Description

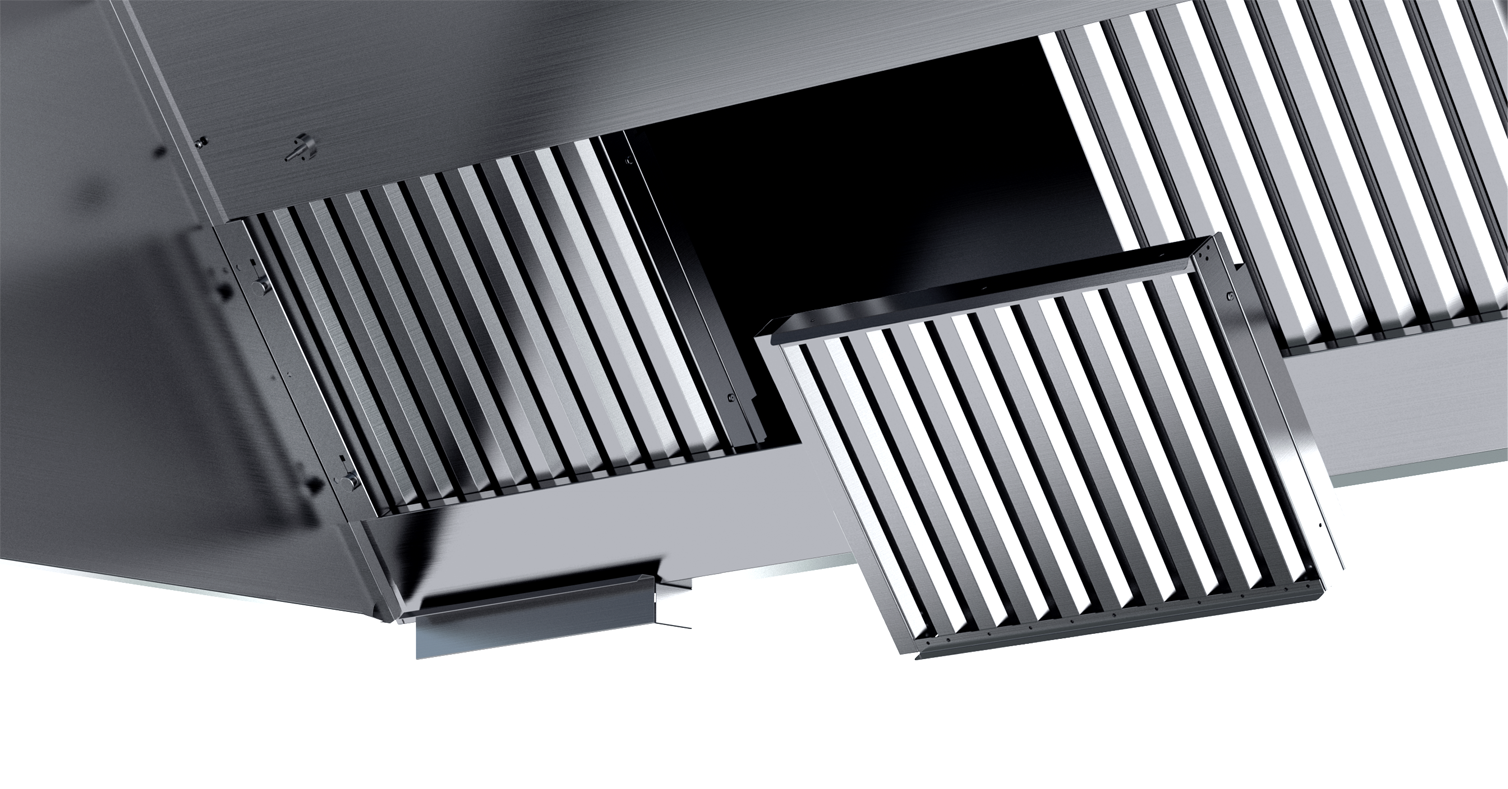

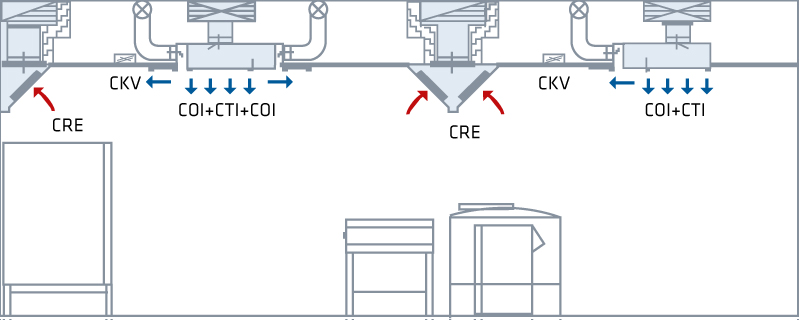

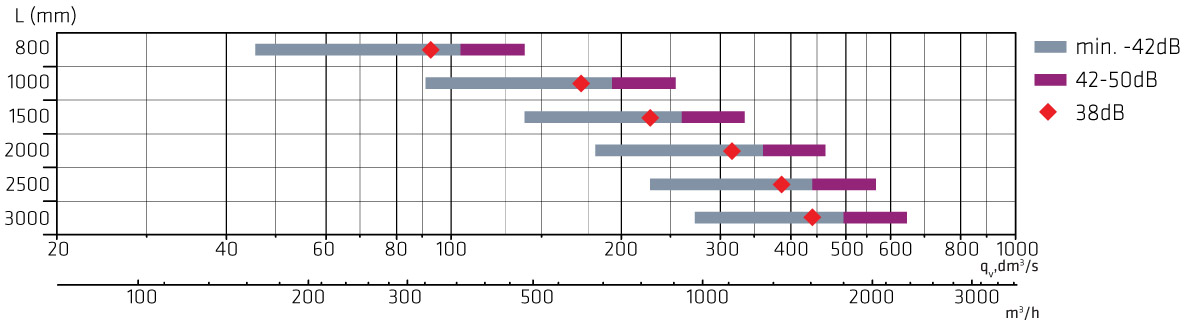

Climecon’s ceiling ventilation solutions include a wide selection of different ventilation units like supply air, capture air, exhaust air units, and air curtain units that prevent dirty air from spreading outside the frying stations. A ceiling ventilation solution can be equipped with dampening elements that dampens efficiently noises and improves working conditions.

Combining different kinds of components, the ventilation system of the kitchen can be built based on its unique needs.

The choice is CleanMaster

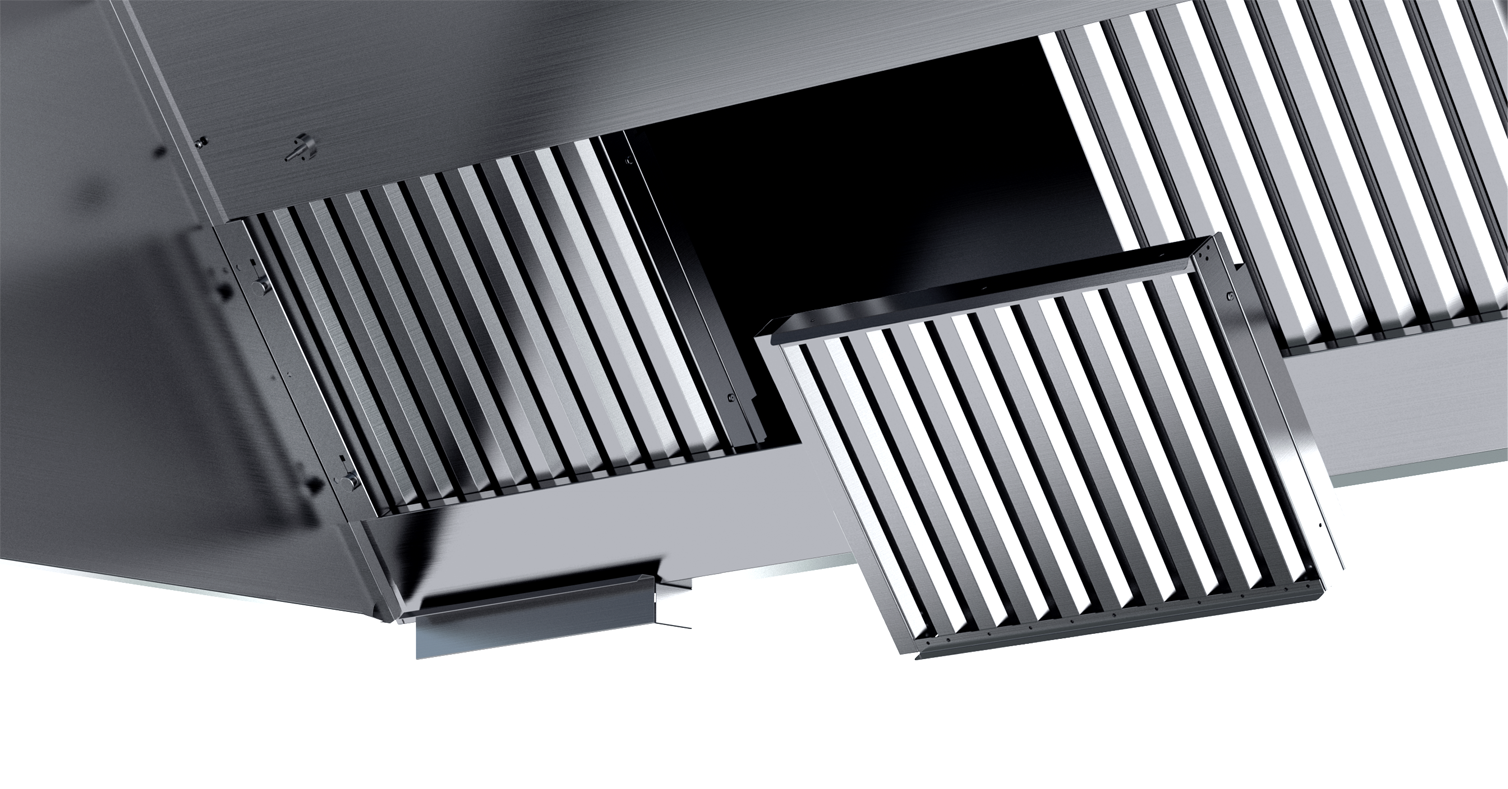

A masterpiece of engineering excellence, CleanMaster hoods are equipped with the most advanced grease filtration rate and outstanding features for easy and safe usage in addition to a significantly high level of fire safety.

