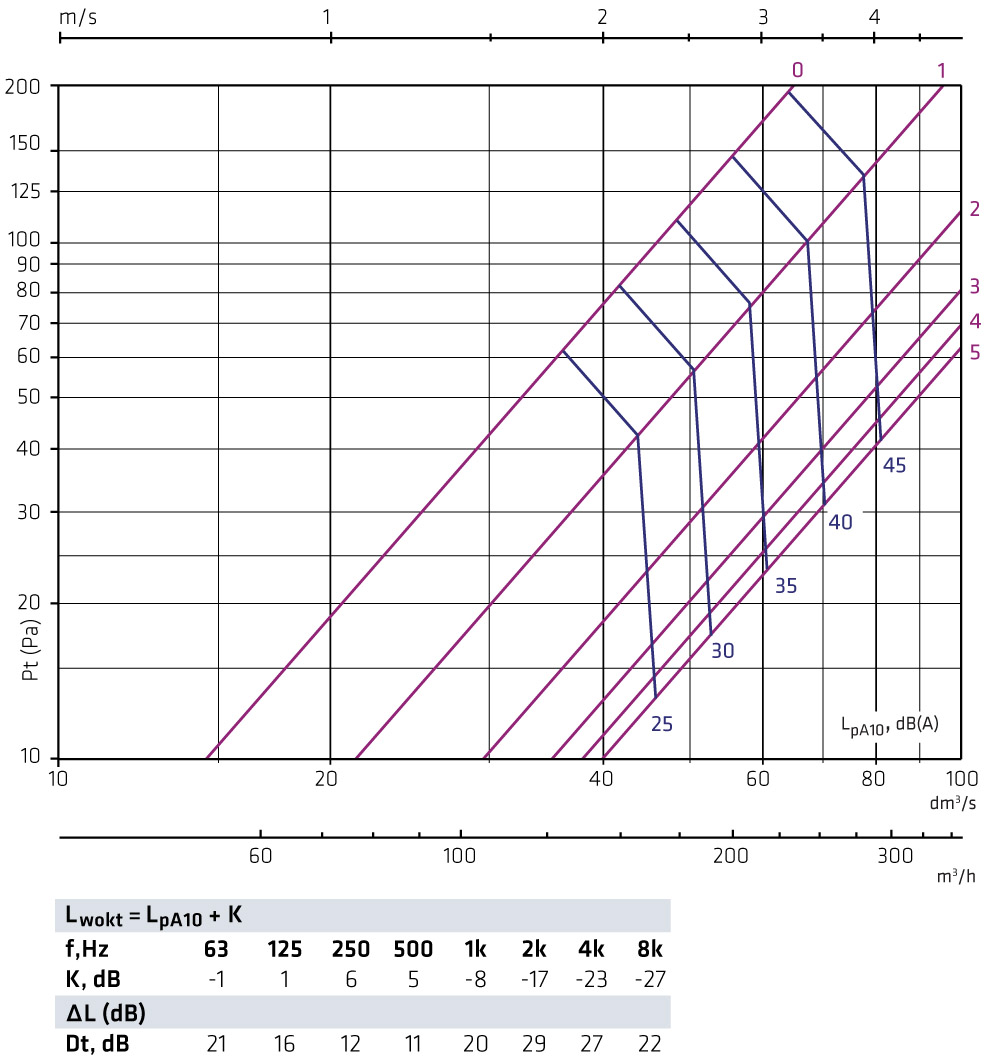

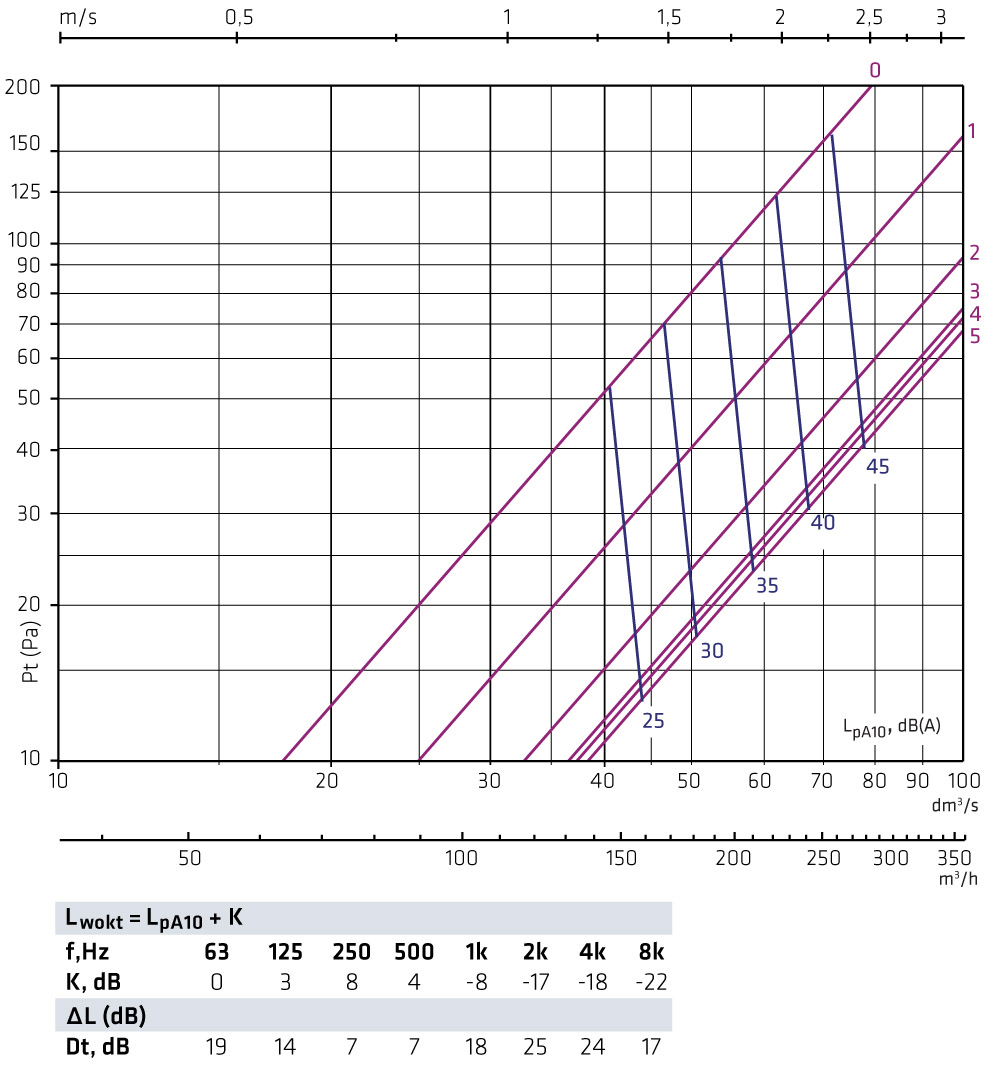

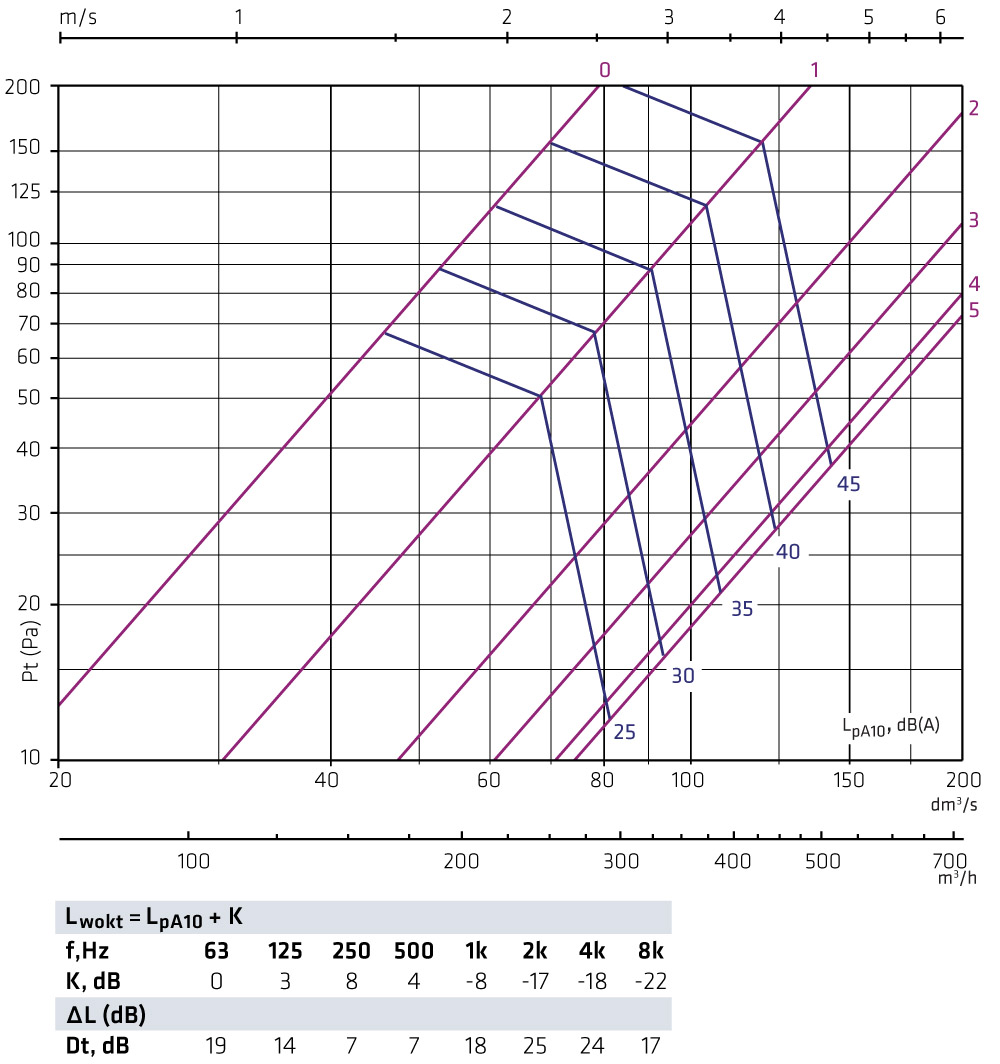

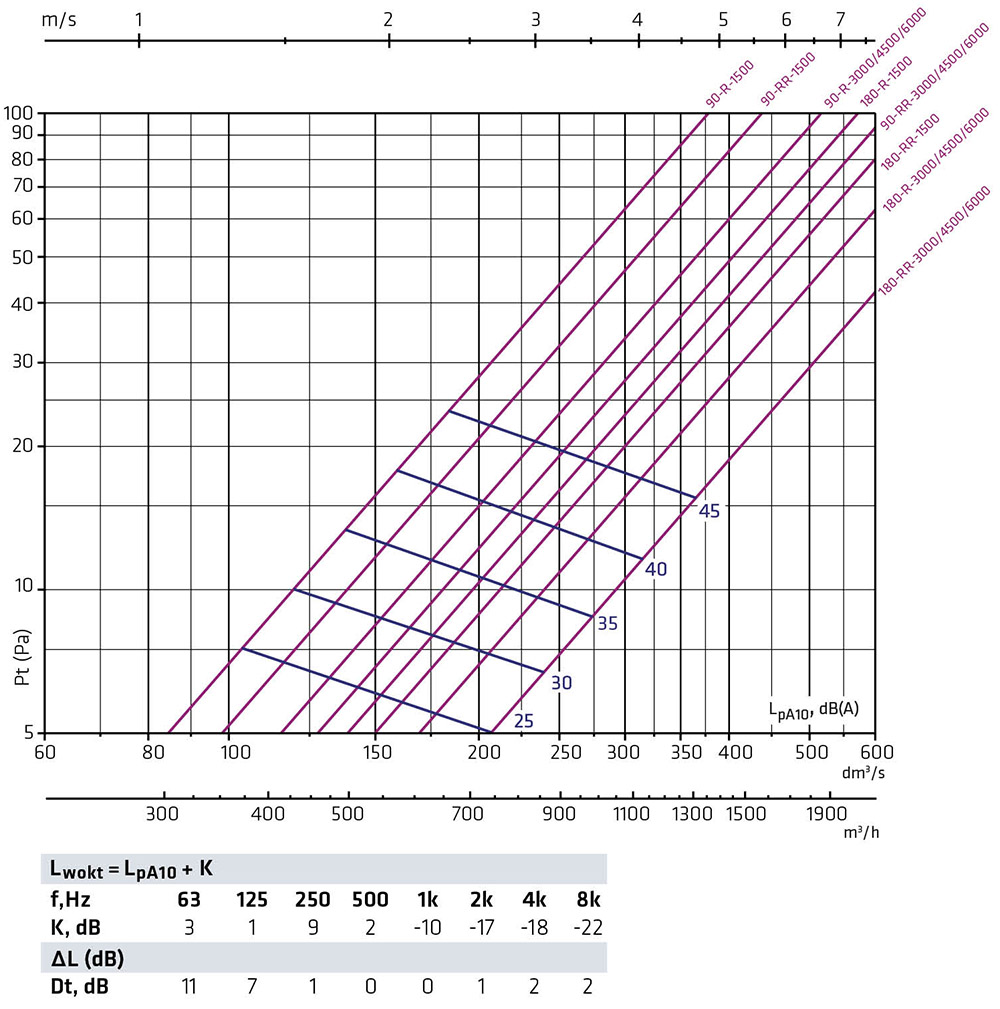

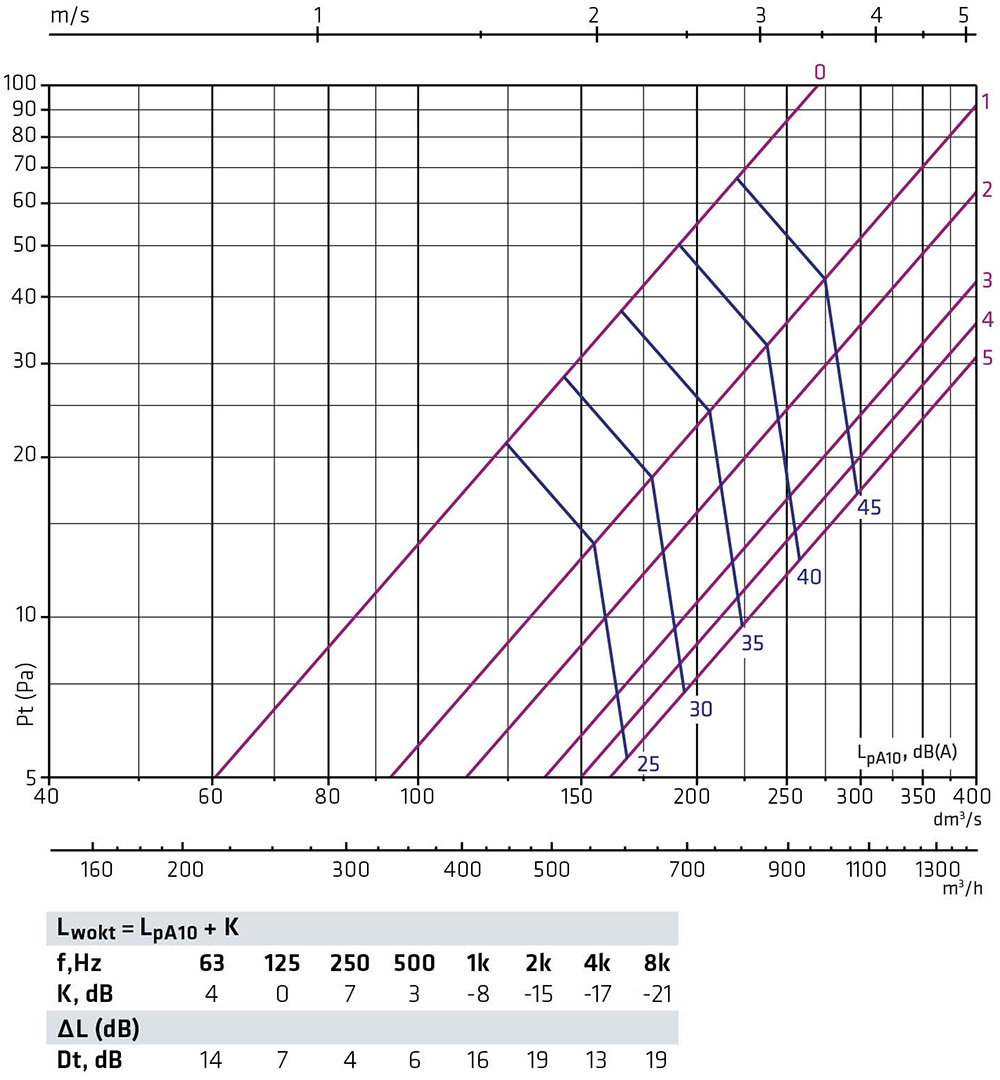

ROX 160

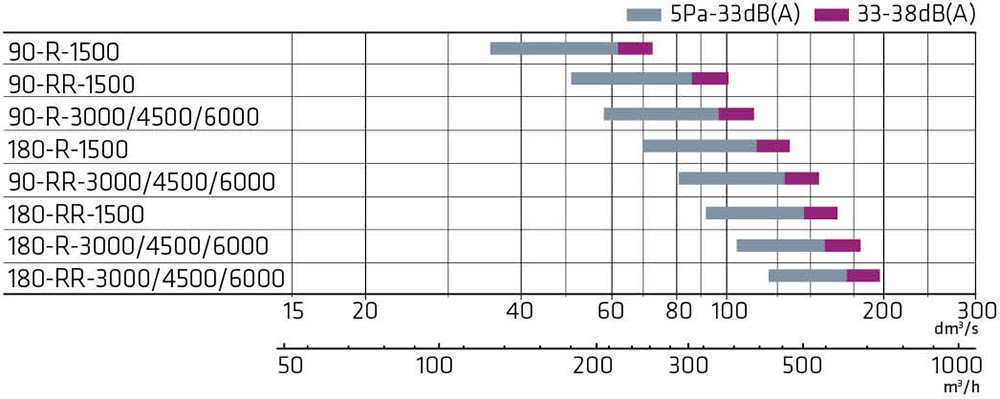

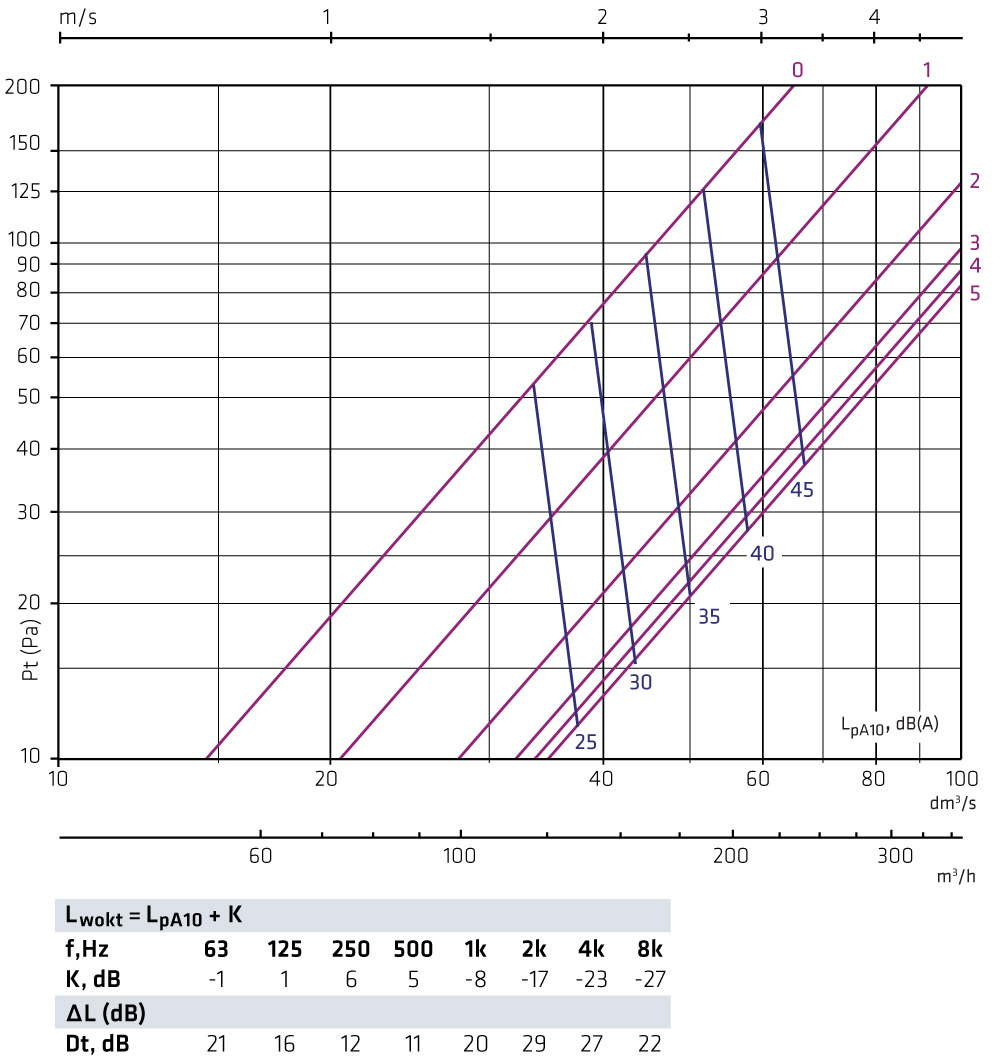

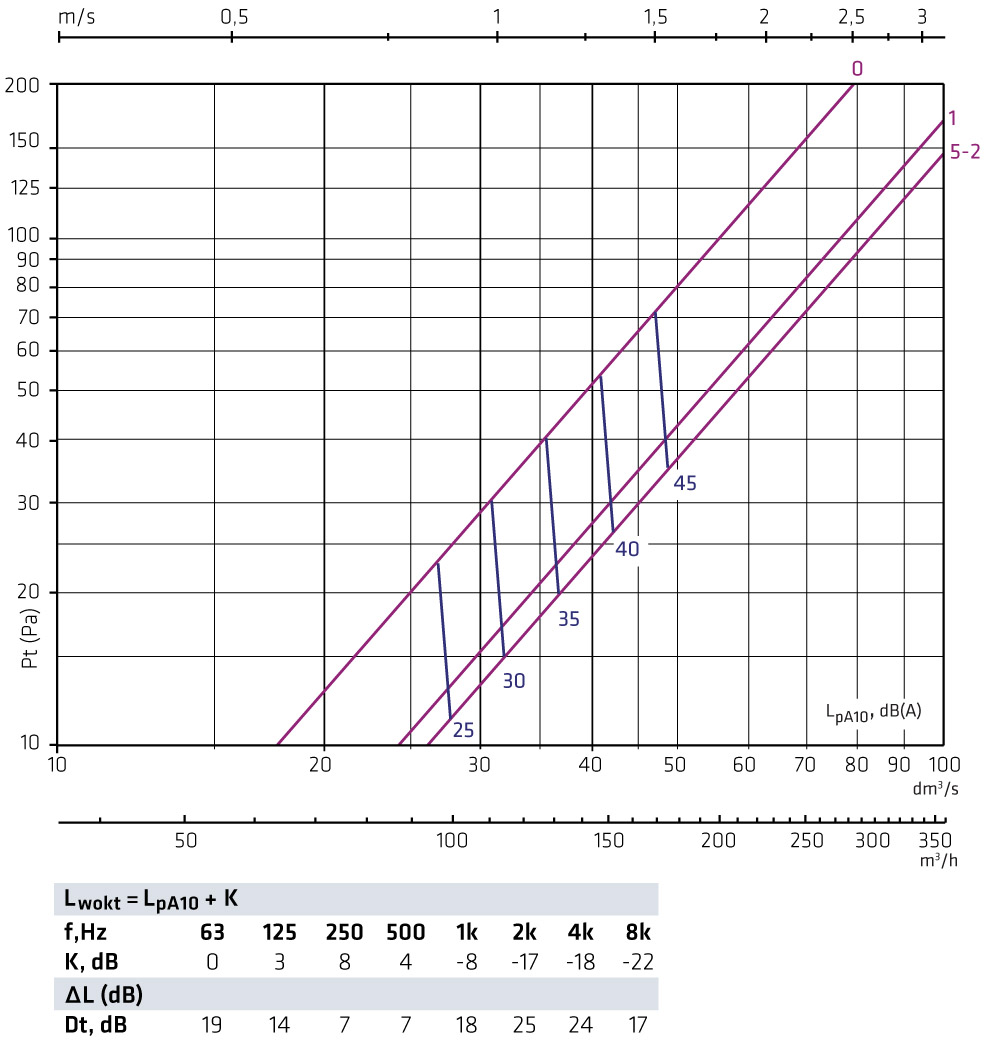

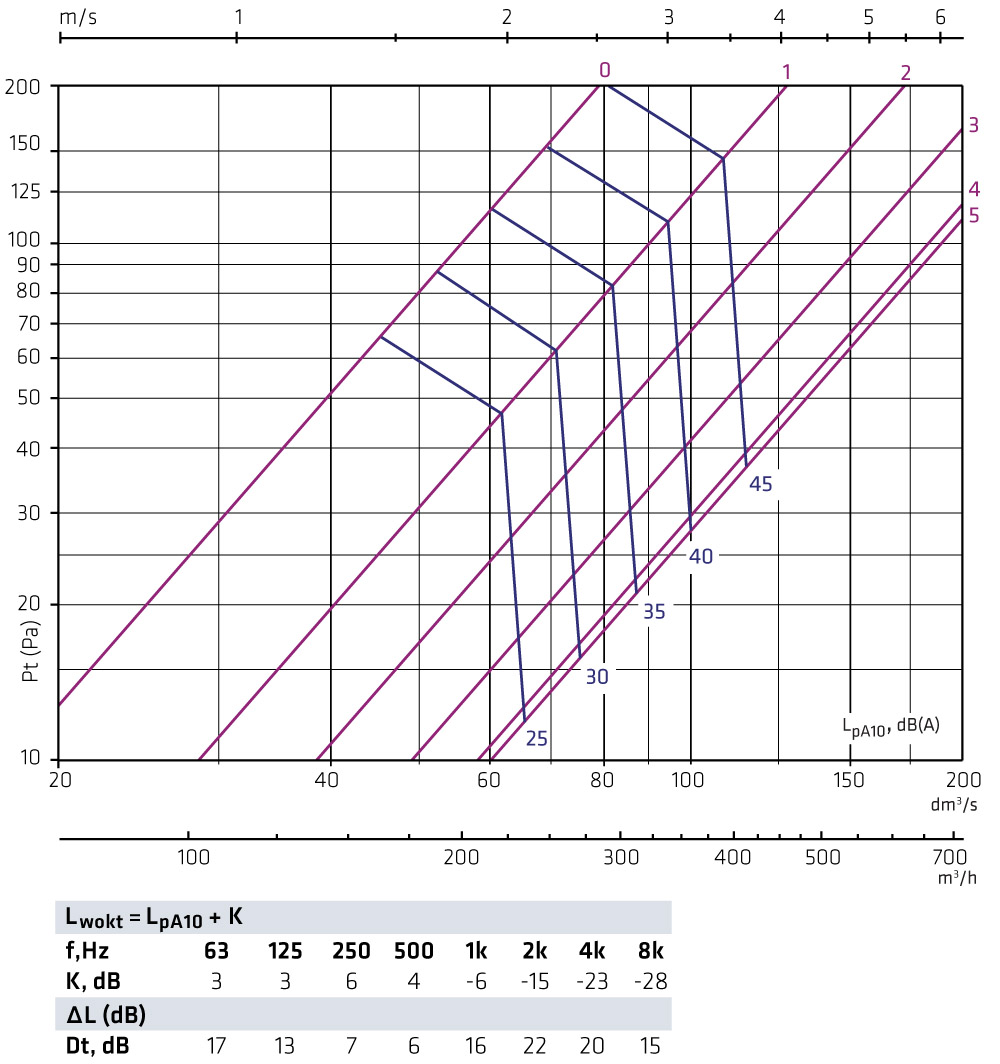

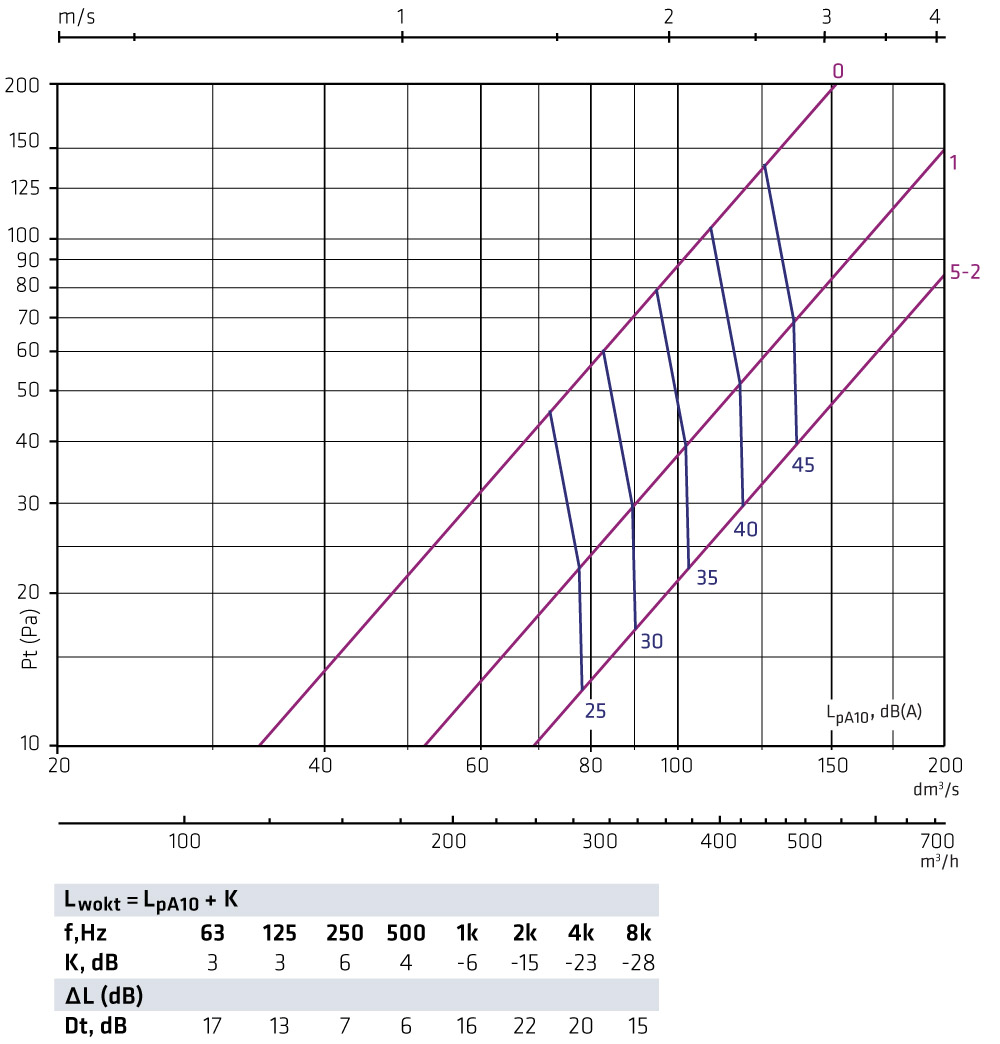

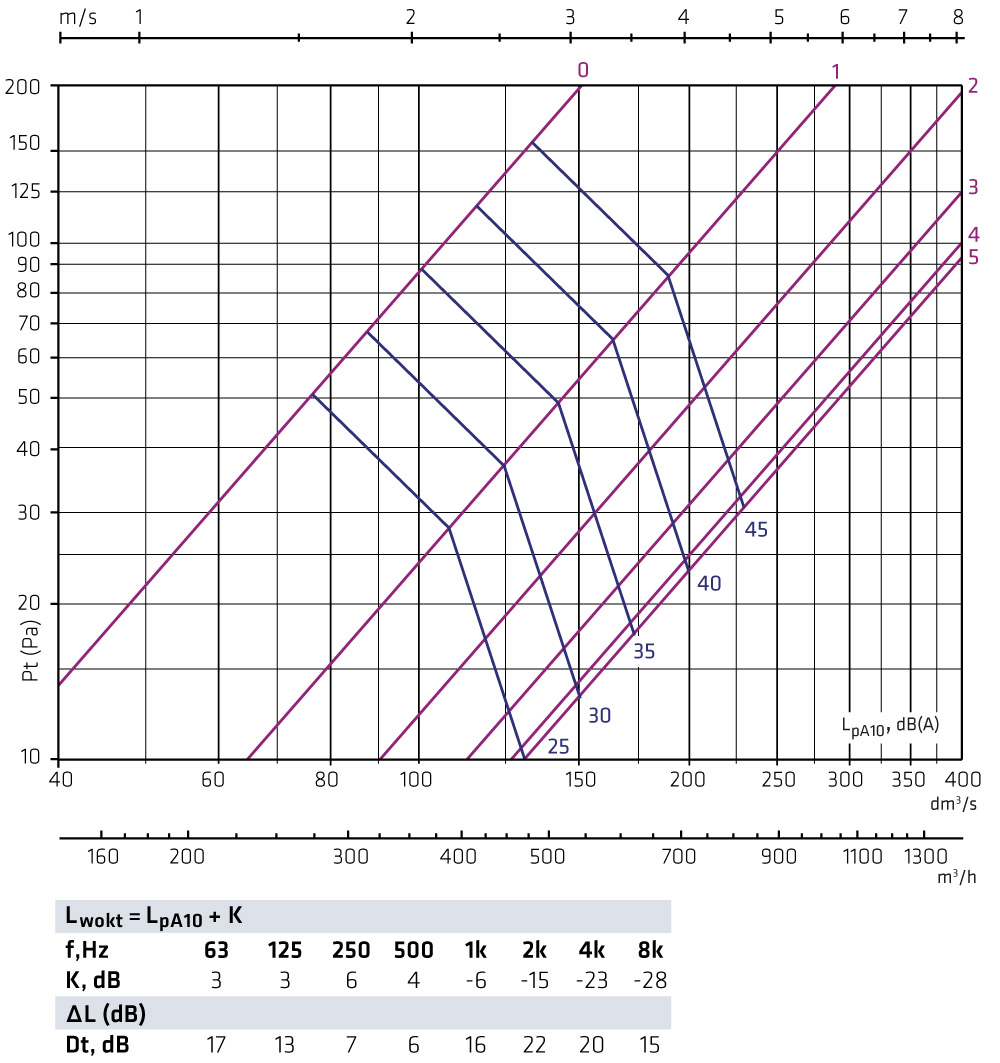

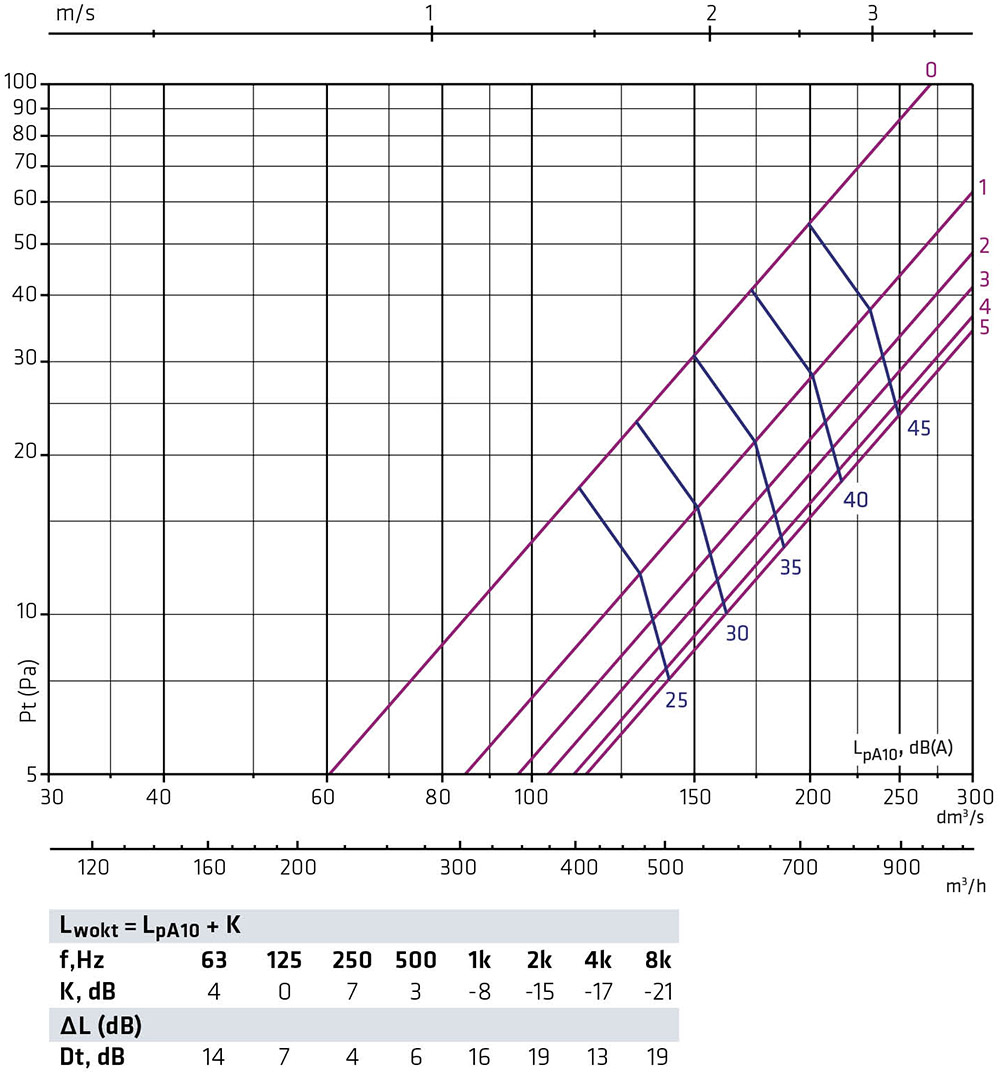

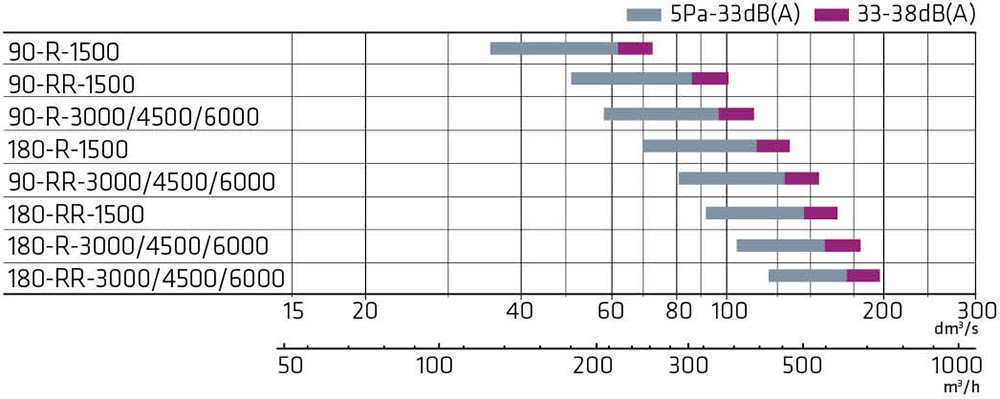

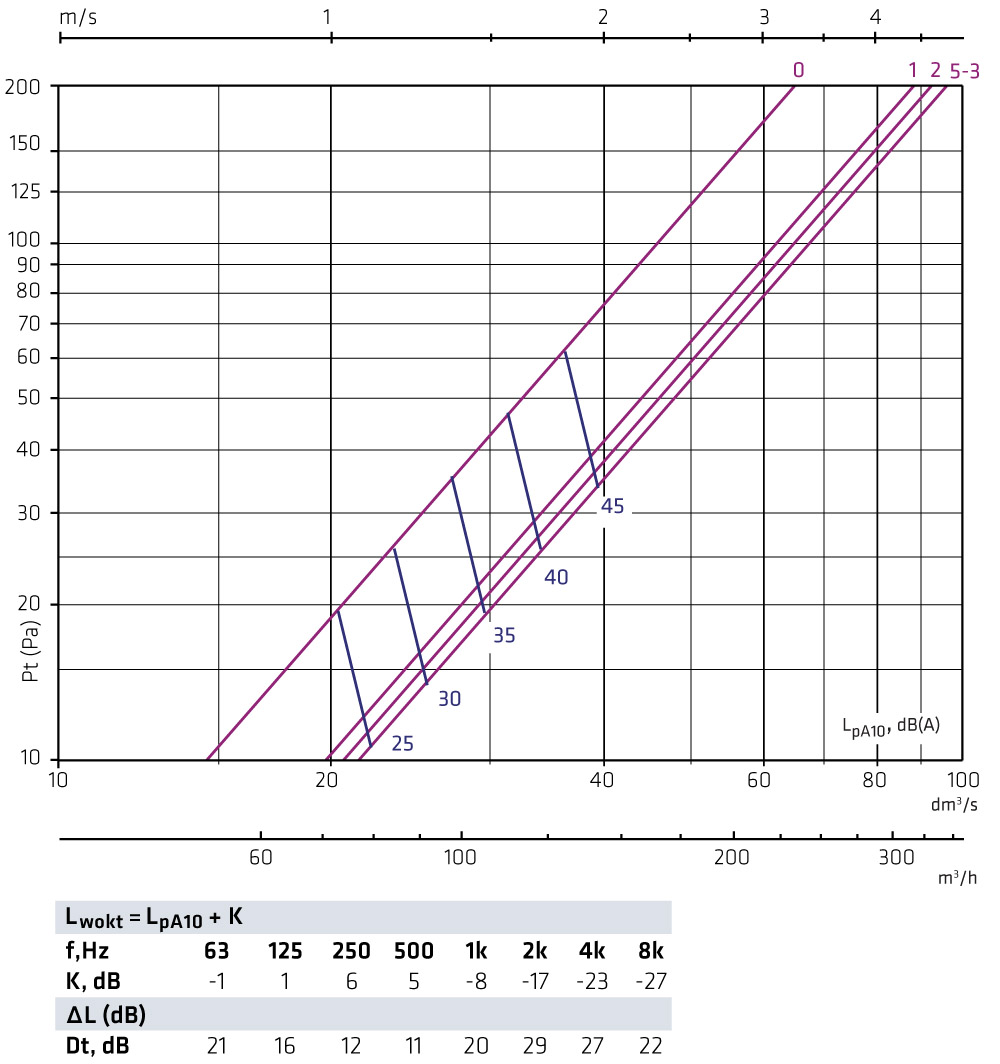

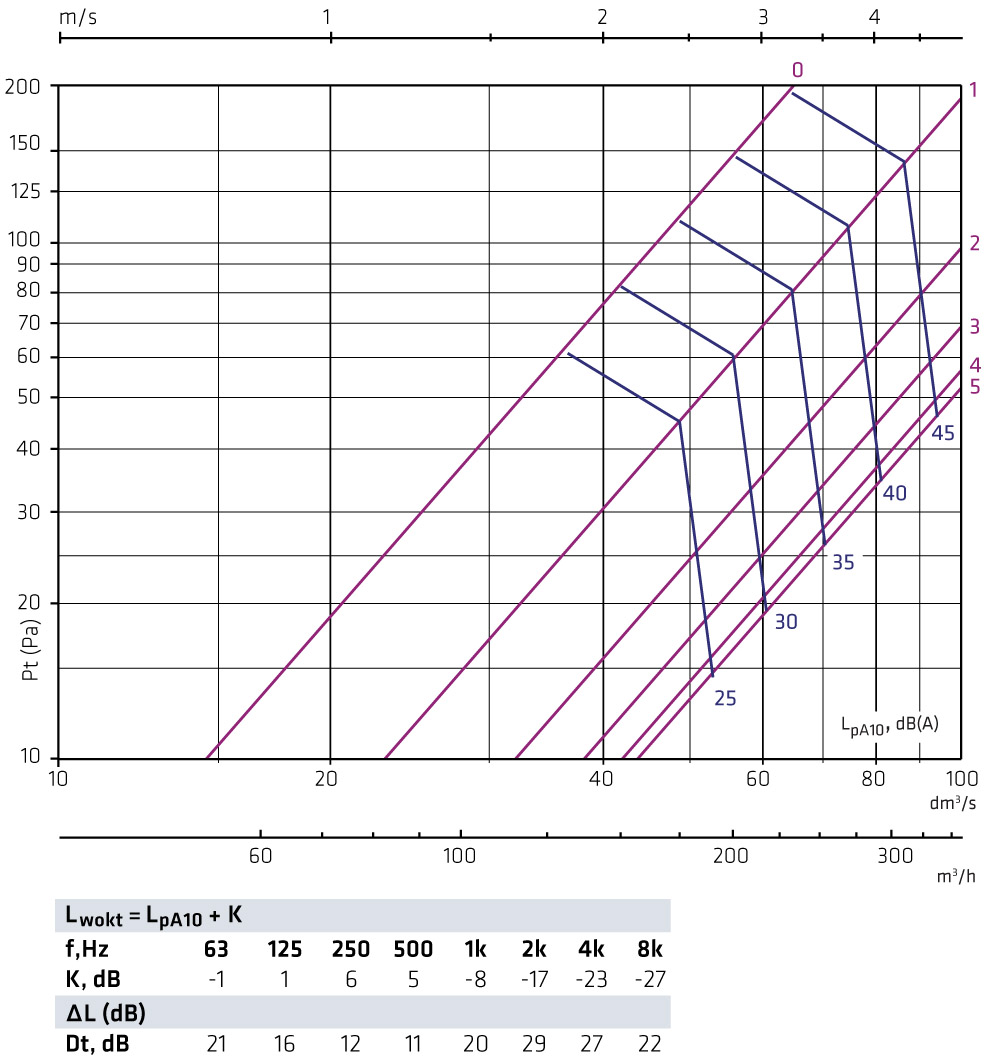

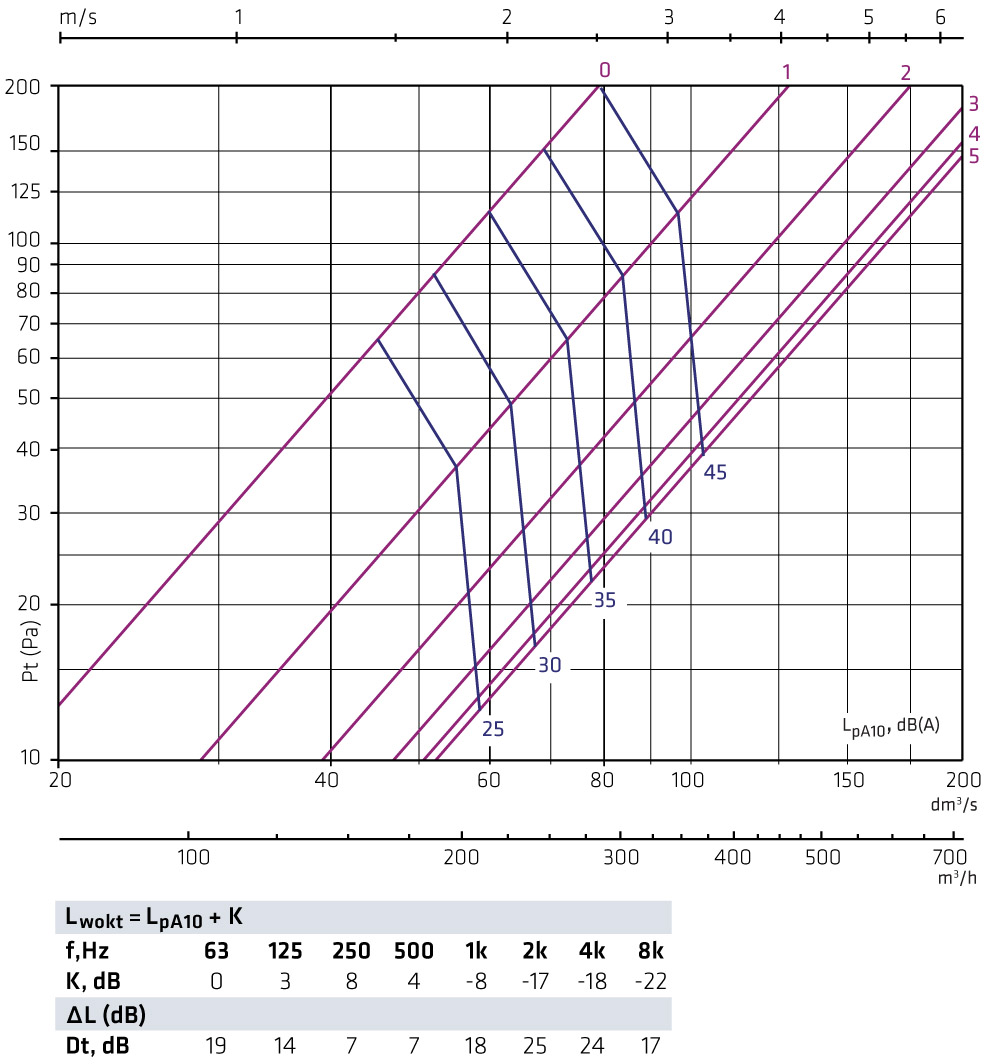

