Description

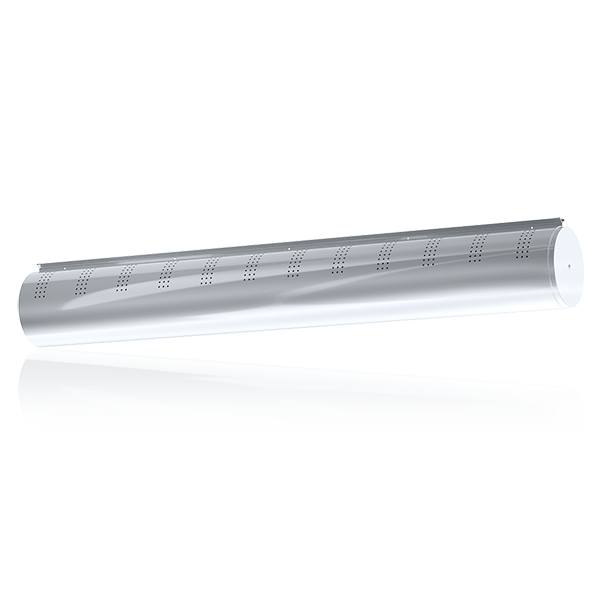

The ROL nozzle duct features optimally sized perforation with a precisely defined perforation pattern. This results in air distribution with extremely good mixing that grabs a large volume of surrounding air. Thanks to the high mixing ratio, ROL is perfectly suited for cooled air.

ROL-S adjustment and silencer unit is the best and safest option for applications where high standards are set for adjustability, noise level and appearance. ROL-S consists of the opened adjustment unit functioning also as a cleaning hatch and of a high quality silencer unit after the adjustment unit. The silencer absorbs the sounds coming from the adjustment and also effectively inhibits the migration of the air sounds coming from the duct work going into the room.

Features:

- ROL works well in both small and large rooms. ROL is generally used in offices, schools, research and industrial premises.

- Smooth surface, attractive appearance and easy to clean

- New installation methods, fast and easy

- Draft-free, even air distribution

- Extremely silent

- Well suited for low-temperature air

- Installation-ready, painted unit

- Ø 125-500mm, lengths 1500-6000mm

- Standard finish painted steel

- Also available in stainless, acid-proof and gloss lacquered steel

- New adjustment and silencer unit ROL-S and non-perforated joint duct ROL-0 available as accessories

