CleanMaster® hoods

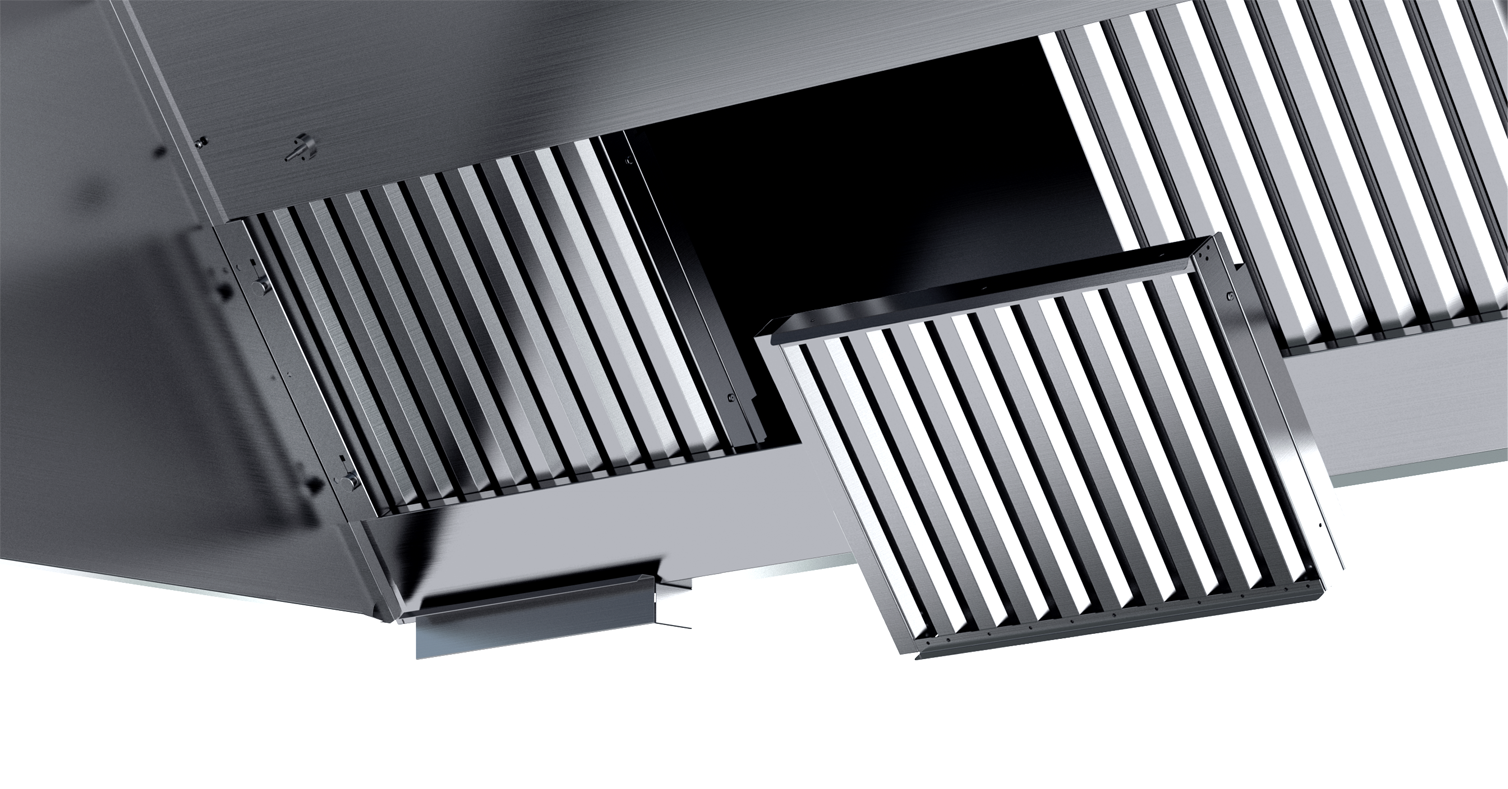

CleanMaster® hoodsCleanMaster hoods have been designed to fulfill the air purifying, user-friendliness, and fire-safety requirements at professional kitchens. The advanced, four staged extract air cleaning mechanics combine two different ultraviolet light, ozone, and impact filtration. The highly efficient performance is certain to keep the ducts and grease chambers of the hoods clean. Cleaning technologyFour-step: ozone, UV-A, UV-C, mechanic filtering DescriptionA masterpiece of engineering excellence, CleanMaster hoods are equipped with the most advanced grease filtration rate and outstanding features for easy and safe usage in addition to a significantly high level of fire safety. For well over three decades, CleanMaster has been continuously improved to even better answer to the needs of even the most demanding users in even the most extraordinary professional kitchens. CleanMaster is the choice of a true professional for commercial kitchens from Michelin star restaurants to food services, public facilities, and business premises. When a high filtration rate, low maintenance costs, and high level of fire safety are sought after, the choice is CleanMaster. Advanced four staged cleaning technologyCleanMaster uses the most advanced four staged cleaning technology resulting in clean grease chambers and ducts. CleanMaster contains tested and UV safety certified grease filters. Mechanical filtration / impact filtrationMechanical filtration efficiently filters out large grease particles resulting in the cooking process. The heavy particles are sieved out of the extract air traveling through a filter. UV-CUV-C is a widely used, conventional “germicidal” cleaning technology. It works against micro-organisms, molds, fungi, and bacteria. Vacuum UVVacuum UV is highly efficient in dissolving small grease particles into natural compounds, such as oxygen, carbon dioxide, and water. In addition to traditional UV technology, vacuum UV provides an even higher extract air cleaning rate. OzoneOzone effectively oxidizes whatever little is left of the grease particles and deodorizes air. Tested filtersThe noise data, pressure loss, flame protection and separation degrees of hood filters are certified by Eurofins Expert Services/VTT Expert Services/DAkkS/UL (EUFI29-21002238-T1, EUFI29-21002238-T2, VTT-S-7826, VTT-CR- 04456, DAkkS_23368, UL-R39744).