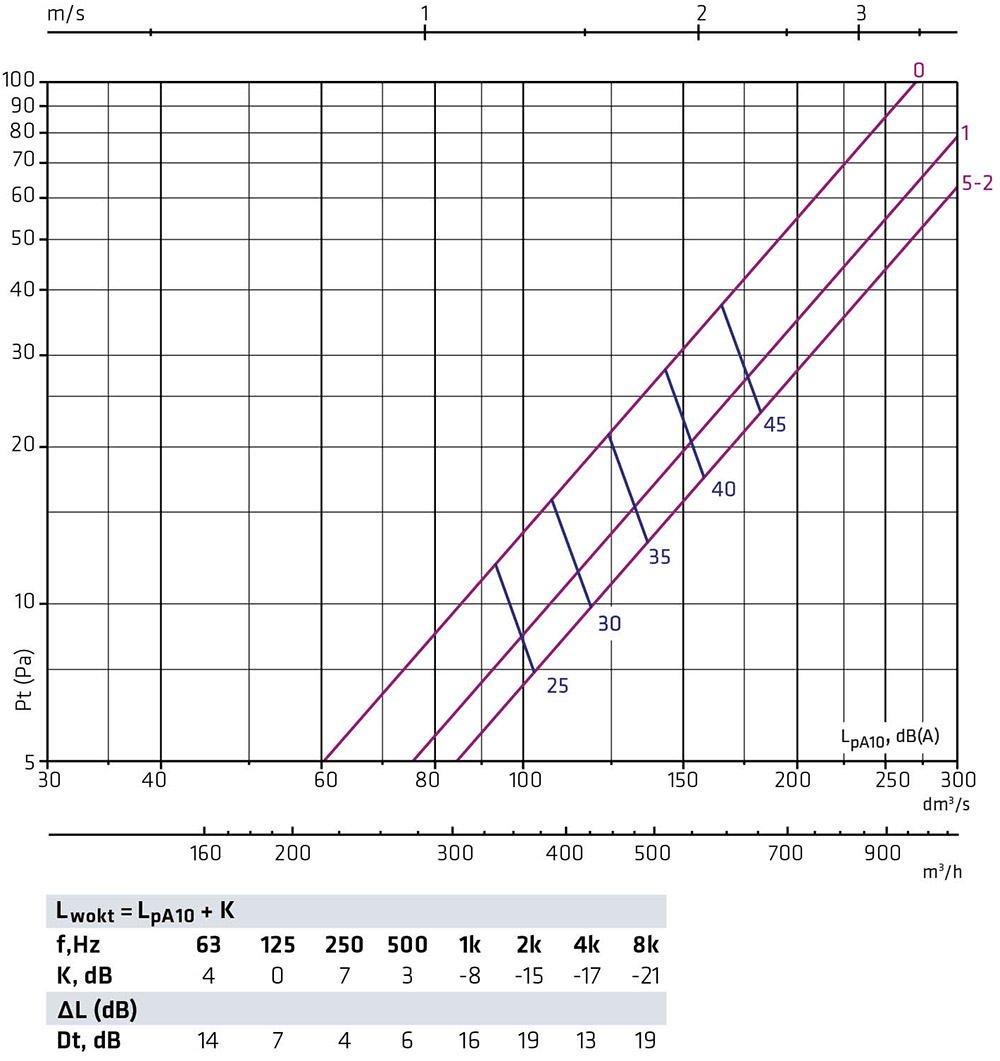

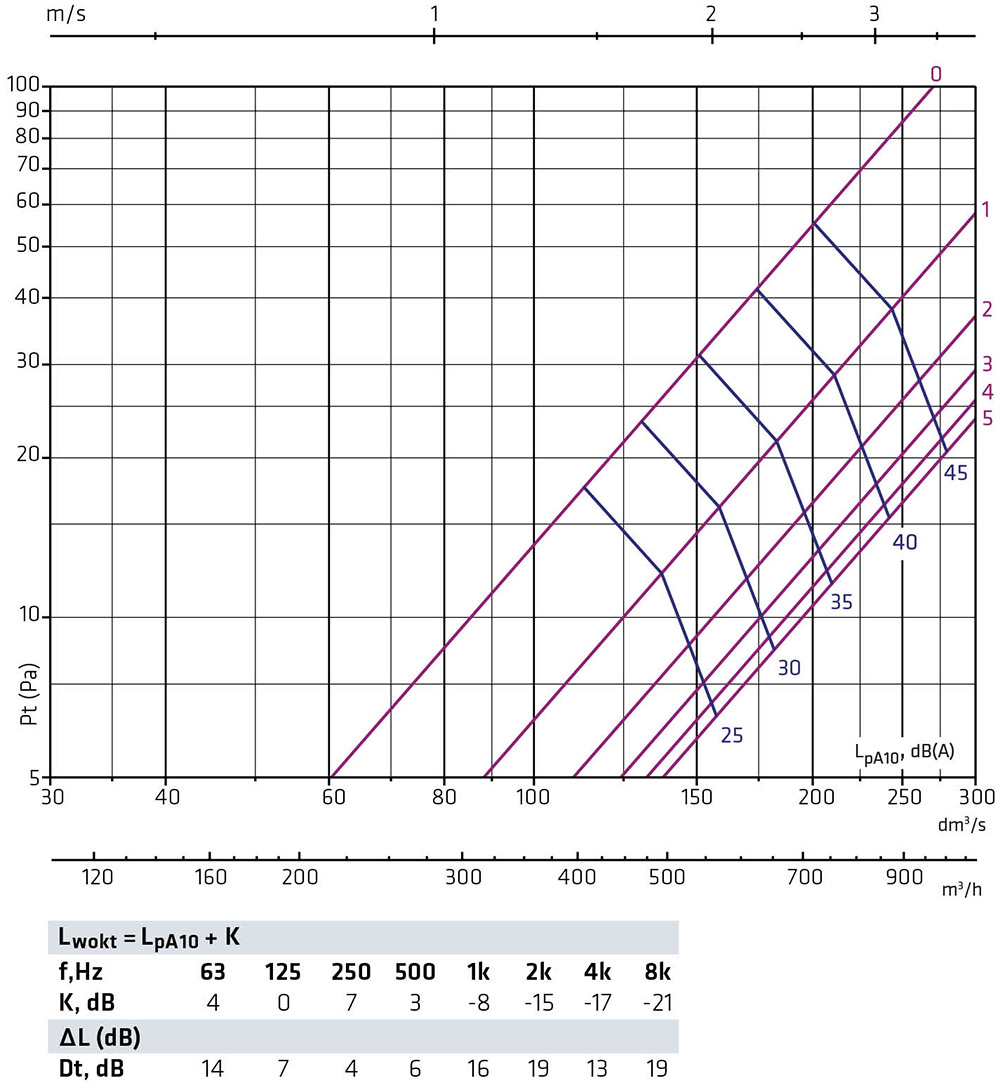

ROX 200

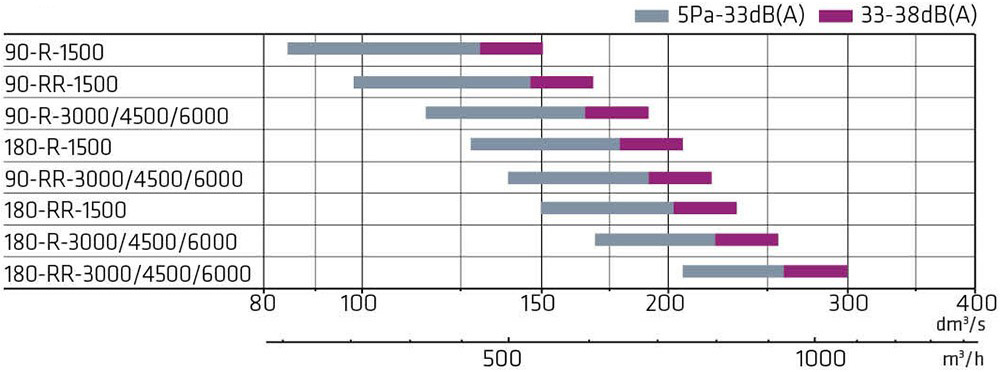

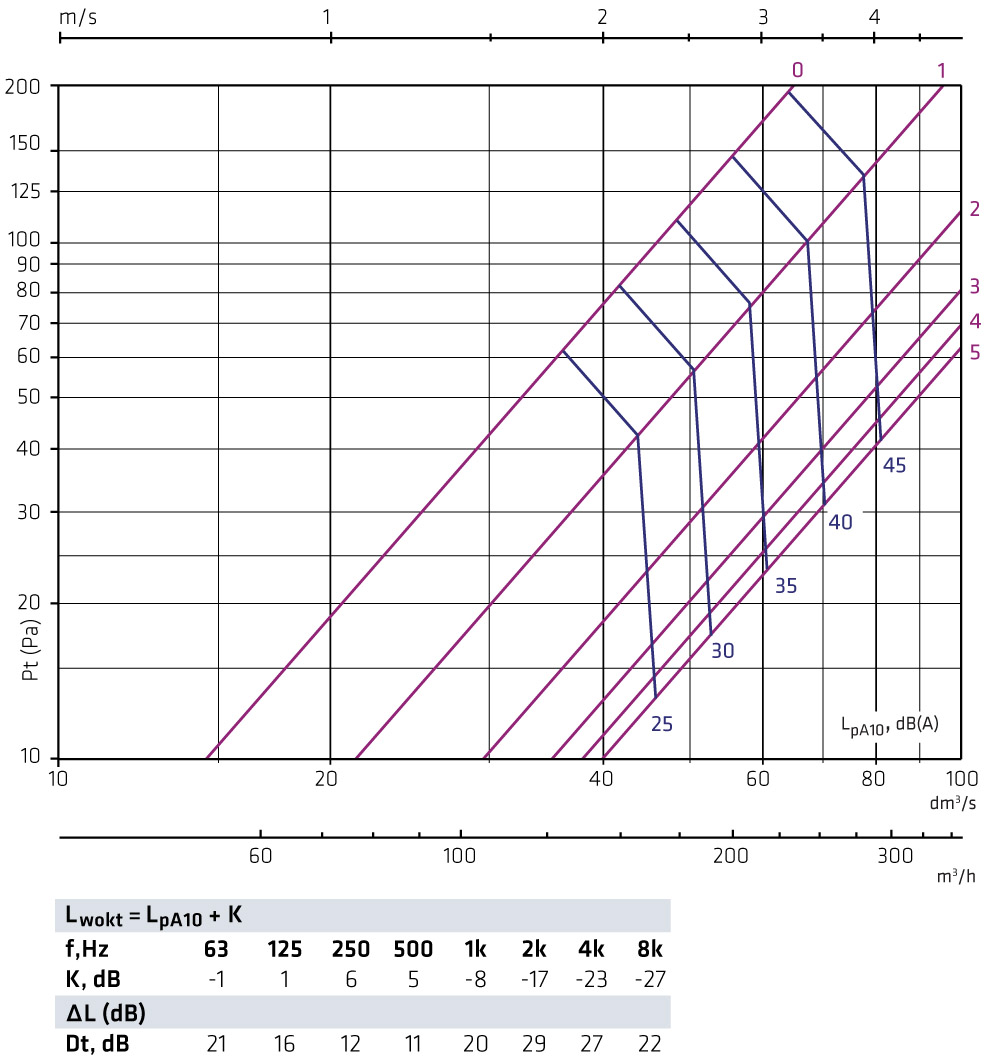

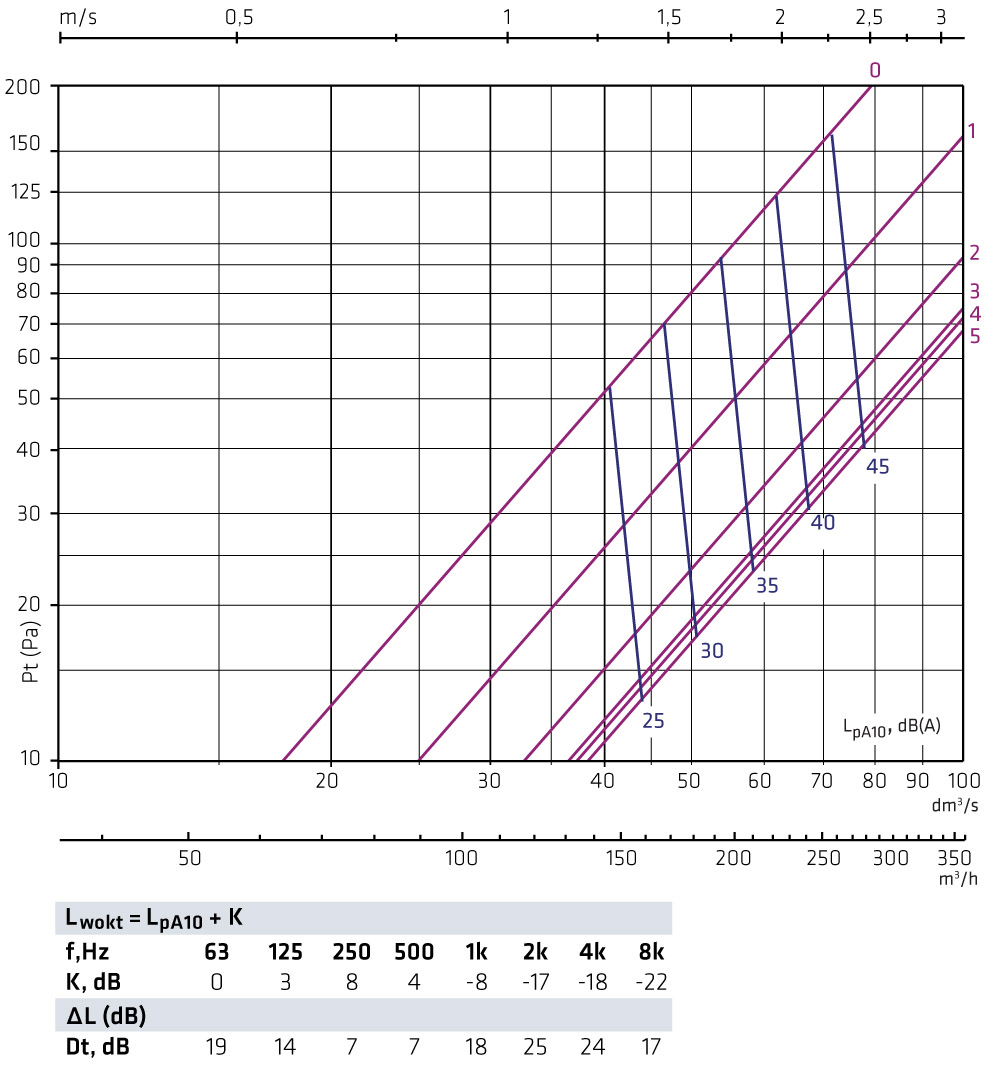

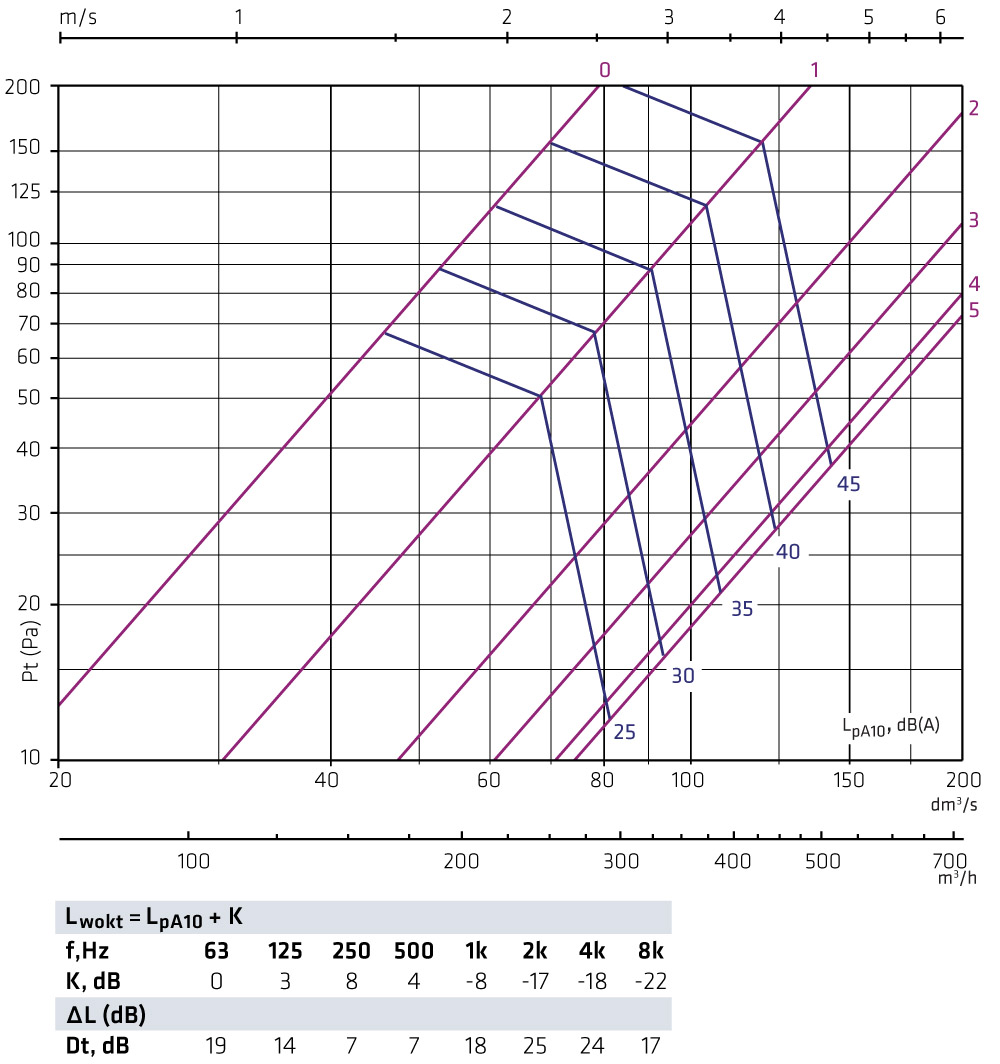

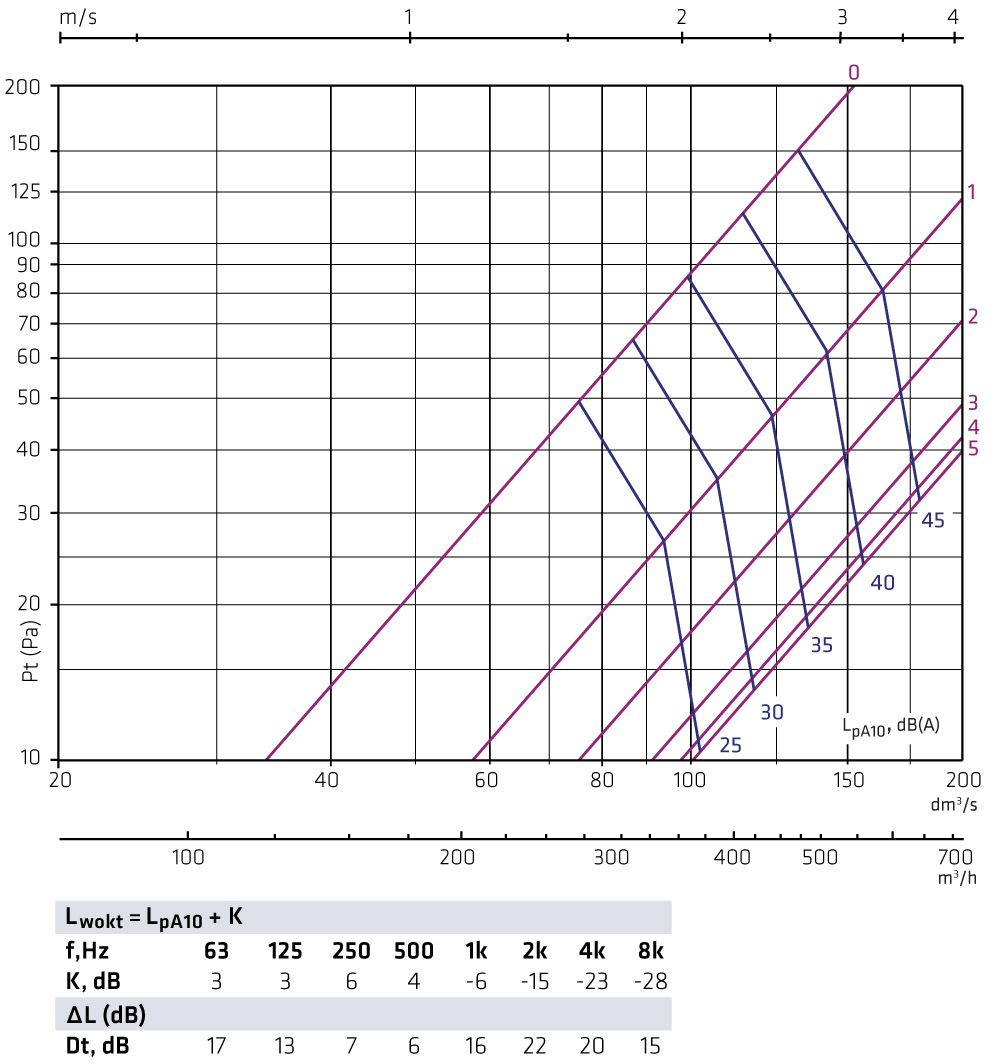

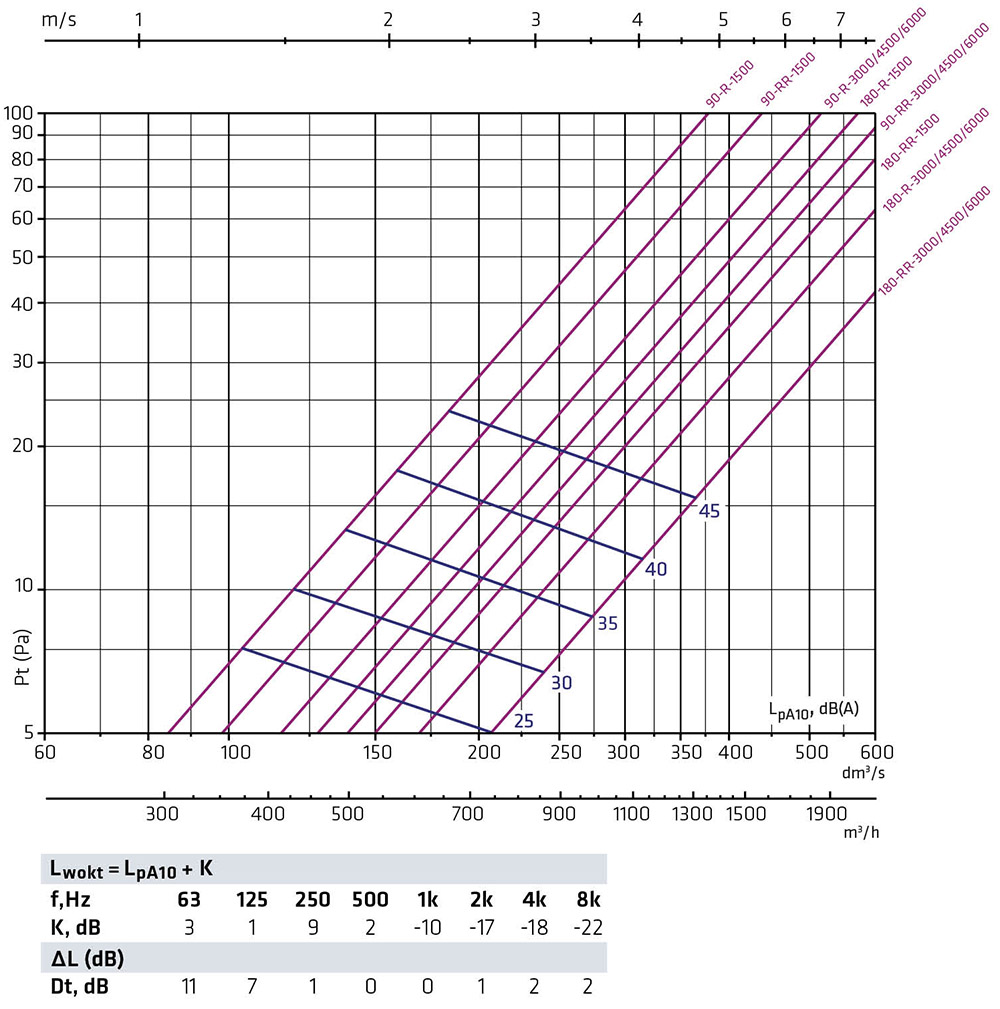

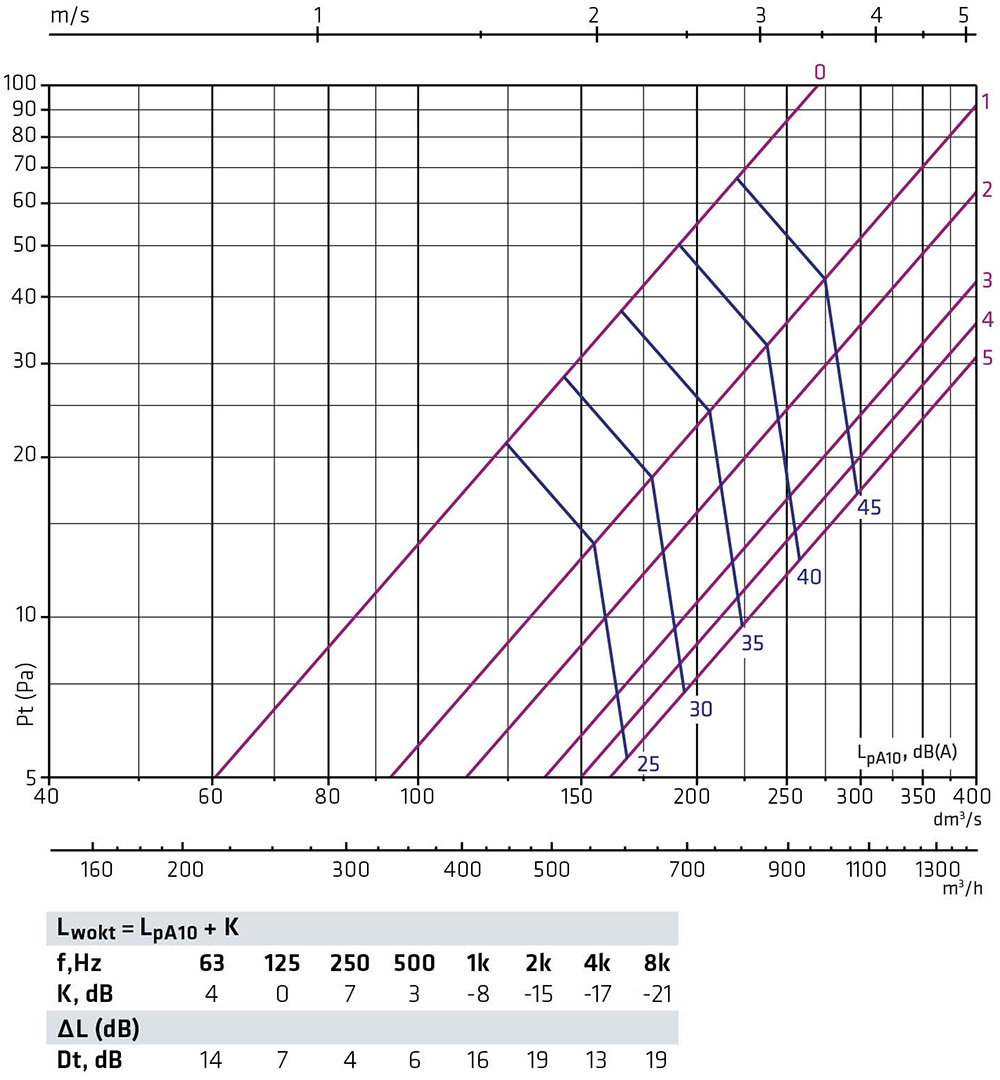

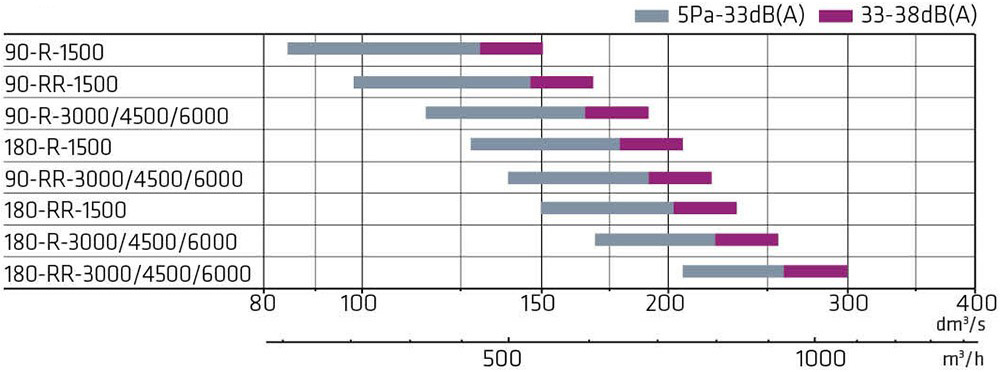

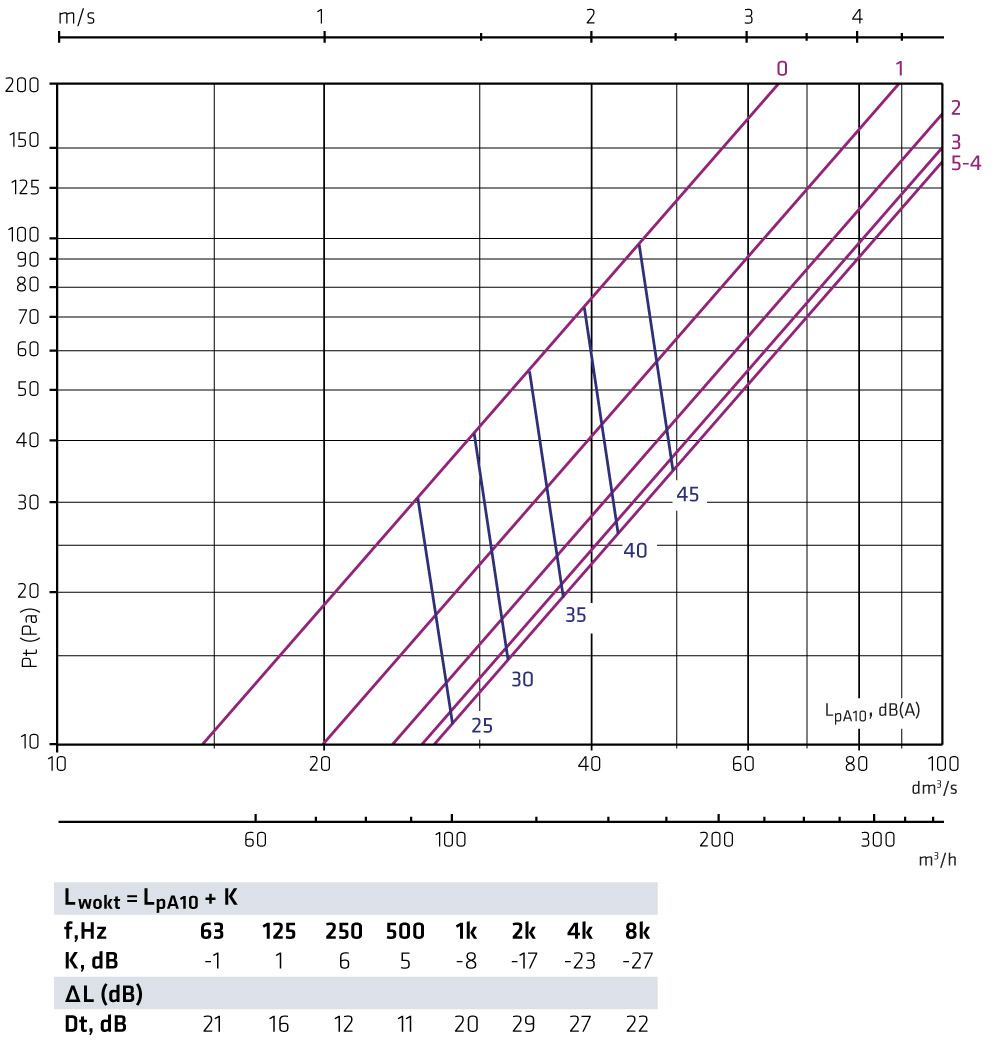

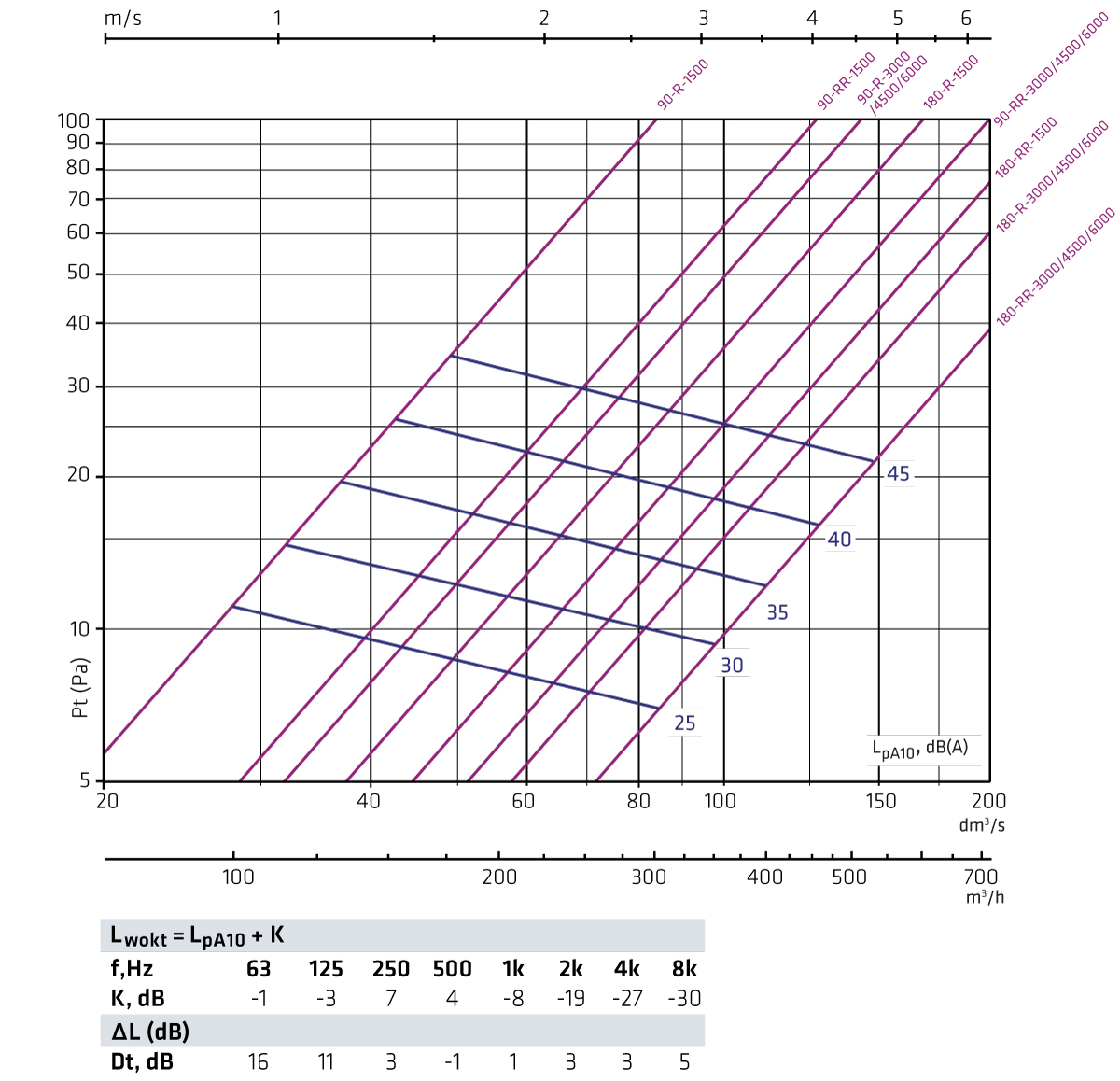

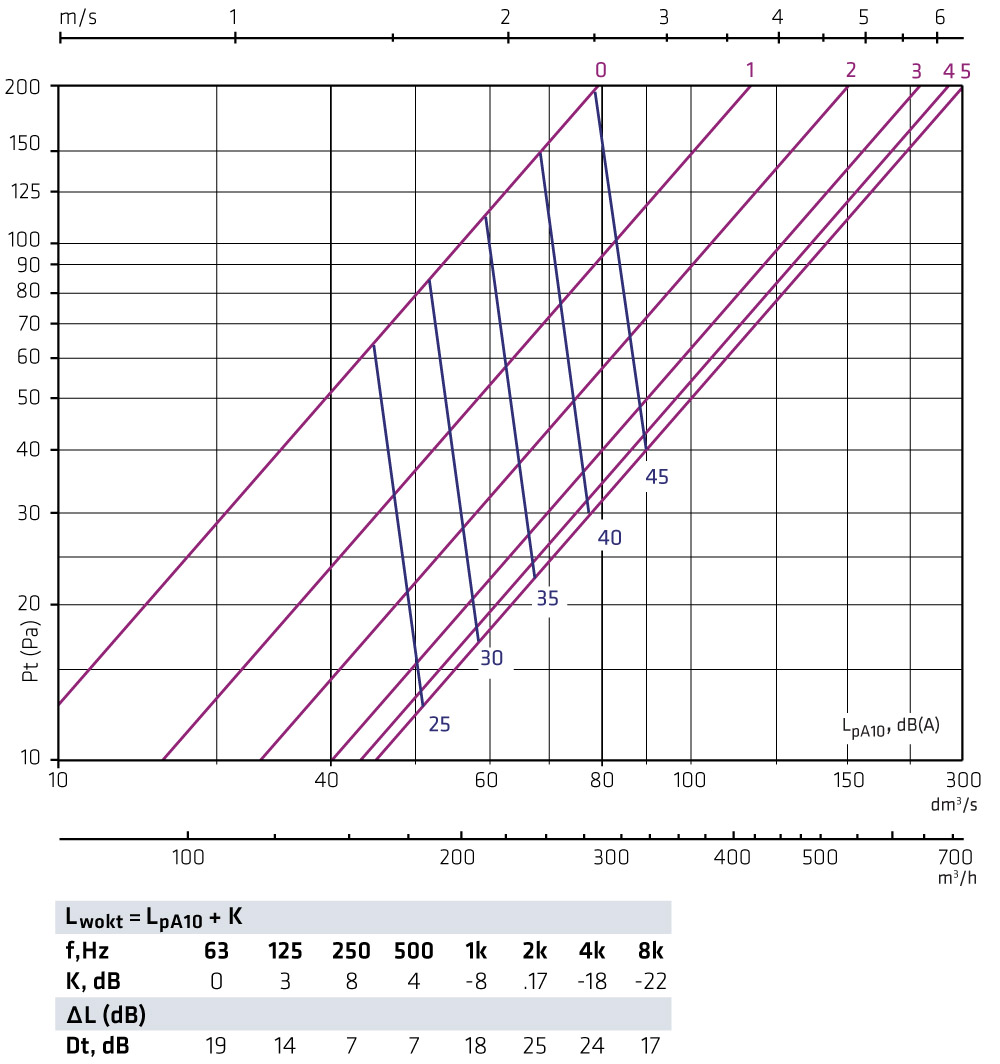

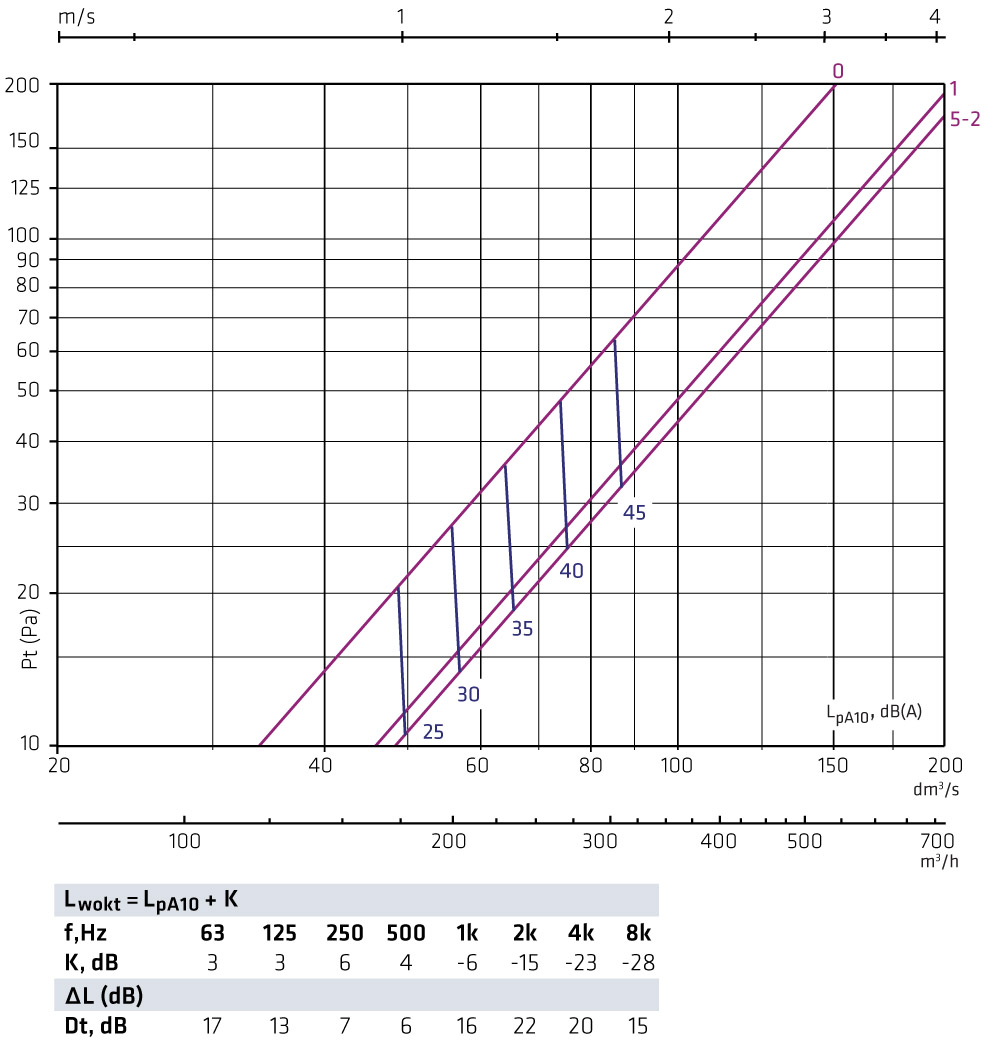

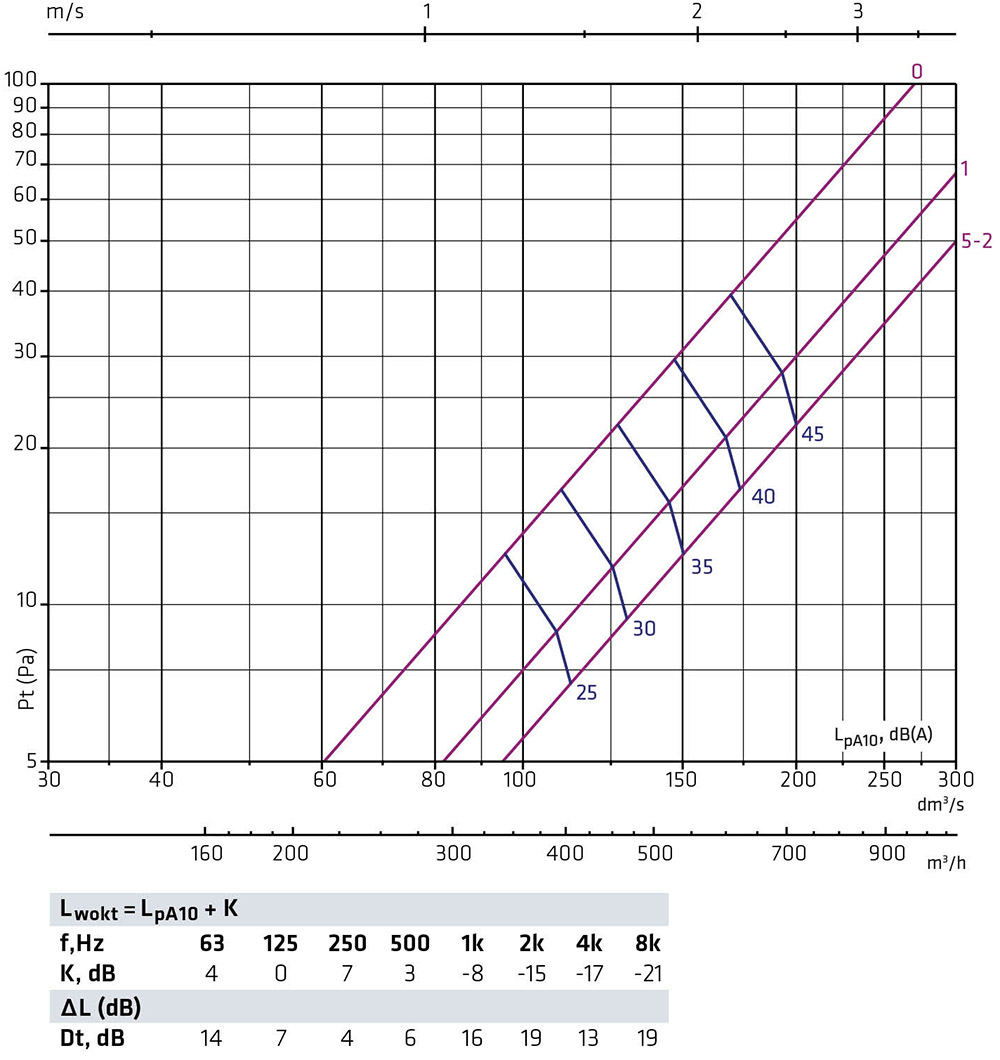