- Tested by Finnish Technical Research Center VTT

Product code

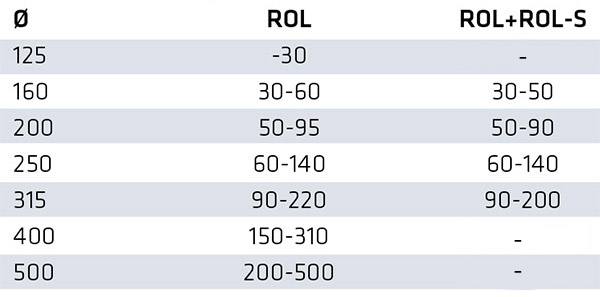

| ROL |

– |

200 |

/ |

180 |

– |

1 |

+ |

ROL-S* |

|

|

1 |

|

2 |

|

3 |

|

4 |

1 = Size (diameter) 125 – 500 mm

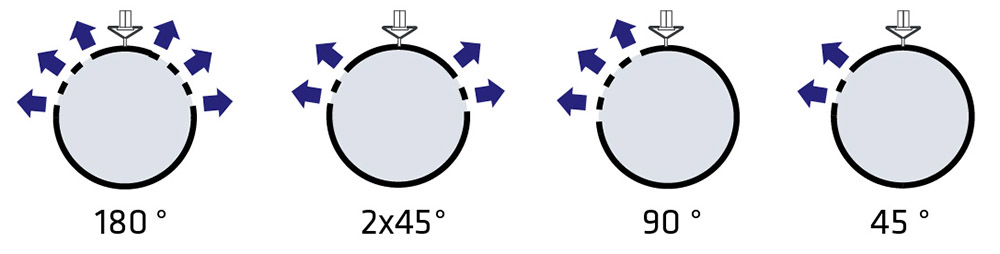

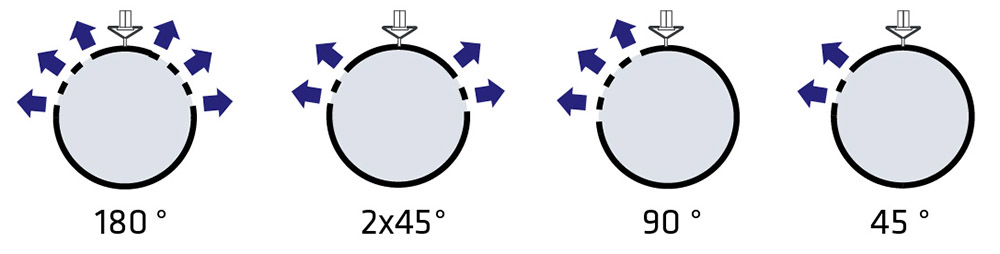

2 = Supply air sector

3 = Number of modules (=length, 1=1500, 2=3000, 3=4500)

4 = Adjustment/damper unit as an accessory

*ROL-S is not mandatory.