For well over three decades, CleanMaster has been continuously improved to even better answer to the needs of even the most demanding users in even the most extraordinary professional kitchens. CleanMaster is the choice of a true professional for commercial kitchens from Michelin star restaurants to food services, public facilities, and business premises.

Advanced four staged cleaning technology

CleanMaster uses the most advanced four staged cleaning technology resulting in clean grease chambers and ducts. CleanMaster contains tested and UV safety certified grease filters.

Mechanical filtration / impact filtration

Mechanical filtration efficiently filters out large grease particles resulting in the cooking process. The heavy particles are sieved out of the extract air traveling through a filter.

UV-C

UV-C is a widely used, conventional “germicidal” cleaning technology. It works against micro-organisms, molds, fungi, and bacteria.

Vacuum UV

Vacuum UV is highly efficient in dissolving small grease particles into natural compounds, such as oxygen, carbon dioxide, and water. In addition to traditional UV technology, vacuum UV provides an even higher extract air cleaning rate.

Ozone

Ozone effectively oxidizes whatever little is left of the grease particles and deodorizes air.

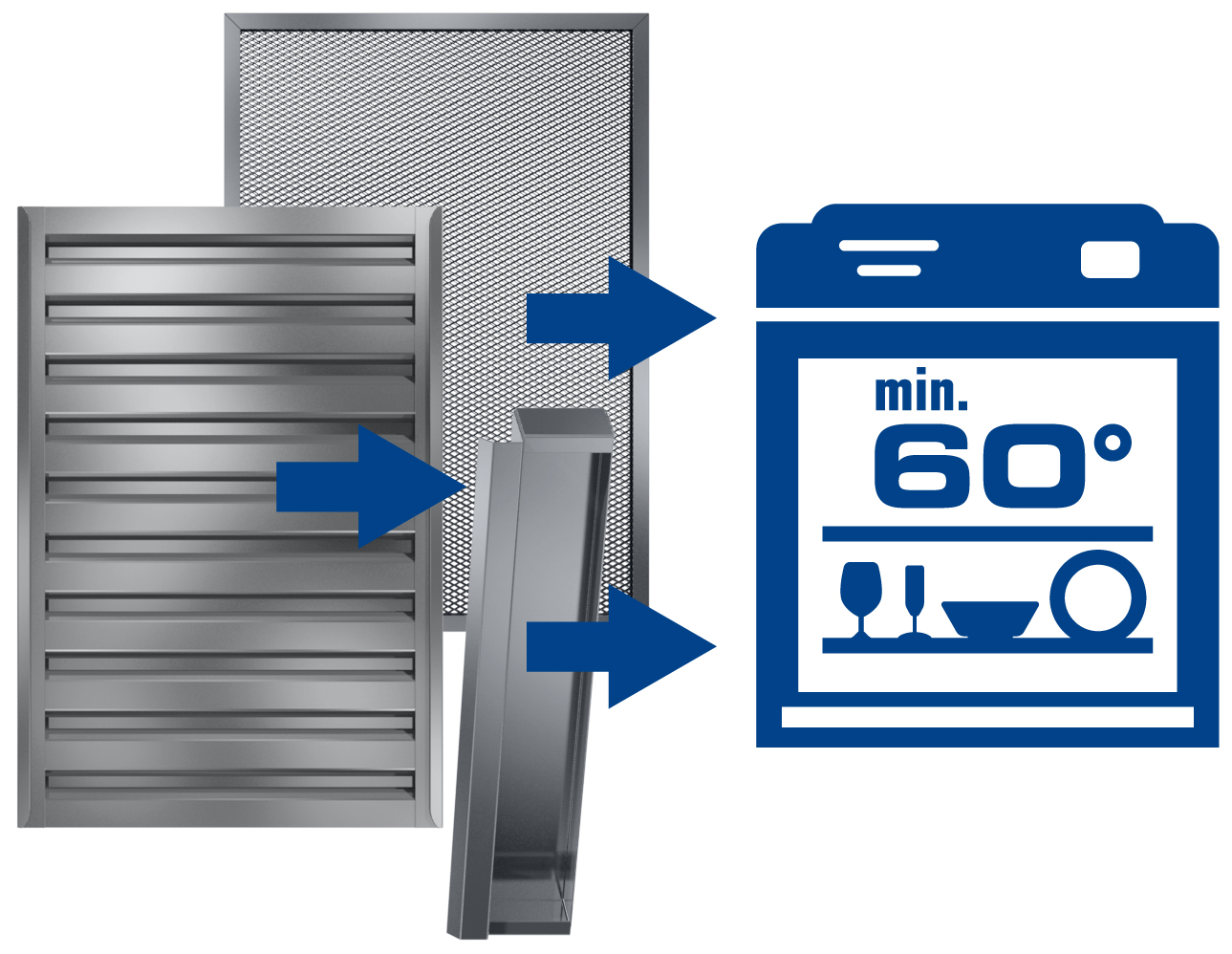

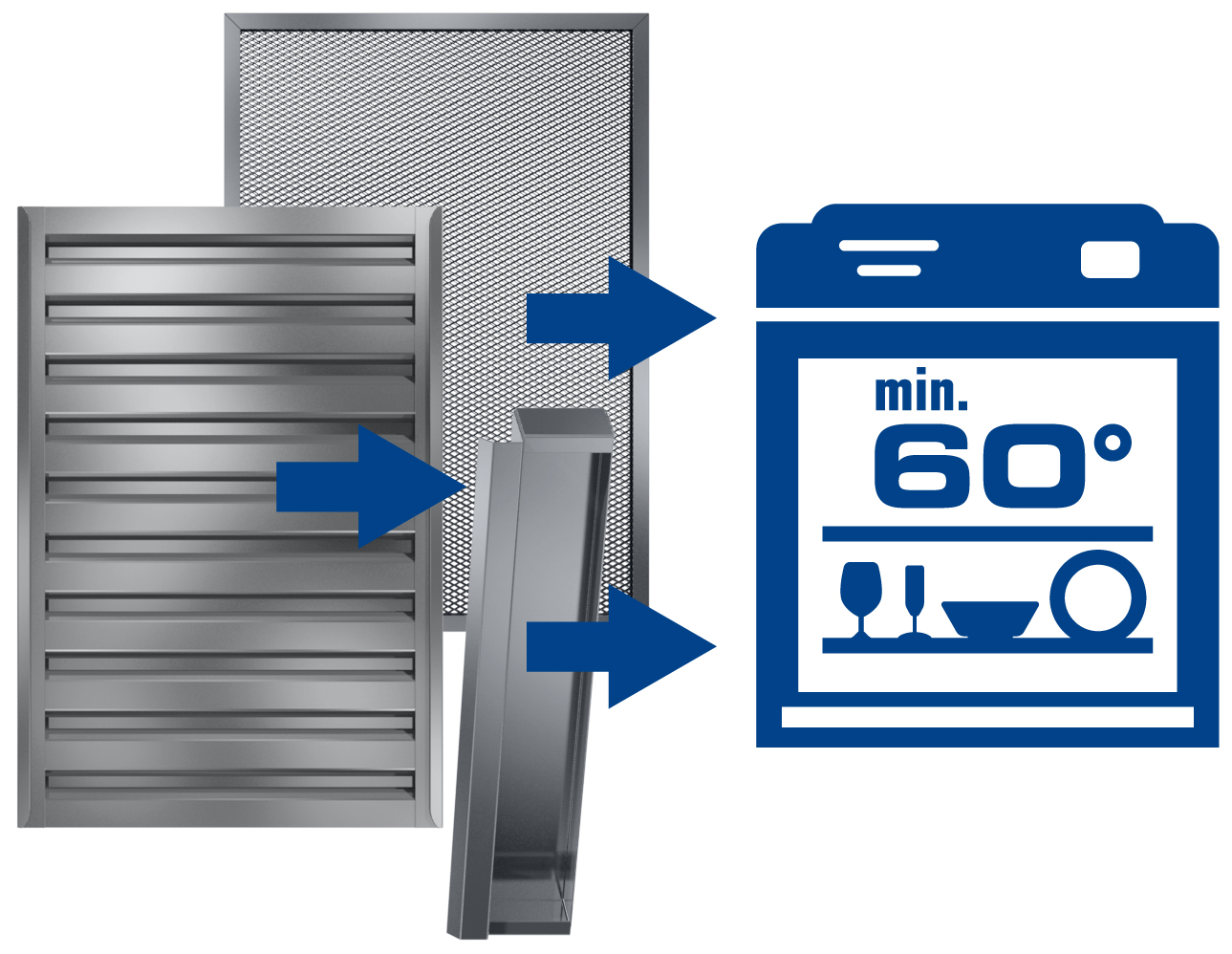

EasyCare concept

The features of EasyCare concept aim at ensuring a high-level of hygiene. When the solutions are easily maintained, they remain in good condition, performing in full-capacity. Additionally, with easily detached and machine washable parts, effortless and quick cleaning leads to less down-time and lower maintenance costs.

- The ducts are easily sweeped through supply and exhaust air units

- All surfaces are dent-free and easily swiped clean

- Grease filters, grease trays, and supply air grilles are machine washable

The ducts can be cleaned through supply and exhaust air units.

|

|

|

| All hood surfaces can be swept clean. |

Design and functionality

Climecon’s ceiling ventilation solutions are designed with special attention to their appearance. A modern design combined with a low structure brings architecturally important spaciousness to the kitchen space.