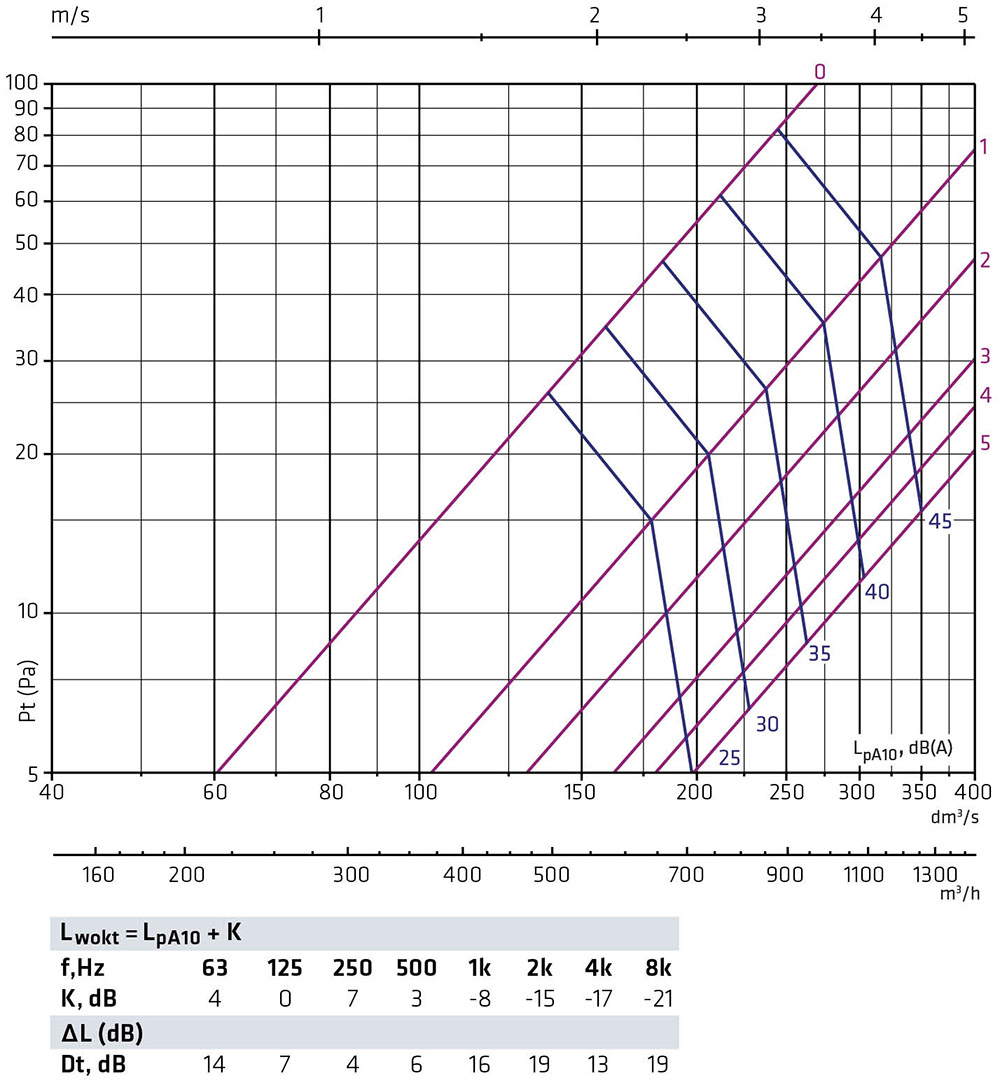

ROX 250

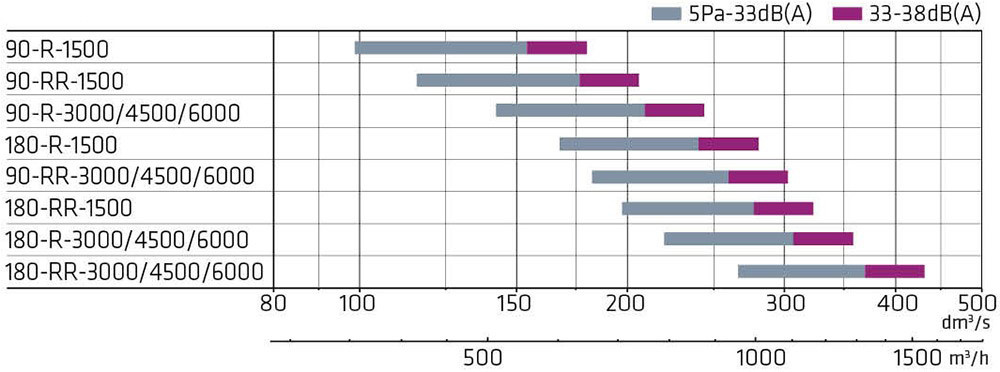

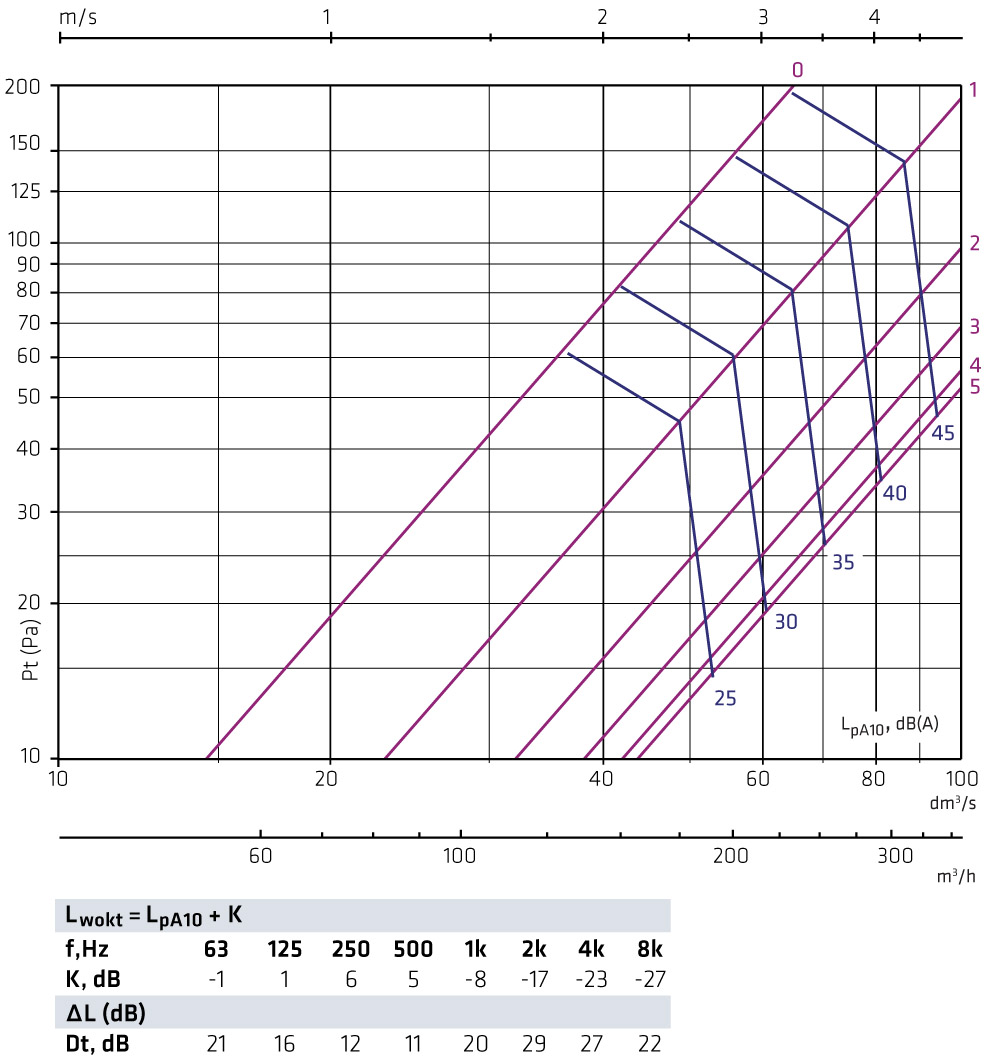

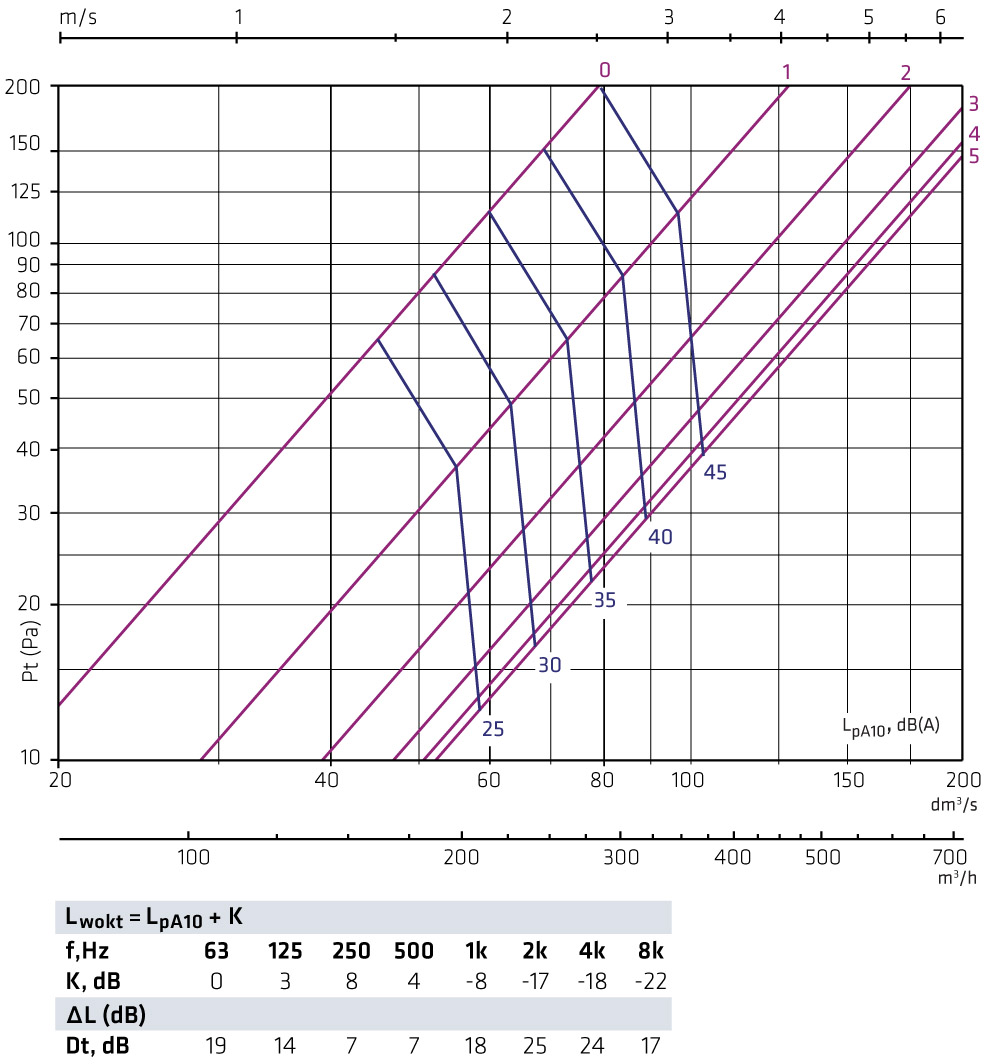

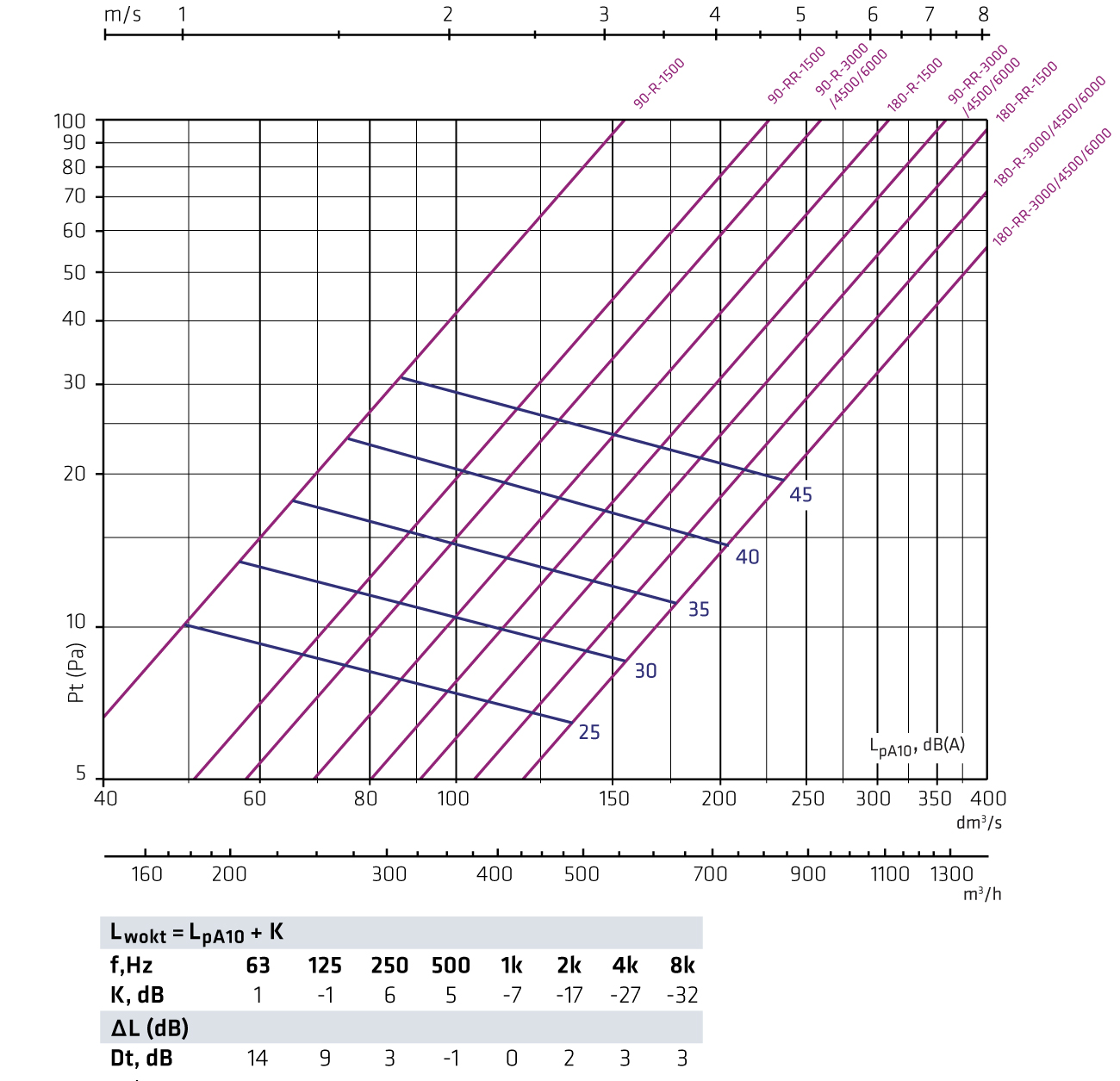

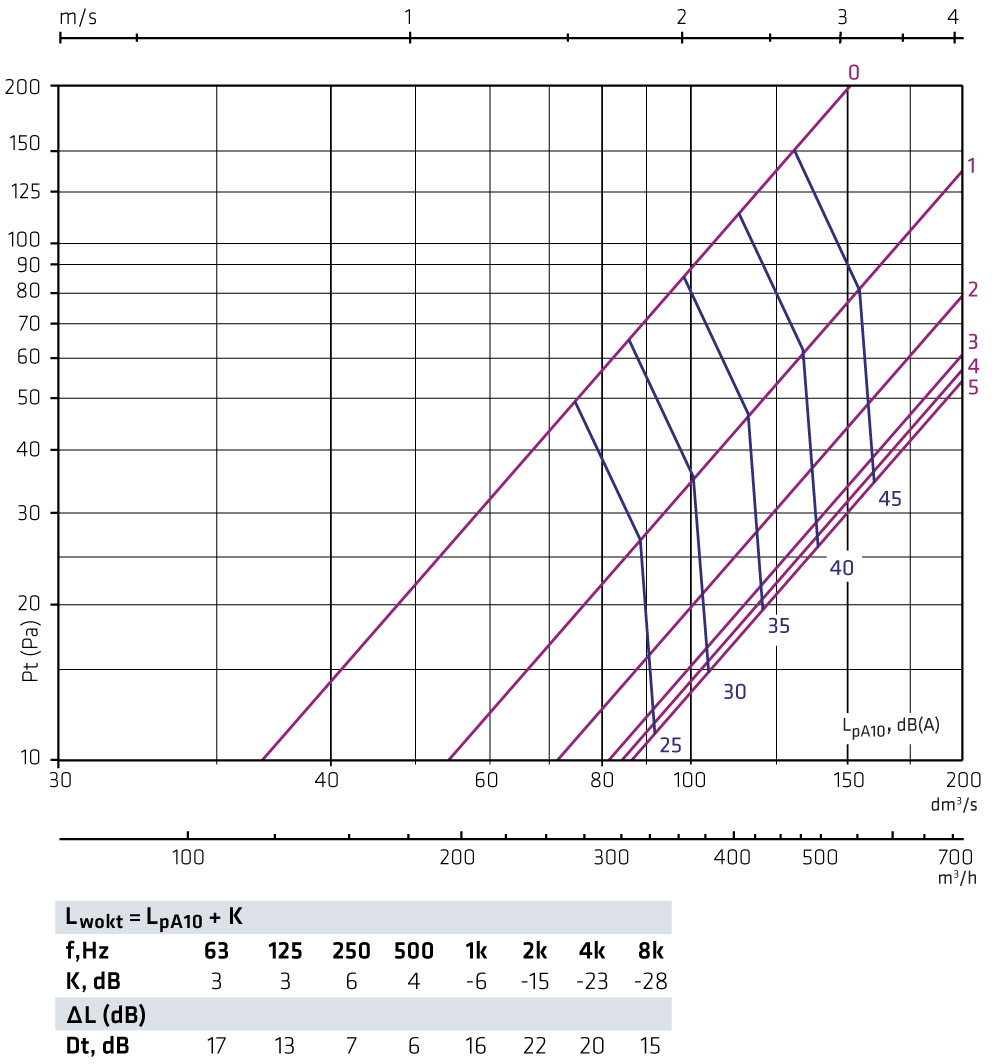

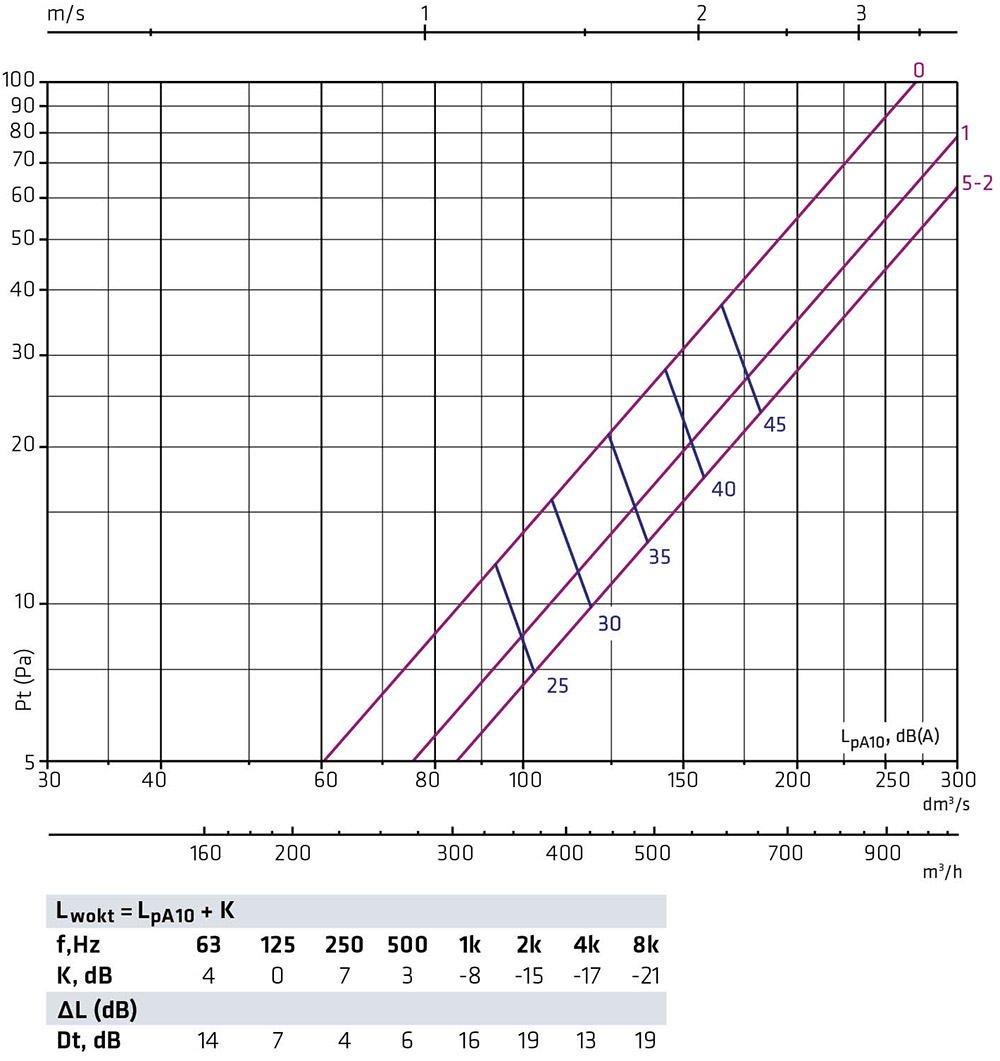

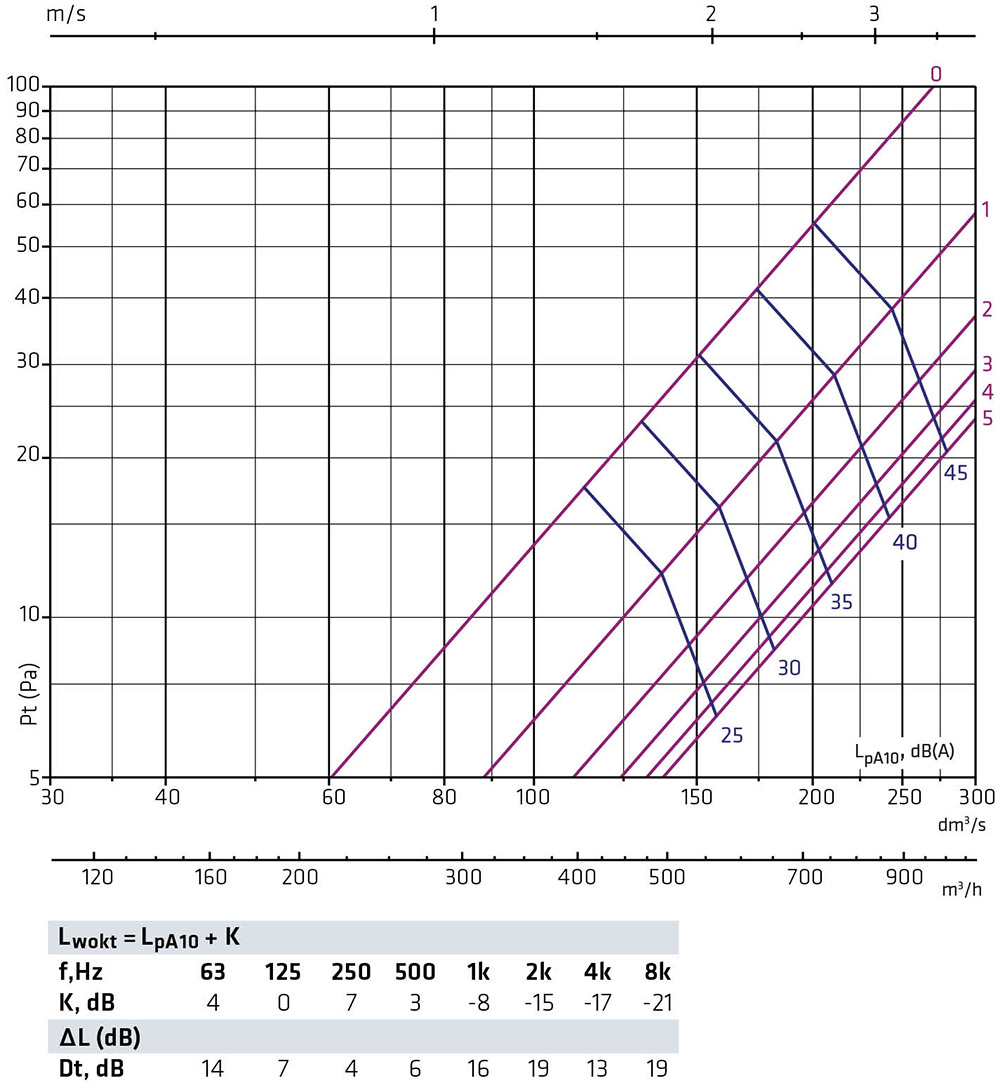

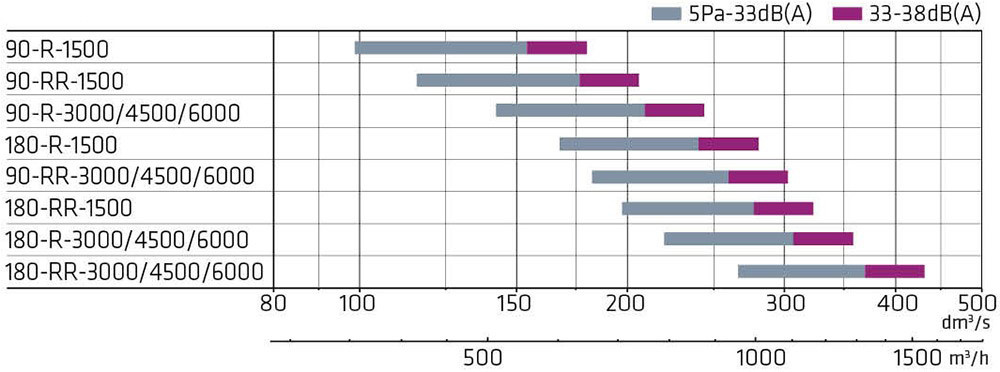

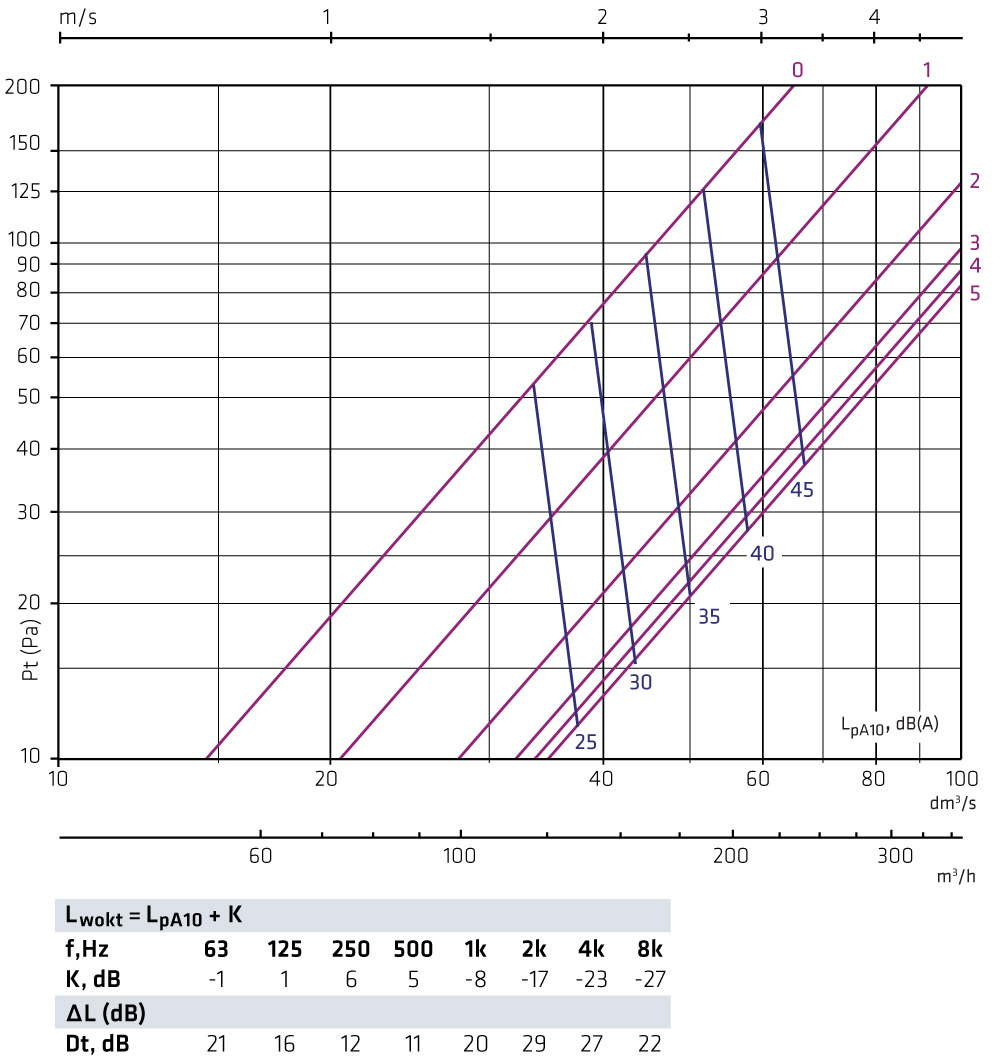

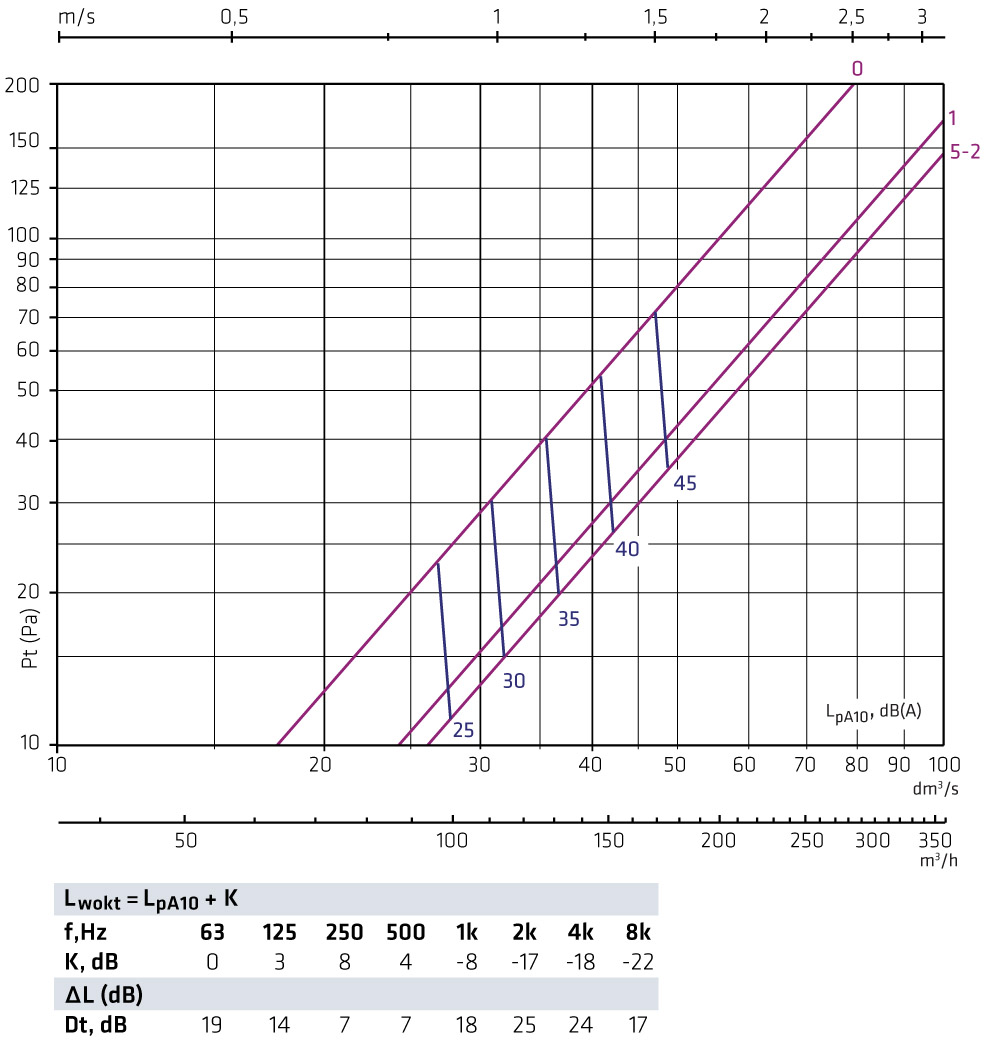

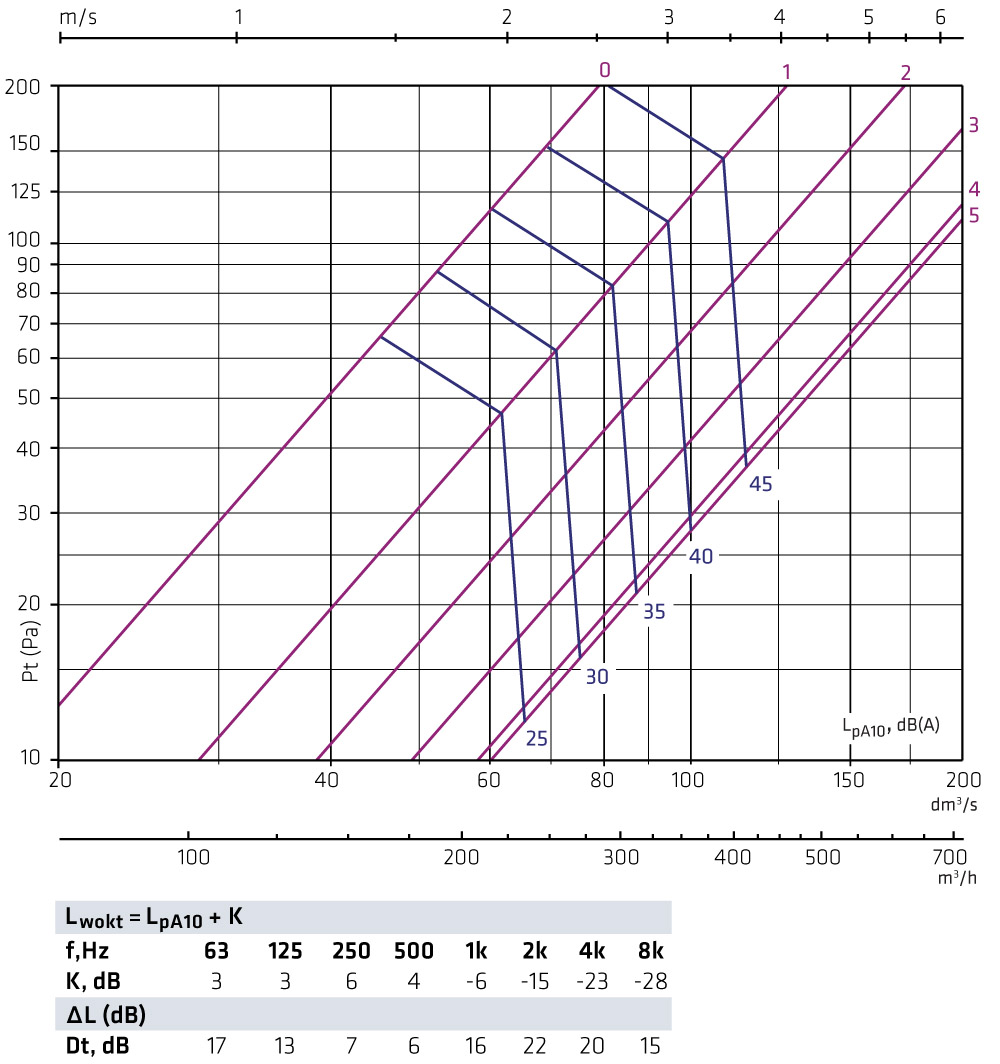

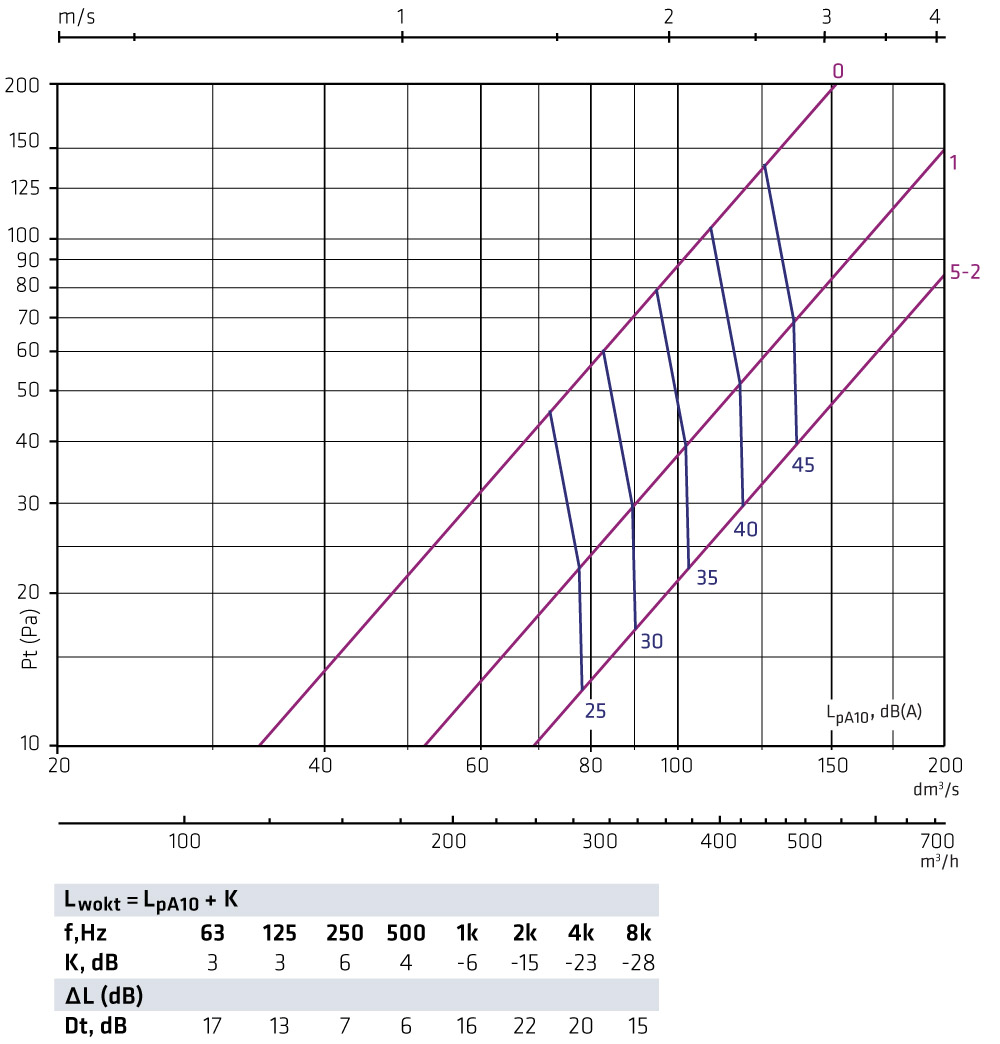

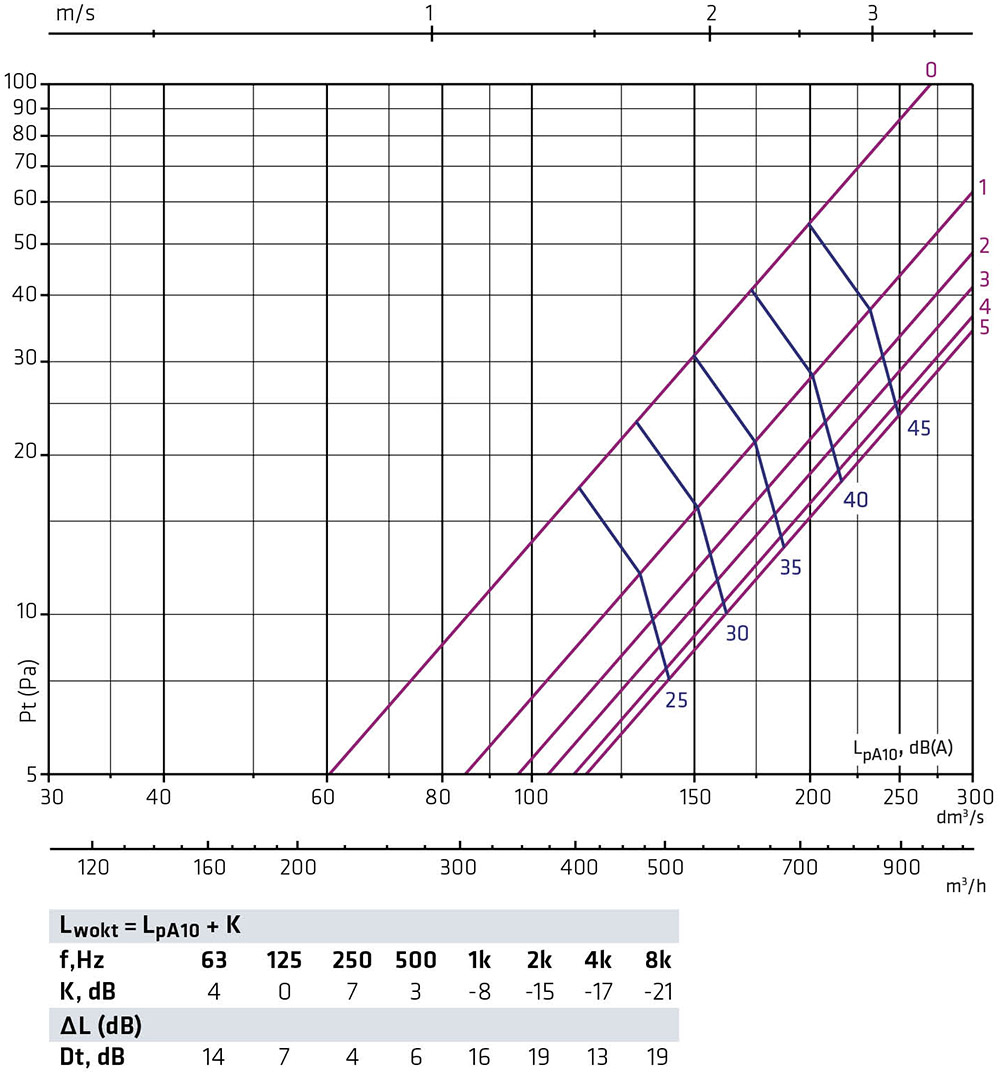

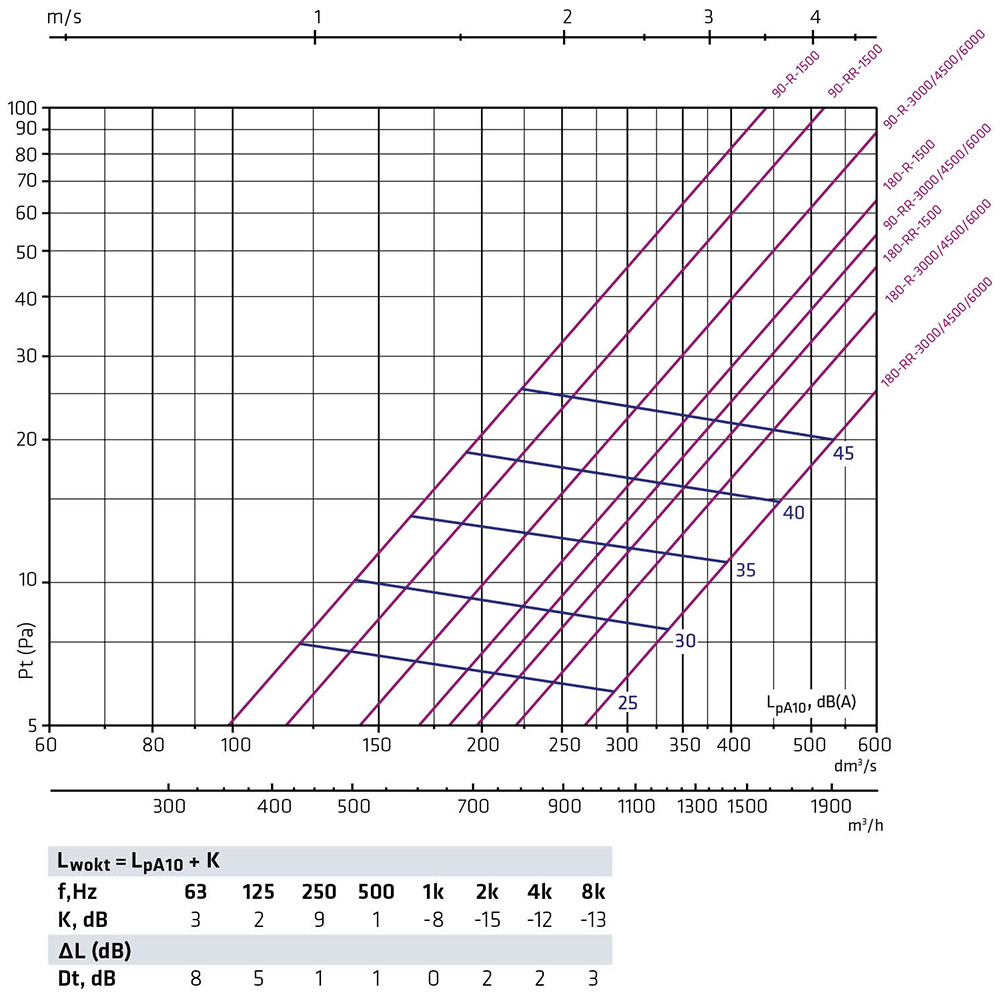

ROX 315

ROX 400

ROX 500