Dual UV Kitchen ProAt the core of harnessing the cleaning potential of two different UV wavelengths are the technically superior DualWave KitchenPro lamps. The UV lamps offer high-performing disinfection, oxidation, and photochemical dissolving of grease. The DualWave KitchenPro technology provides a significantly high UV intensity and long lifetime. This results in less need for sweeping or lamp changes, leading to decreased maintenance costs, especially in the long run.

OptiLumo professional kitchen luminaireClimecon OptiLumo luminaires are especially designed for professional kitchen use. They play a huge role in work-place safety and working conditions of the kitchen staff. The ingenious optics enable evenly distributed light onto the work station without glare. Kitchen professionals praise the illuminance, light output and color reproduction of OptiLumo stating that even a long work day will not strain eyes.

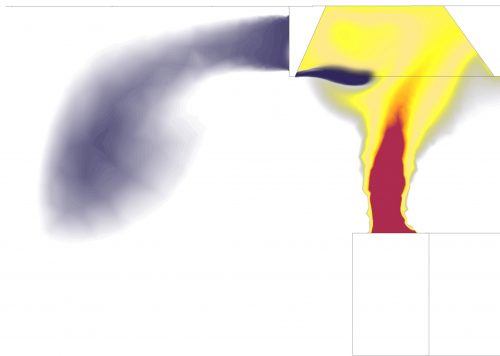

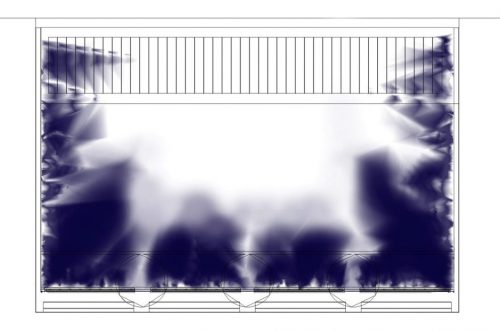

AirBoost Capture airClimecon hoods have been equipped with an efficient AirBoost capture air feature. It efficiently directs grease fumes towards the exhaust air chambre and enhances the hoods’ performance even in demanding circumstances.

The air from the cooking station is directed from the front and sides of the hood towards the extract area. AirBoost efficiently prevents air overflow.

Carbon footprintRTS EPD verified professional kitchen solutionsThe carbon footprint of hoods intended for professional kitchens has been calculated as part of the requirements of the Building Information Foundation’s EPD environmental statement.

