Description

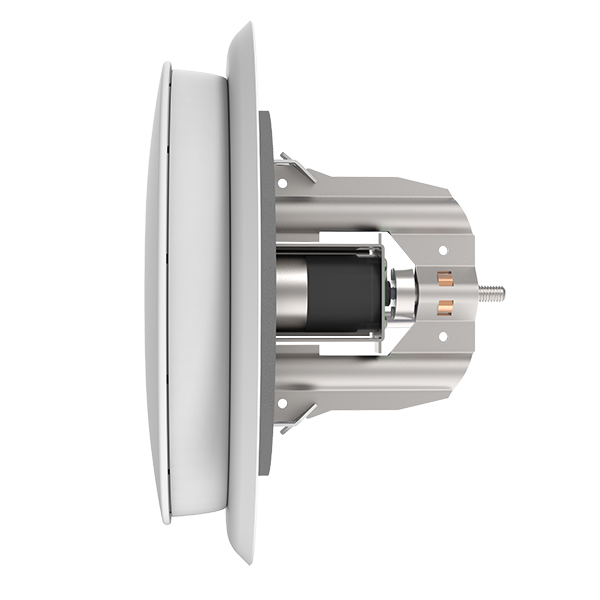

MyAir exhaust air valves are a crucial part of MyAir smart ventilation system.

The valves are equipped with sensors that measure from the air:

- pressure difference across the valve (Pa)

- valve air volumes (l/s)

- room air temperature (°C)

- room air humidity (RH %)

- absolute humidity (g H2O/ kg ki)

Demand-controlled ventilation

The operation of the MyAir ventilation system is based on intelligent exhaust air valves. MyAir offers residential apartment buildings intelligent and demand-controlled ventilation by automatically adjusting the ventilation according to the rhythm of living. The system uses wireless data transmission. The measurement data is collected in a cloud service, from where it is available using the user interface.

MORE INFORMATION ABOUT MYAIR

Features:

- Wireless data transfer

- Two models: battery operated and power supply (7-15 VDC)

- Reliable, precise and automatic adjustment

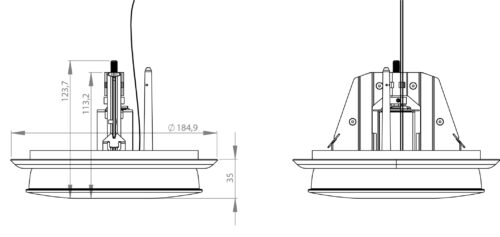

- Easy and quick installation

- Duct sizes 100 and 125 mm

- ‘Meets the conditions set for a smoke damber

Battery or power supply

There are two versions of the MyAir valves, a battery-operated version, and an electric supply version. Depending on the site’s requirements and preferences, either can be chosen for the property. Both versions of the MyAir valve are suitable for all exhaust ventilation systems. Data transmission for both electric supply valves and battery-operated valves is wireless and uses the LoRaWAN radio network.

Power supply version for large sites

The electric supply version has been found to be especially useful in large sites where several smart valves are in use and you want to avoid changing batteries.

7-15 VDC voltage runs through electrically operated MyAir valves. There are several transformers on the market for this.

The battery-operated valve does not require cabling

When installing the MyAir system, cabling is avoided if battery-operated MyAir valves are used. The batteries are remarkably long-lasting, and the MyAir system shows their remaining charge.

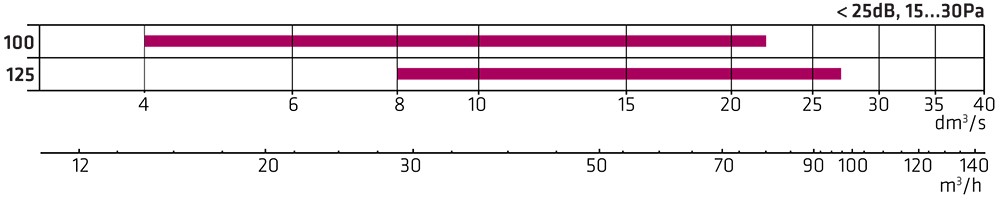

Dimensioning

Not intended for adjusting.

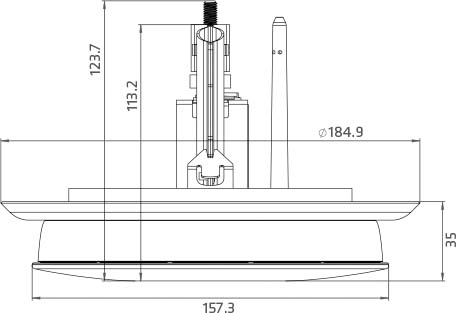

MyAir-100

MyAir-125

MyAir valve tehcnical data

Prosessor and memory ARM Cortex-M4, 256k FLASH, 64k RAM

Radio transmission LoRa

Radio frequency Lora (868)

Radio max. power 14dBm

Power source 4xAA Cell 1,5V

Power use Min. 15 uA

Max 200 mA

IP-class 44

Additives –

MyAir measurements

Temperature, area 0 to +60 °C

Temperature, resolution 0,1 C

Temperature, accuracy ±0.5°C, 15 to +40 °C

Humidity, area 0 to 100% rH

Humidity, resolution 0,1 % rH

Humidity, accuracy ±3.5% rH, 20 to 80% rH; ±5% rH, 0 to 100% rH

Static pressure, area 260-1260 hPa

Static pressure, resolution 0,1 hPa

Pressure difference , area -50 to +1000 Pa

Pressure difference, resolution 0,1 Pa

Central unit

The central unit controls MyAir valves based on the collected data. It is ideally placed centrally to the valves, into a room with no public access.

Technical data

Processor and memory ARM9 32-bit, 400 MHz, 16K Data Cache, 16K Guide Cache, 128×16 DDR RAM, 256MB Flash-memory

Radio Mobile, LoRA

Radio frequency 4G (800/1200/2600), 3G (850/900/2100),2G (900/1800); LoRa (915/868)

Radio transmission max. power 27dBm@ 868 MHz, / 20dBm@ 915 MHz

Power source 5VDC at 1,7A

Power consumption

IP class 21

Additives RJ-45 Ethernet 10/100, uSIM, Power

Surroundings

Usage temperature -10 – +60C

Storage temperature -40 – +85C

Relative humidity 20% to 90%, non-condensate