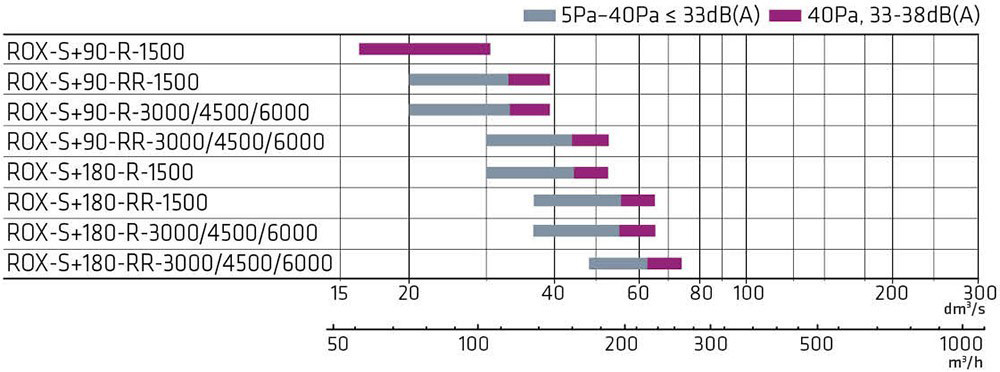

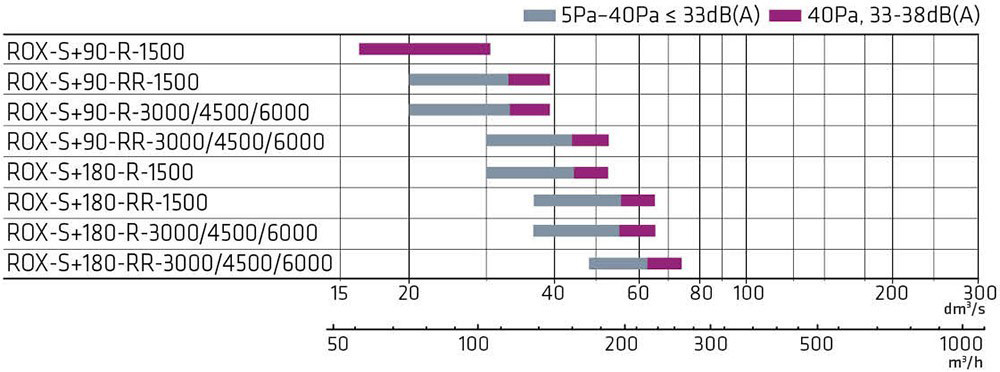

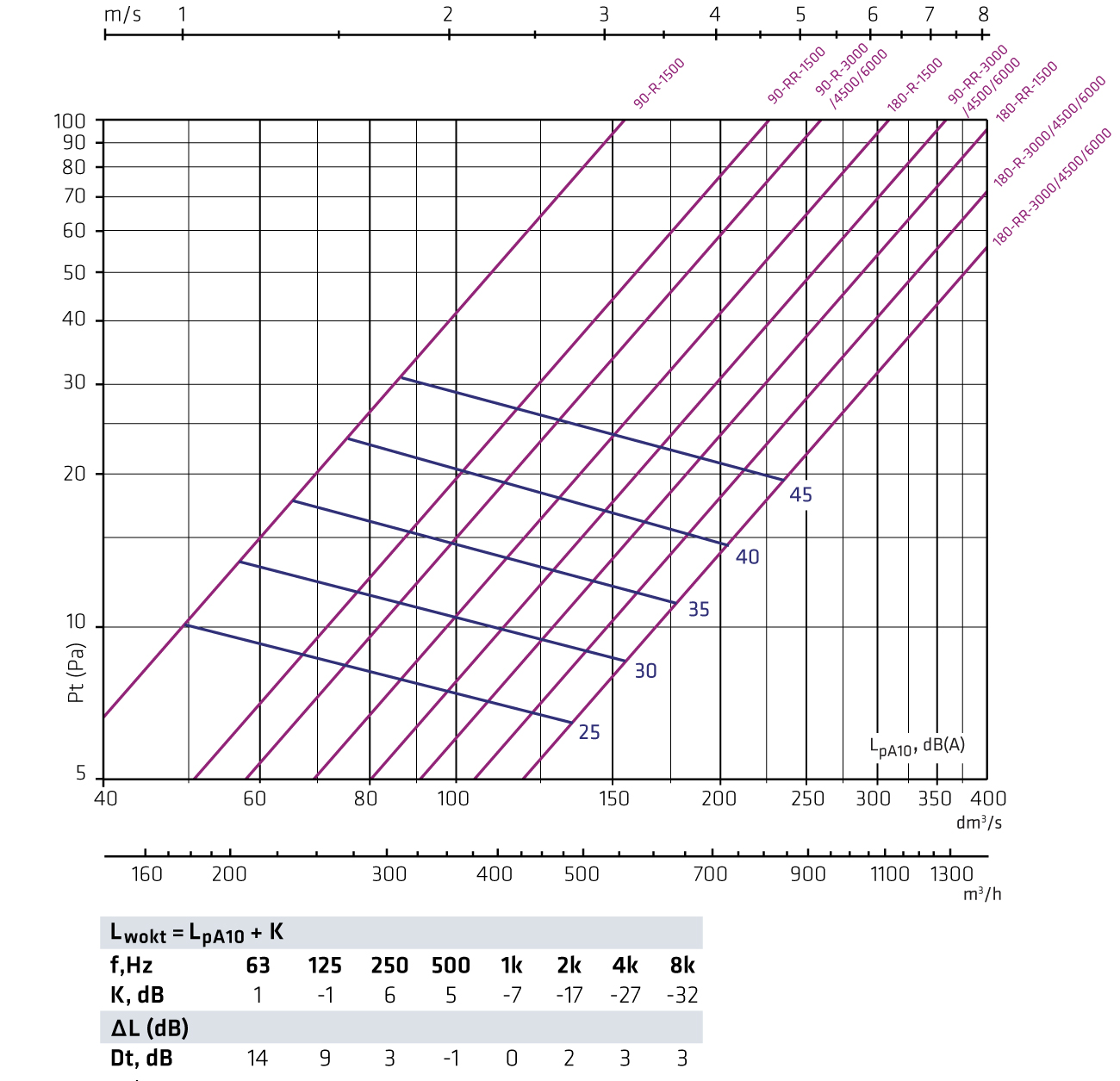

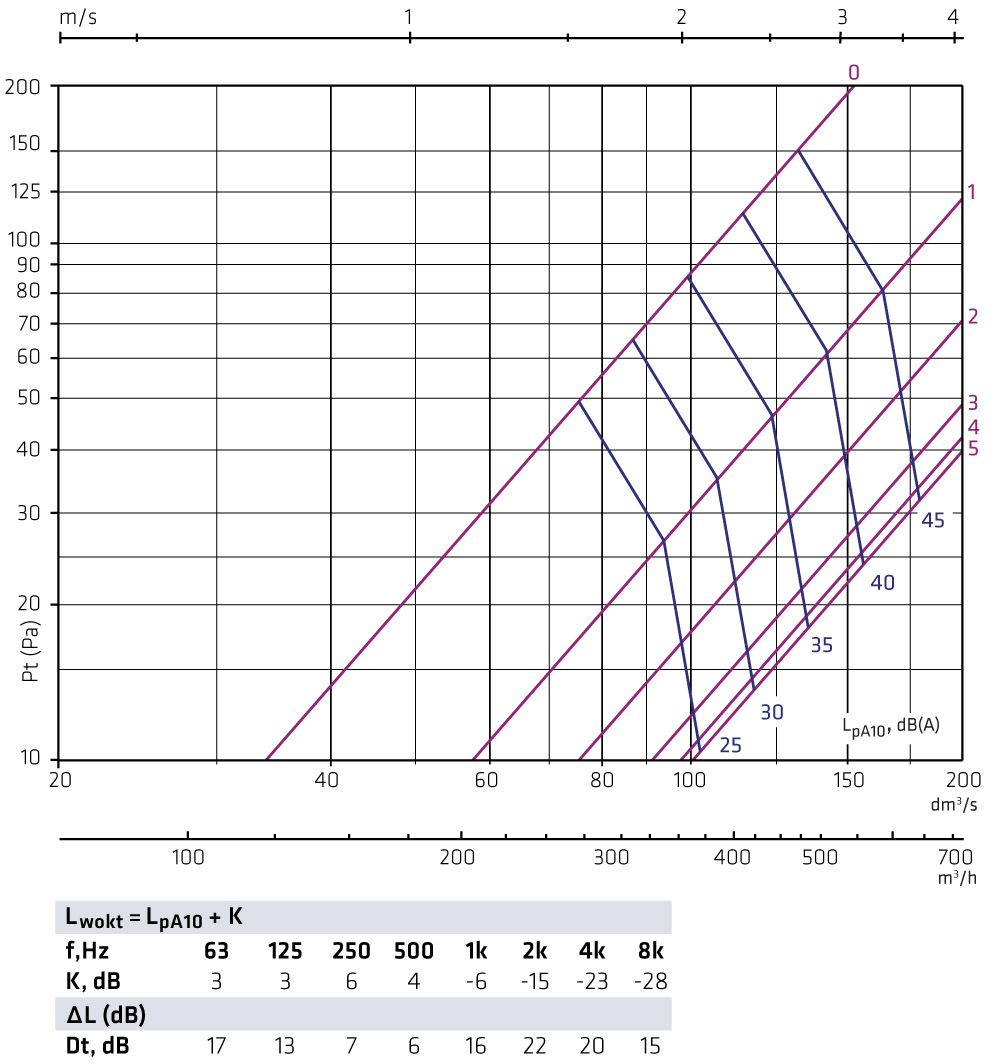

ROX-S + ROX 160

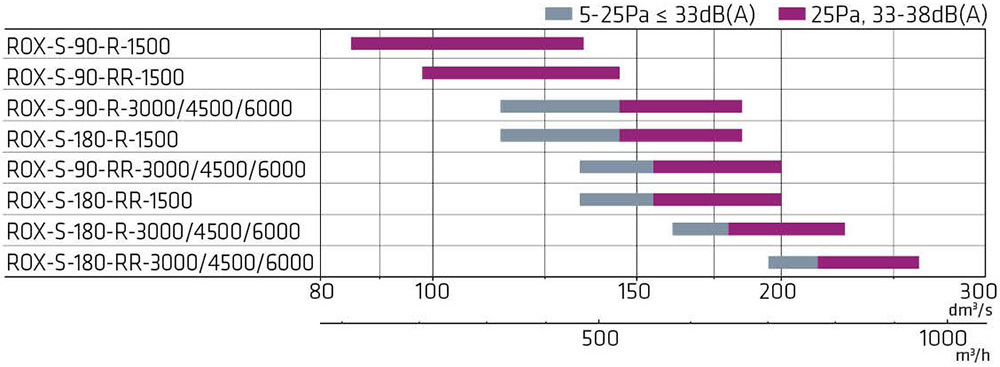

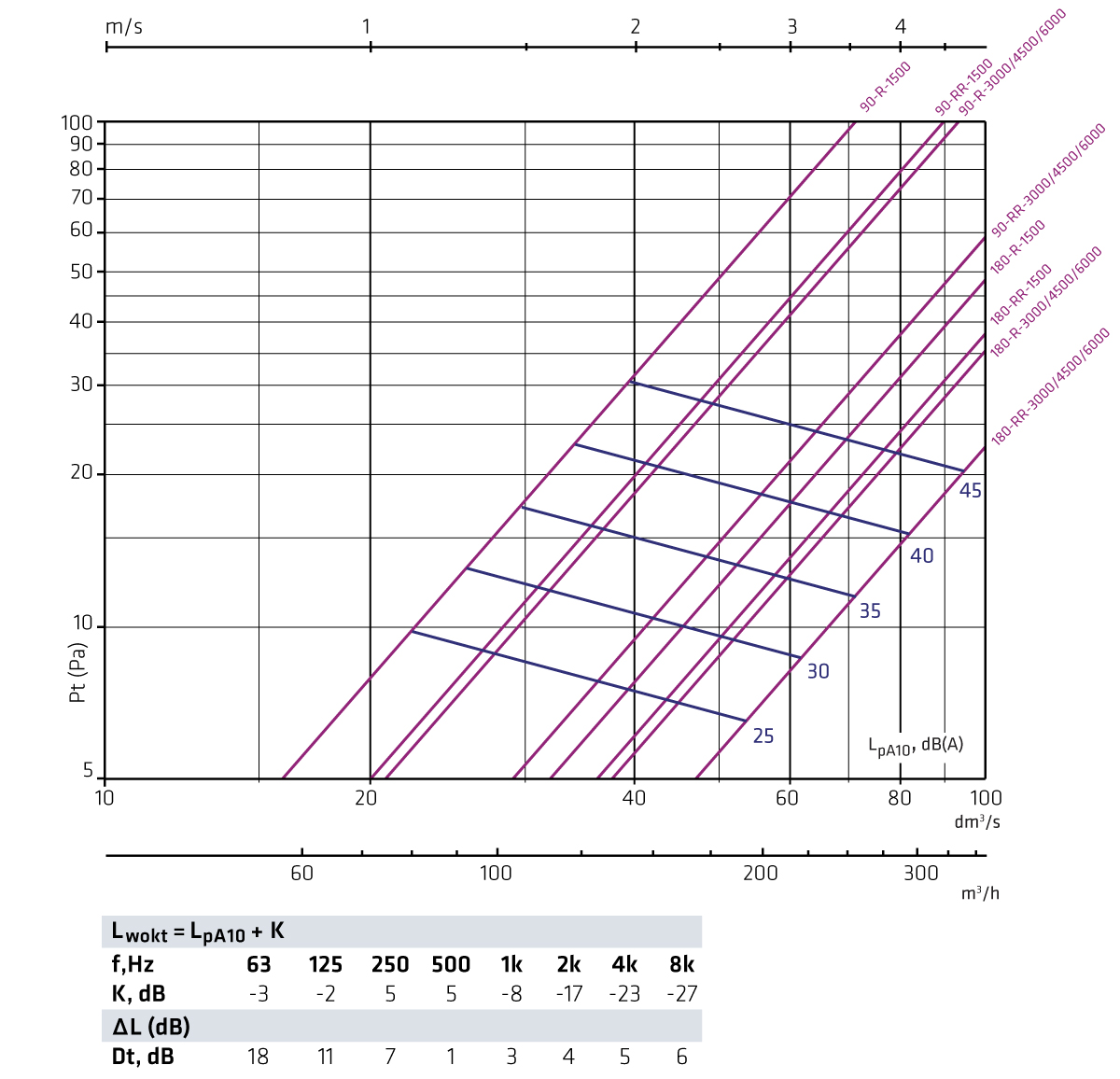

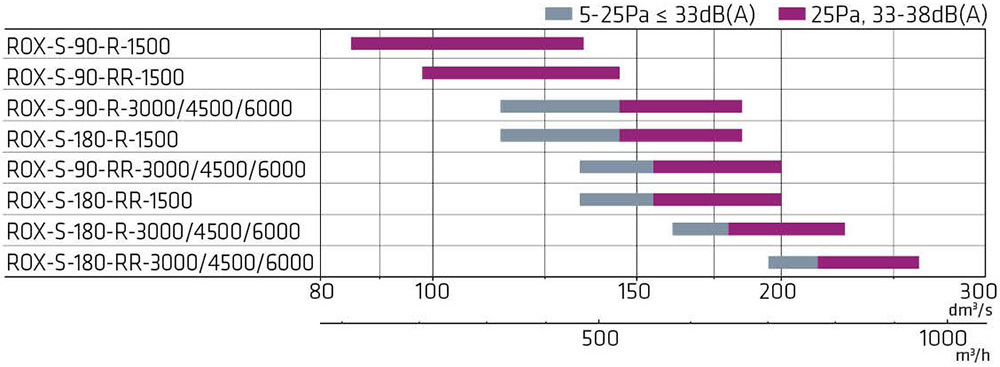

NOTE! In the model 90-R-1500 purple area = 5Pa – 40Pa ≤ 38dB (A)

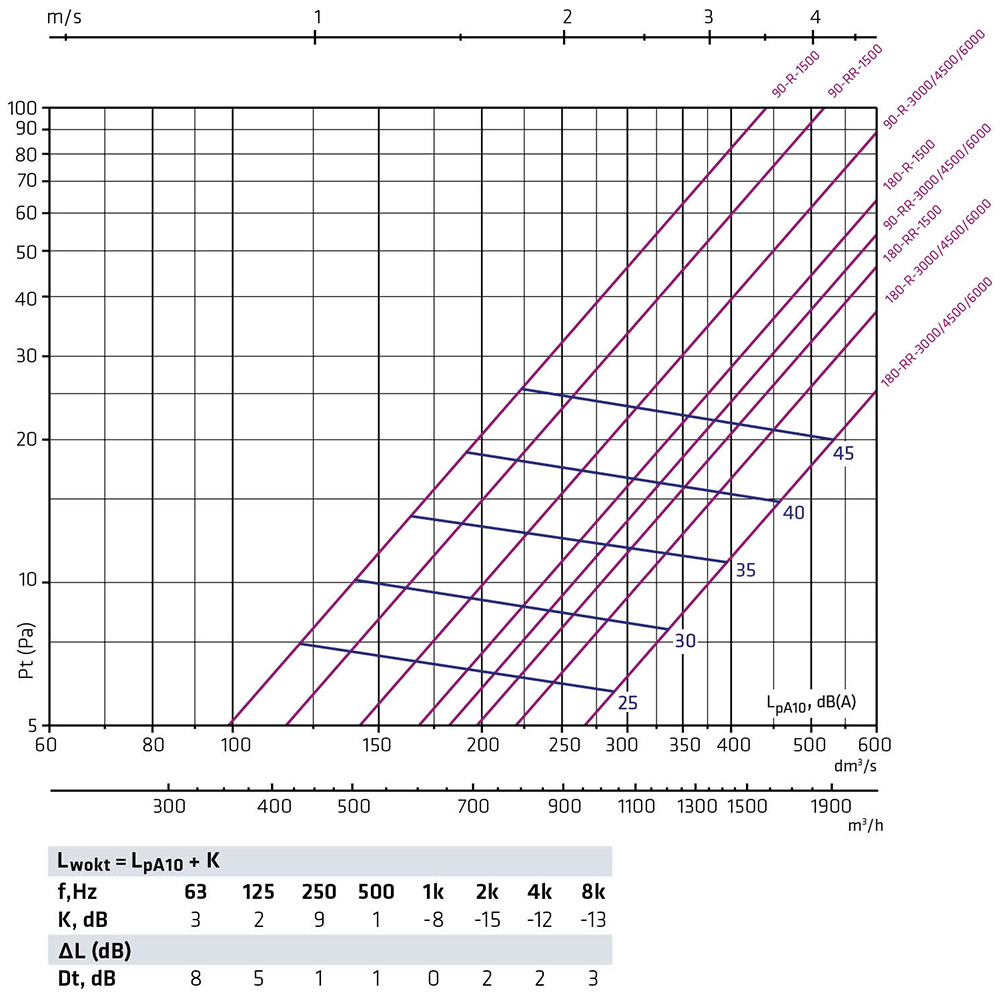

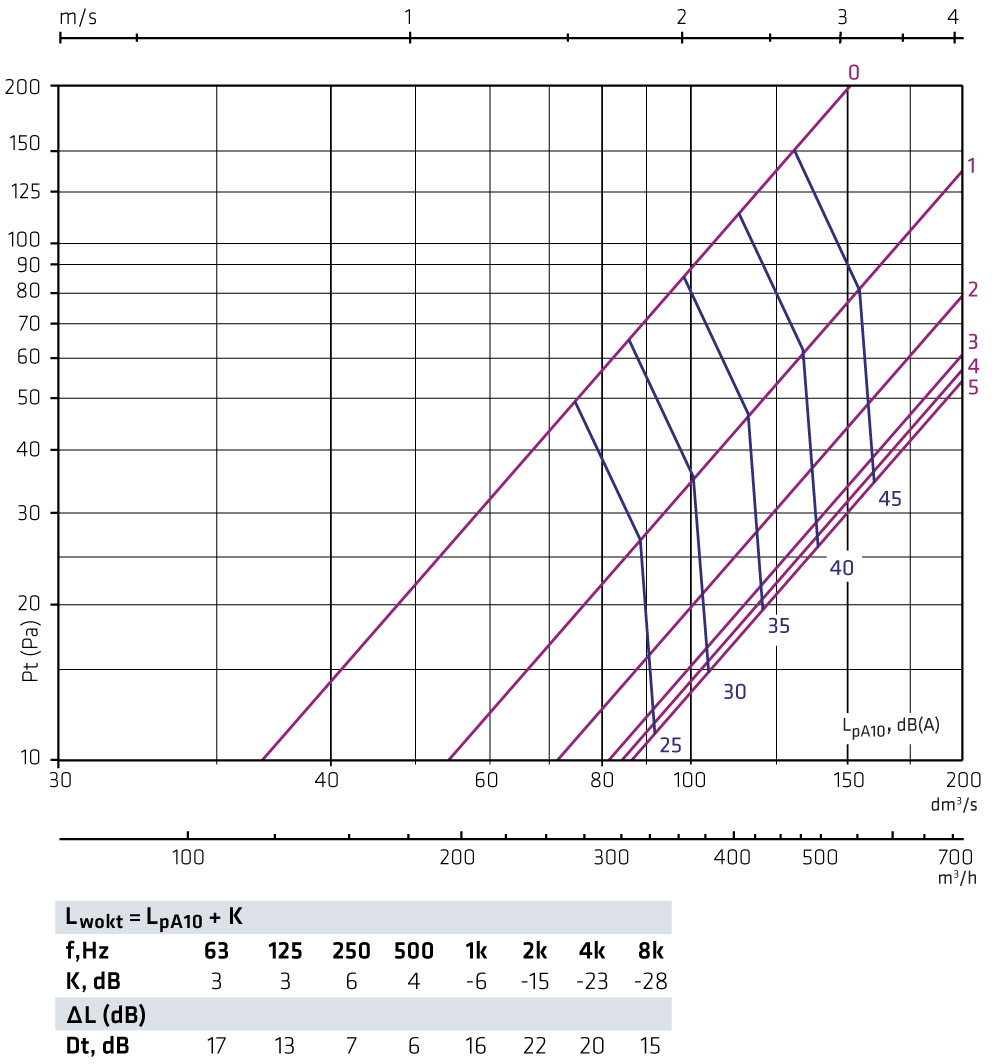

ROX-S + ROX 200

NOTE! In the model 90-R-1500 purple area = 5Pa – 40Pa ≤ 38dB (A)

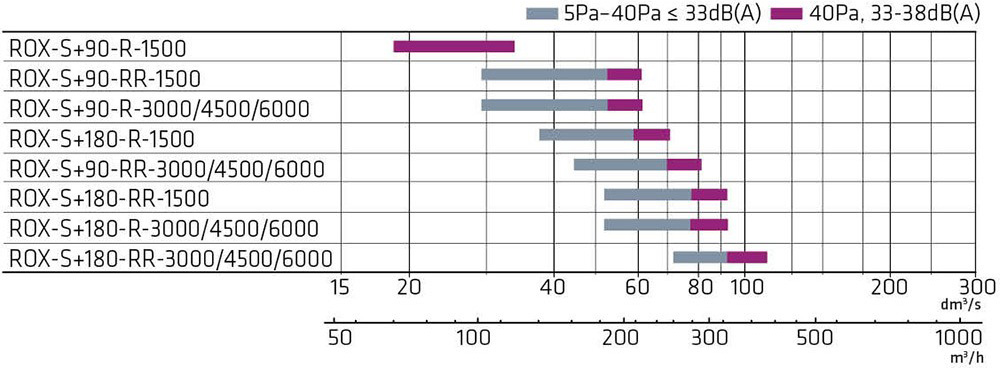

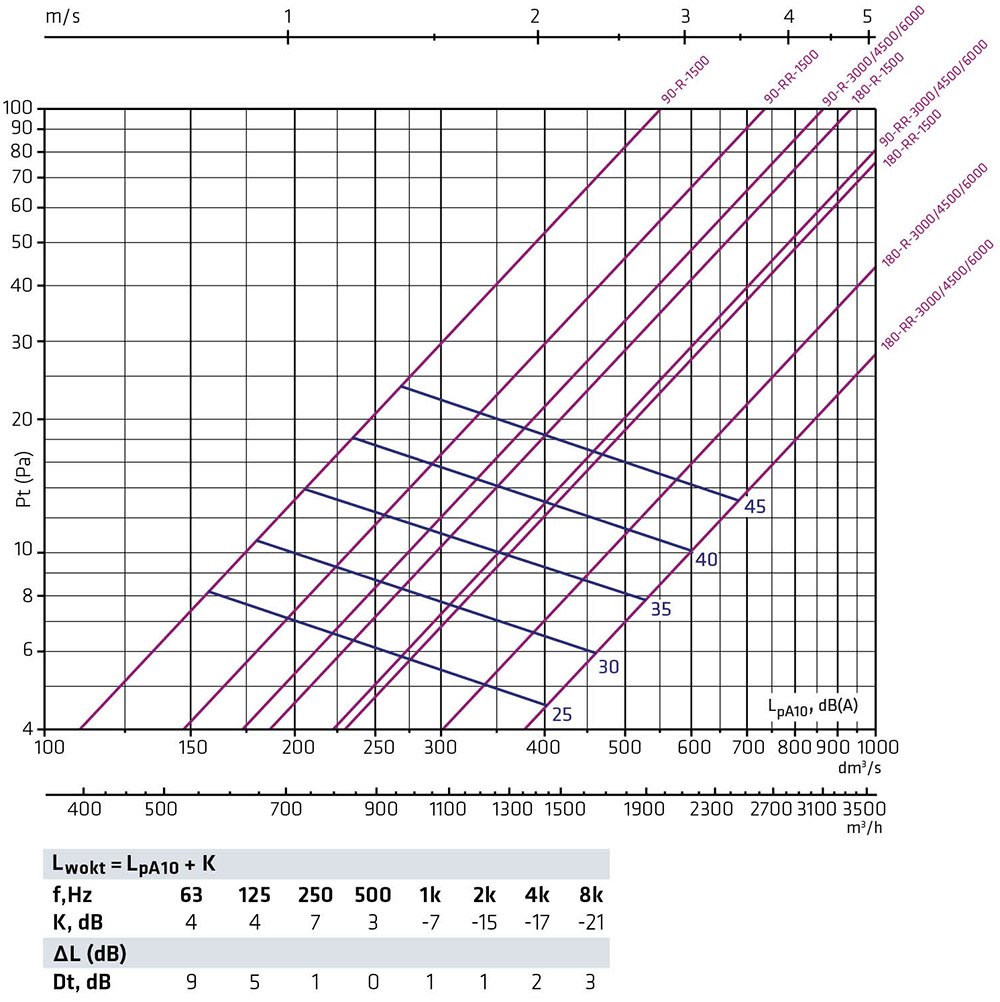

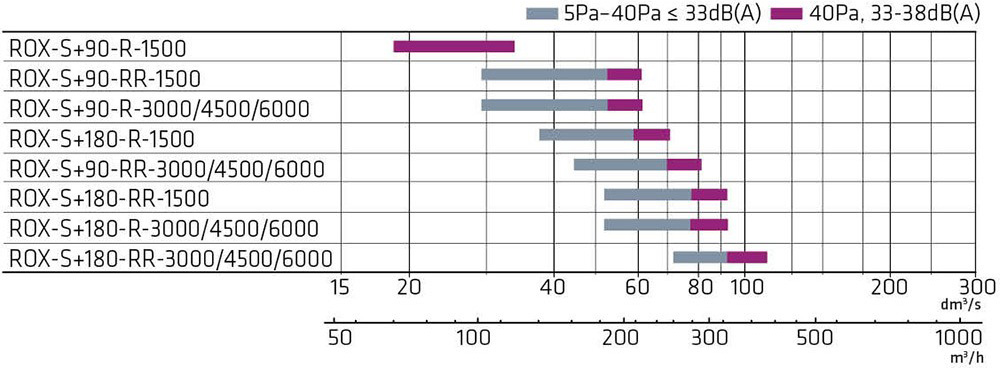