All of the components of the ceiling ventilation solution are made from stainless steel. The product selection also includes supply and exhaust air devices for general spaces, which can be painted in the desired color.

Design service

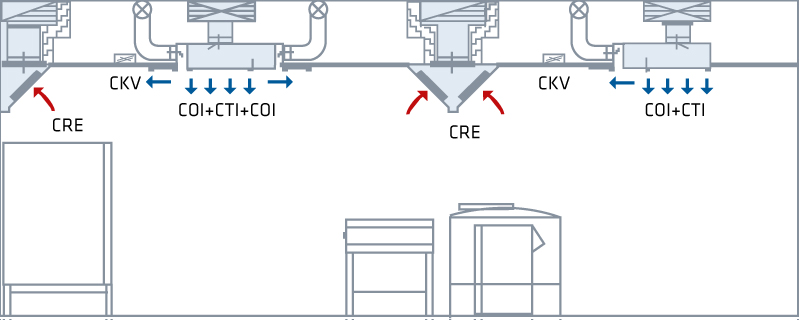

The design service of Climecon helps to make sure that the ventilation devices are correctly dimensioned and designed considering the individual needs of every kitchen.

Functional ceiling ventilation solution includes:

- Efficient and correctly places exhaust air devices

- Correctly places supply air devices that make sure the supply air is distributes evenly and draft free in the kitchen

- Correct placement of capture air and air curtains

- Correct placement of lightning that also improves the working conditions

- Dampening panels that also improve the acoustics and working conditions in the kitchen

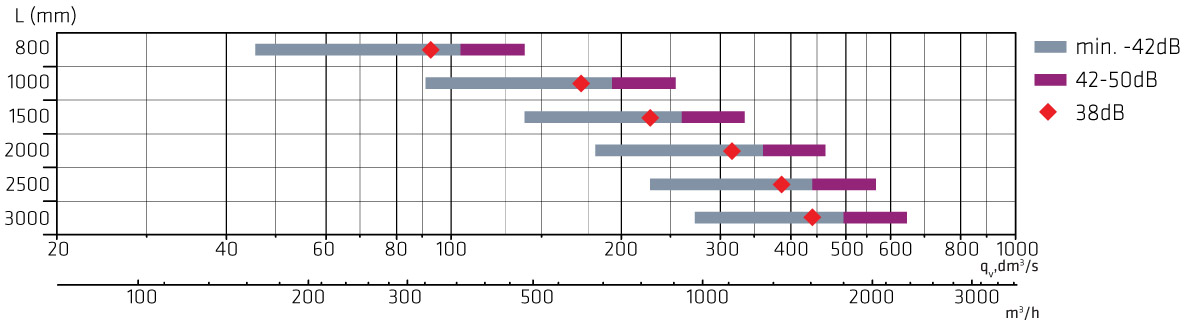

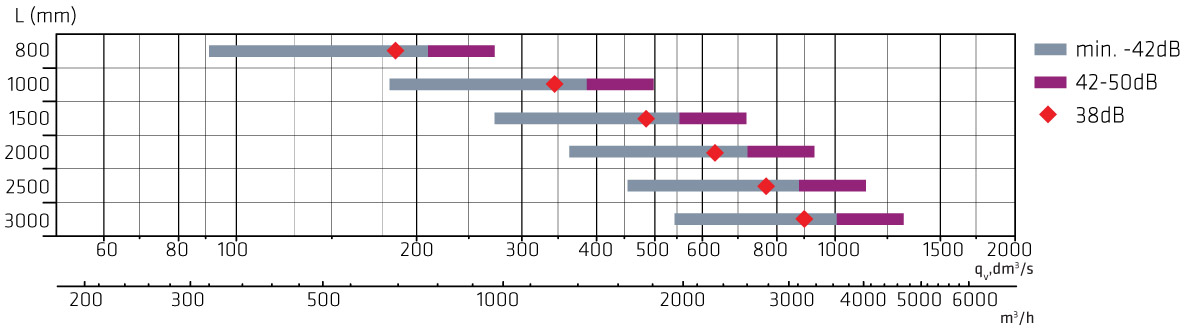

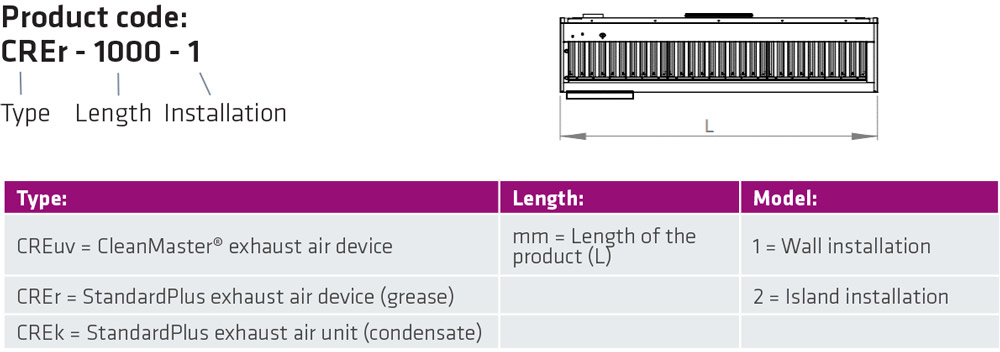

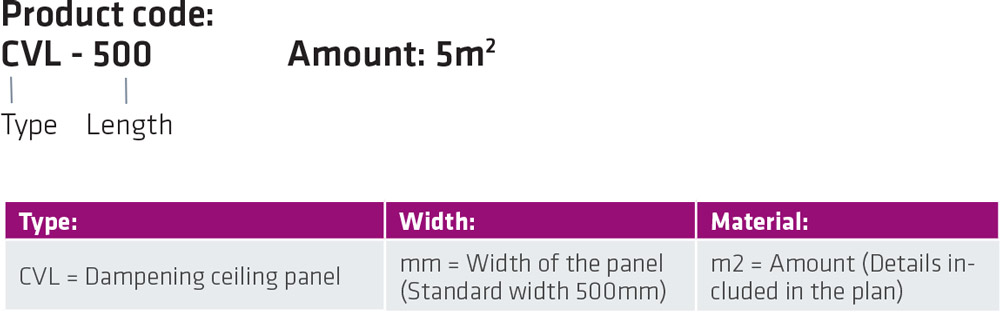

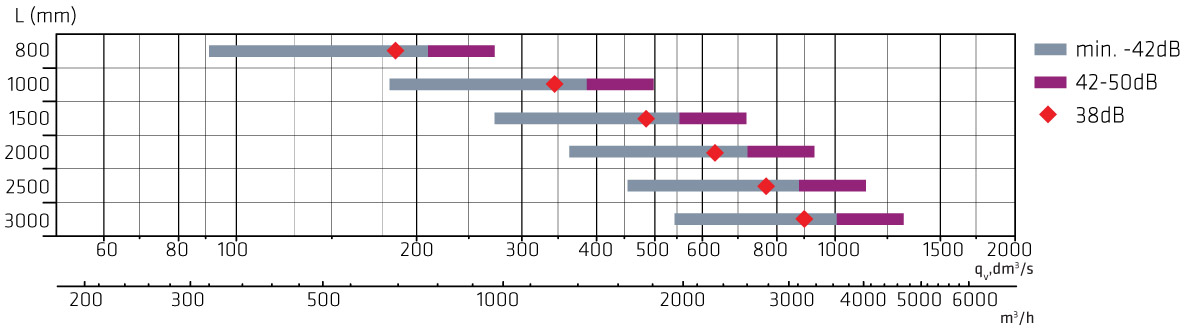

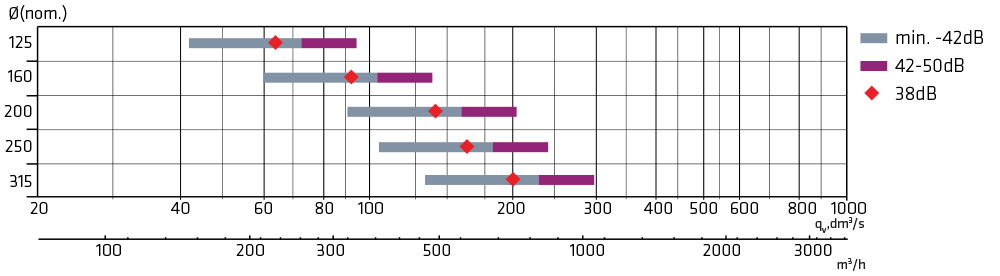

CRE exhaust air device

CRE exhaust air device is designed to exhaust the grease steam airising from the frying stations.