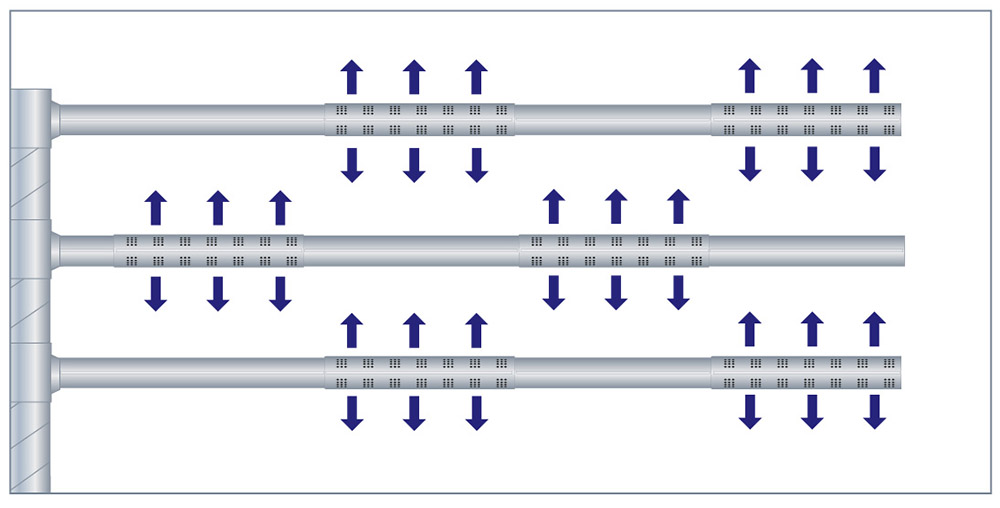

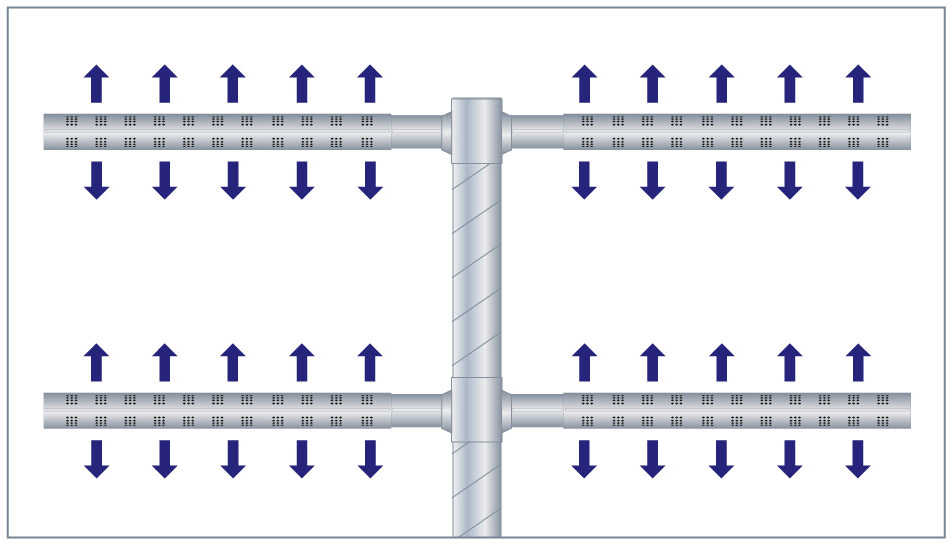

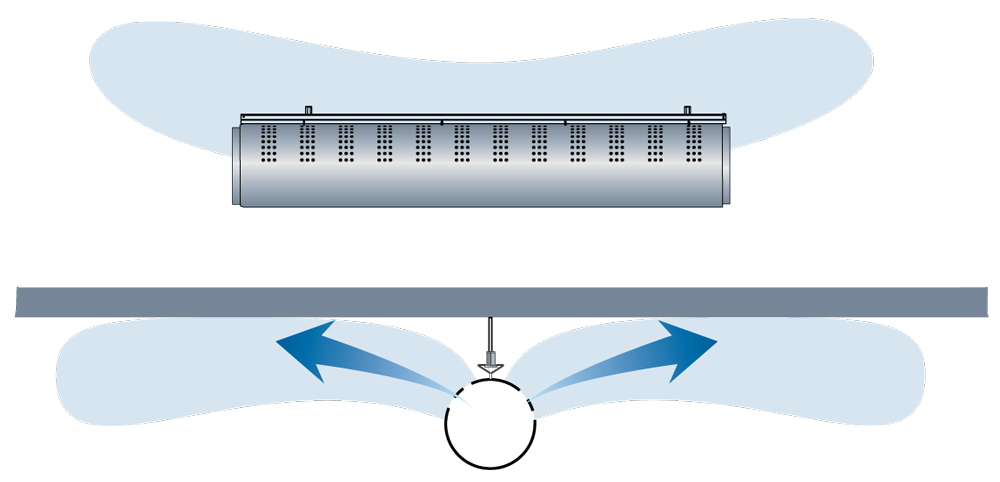

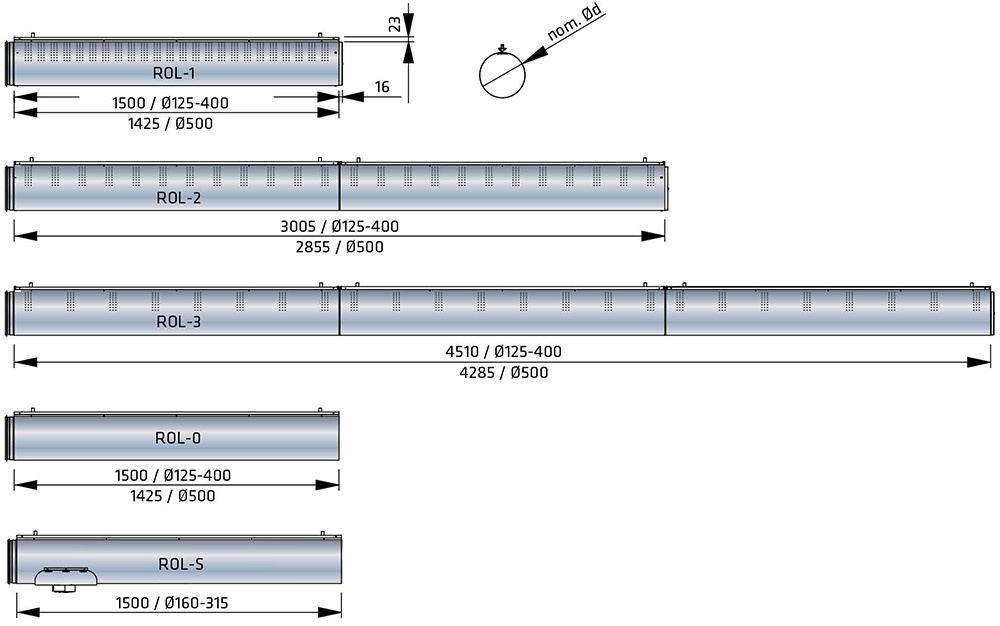