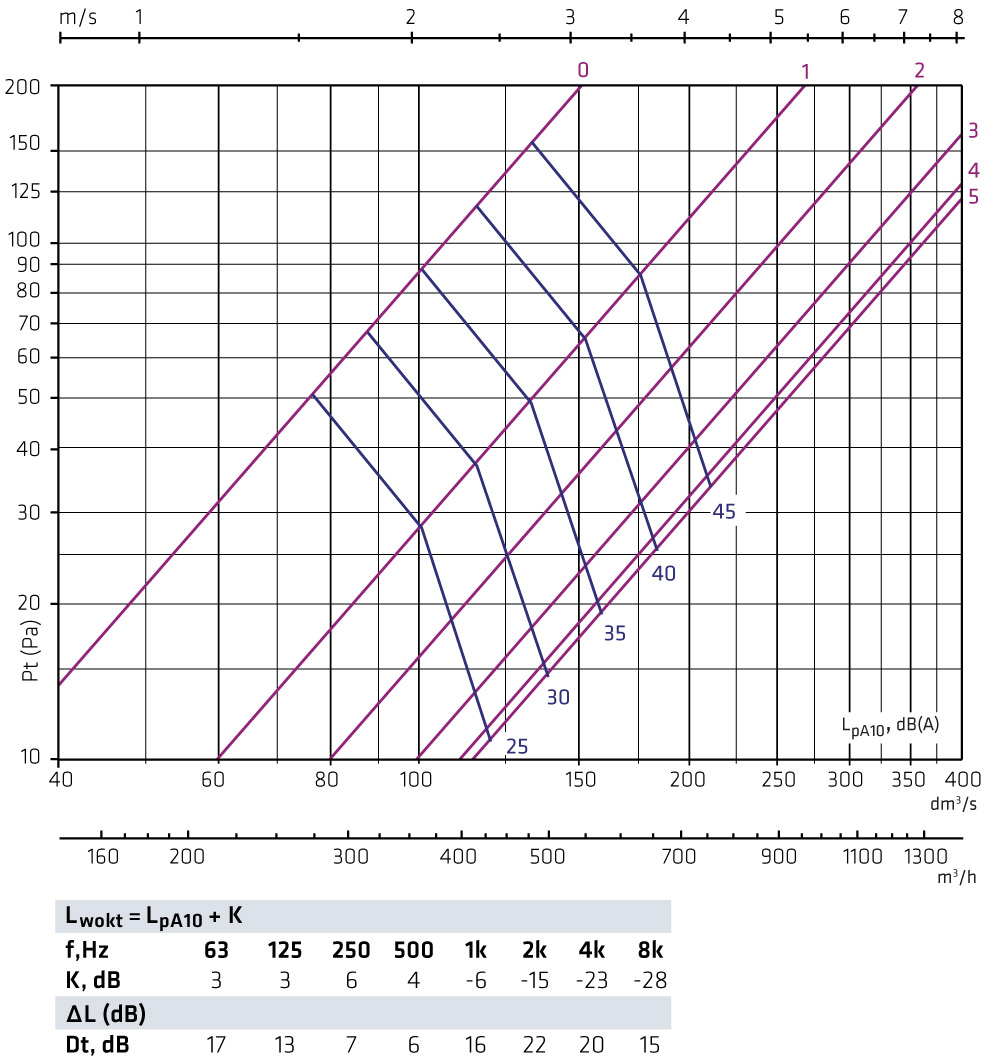

ROX-S + ROX 250

NOTE! In the model 90-R-1500 purple area = 5Pa – 40Pa ≤ 38dB (A)

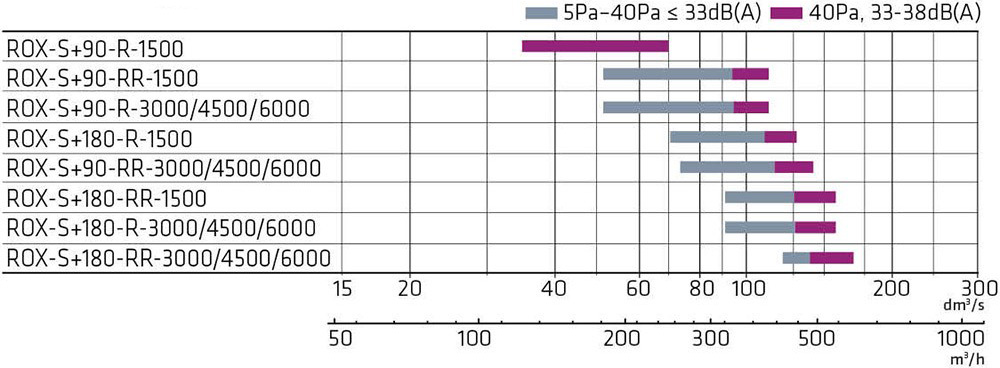

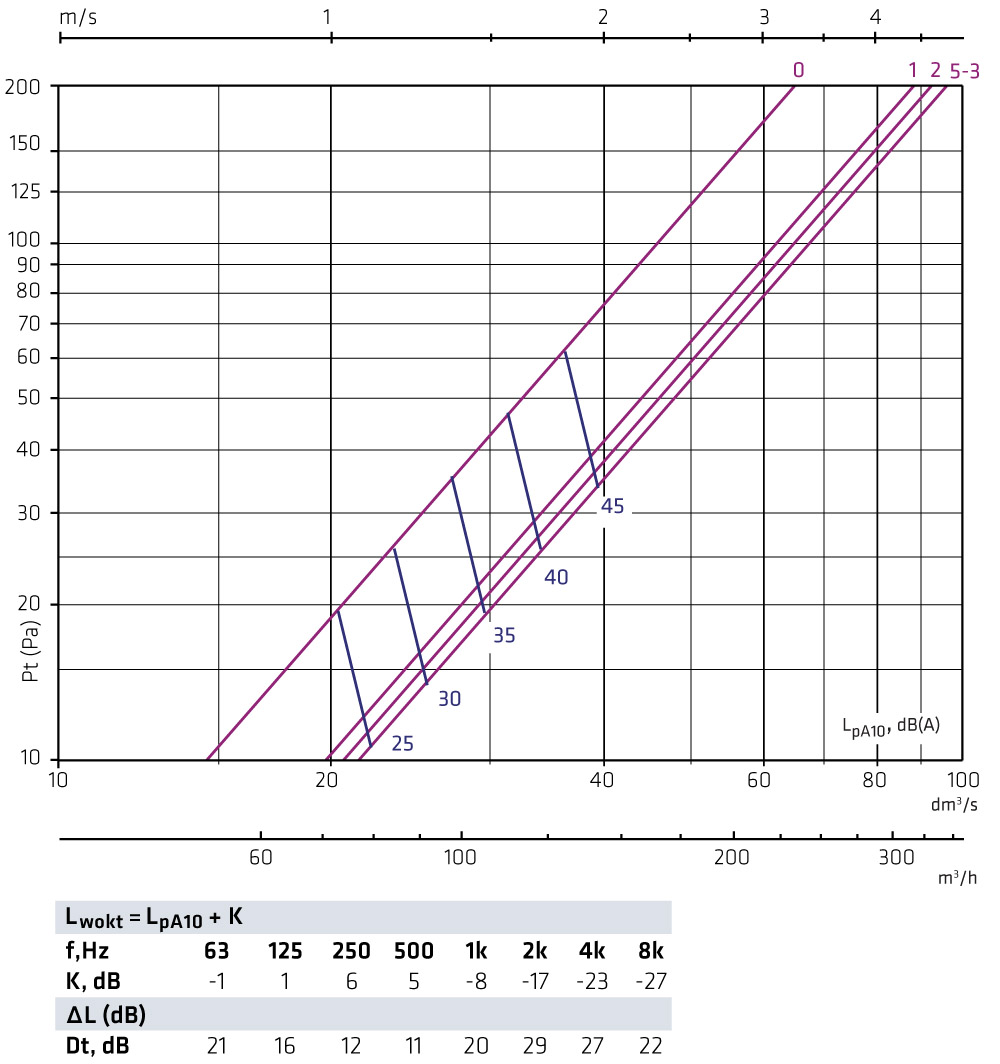

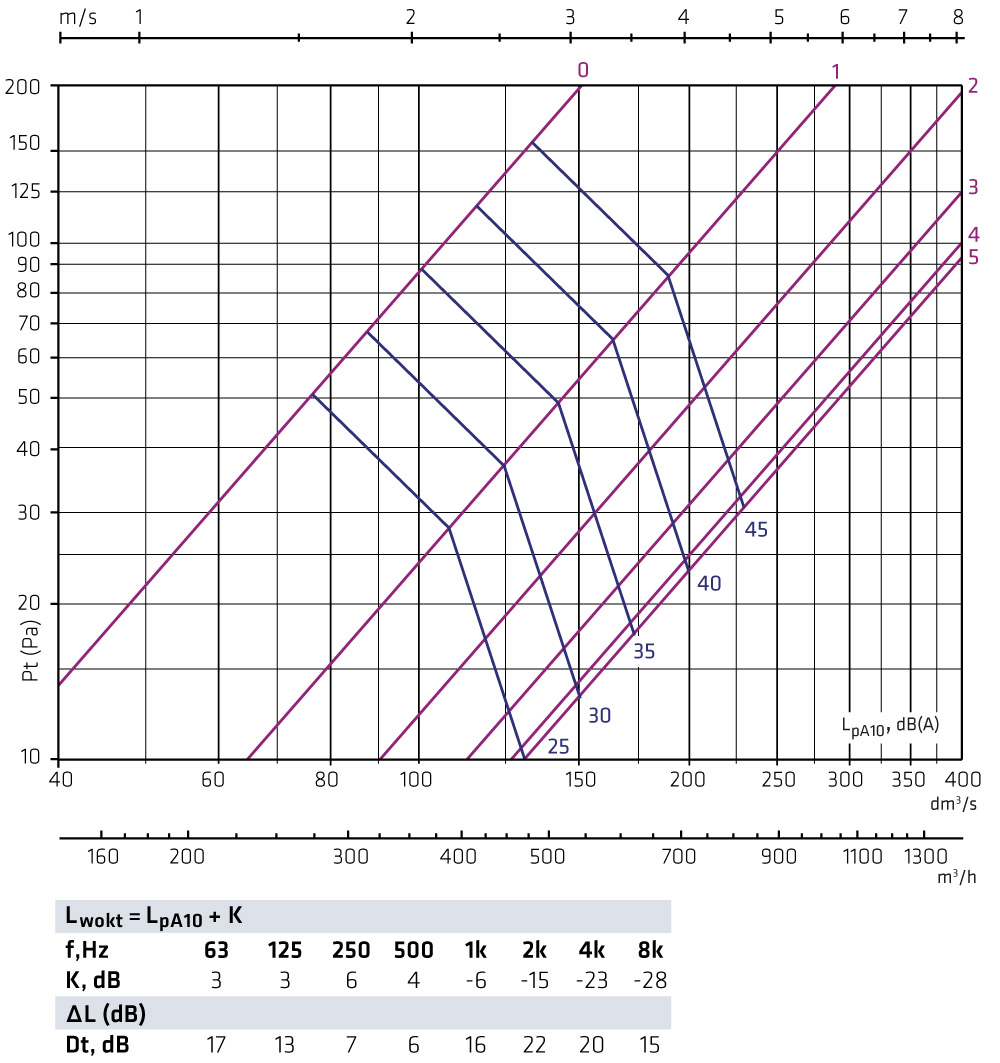

ROX-S + ROX 315

NOTE! In the model 90-R-1500 purple area = 5Pa – 40Pa ≤ 38dB (A)

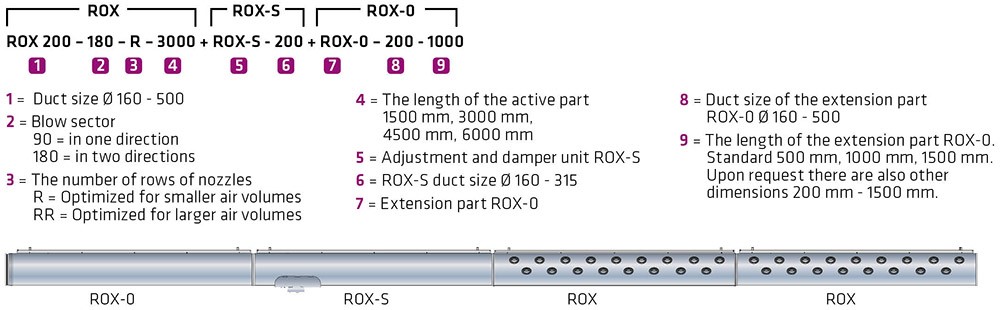

Product code

A stylish package

ROX is the most stylish nozzle duct in the market that is equipped with the directable nozzles. The clean, flat surface of ROX is easy to keep clean. The nozzle unit ROX, adjustment and damper unit ROX-S as well as the extension part ROX-0 form a coherent and stylish package.