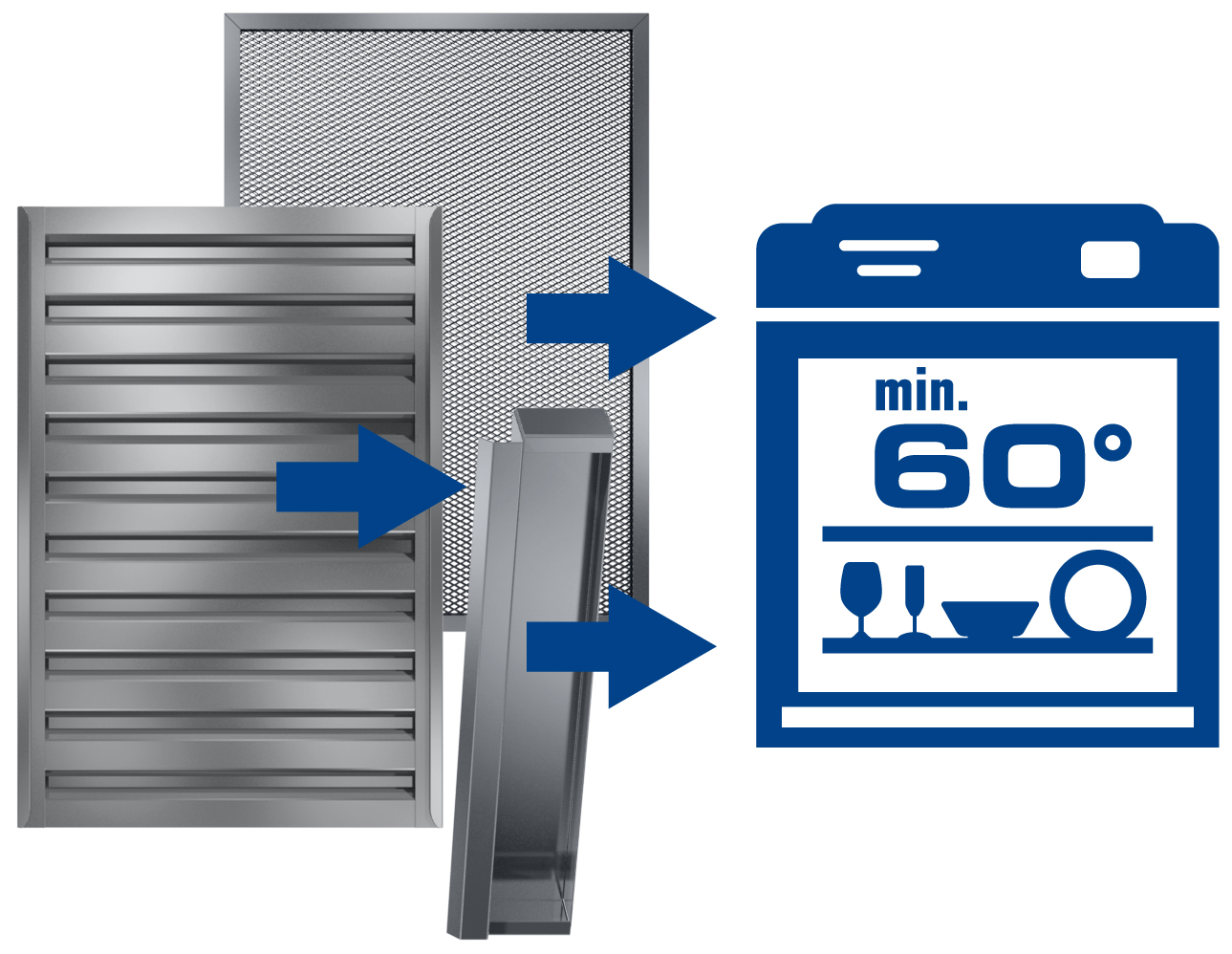

Innovative featuresThe features of EasyCare concept aim at ensuring a high-level of hygiene. When the solutions are easily maintained, they remain in good condition, performing in full-capacity. Additionally, with easily detached and machine washable parts, effortless and quick cleaning leads to less down-time and lower maintenance costs.

The ducts can be cleaned through supply and exhaust air units.

Plug n Play – Fast commissioningThe plug n play function is integrated into CleanMaster hoods for simplified commissioning. A separate control unit is not needed, which makes them easy to design and install. Turn on the power and the hood is ready for use. SlideSafe for safe UV handling during maintenanceThe patented Slide Safe technology guarantees the safe handling of hoods that utilize UV light during installation and maintenance. The feature is a standard in all CleanMaster hoods and ventilation ceilings. Design and functionality

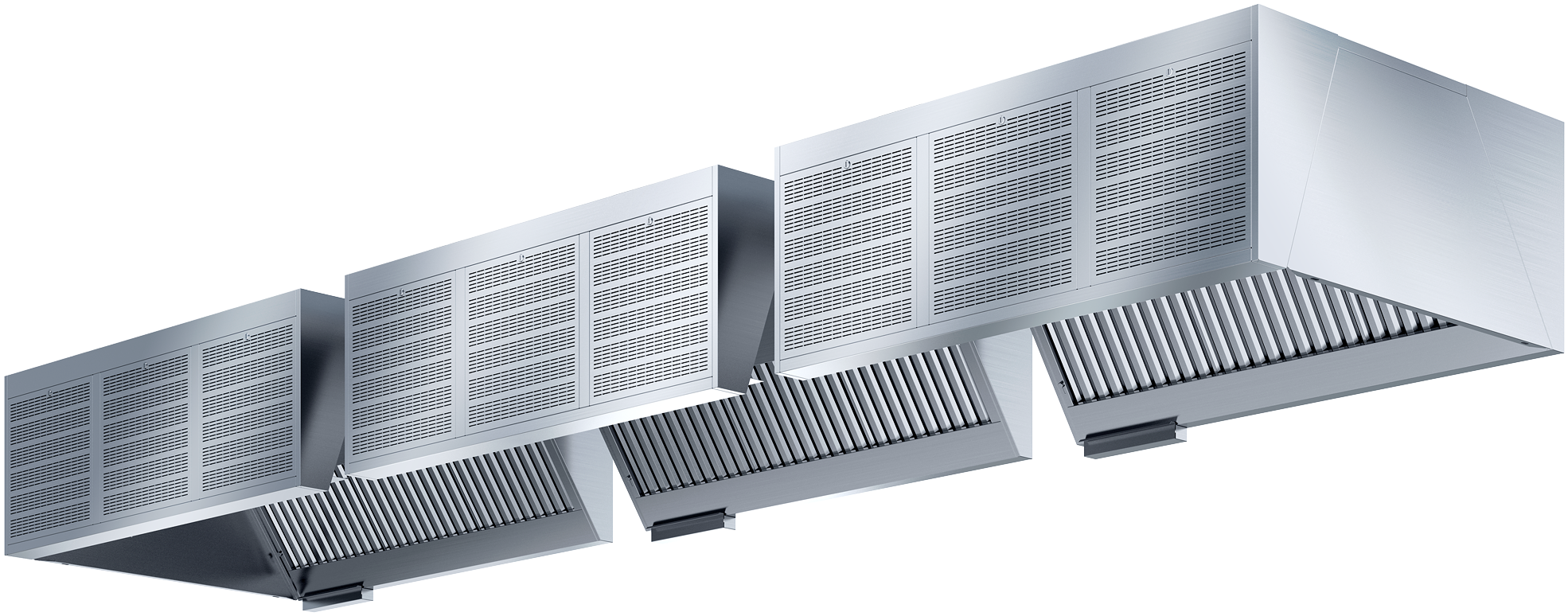

All standard-sized Climecon hoods of all purification technologies can be connected into a seamless, functional entity. The connection can be done without partitions and the dividing walls can be removed retroactively. The hoods’ performance can be managed and monitored directly from an integrated control panel. At large scale sites the hoods can be grouped or operated directly via the building automation system.