- Grease separation rate tested in the VTT Technical

Research Centre of Helsinki

- UV-certified grease filters according to norm

DIN 18869-7:2006-06

- Easily removable and machine washable

grease filters

|

|

|

Quick guide, wall installation

Quick guide, island installation

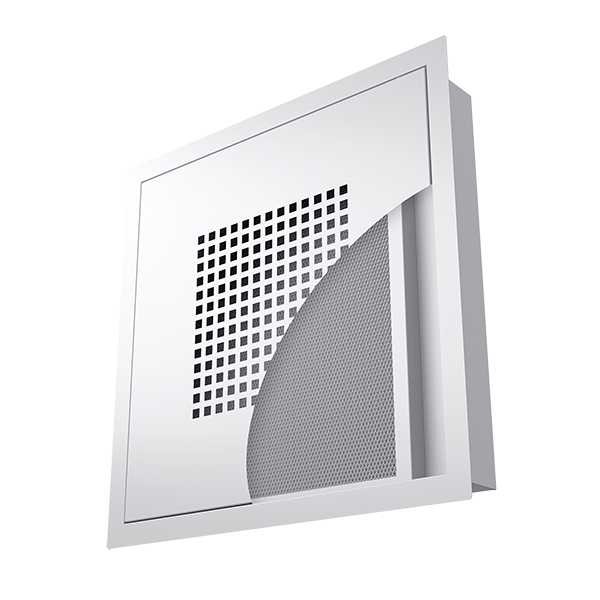

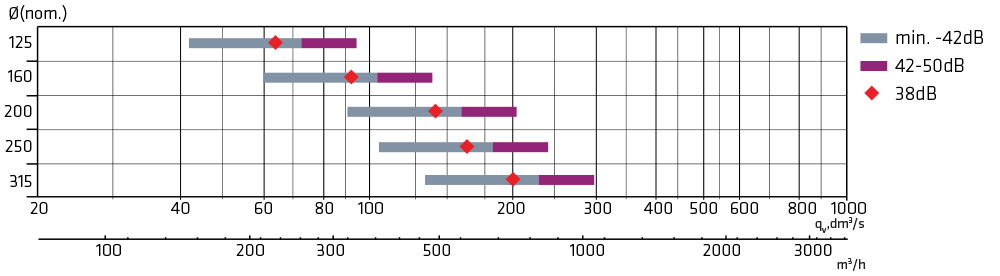

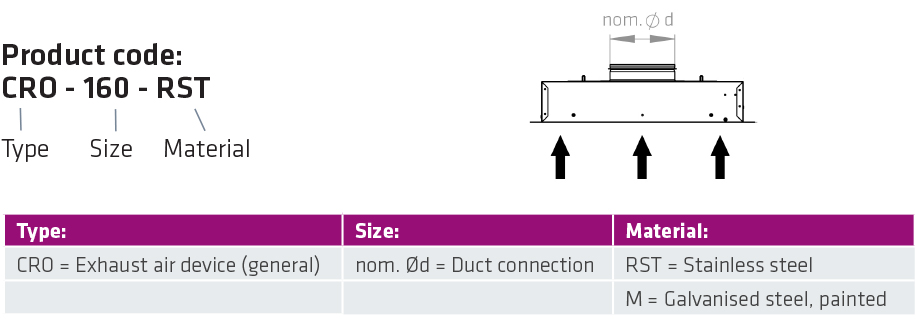

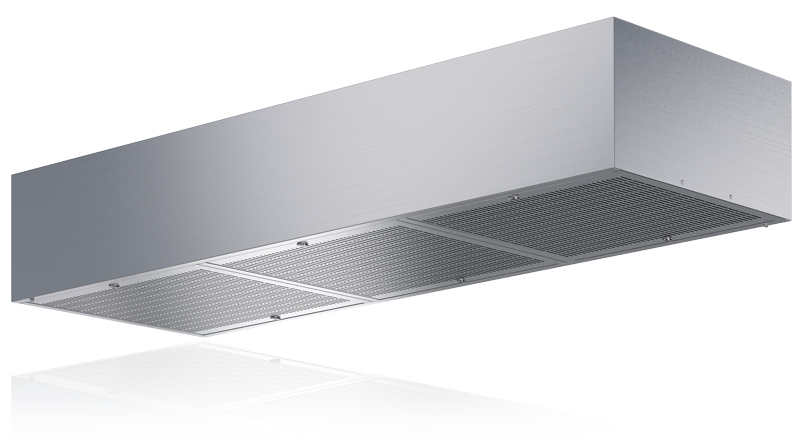

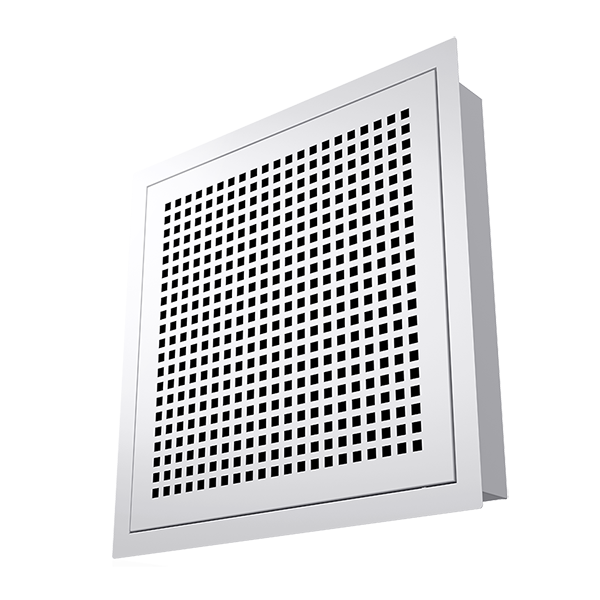

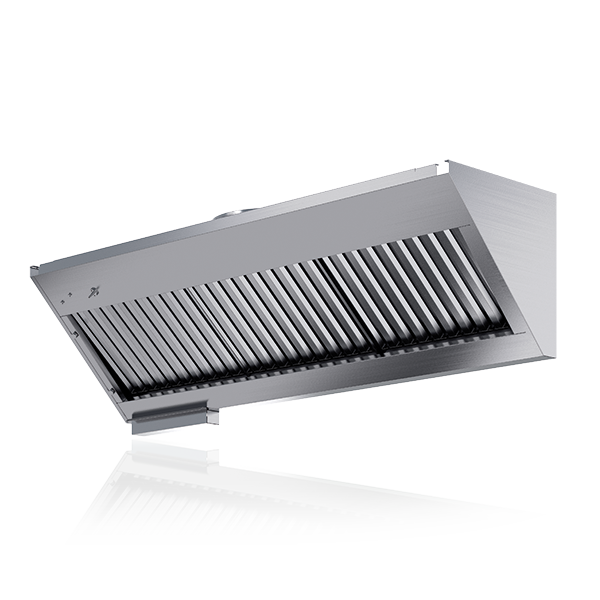

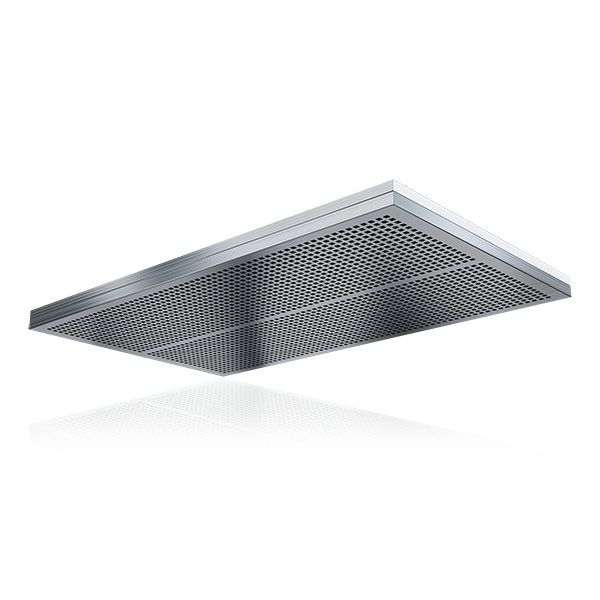

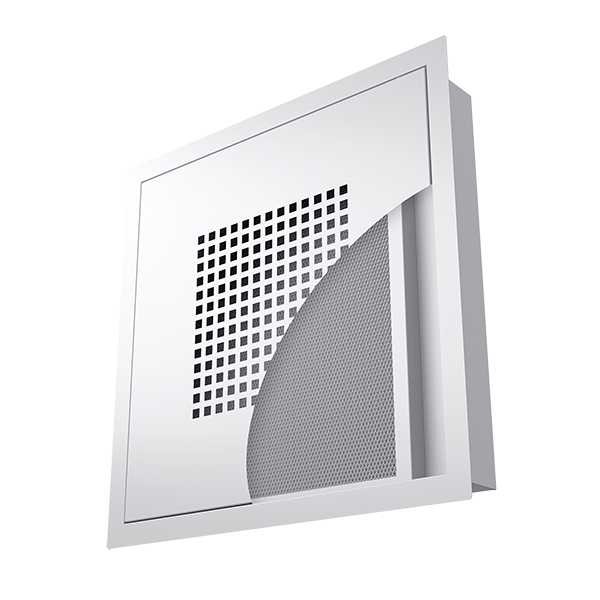

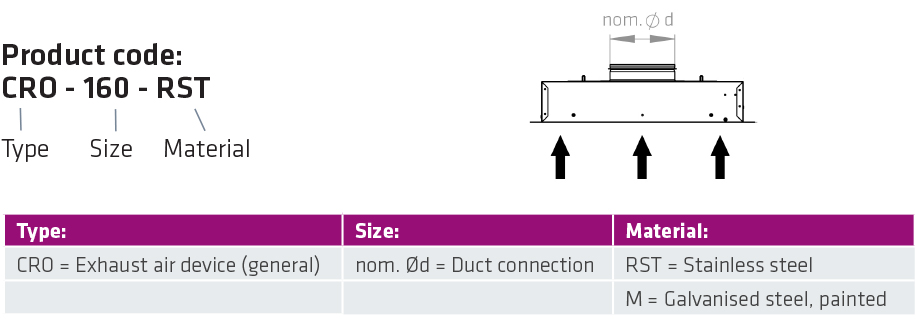

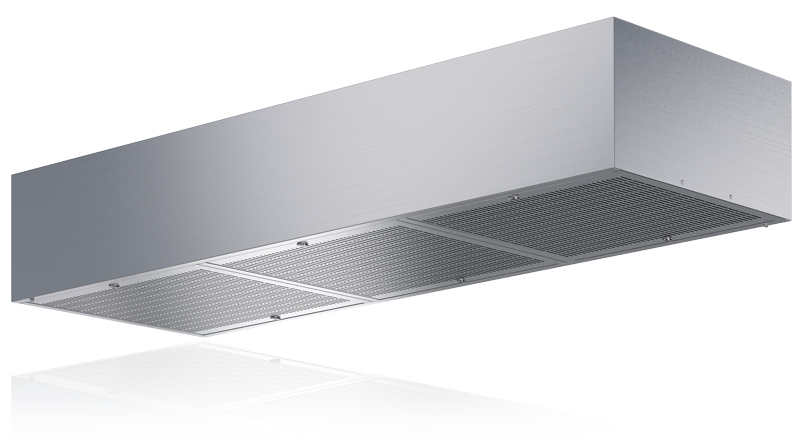