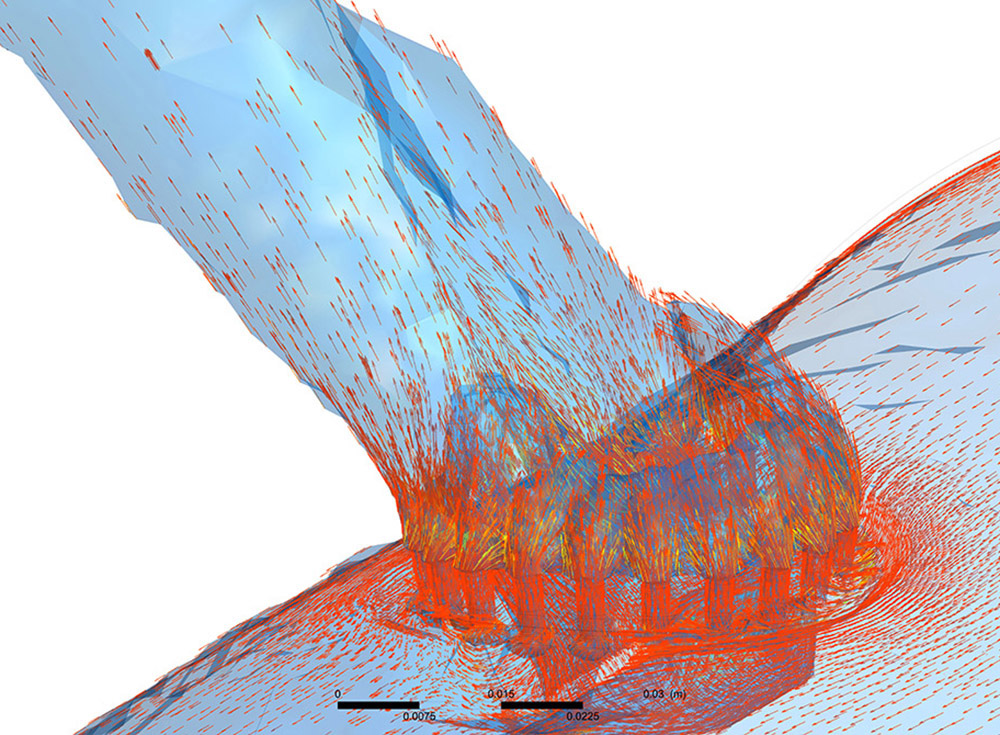

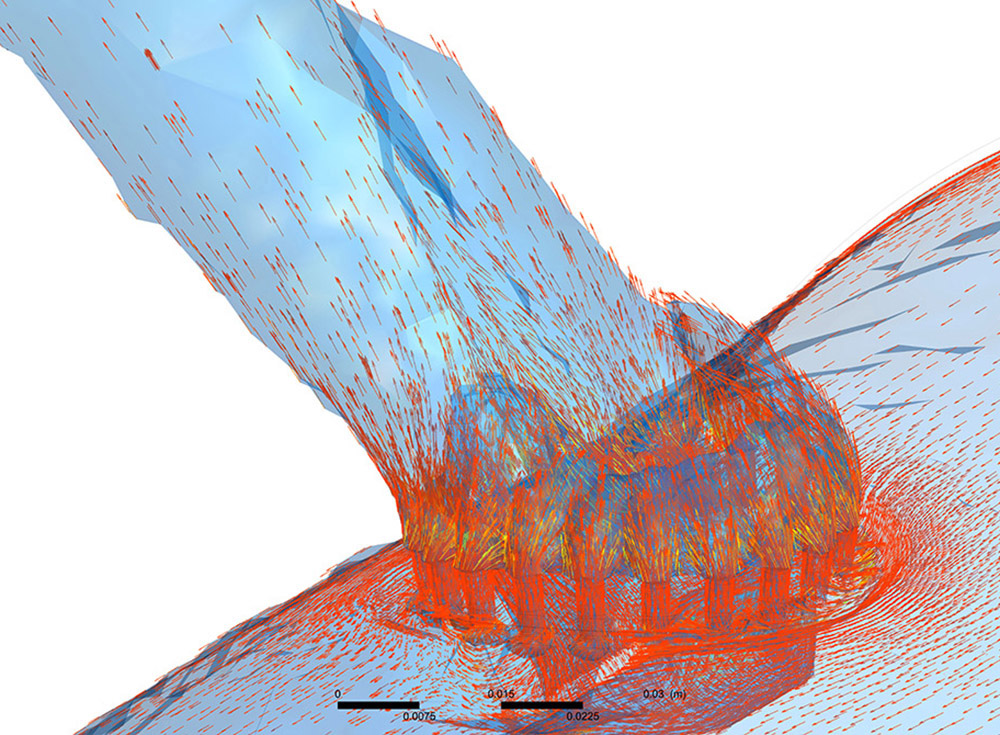

Unique CliMix® nozzles

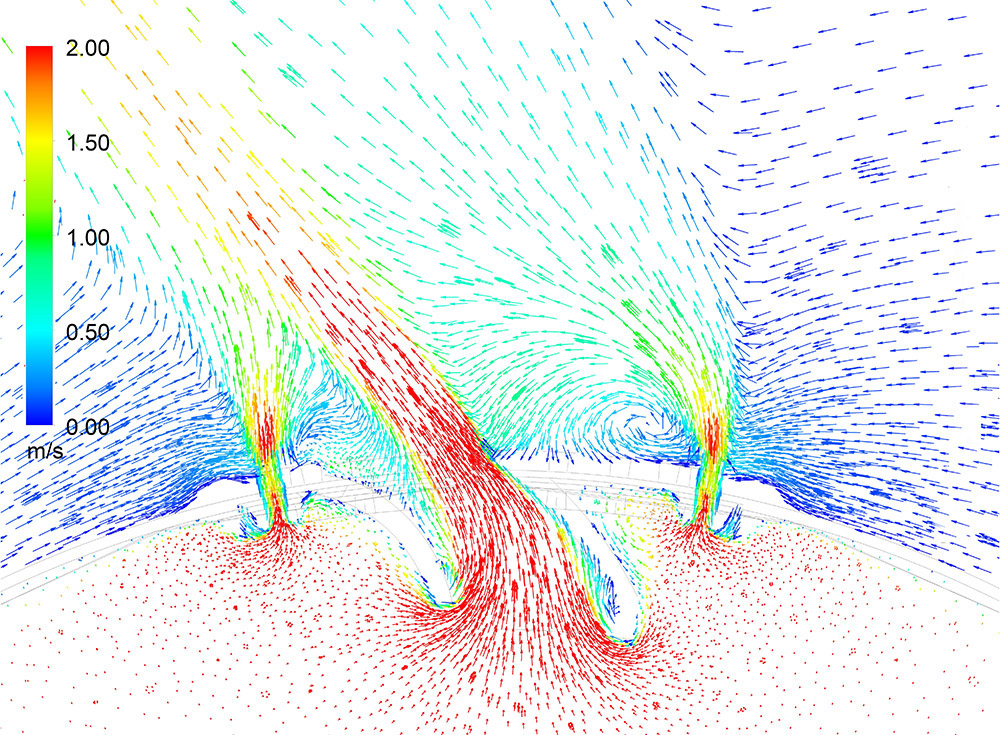

ROX is equipped with the most advanced CliMix® nozzles in the market, which combine 100% adjustable throw pattern and a high induction rate, i.e., good miscibility with the room air.

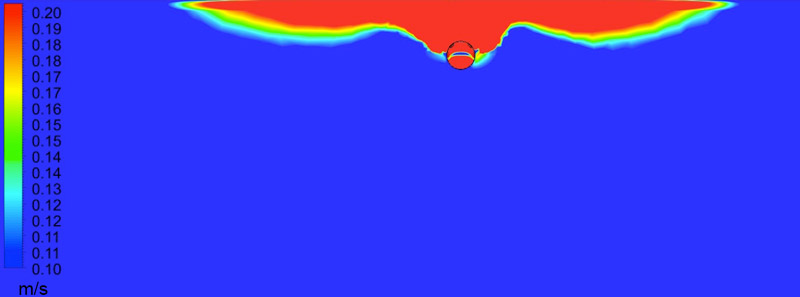

Superior functioning of CliMix® nozzles is based on two technologies, as a result of which:

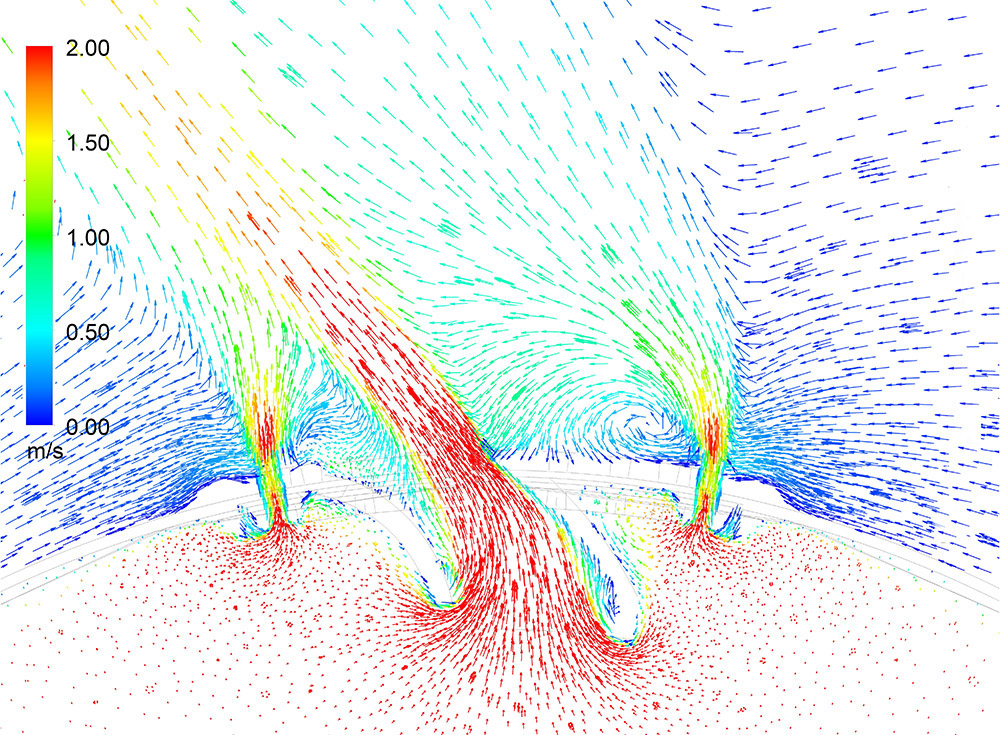

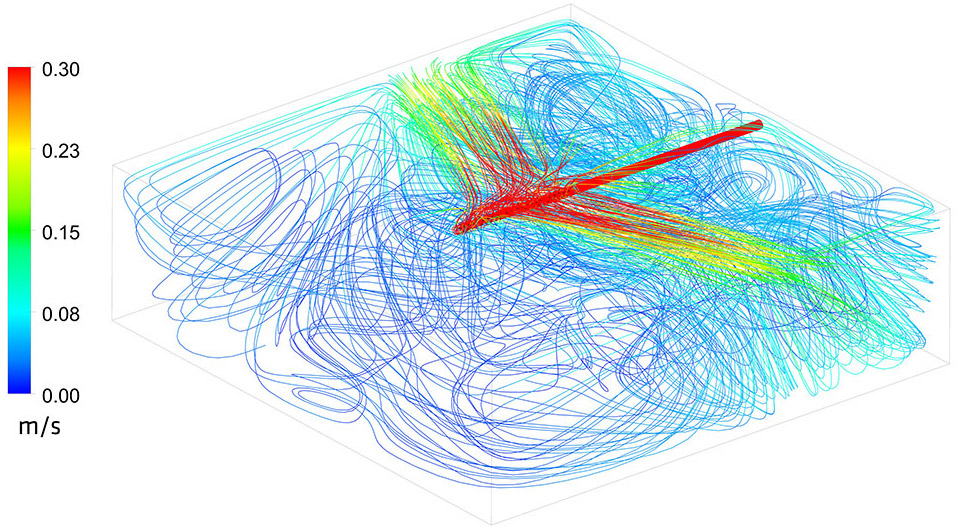

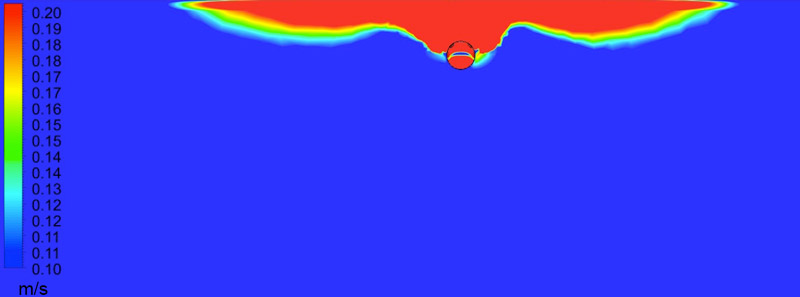

1. The supply air mixes efficiently with the room air, which in turn will level the room temperature differences and reduces the flow velocities in the living zone.

2. The ingenious structure of CliMix® nozzles prevents

the air flow jet from hitting the surface of product, which prevents the dirt particles in the secondary air from sticking to the surface of the product.

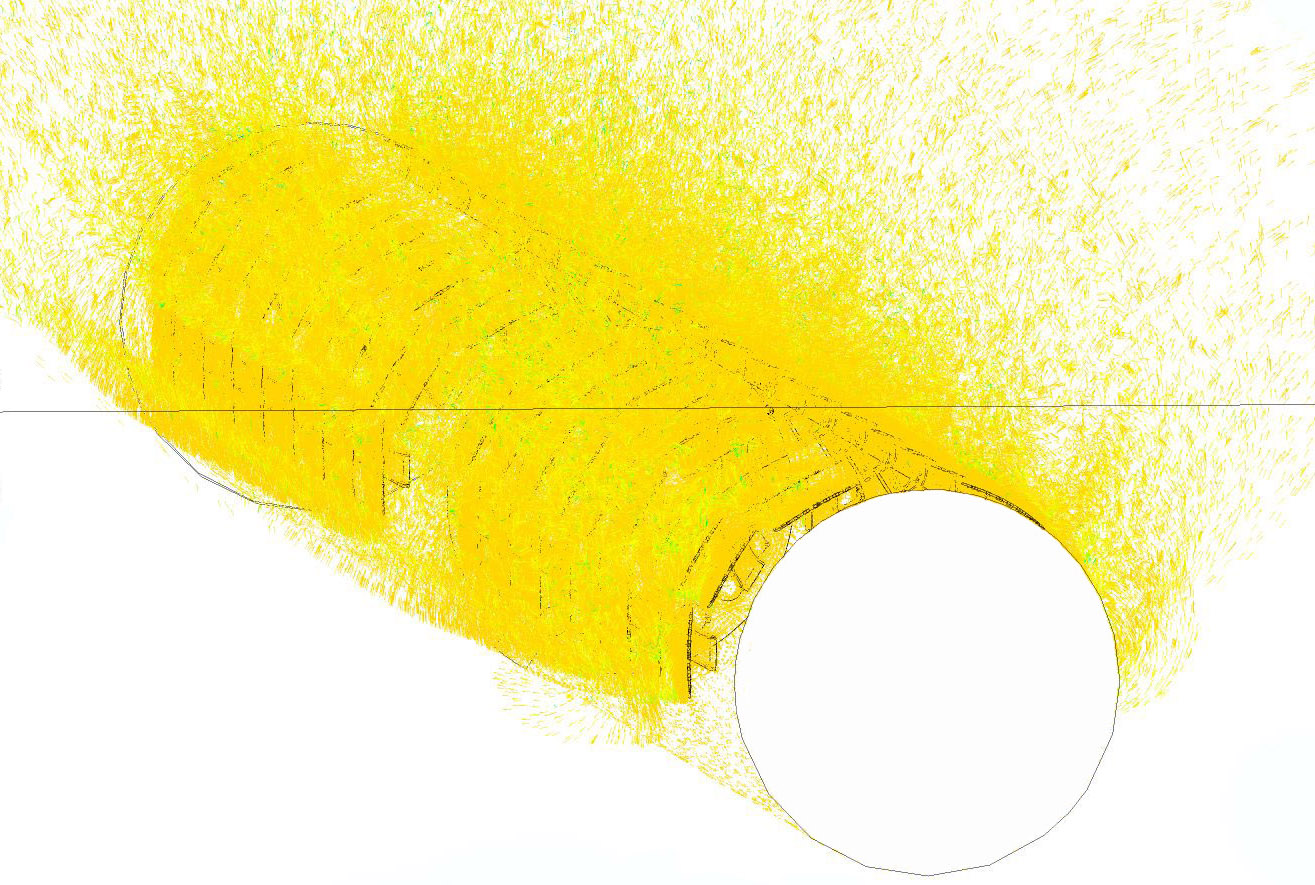

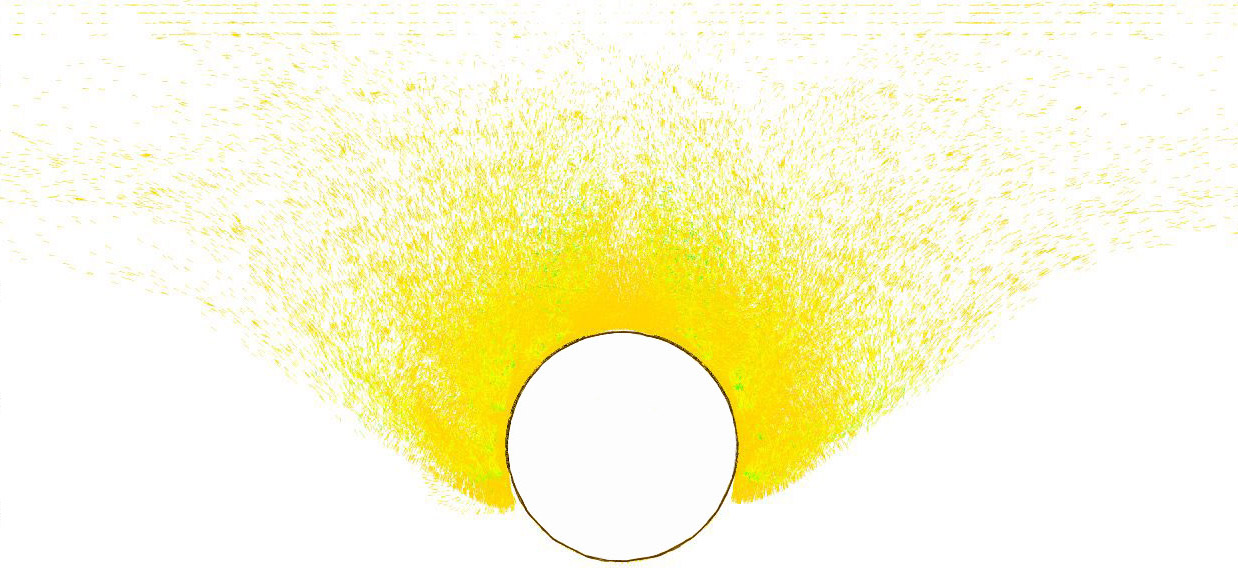

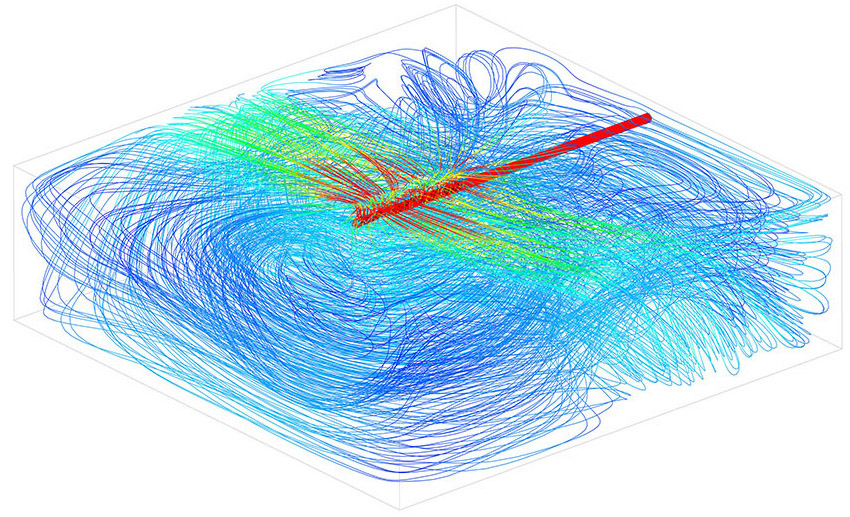

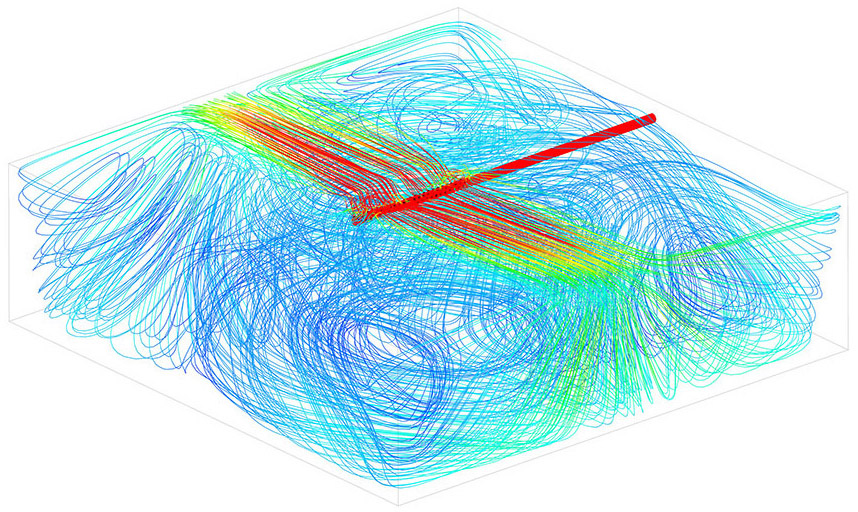

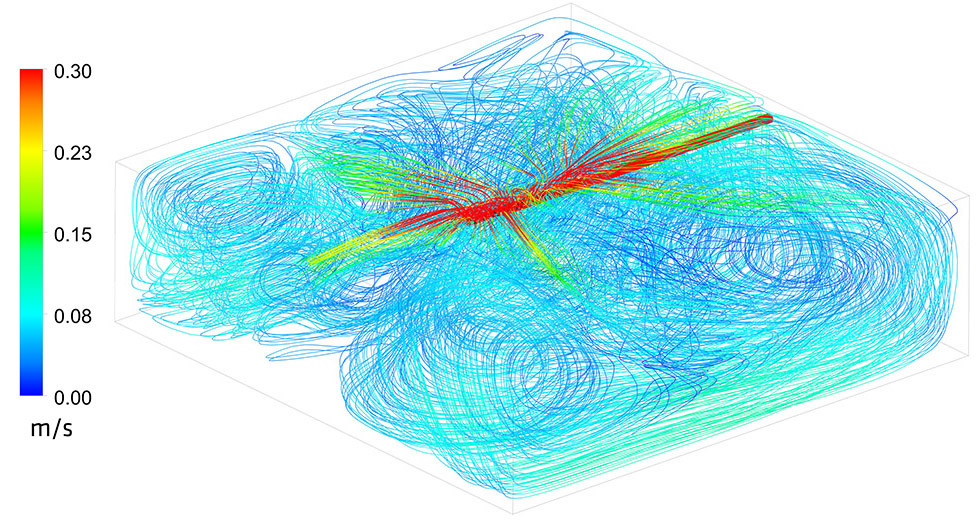

Pleasant and draught-free indoor air

Thanks to the high mixing ratio, pleasant and even indoor air is achieved with ROX. CliMix® nozzles allow the supply air to be distributed evenly and at a low speed over a wide area.

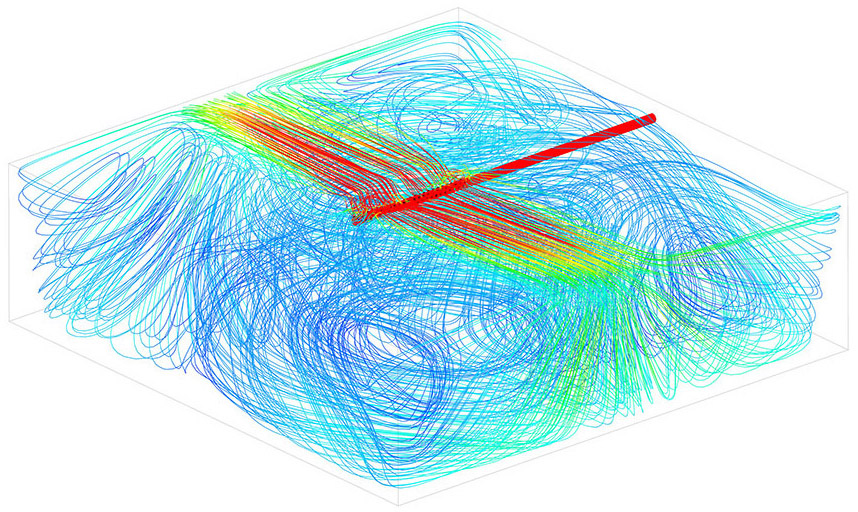

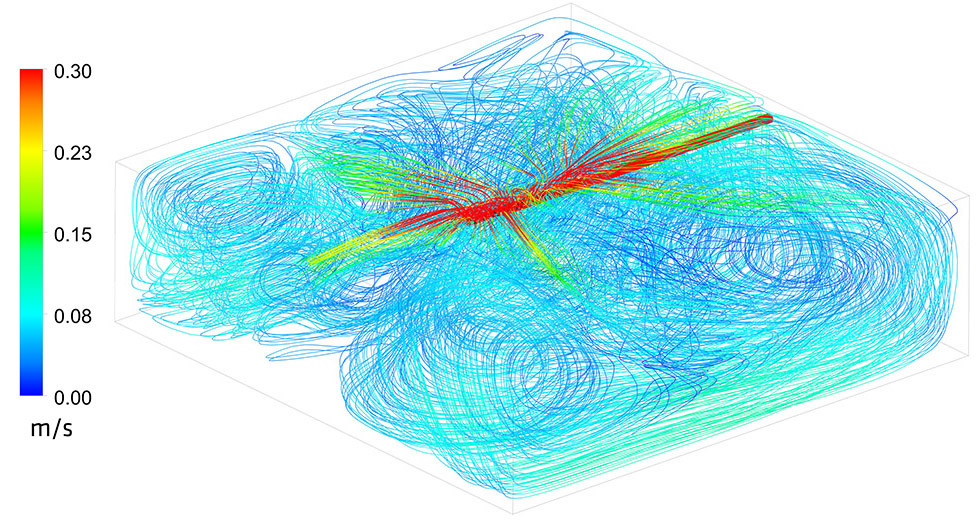

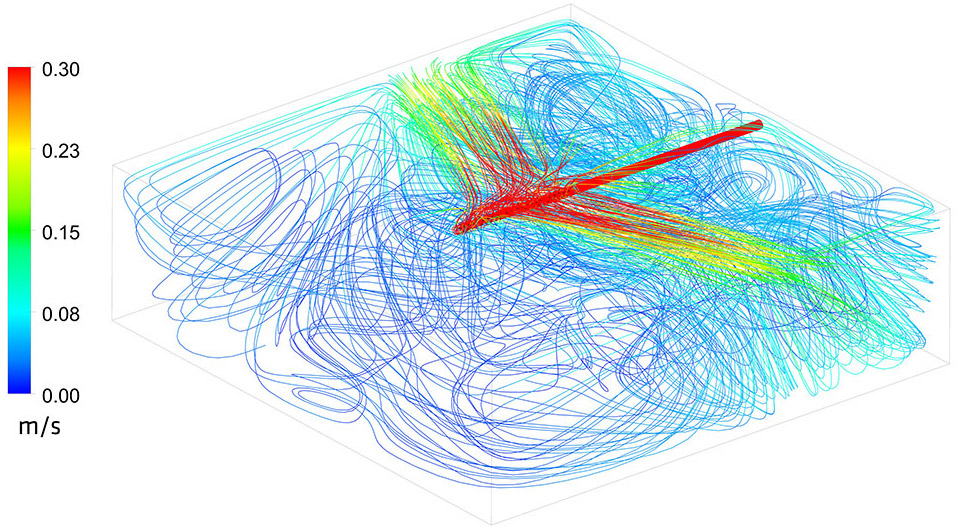

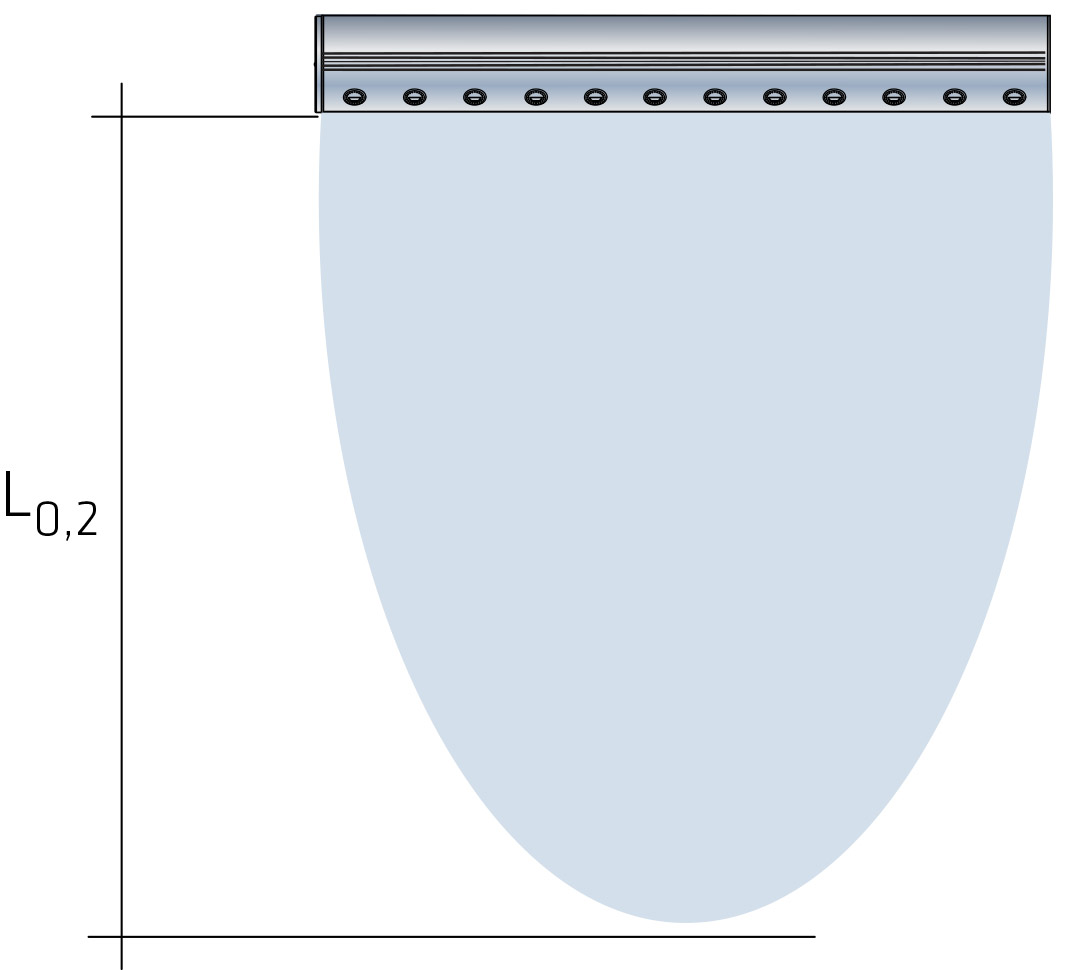

Supply air is evenly distributed over a wide area into the room

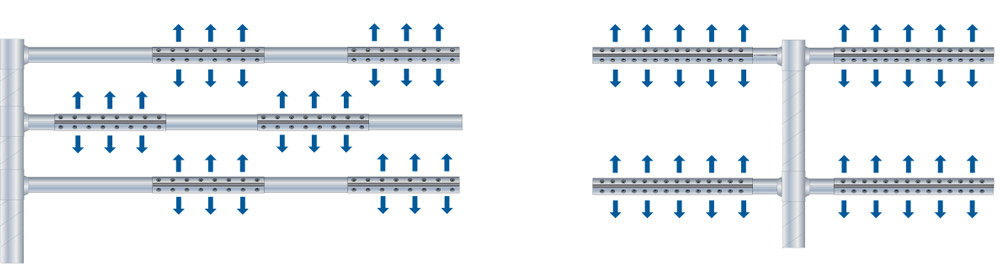

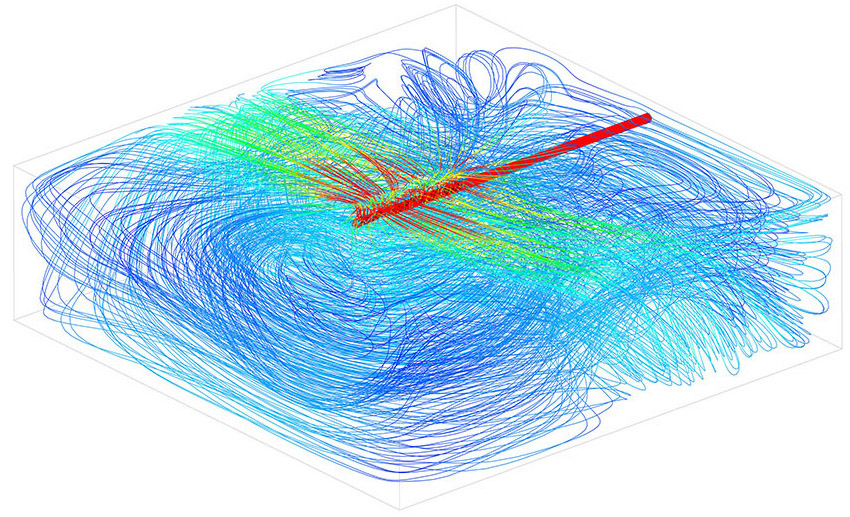

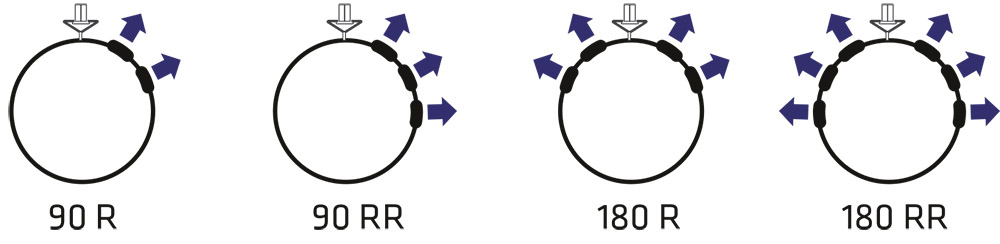

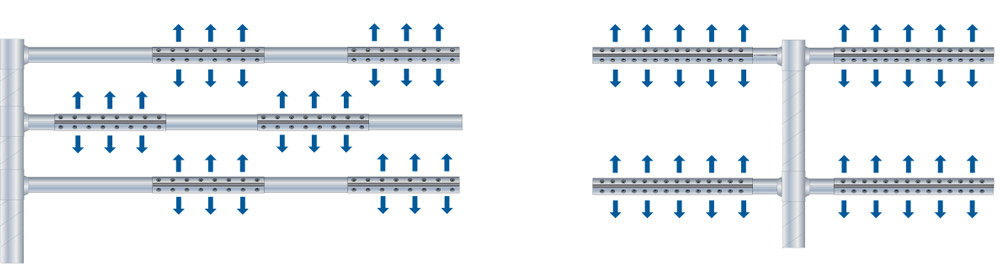

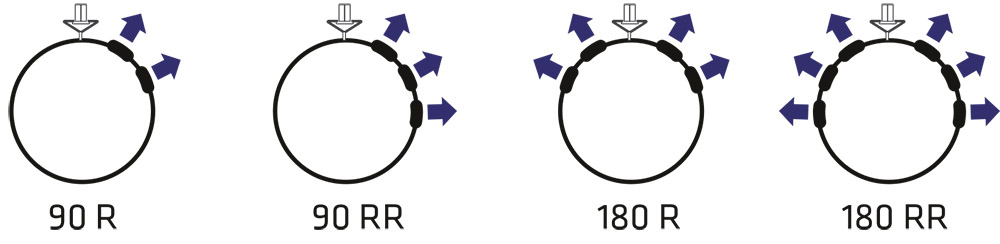

Throw patterns

The throw pattern of ROX is easy to change in connection with the rearrangement of the space

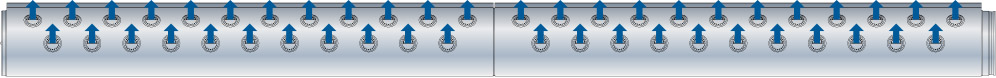

Standard throw pattern in which all the nozzles are turned upwards.

Long and narrow throw pattern. The uppermost nozzle row is directed downwards and the other nozzles straight up.

360° degrees diffusive throw pattern. The nozzles directed both upwards and 45° to the sides.

Throw pattern diagonally directed towards the air inlet direction. The nozzles directed at 45 ° diagonally upward toward the air inlet.