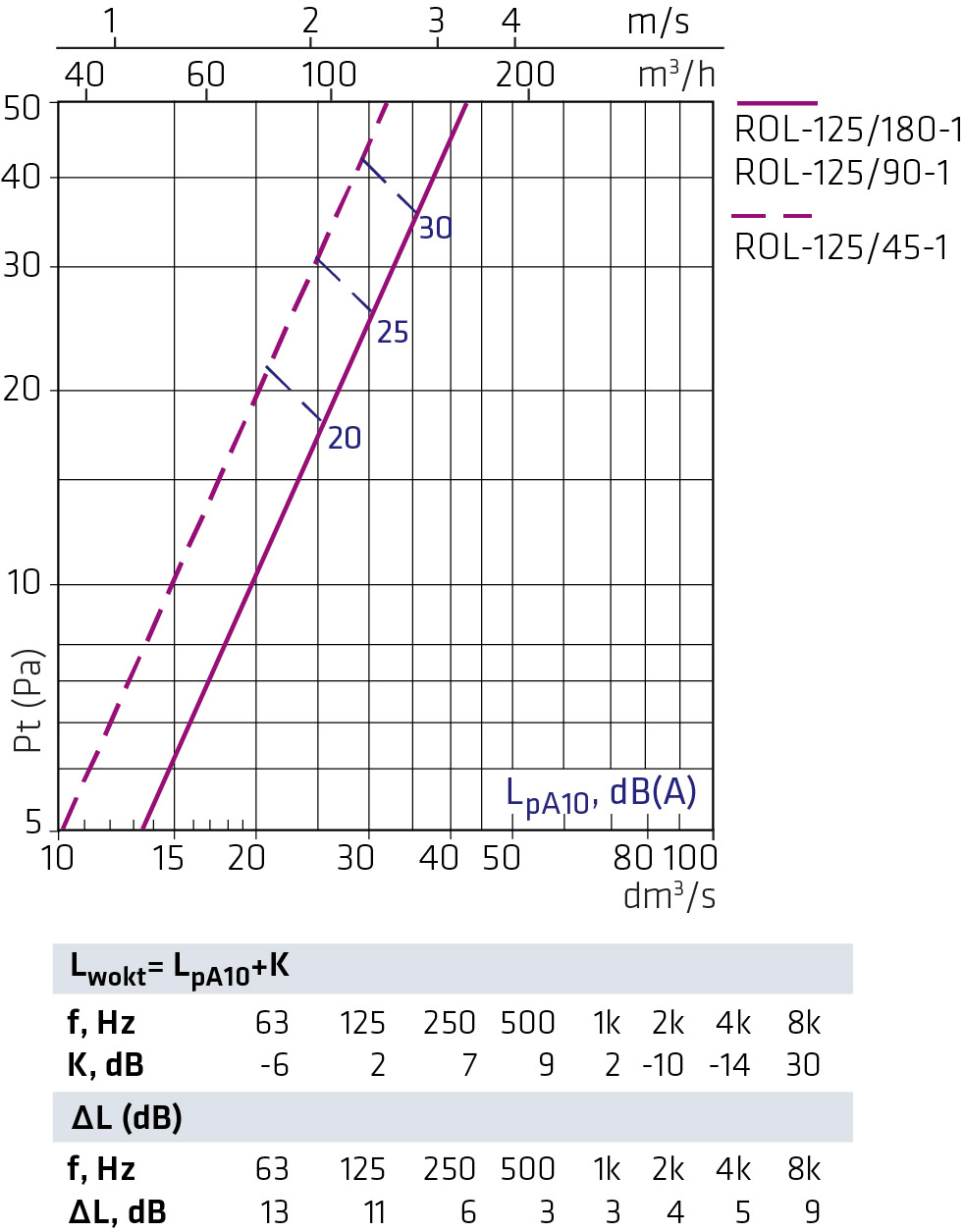

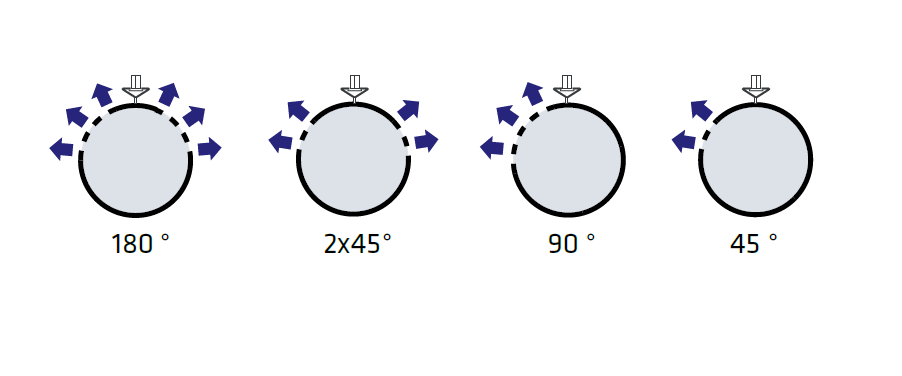

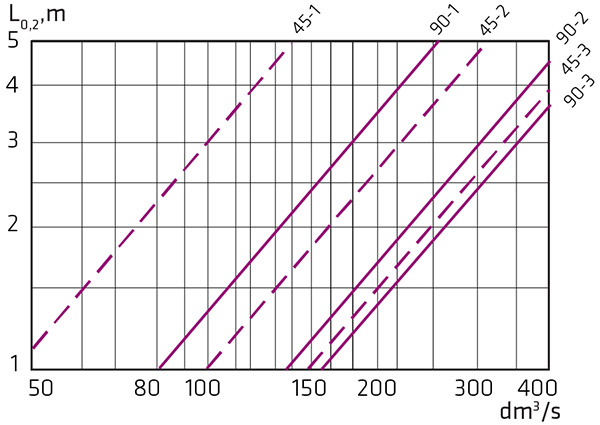

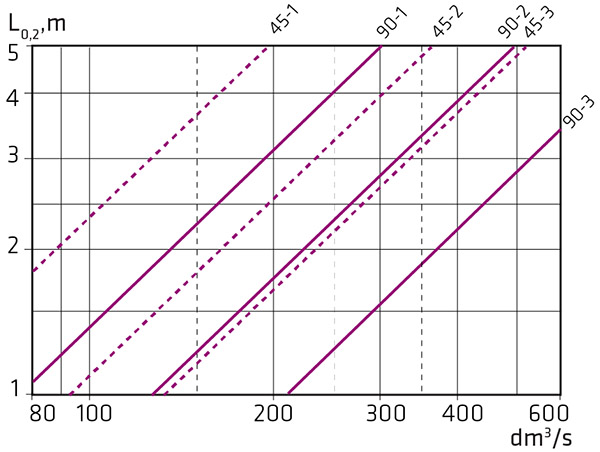