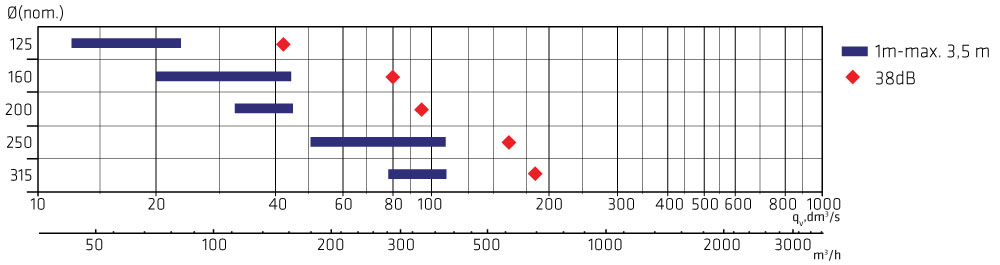

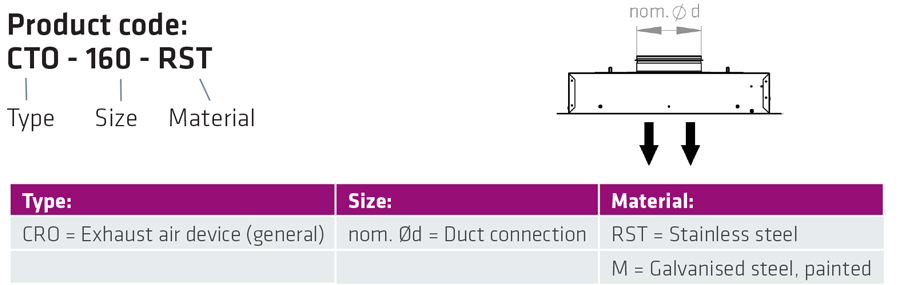

CRO exhaust air device

CRO exhaust air device is designed to general exhausting of the air.

- Equipped with removable and machine washable filter

- Installed in suspended ceiling

- Product material is stainless steel, but is also available painted in RAL 9016

Quick guide CRO

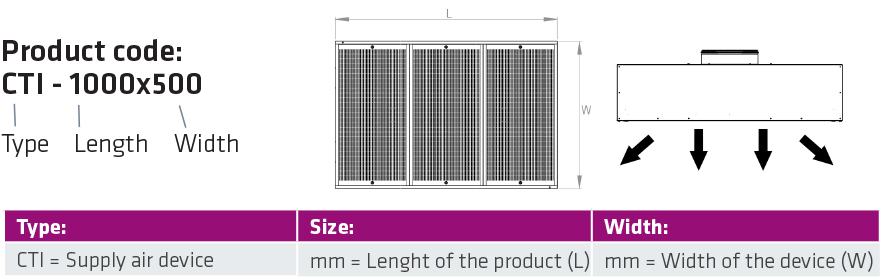

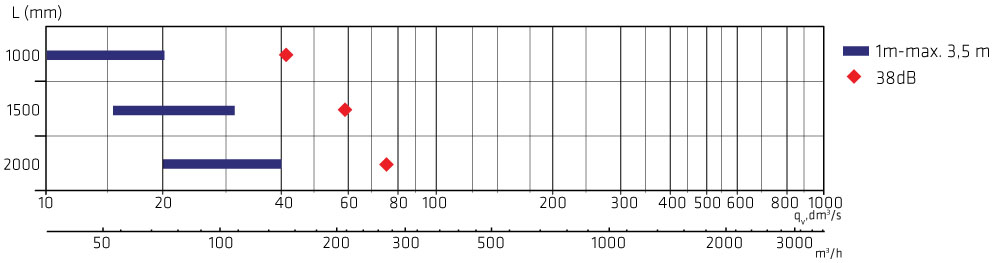

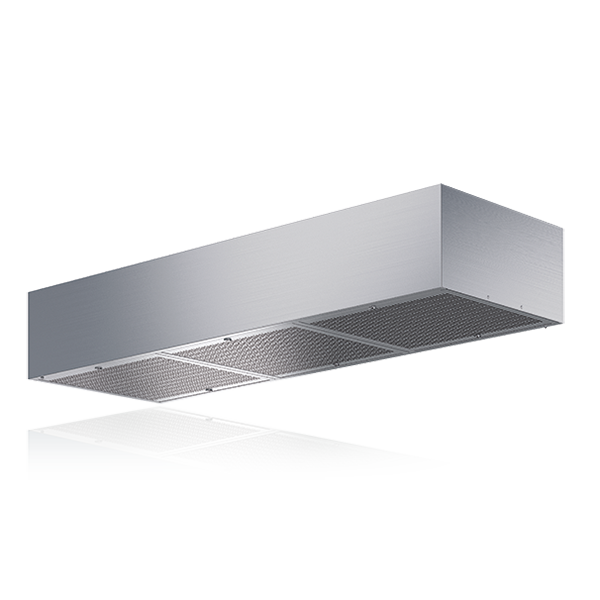

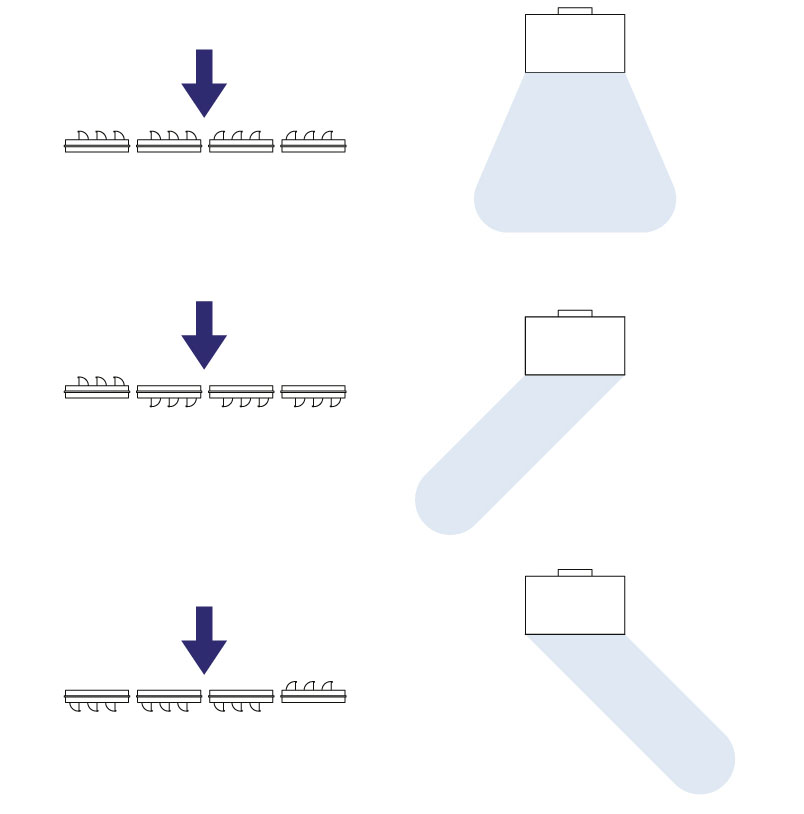

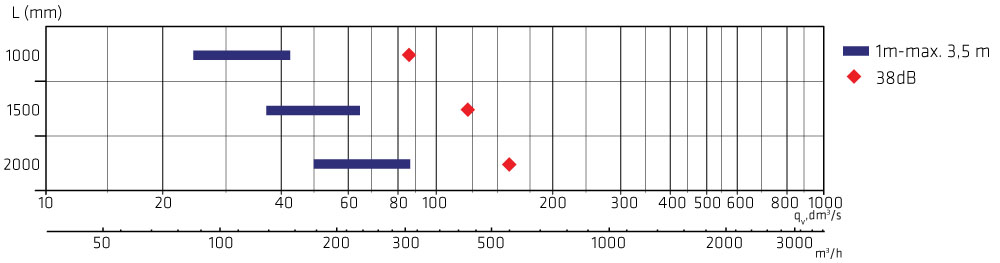

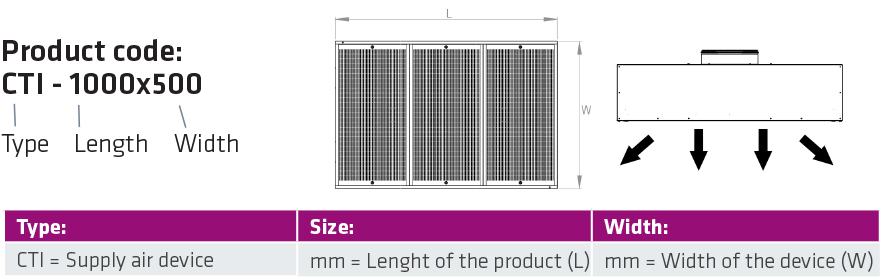

CTI supply air device

CTI supply air device guarantee even and draft free air distribution in the kitchen.