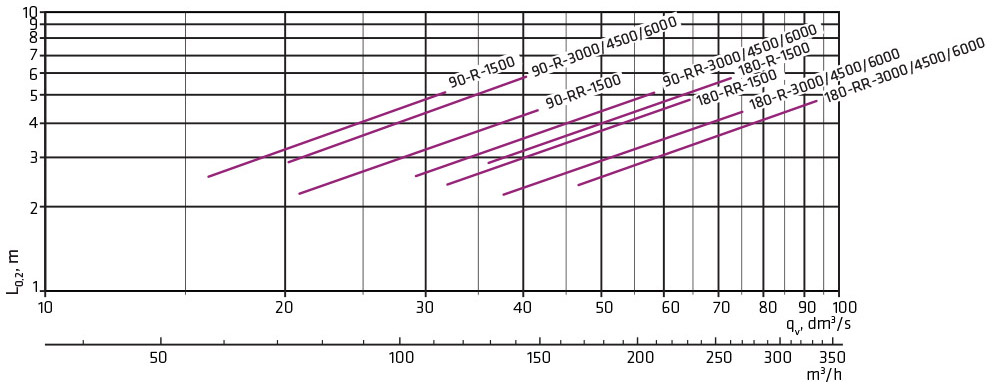

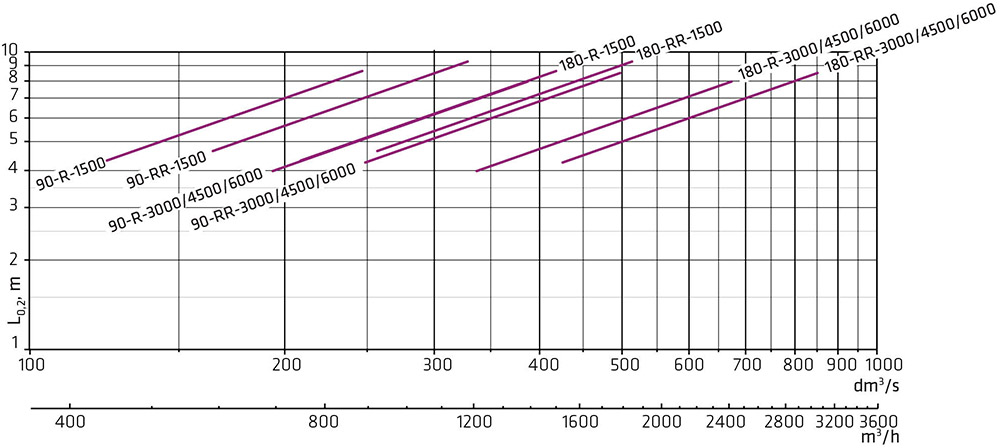

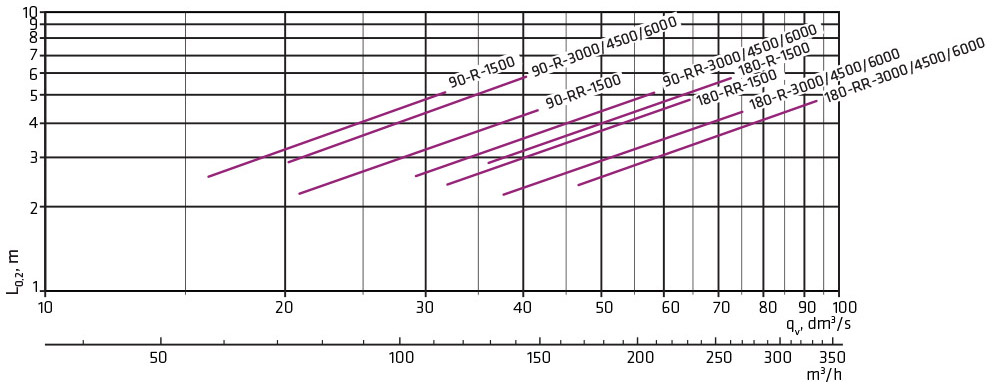

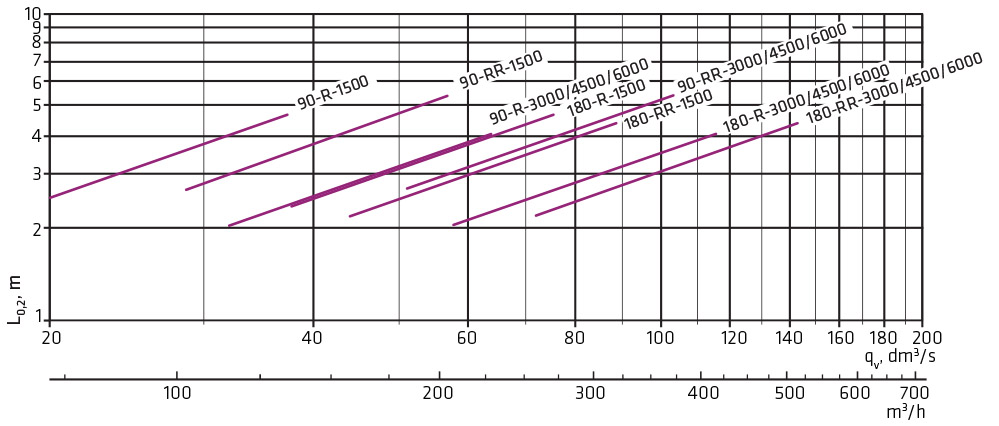

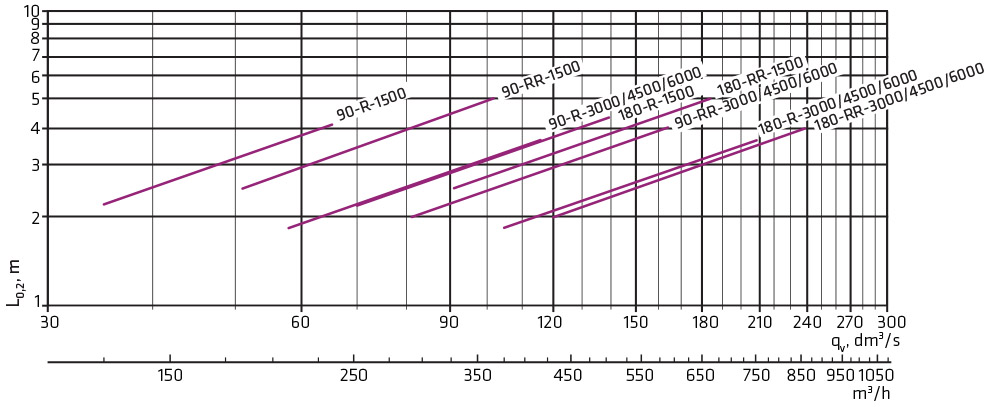

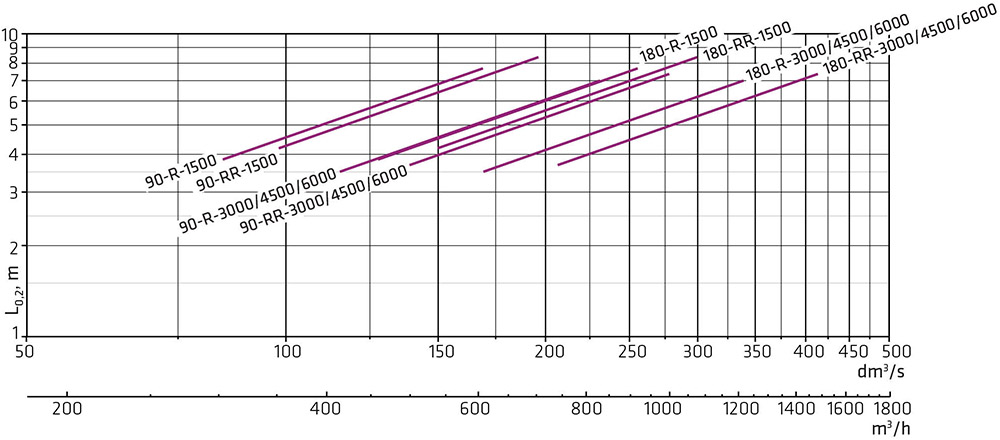

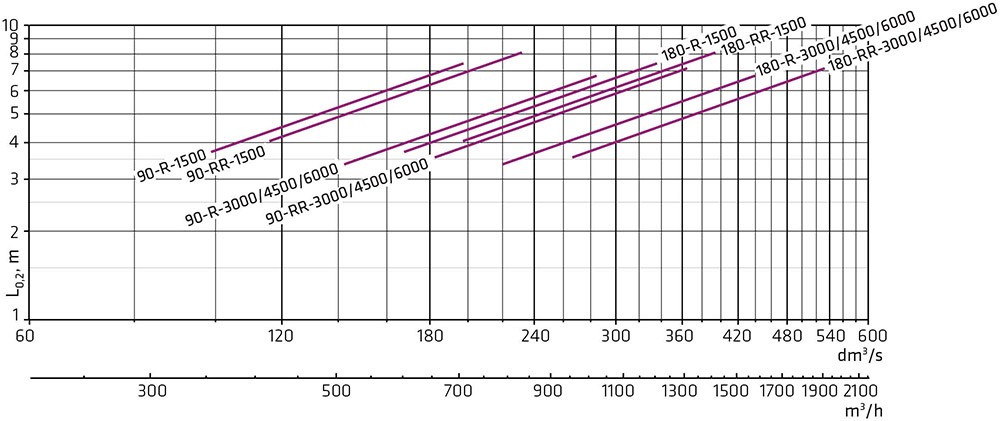

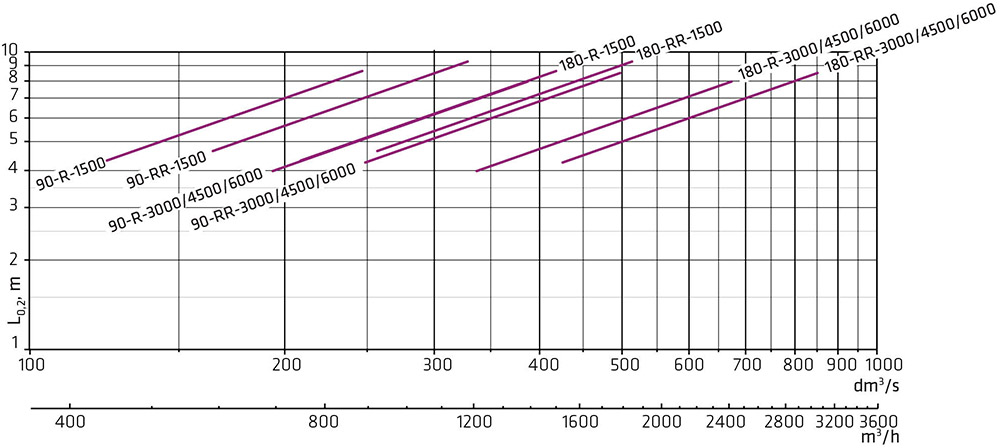

Throw lengths

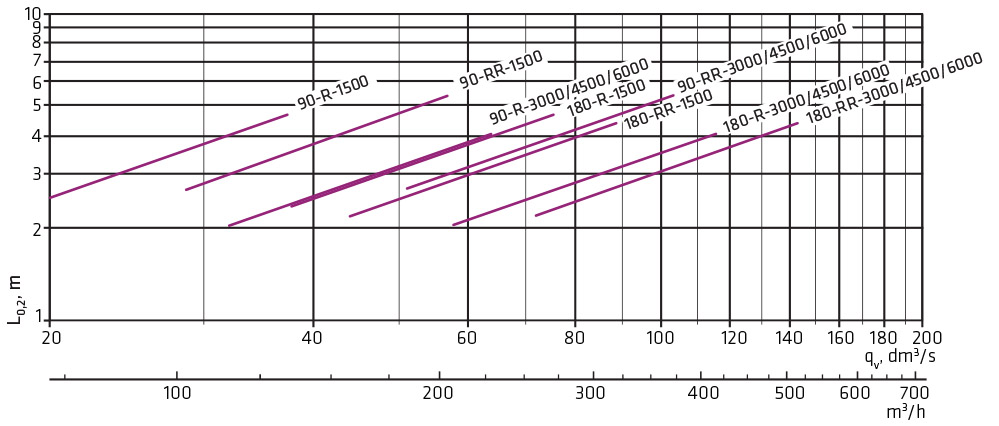

ROX 160

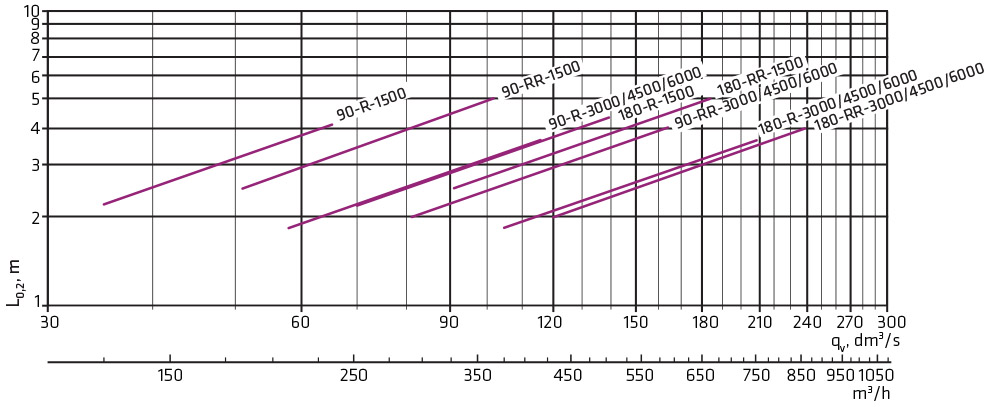

ROX 200

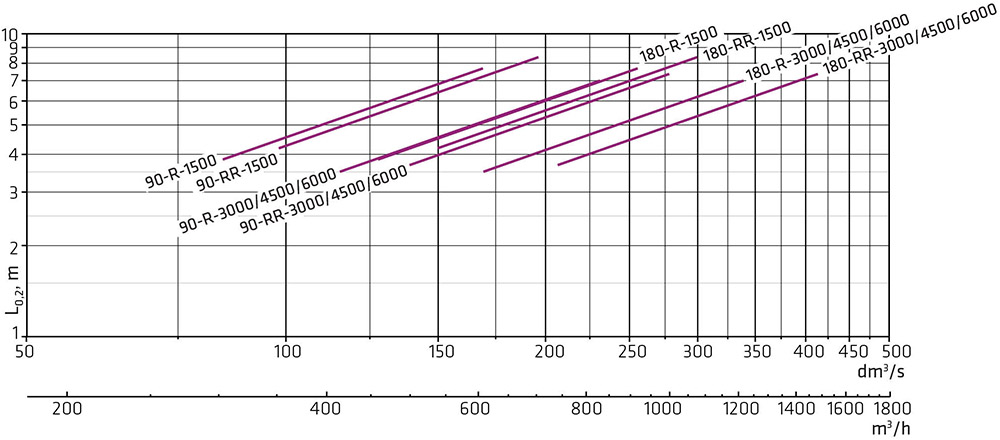

ROX 250

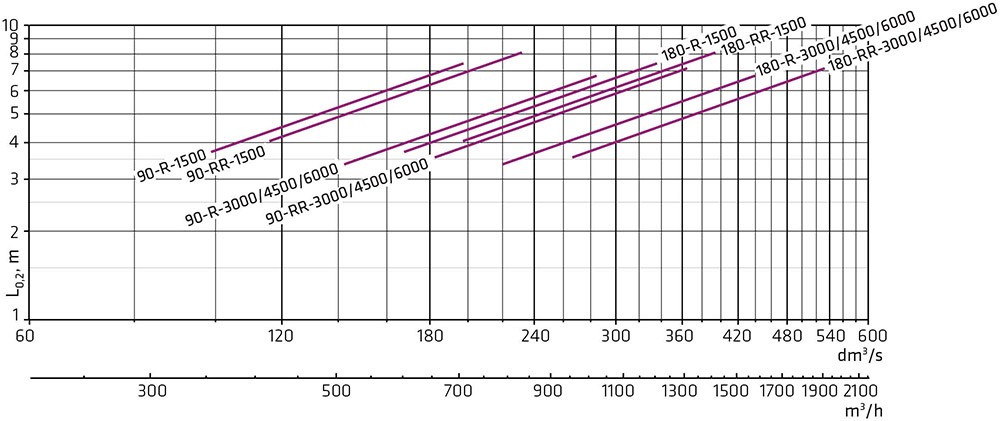

ROX 315

ROX 400

ROX 500

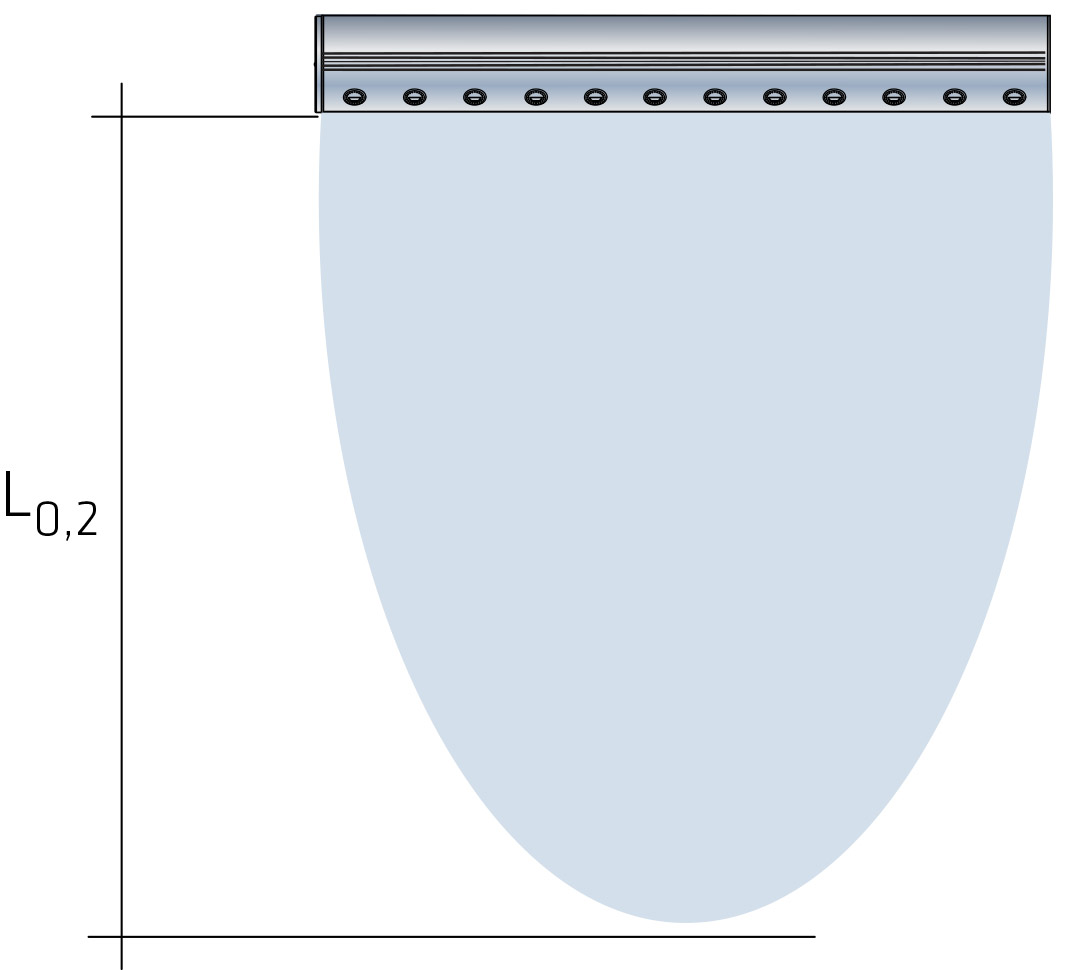

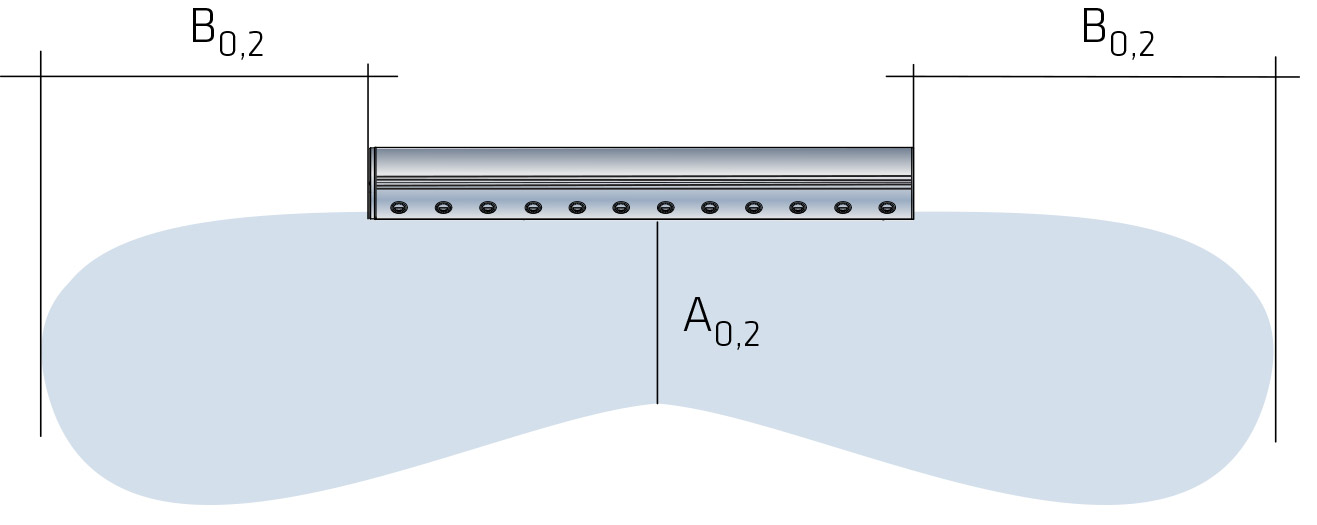

Throw patterns

Standard throw pattern L0,2 (All nozzles directed upwards)

The throw pattern, where the nozzles are directed at an angle of 45° degrees and 90° degrees

A0,2 = L0,2 x 0,6

B0,2 = L0,2 x 0,8

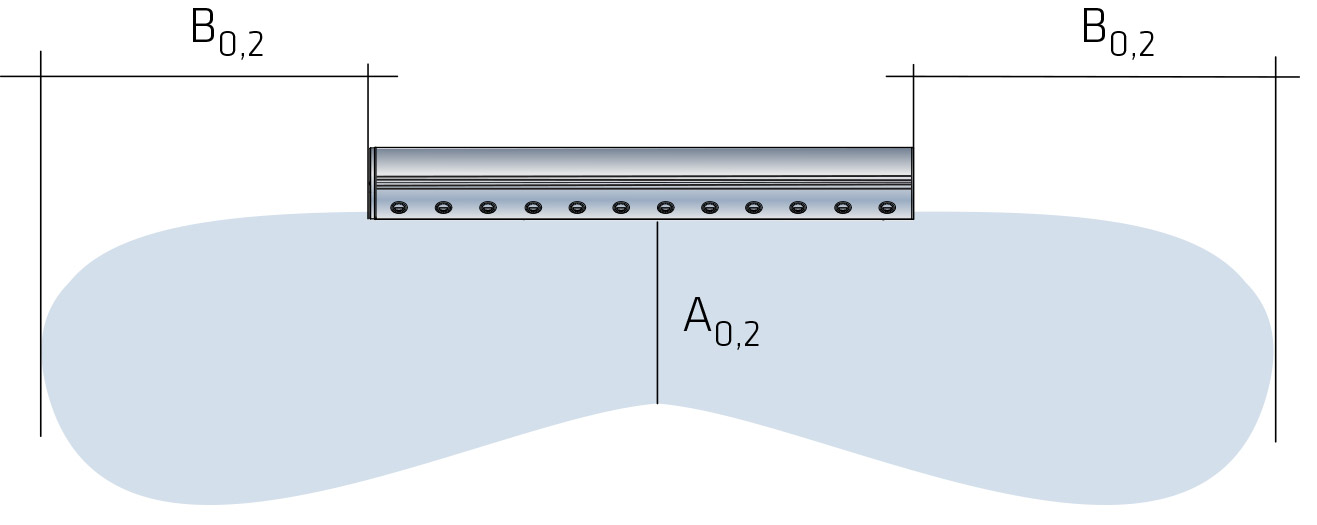

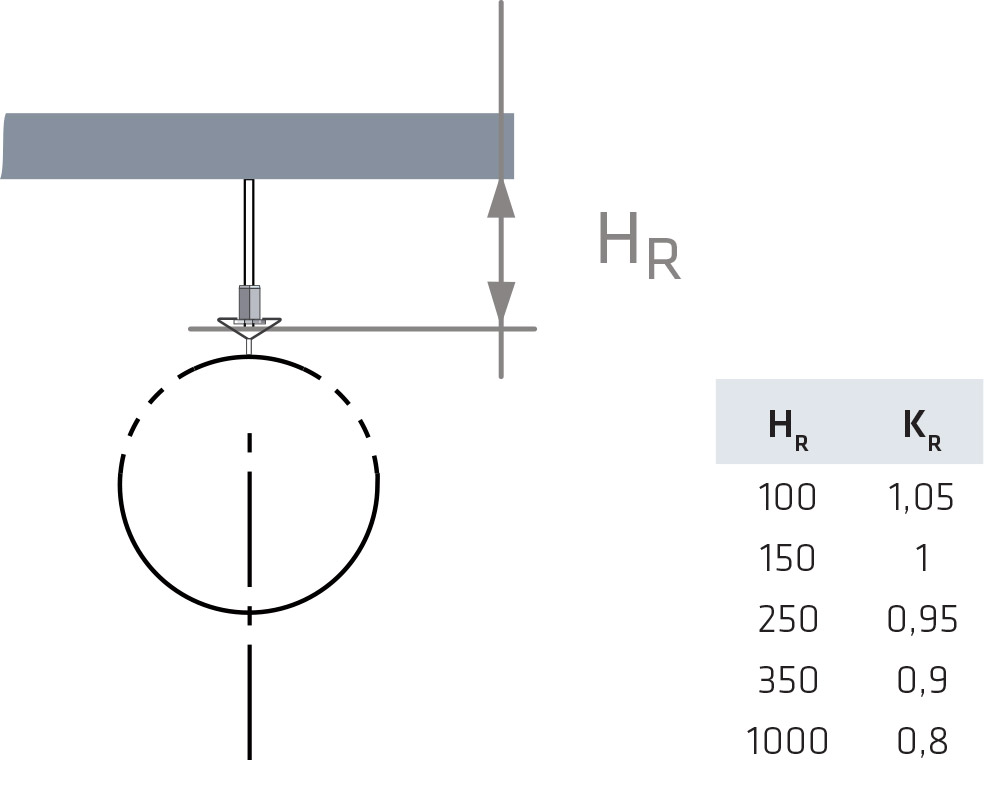

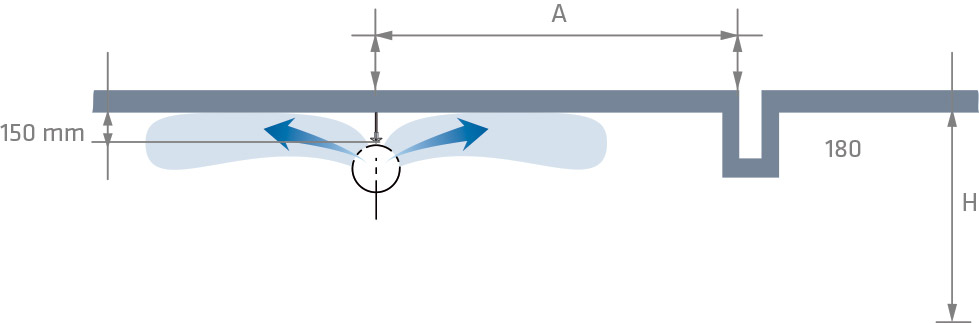

Impact of the installation height (from the ceiling) on the throw length

L0,2KR = L0,2 x KR

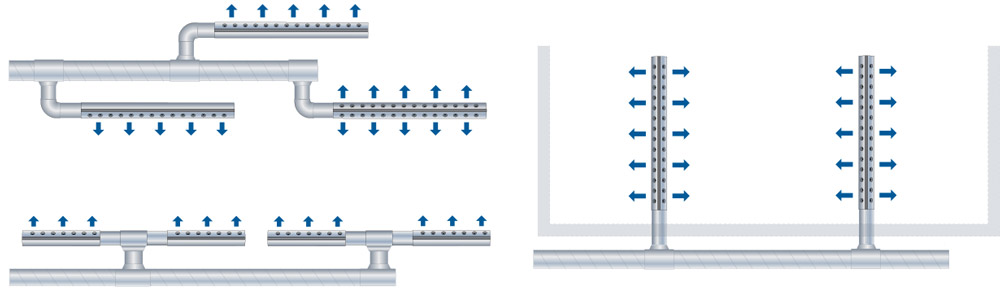

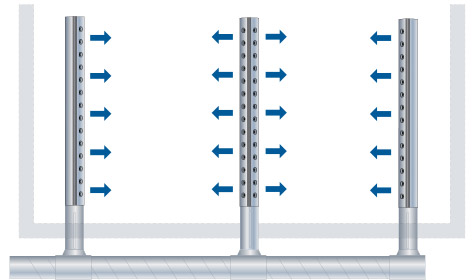

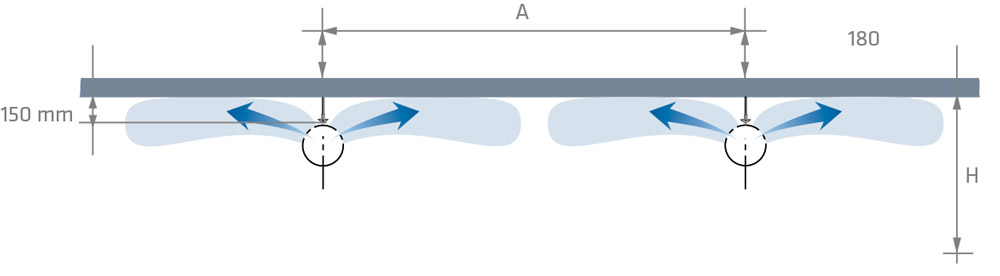

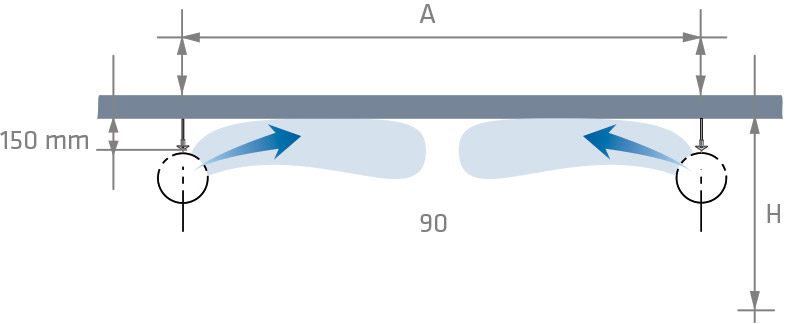

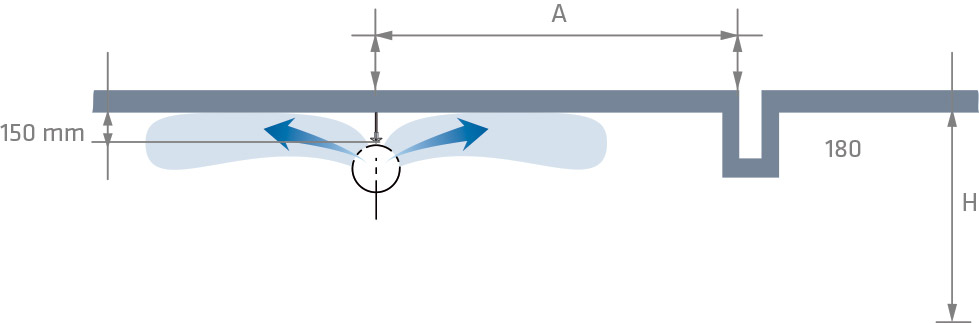

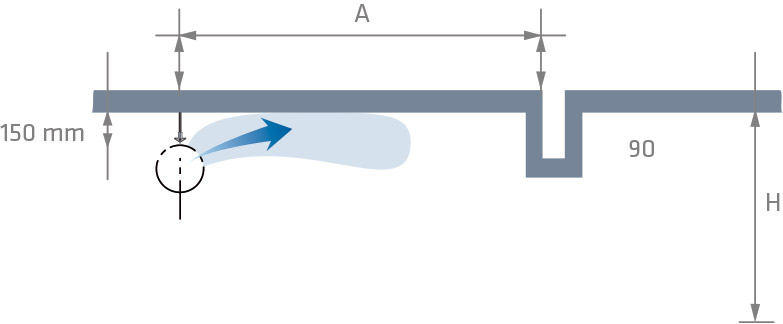

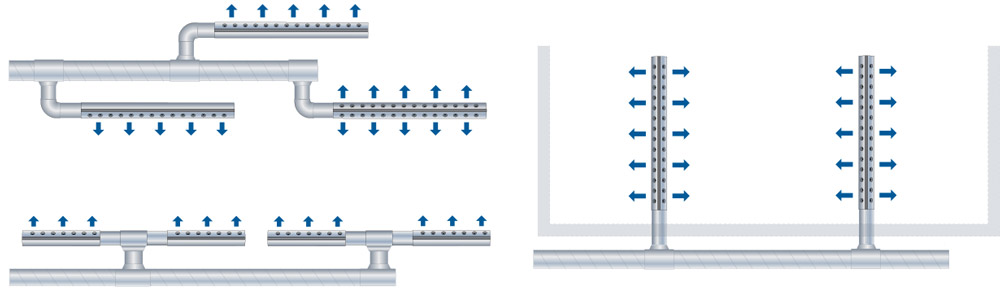

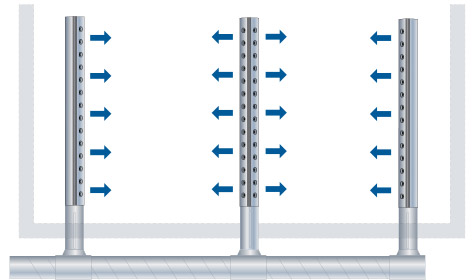

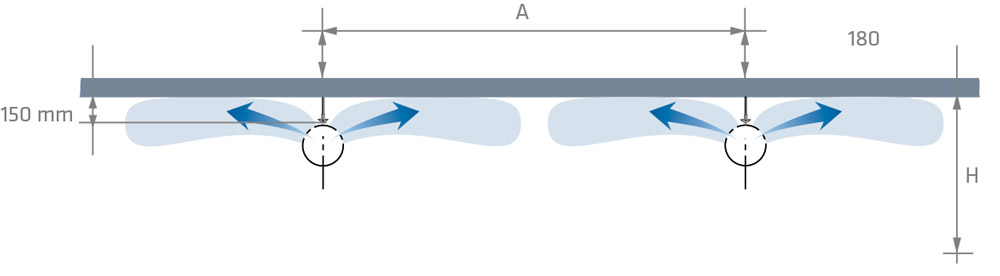

Installation distances

A = the minimum installation distance

H < 3,5 m

A = 2 x (L0,2 x 0,7)

H > 3,5 m

A = 2 x (L0,2 x 0,6)

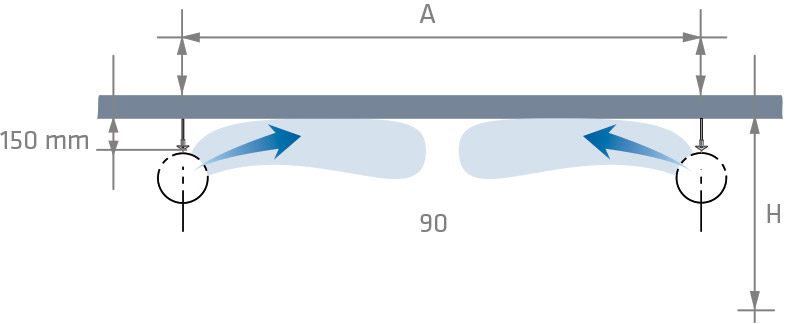

A = the minimum installation distance

H < 3,5 m

A = L0,2 x 0,8

H > 3,5 m

A = L0,2 x 0,7

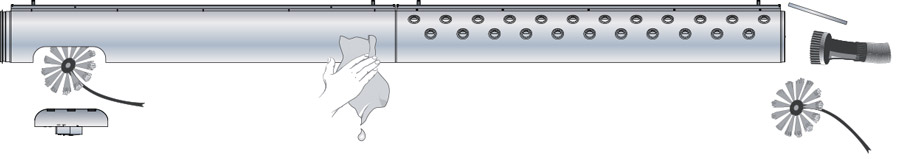

ROX-S adjustment and damper unit

ROX-S adjustment unit based on the static pressure difference measurement enables highly accurate air flow measurement and control. The adjustment unit allows a precise adjustment of airflow (± 5%) even at low airflows and duct speeds. ROX-S forms an openable clean-out hatch.