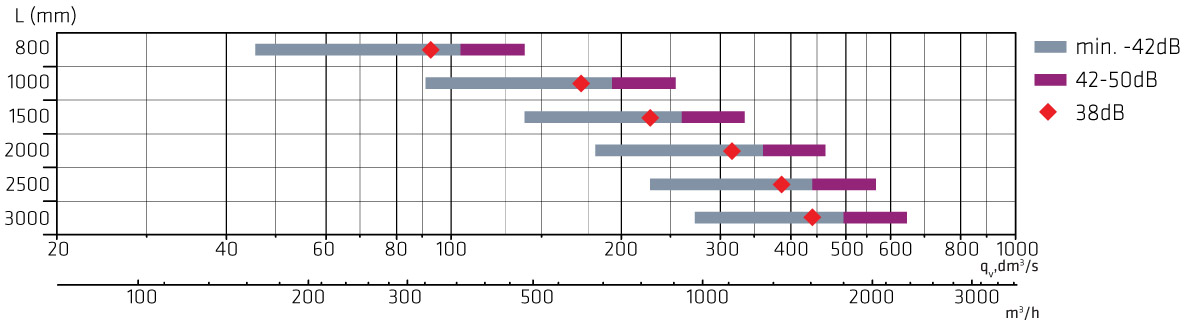

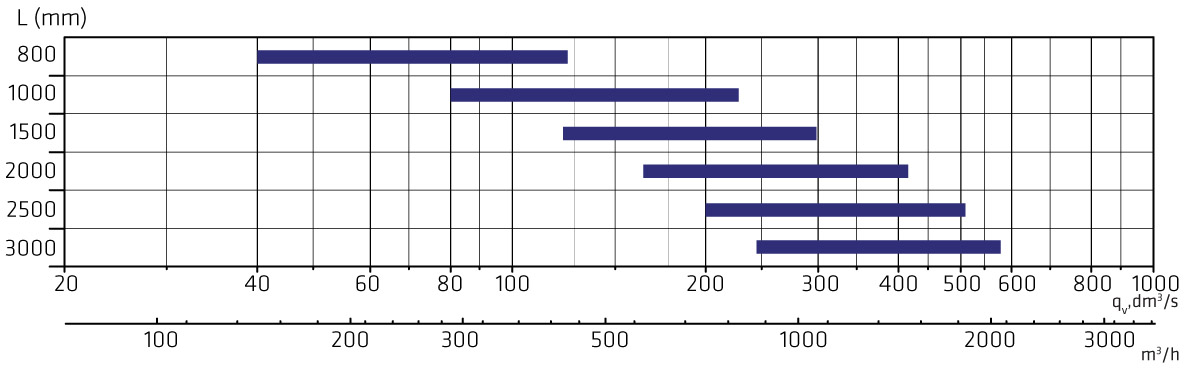

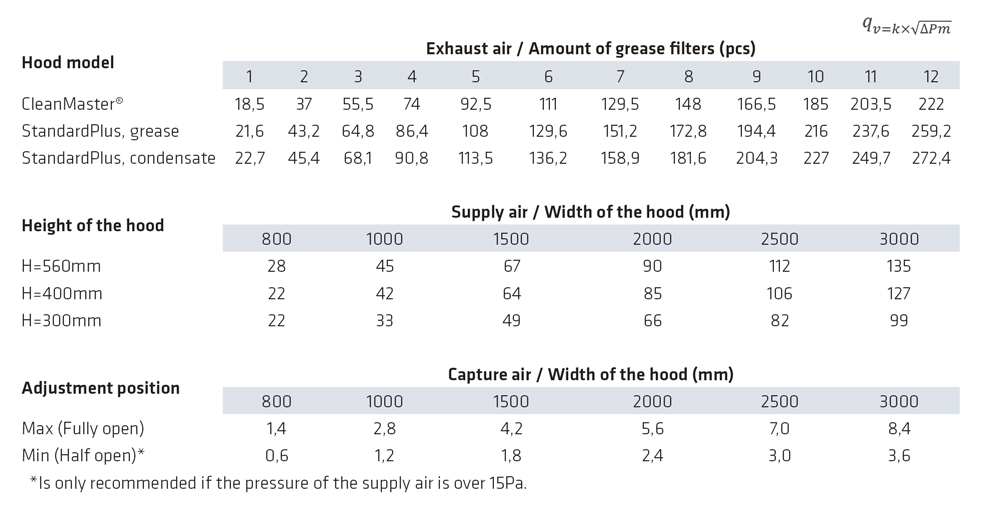

Quick guideQuick guide for exhaust air

Quick guide for supply and capture air

The heighth of the hood represented in the quick guide is h=560. When using other models, the airflow should be measured:

Please check the spesific airflows with Hood.X -selection tool. Dimensions

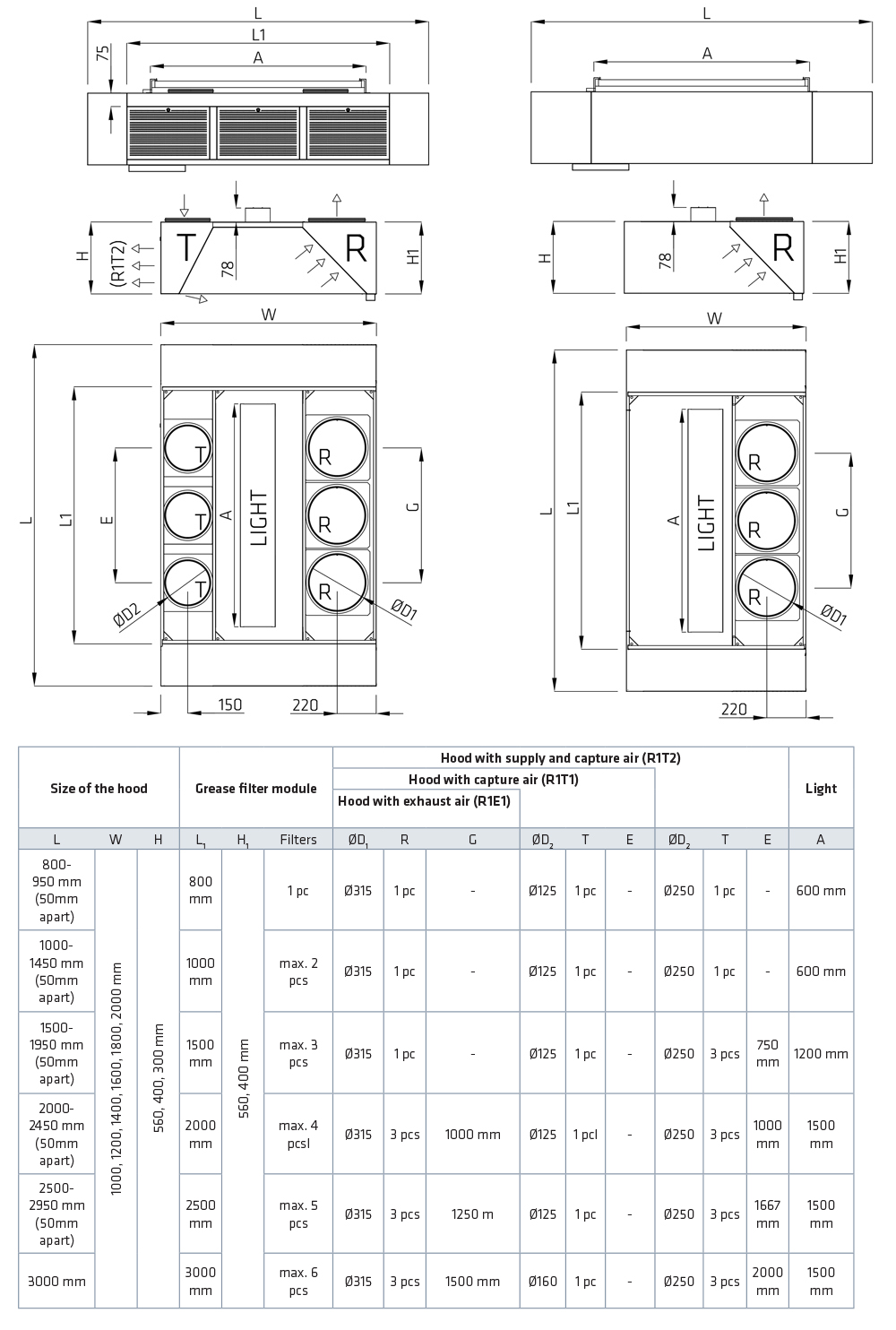

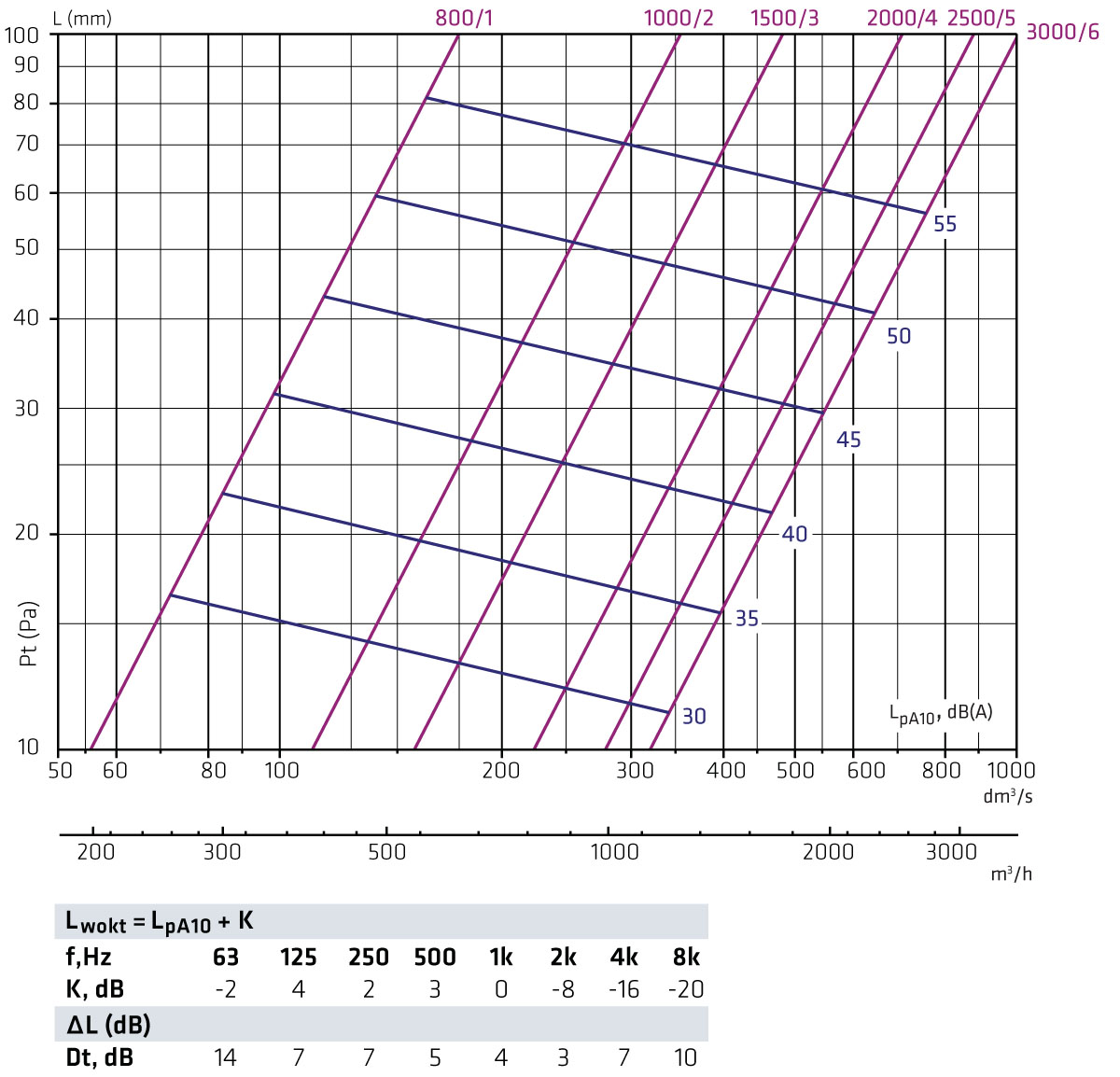

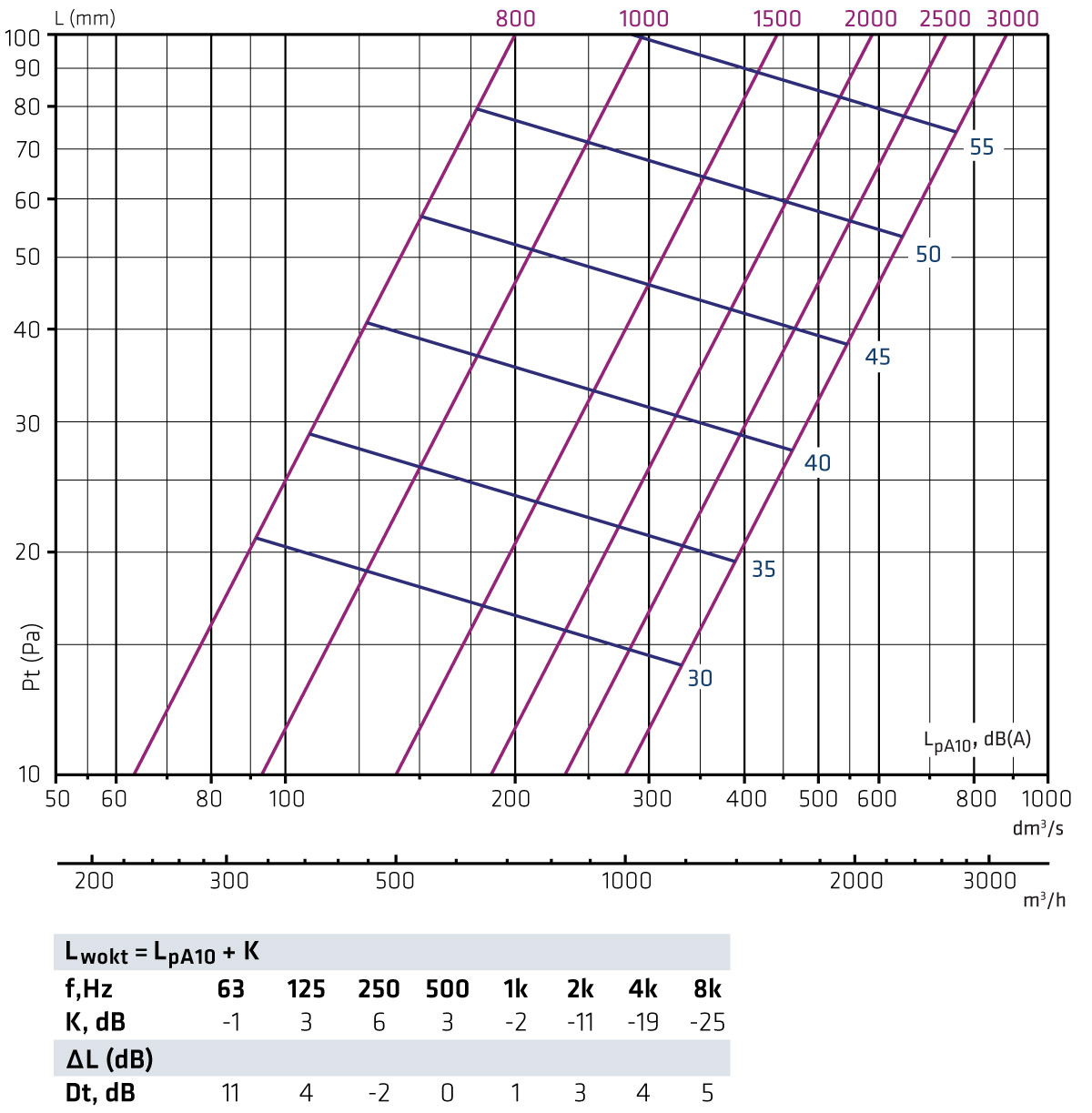

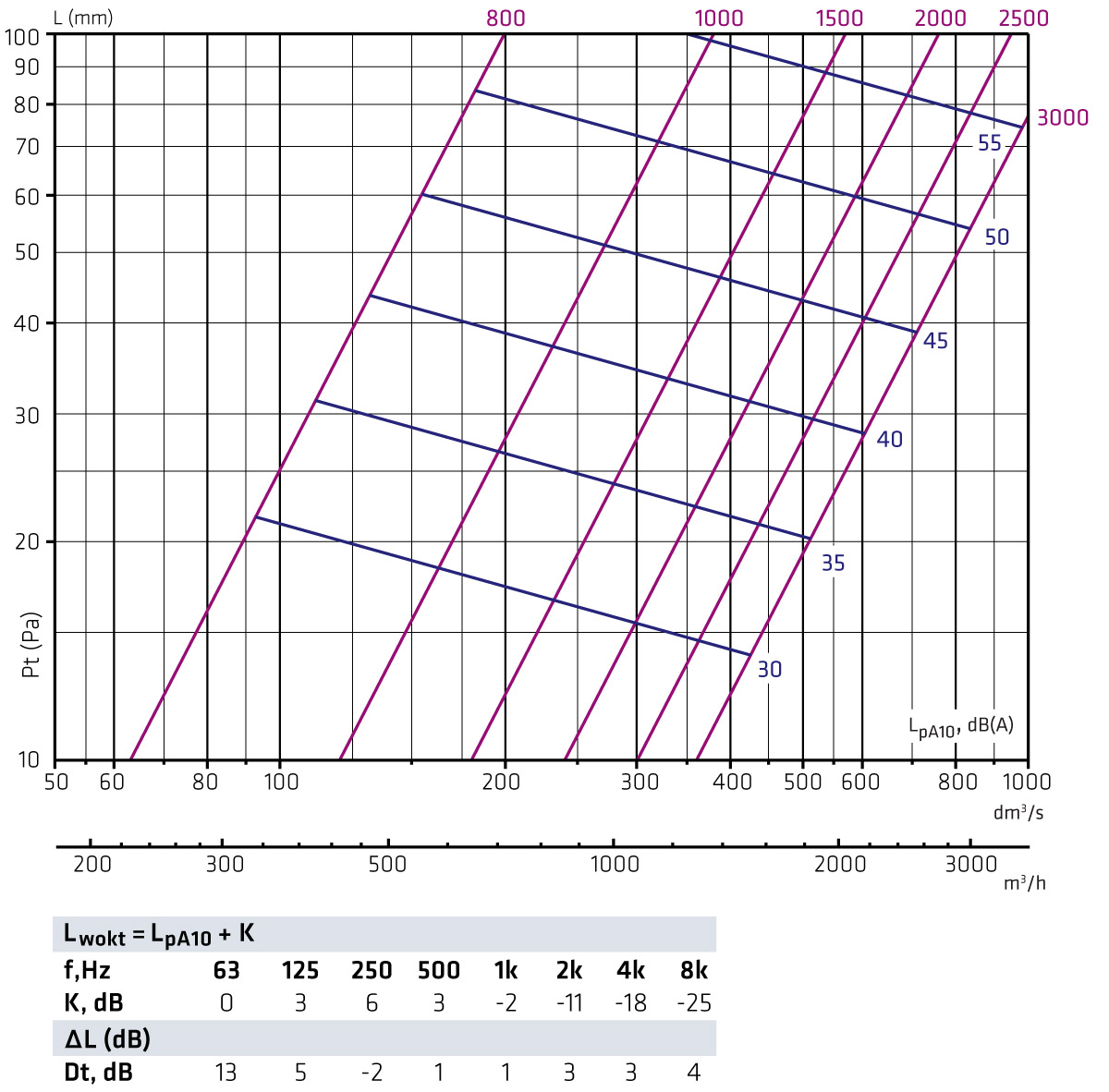