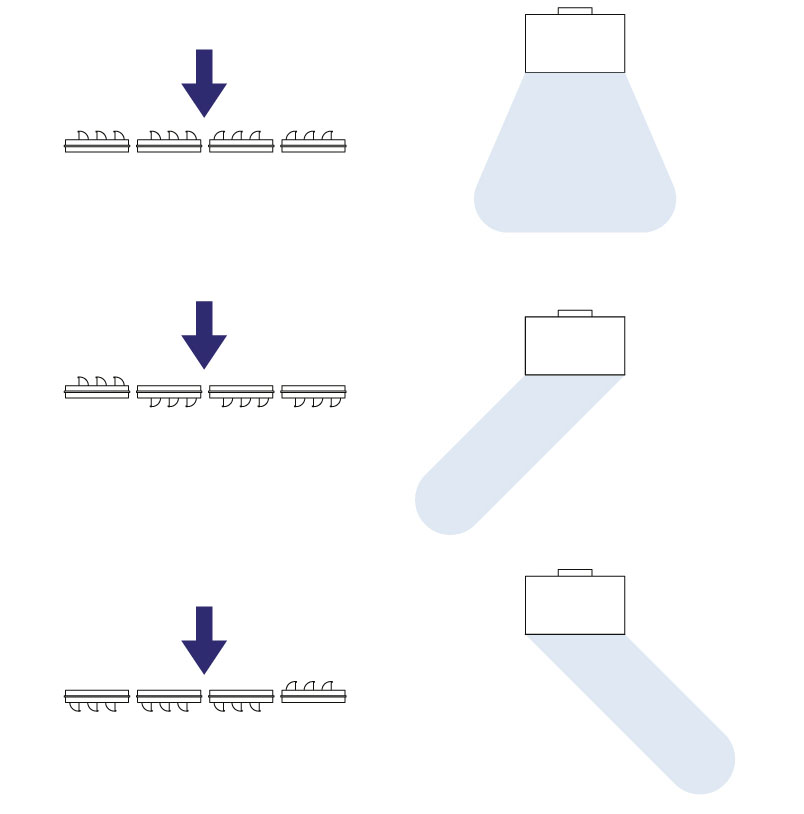

- Directable throw pattern

- Removable and machine washable supply air modules

|

|

|

Throw patterns

The throw pattern of CTI can be easily directed.