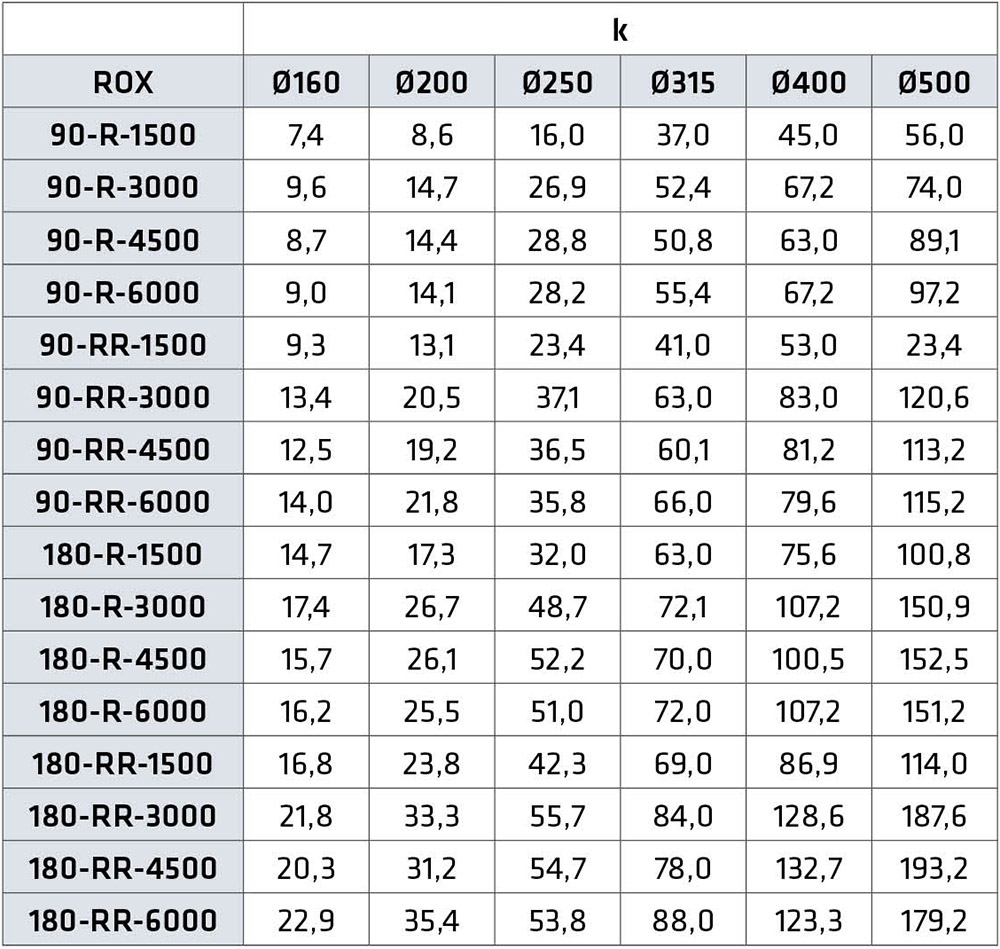

ROX-S is very easy to adjust

1. The pressure difference is measured from the measuring socket of the control unit.

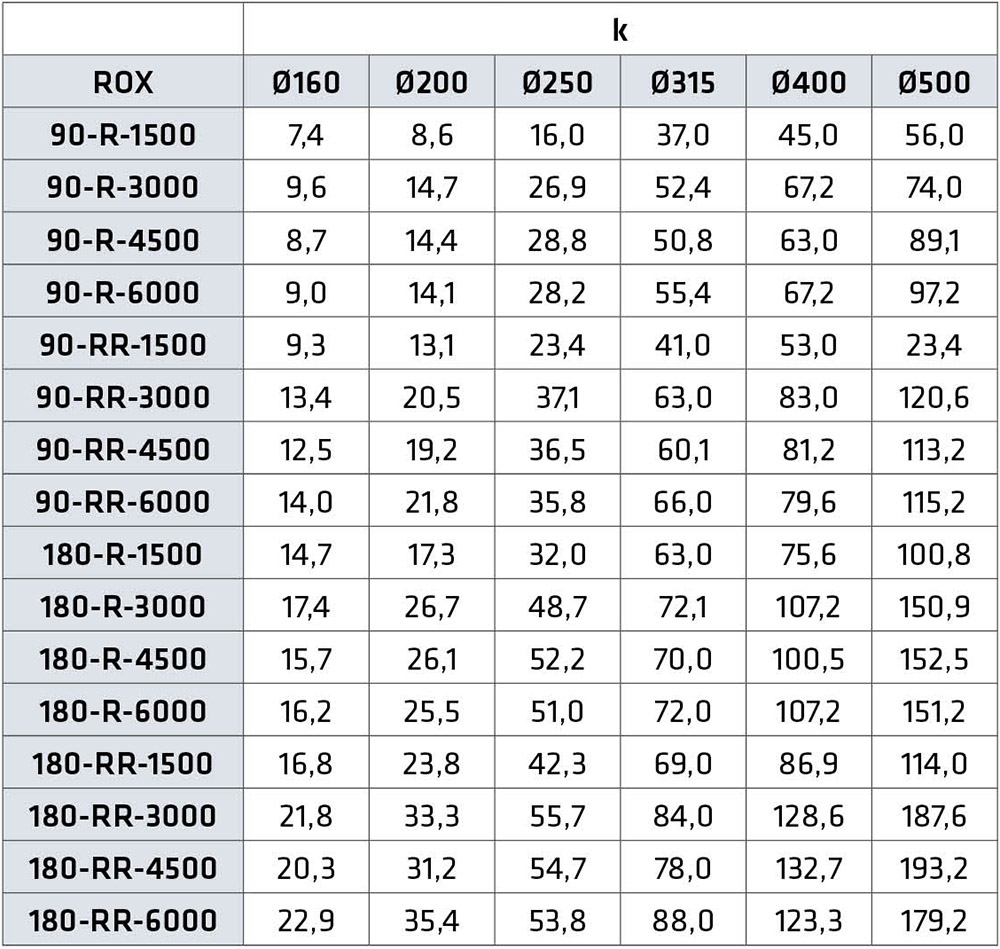

2. This adjustment can be made by a screwdriver. The adjustment is done by rotating the control dial with the tool. The control dial readings correspond to separate k-values that can be found on the side of the adjustment unit.

3. The adjustment position can be locked with a screw.

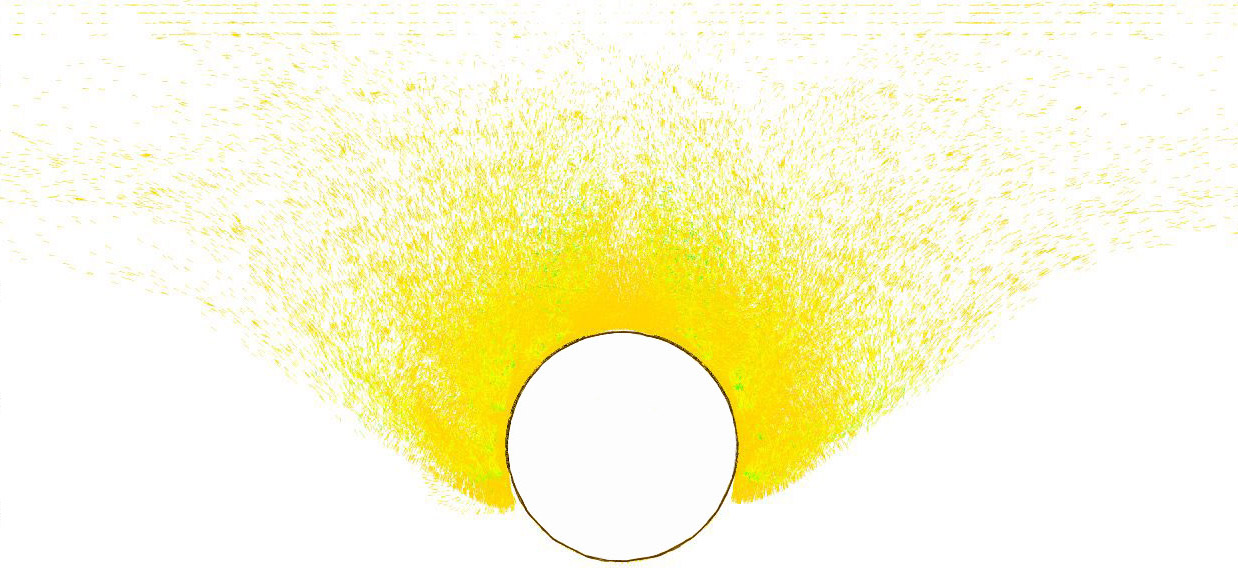

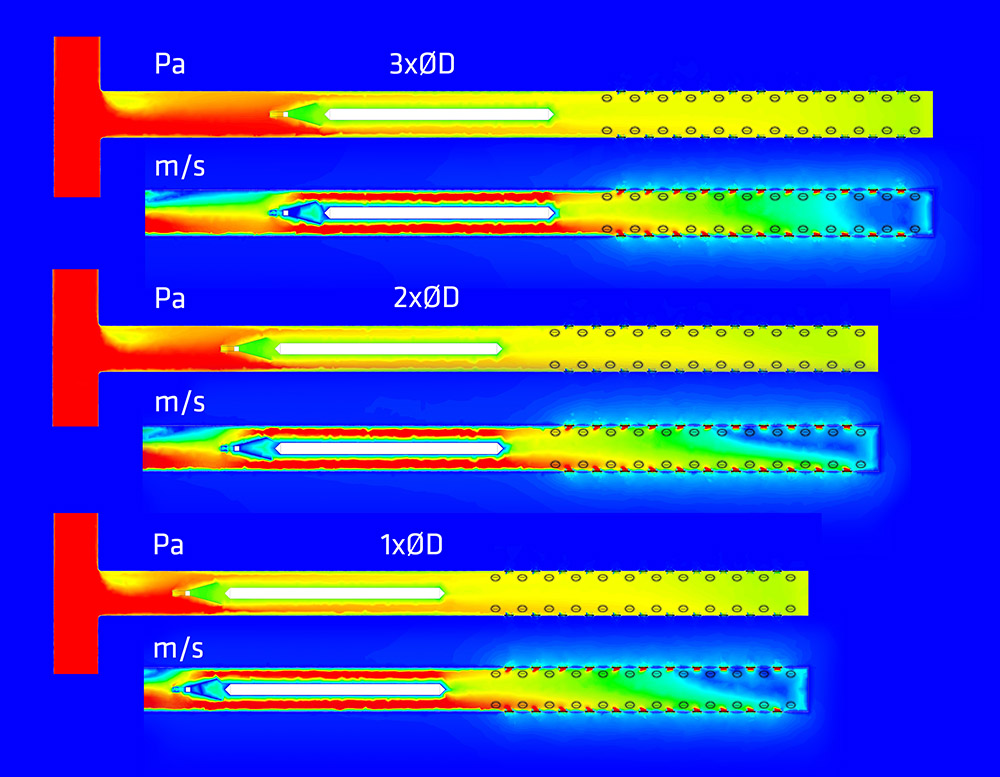

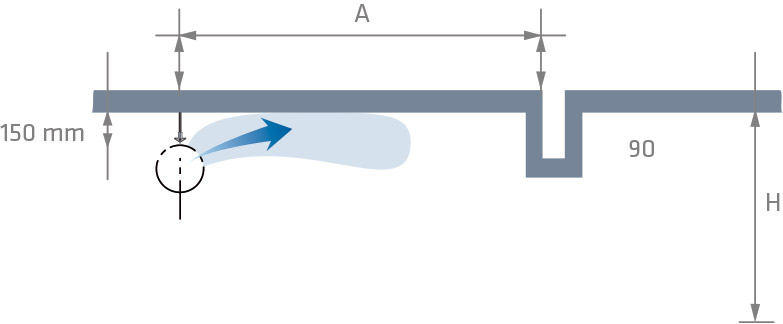

Safety distances

ROX-S works accurately and reliably even at short safety distances. Due to steady pressure distribution the throw pattern is steadily and reliably directable.

Principle of operation

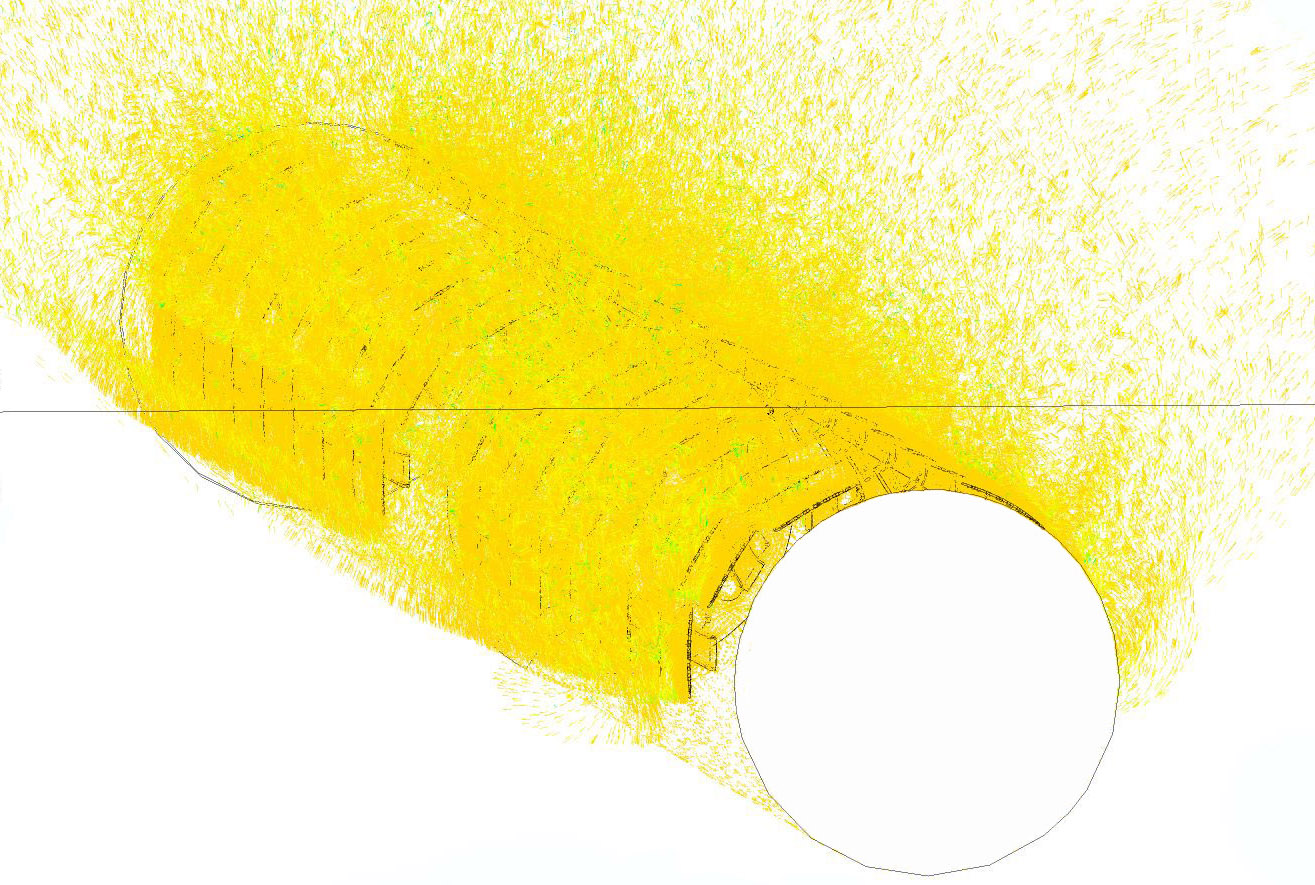

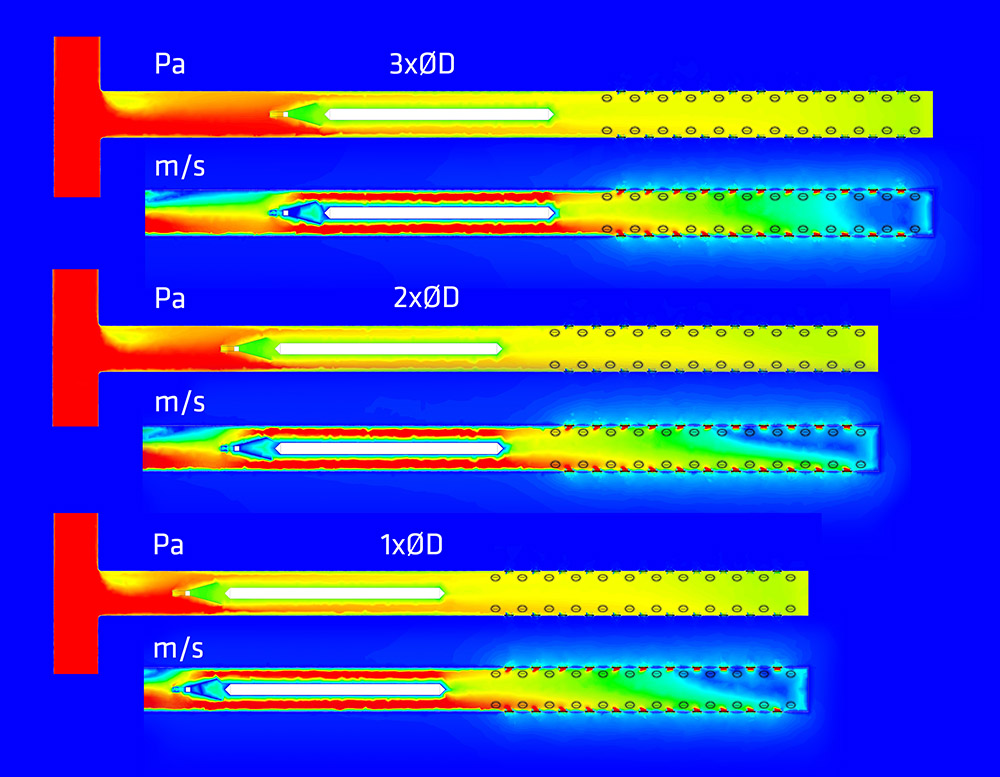

To achieve an even air distribution, ROX is available in four different air supply sectors.

90 R = The throw pattern in only one direction. Optimized for smaller airflows and duct velocities.

90 RR = The throw pattern in only one direction. Optimized for larger airflows and duct velocities.

180 R = The throw pattern in both directions of the product. Optimized for smaller airflows and duct velocities.

180 RR = The throw pattern in both directions of the product. Optimized for larger airflows and duct velocities.

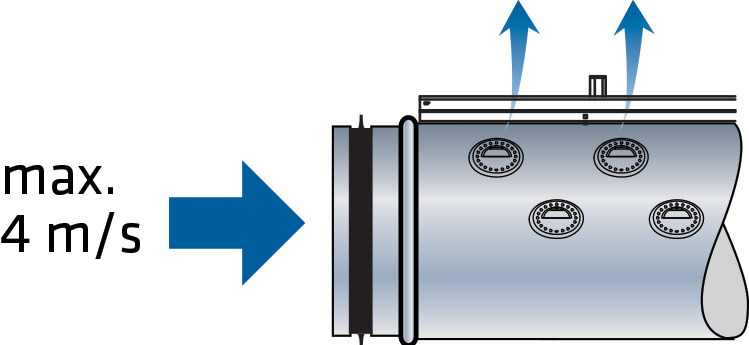

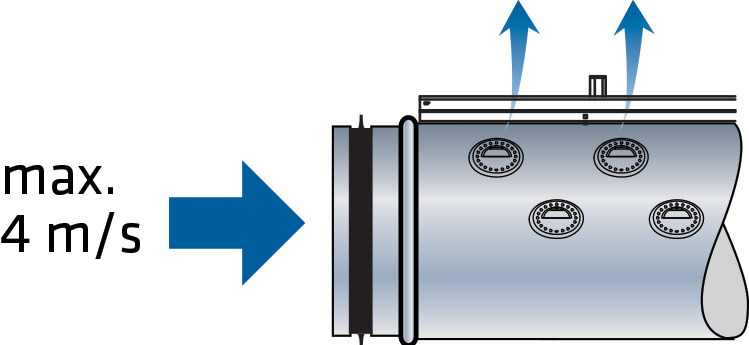

Duct velocities

ROX functions excellently also at higher duct velocities. The throw pattern can be directed precisely in the desired direction up to 4 m/s duct velocities while keeping the sound level low. Technically ROX also works well with even higher duct velocities.

The Coanda effect

In measurement, please also take into account the sufficient pressure drop. This will ensure the emergence of a Coanda effect, which ensures evenly spread and well mixing of the supply air. In this case, ROX operate as planned also at low-temperature supply air. The recommended minimum pressure drop is 5 Pa.

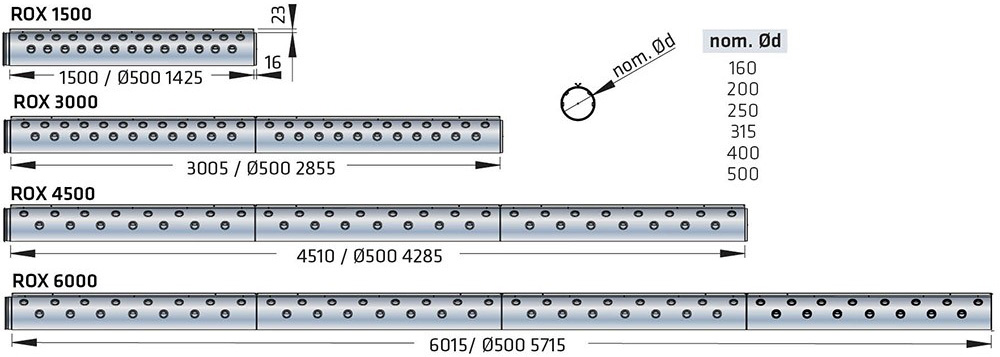

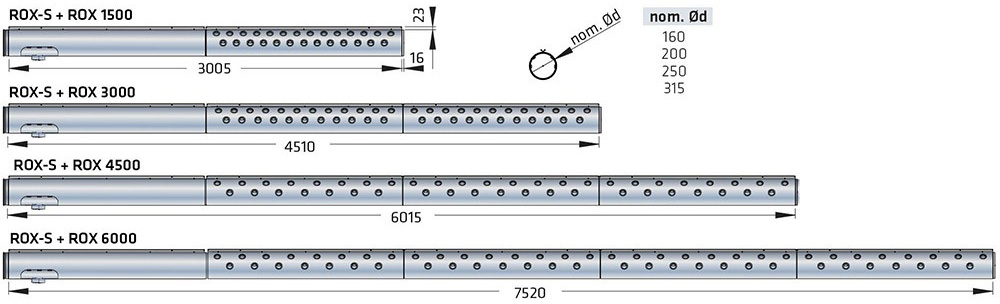

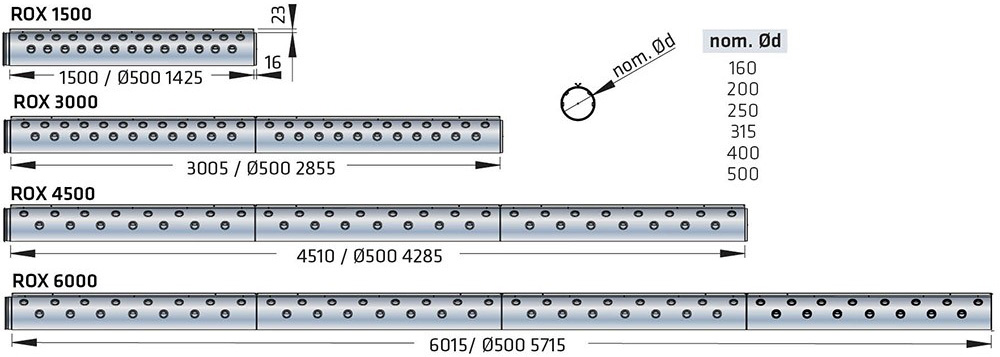

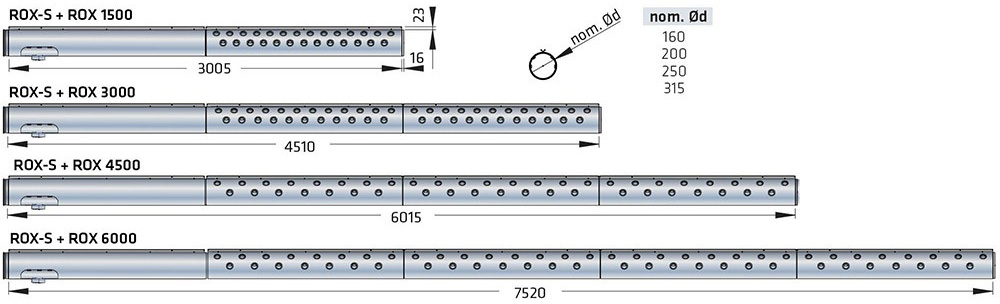

Dimensions

ROX dimensions

ROX-S dimensions

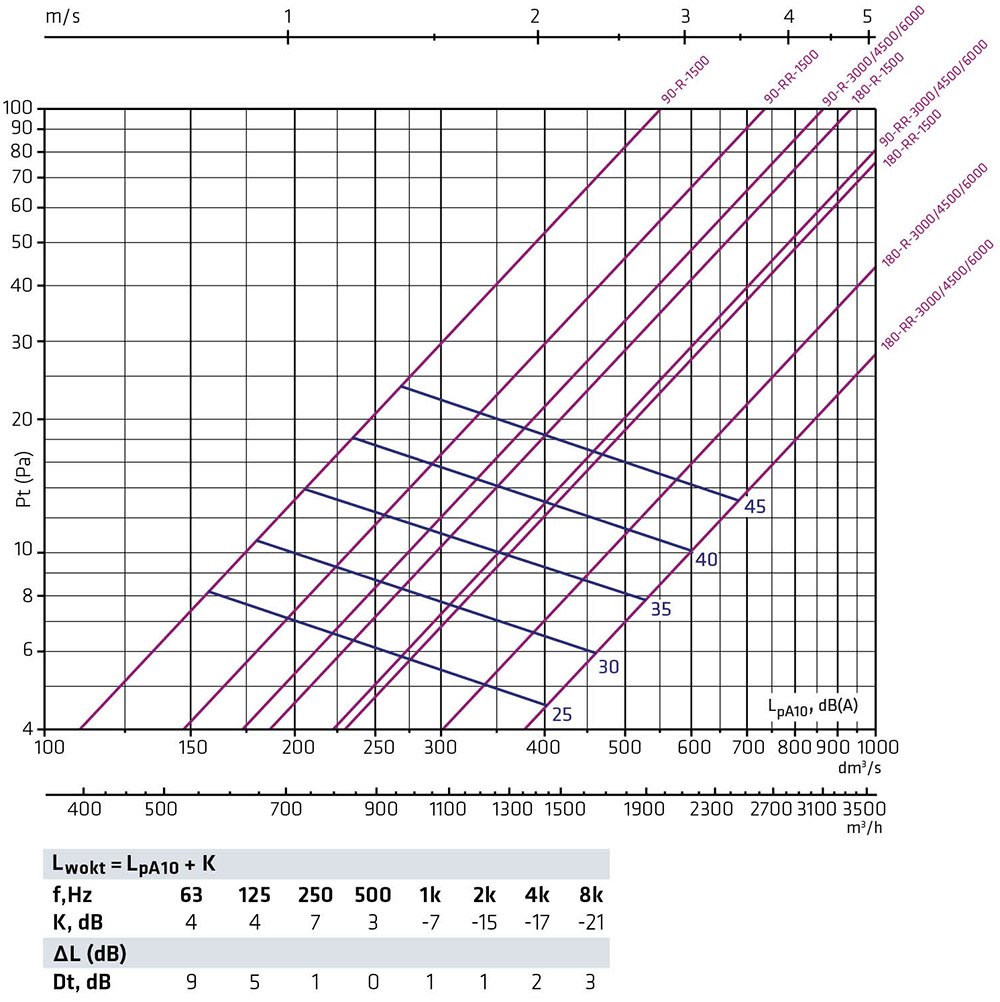

Selection diagrams

ROX 160

ROX-S + ROX 160-90-R-1500

ROX-S + ROX 160-90-RR-1500 and ROX-S + ROX 160-90-R-3000/4500/6000

ROX-S + ROX 160-90-RR-3000/4500/6000 and ROX-S + ROX 160-180-R-1500

ROX-S + ROX 160-180-R-3000/4500/6000 and ROX-S + ROX 160-180-RR-1500

ROX-S + ROX 160-180-RR-3000/4500/6000

ROX 200

ROX-S + ROX 200-90-R-1500

ROX-S + ROX 200-90-RR-1500 and ROX-S + ROX 200-90-R-3000/4500/6000

ROX-S + ROX 200-90-RR-3000/4500/6000

ROX-S + ROX 200-180-R-1500

ROX-S + ROX 200-180-RR-1500 and ROX-S + ROX 200-180-R-3000/4500/6000

ROX-S + ROX 200-180-RR-3000/4500/6000

ROX 250

ROX-S + ROX 250-90-R-1500

ROX-S + ROX 250-90-RR-1500 and ROX-S + ROX 250-90-R-3000/4500/6000

ROX-S + ROX 250-90-RR-3000/4500/6000

ROX-S + ROX 250-180-R-1500

ROX-S + ROX 250-180-RR-1500 ja ROX-S + ROX 250-180-R-3000/4500/6000

ROX-S + ROX 250-180-RR-3000/4500/6000

ROX 315

ROX-S + ROX 315-90-R-1500

ROX-S + ROX 315-90-RR-1500

ROX-S + ROX 315-180-R-1500 and ROX-S + ROX 315-90-R-3000/4500/6000

ROX-S + ROX 315-180-R-3000/4500/6000

ROX-S + ROX 315-180-RR-1500 and ROX-S + ROX 315-90-RR-3000/4500/6000

ROX-S + ROX 315-180-RR-3000/4500/6000

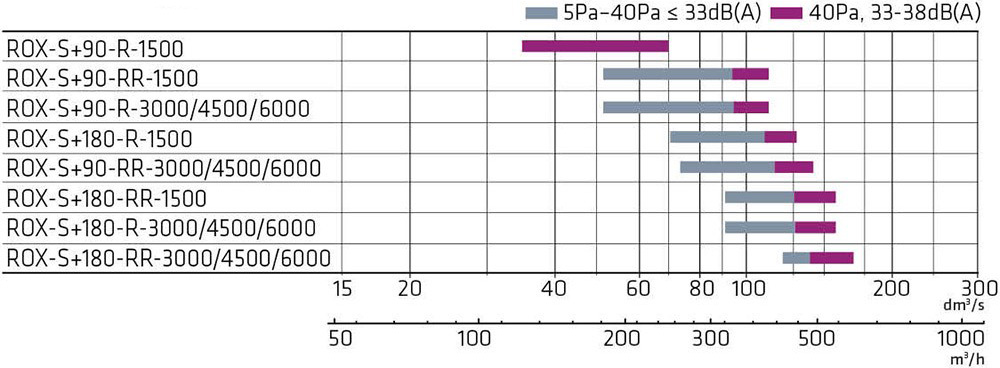

ROX 400

ROX 500

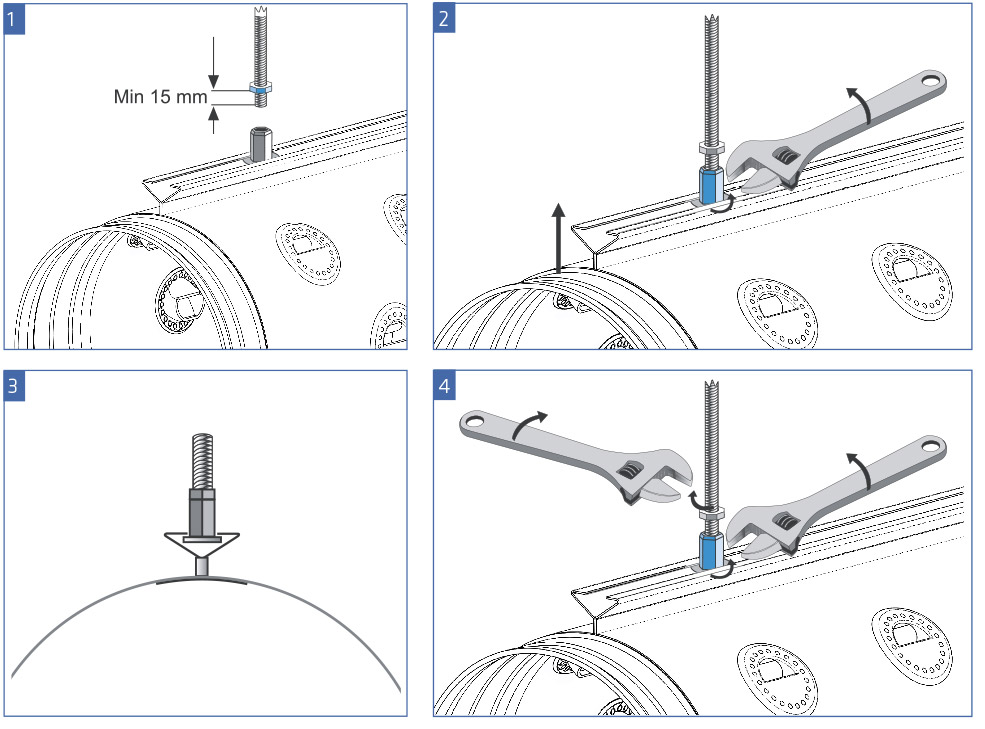

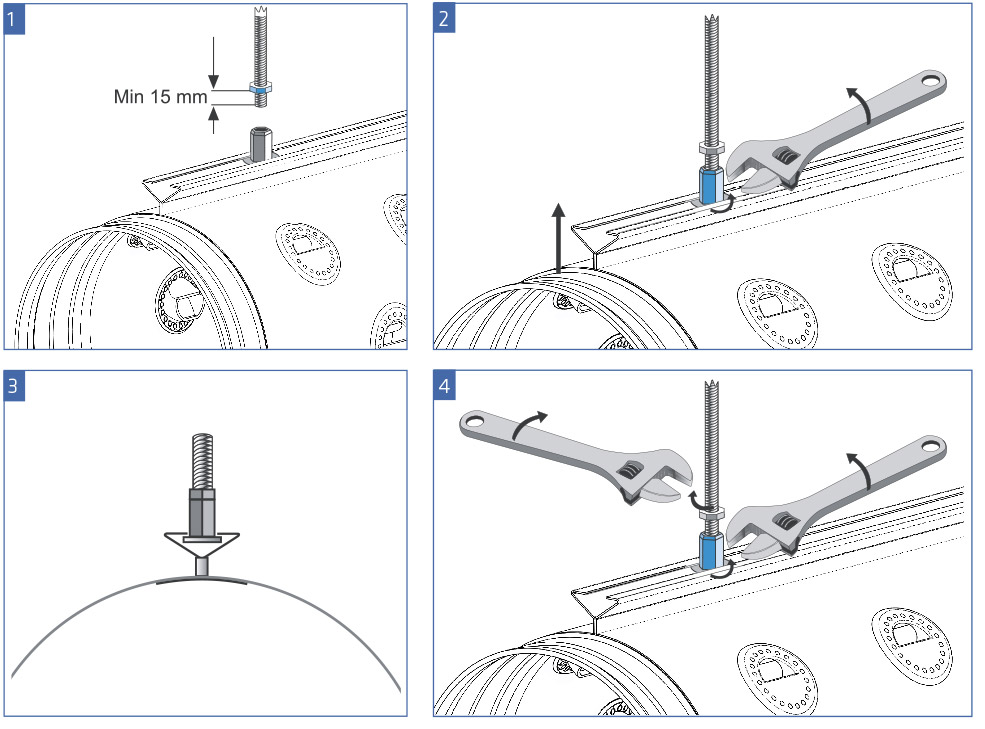

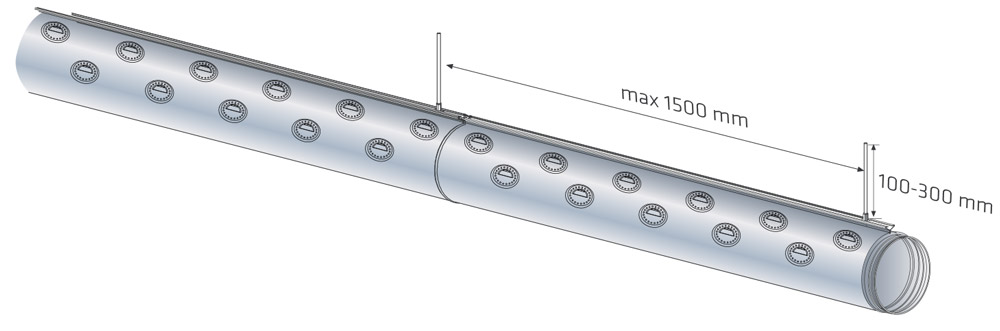

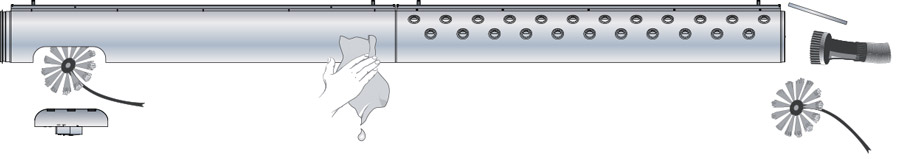

Installation and maintenance

Installation of ROX can be easily performed with the help of the mounting rail attached to the product. The threaded rod is mounted to the counter-thread base in the rail which can be moved in a longitudinal direction. The fine adjustment of the installation height can still be carried out before locking the fastener.

The rotating counter thread rivets located on the mounting rail move freely so that the longitudinal direction mounting position is freely selectable. The rotatable counter thread rivets allow for a very simple and quick mounting and fine adjustment of the height.

Due to the mounting rail, ROX is also easy to carry to the site.

The flat and smooth surface of ROX is quick and easy to clean. Due to the openable end part, the product is also easy to clean on the inside. ROX-S adjustment unit operates as an openable cleaning hatch.

K values