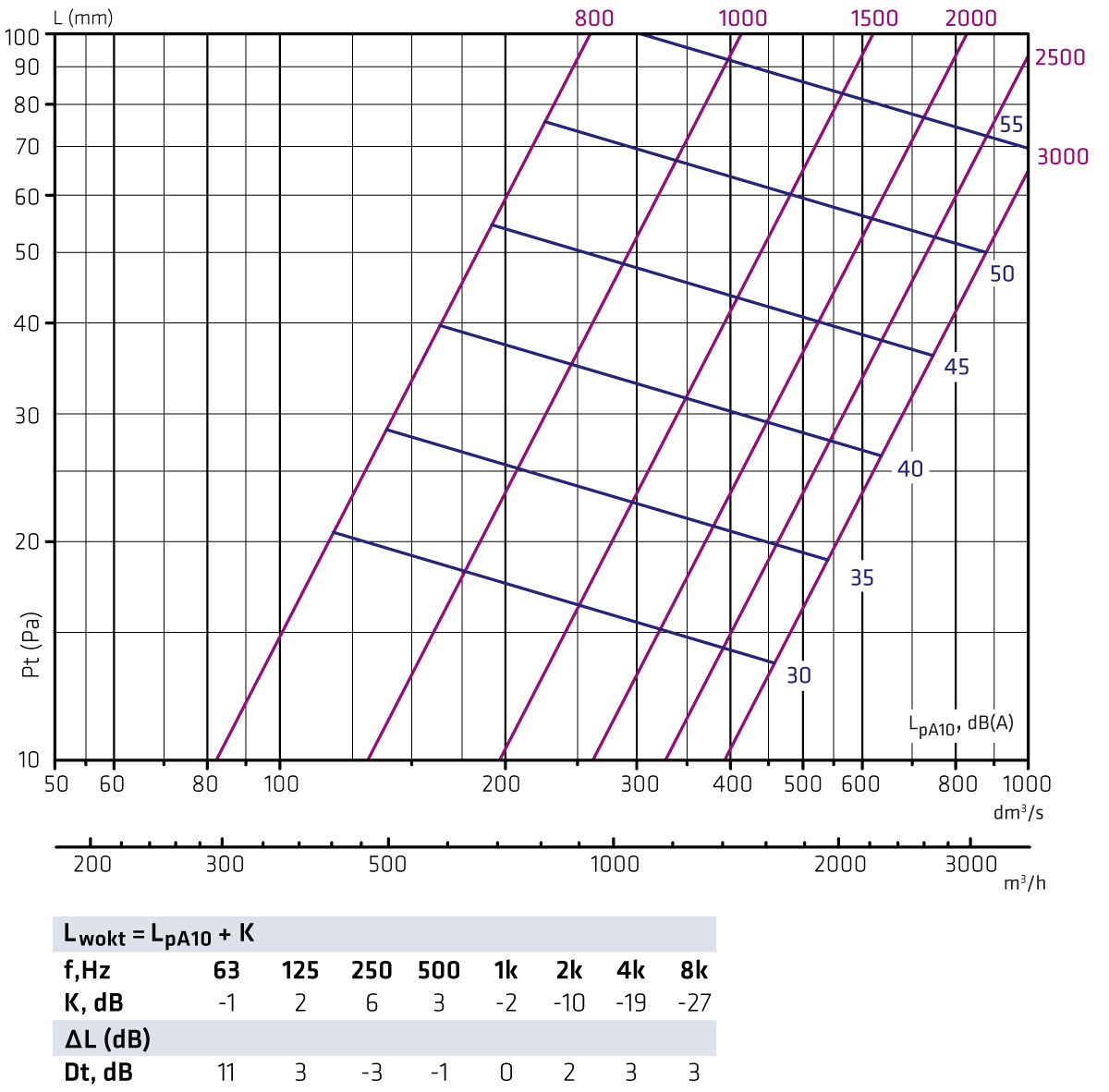

Selection diagramsThe diagrams are not to be used for making adjustments. Pressure loss and noise data for exhaust air

Pressure loss and noise data for capture air and supply air, supply air unit height 300 mm

Pressure loss and noise data are measured for one supply air unit only. In island installation models there are two supply air units. Pressure loss and noise data for capture air and supply air, supply air unit height 400 mm