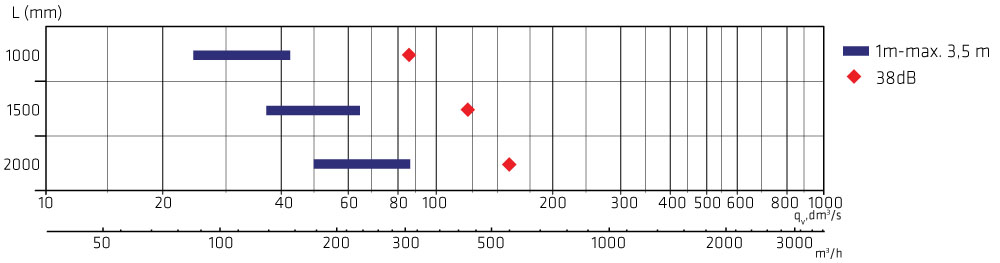

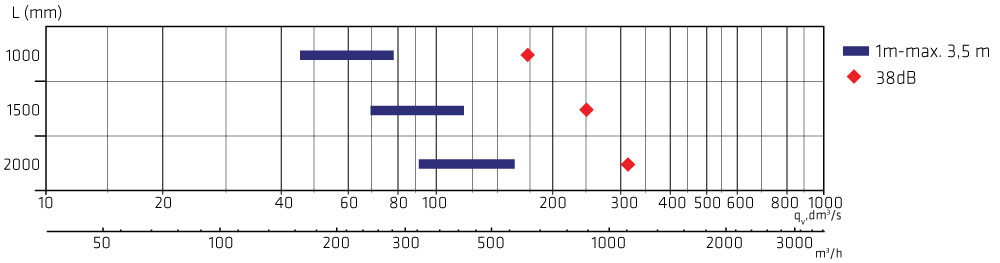

Quick guide CTI W300

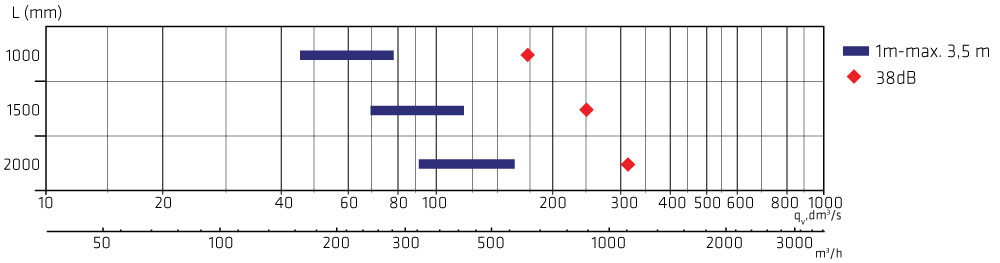

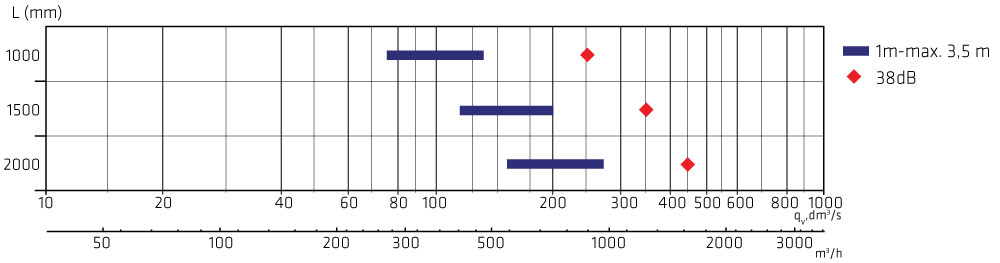

Quick guide CTI W500

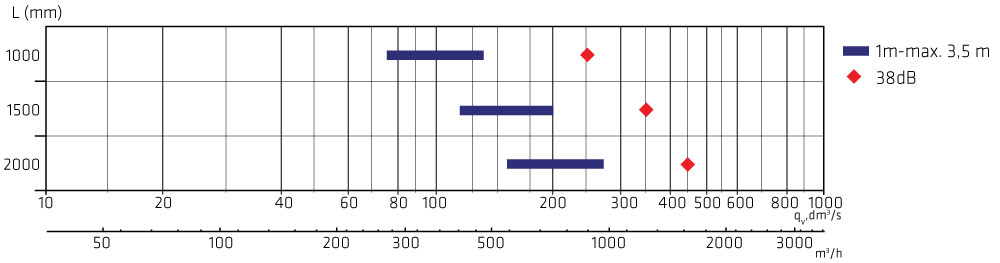

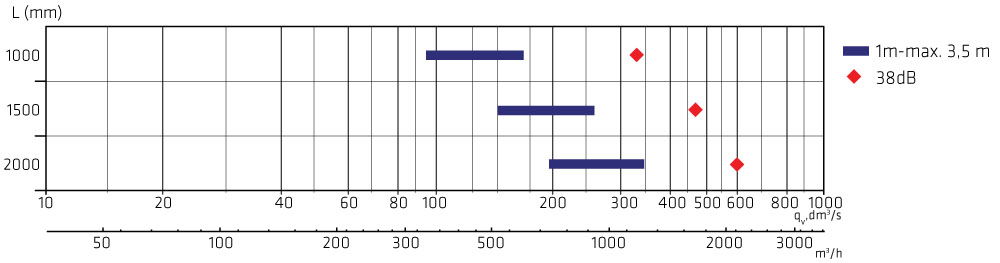

Quick guide CTI W800

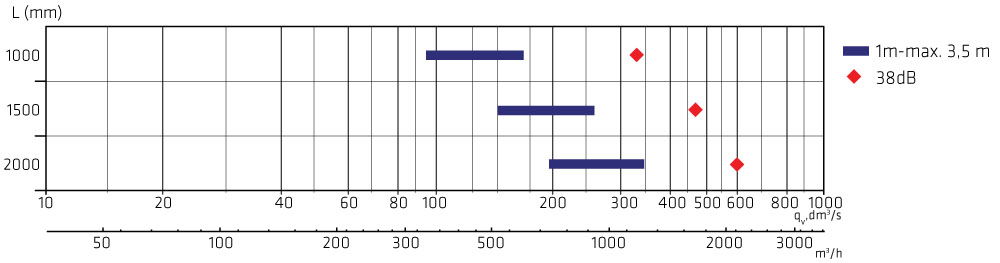

Quick guide CTI W1000

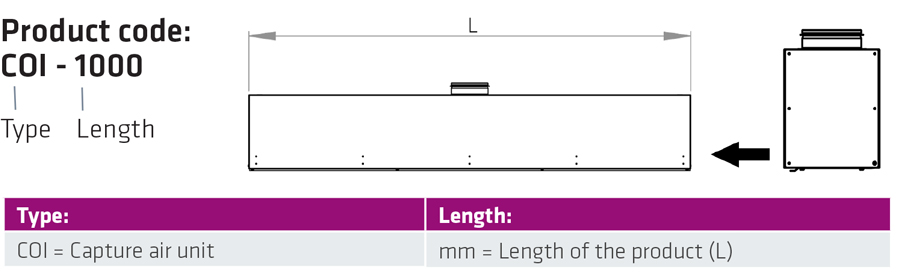

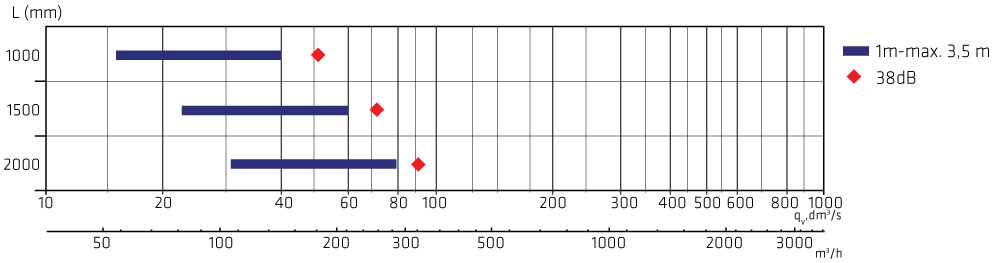

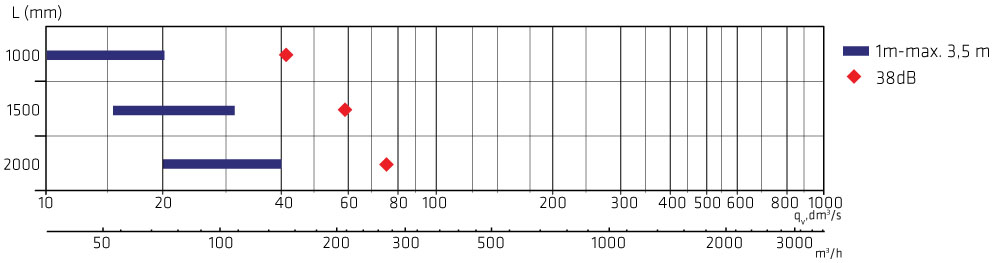

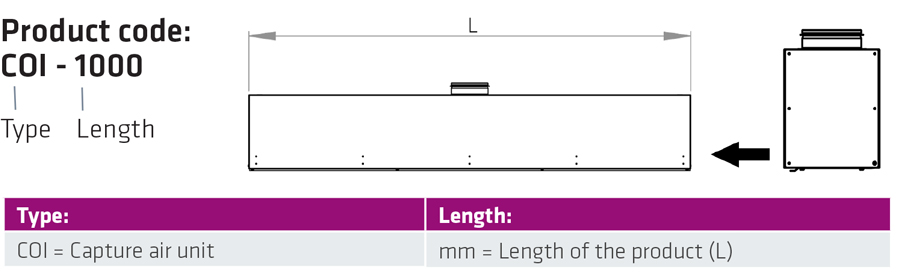

COI capture air unit

COI capture air unit directs the grease fumes efficiently to grease filters.

- Increases the performance of the exhaust air unit

|

|

|

Quick guide COI

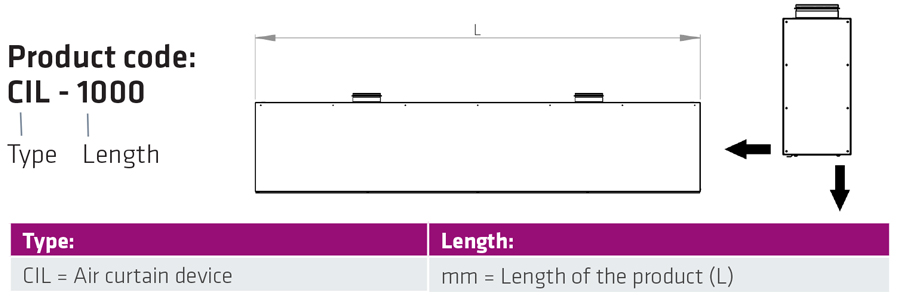

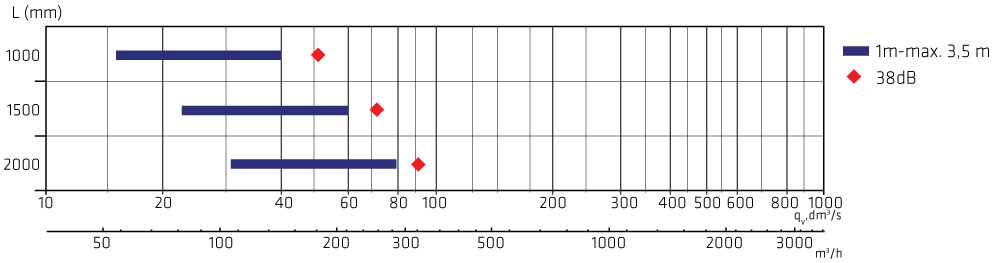

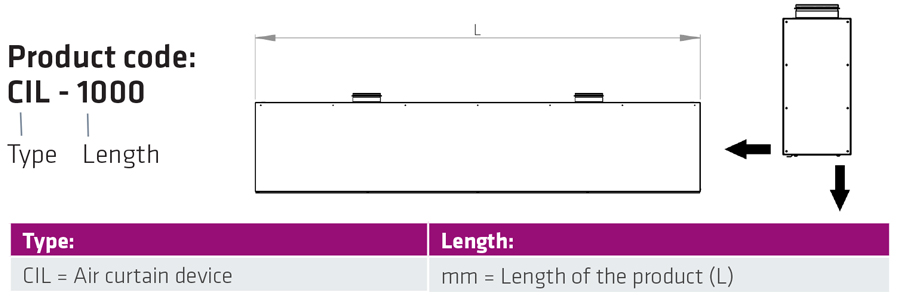

CIL air curtain

CIL air curtain prevent grease steams from drifting outside the kitchen area.

- Are used in the side areas of the kitchen

- Fit well in open plan kitchens

|

|

|

Quick guide CIL

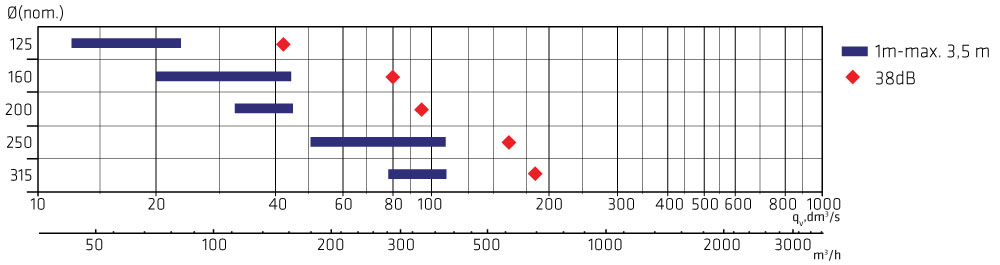

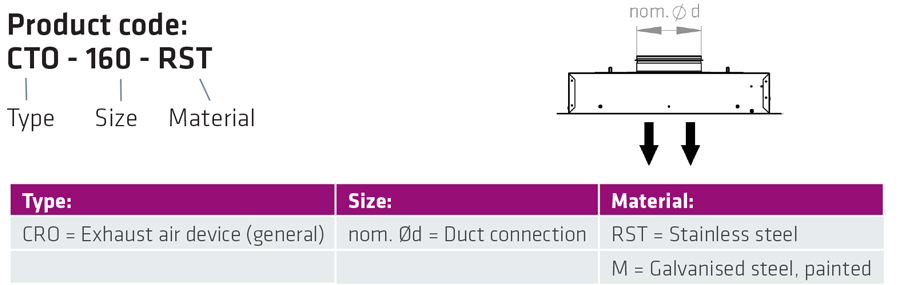

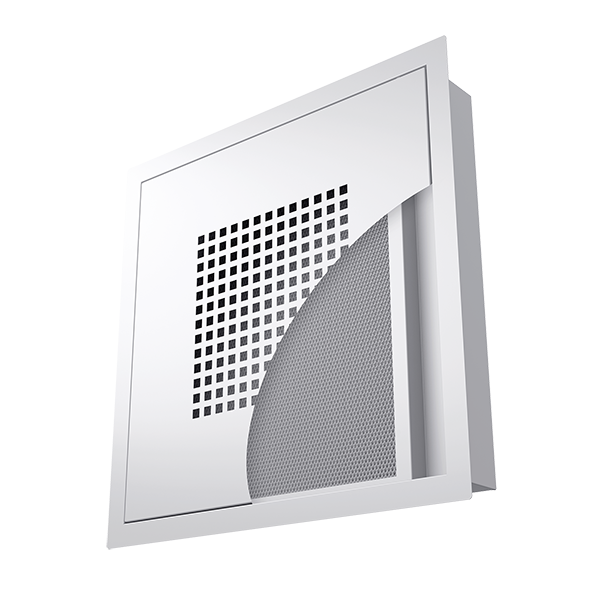

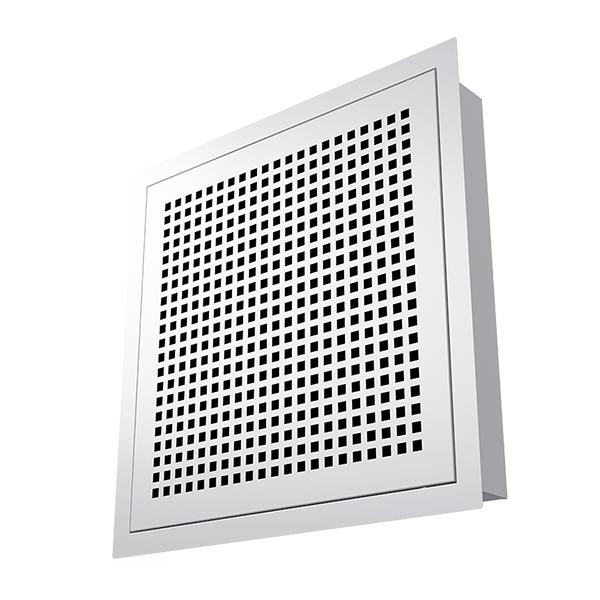

CTO supply air unit

CTO supply air unit is designed to general air supply.

- Installed in suspended ceiling

- Product material is stainless steel, but its also available painted white RAL 9016

Quick guide CTO

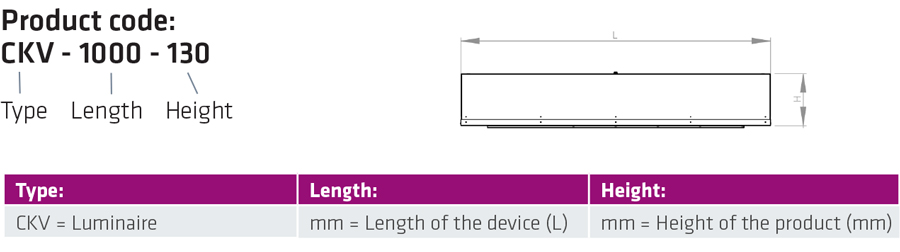

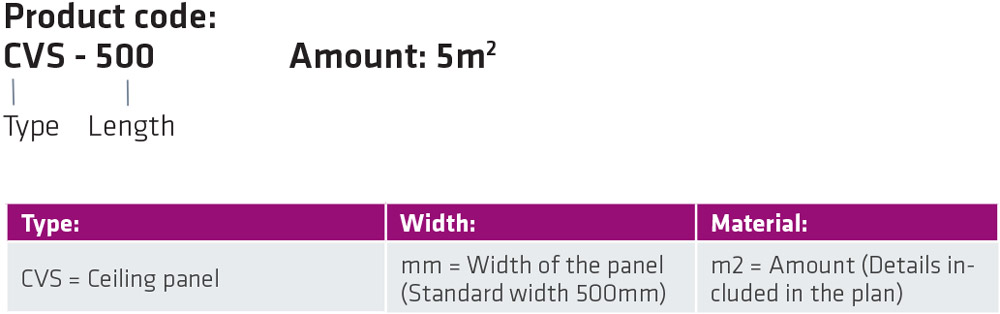

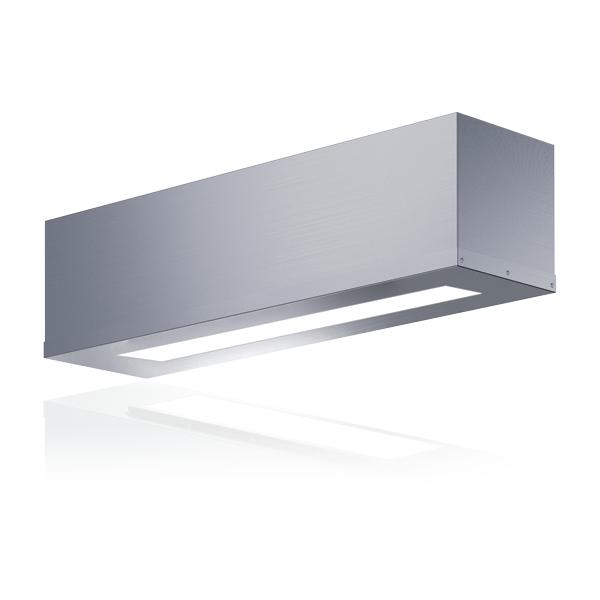

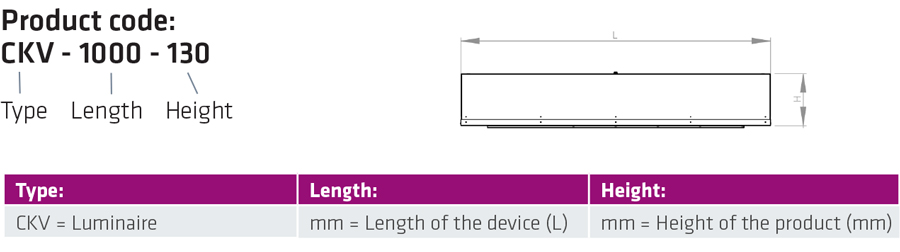

CKV luminaire

CKV luminaire ensures proper and even lightning in the working stations.

- Available in T5 fluorescent lamp or LED lamp

- Steam-tight structure

|

|

|

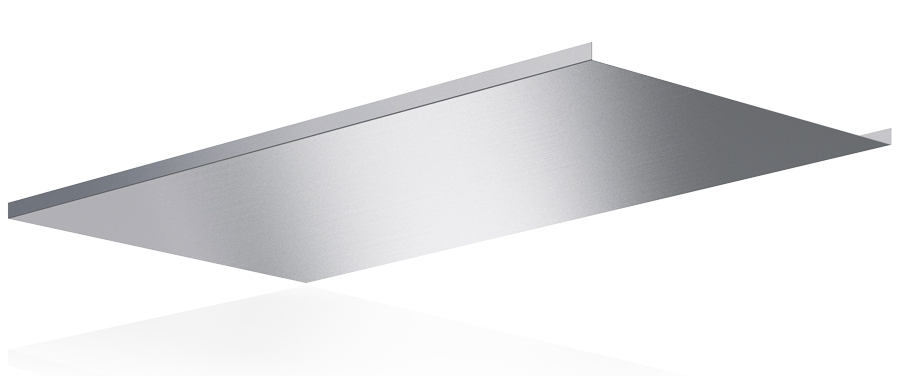

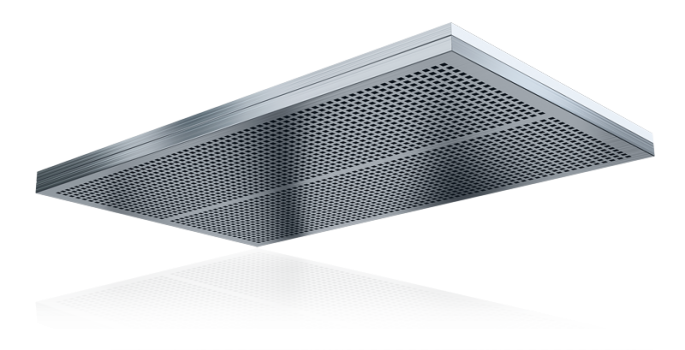

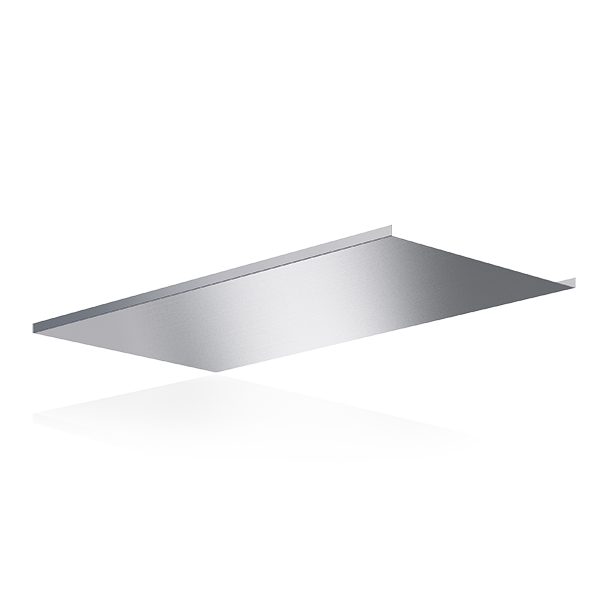

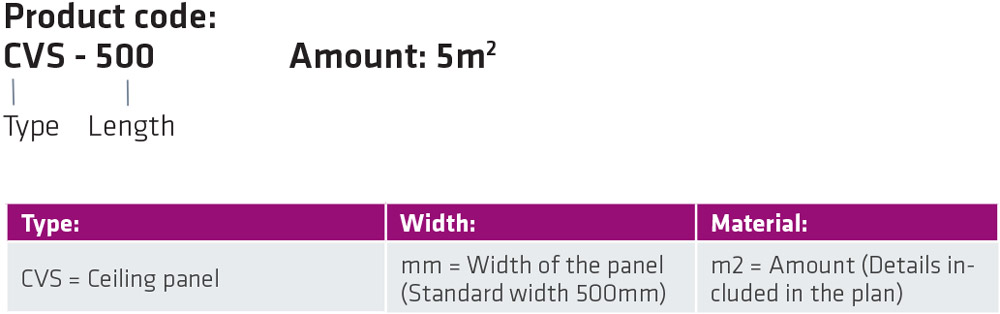

CVS ceiling panel

Stylish CVS ceiling panel is made from stainless steel.

- Ceiling panels are attached to surrounding units with L and T lists included in the delivery

|

|

|

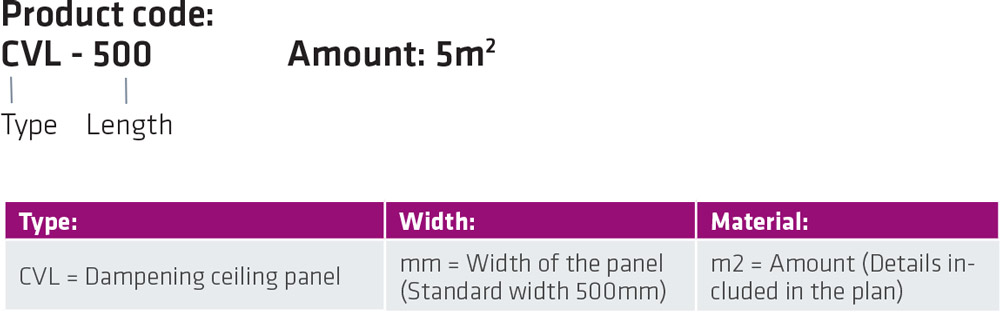

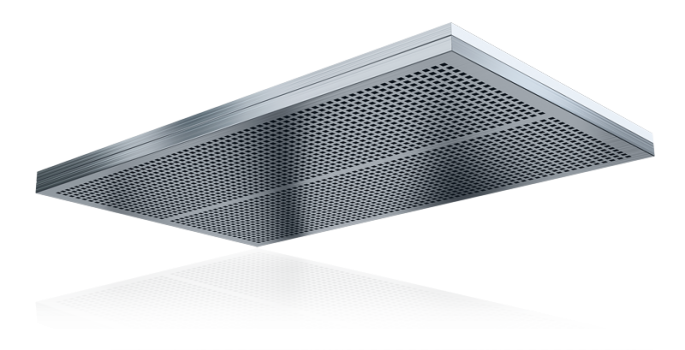

CVL dampening panel

CVL dampening panel reduce background noises and improve the working environment.

- Acoustics panel included in the panel fulfills the hygiene reguirements

- Noice absorption level is D

|

|

|