Pressure loss and noise data are measured for one supply air unit only. In island installation models there are two supply air units. Pressure loss and noise data for capture air and supply air, supply air unit height 560 mm

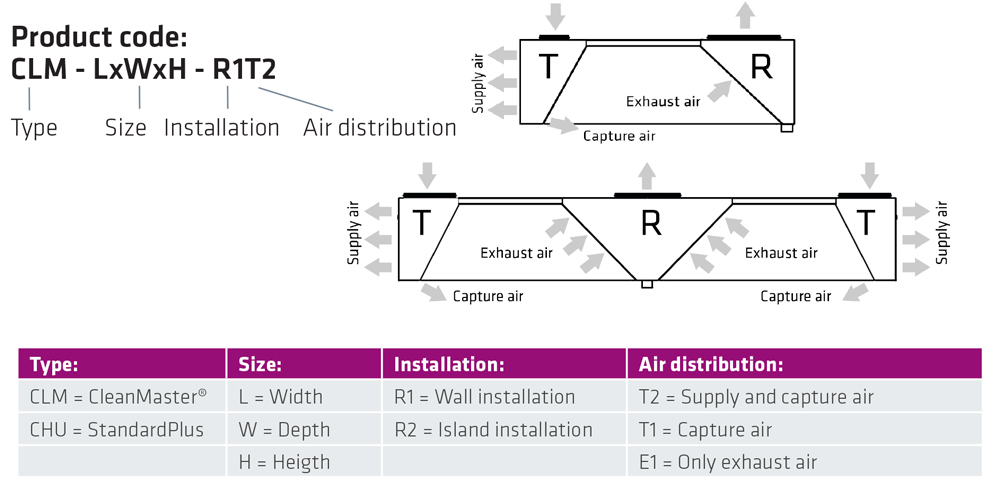

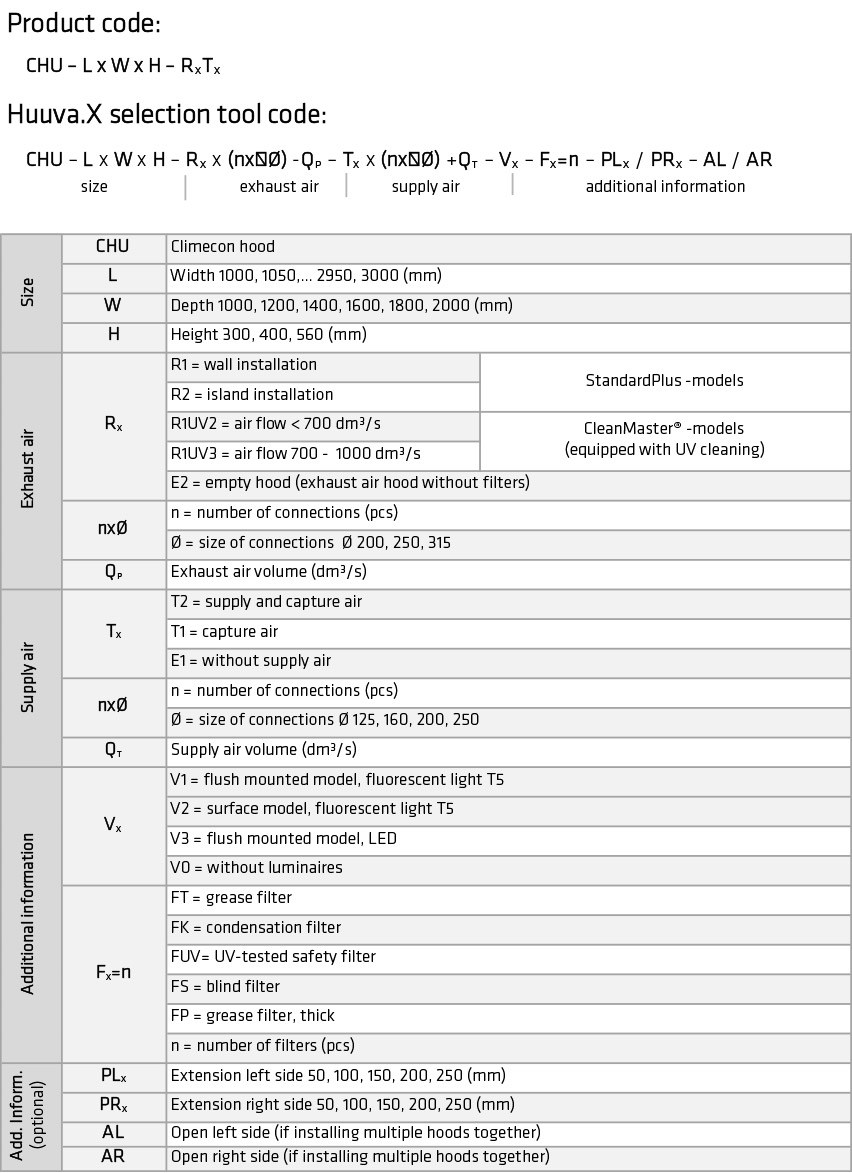

Pressure loss and noise data are measured for one supply air unit only. In island installation models there are two supply air units. Product CodeThe standard hood models are equipped with supply and capture air to ensure balanced and um distracted supply air in the kitchen at low velocity. The hoods are also available with only extract air.

The ordering of CleanMaster® hoods can be done with two different product codes. First product code includes the hoods that have been chosen in the kitchen based on the kitchen equipment. After the hoods have been chosen, its time for the the second product code that includes choosing of the correct CCM control unit. The CCM control unit guides the hoods in the kitchen and is chosen based on the amount of hoods. For example, three CleanMaster® hoods are chosen for the kitchen which means CCM 3 control unit is the best choice to guide the hoods.

Adjustment

|

||||||||