Throw patterns and throw lengths

ROL throw patterns

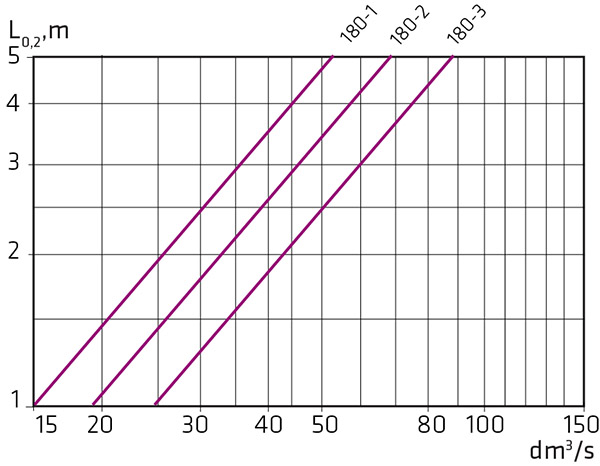

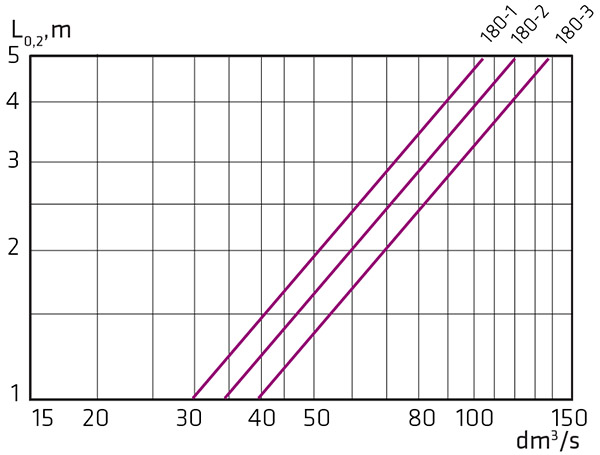

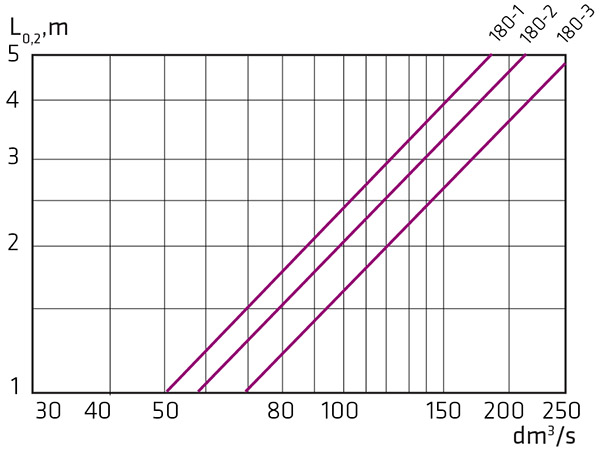

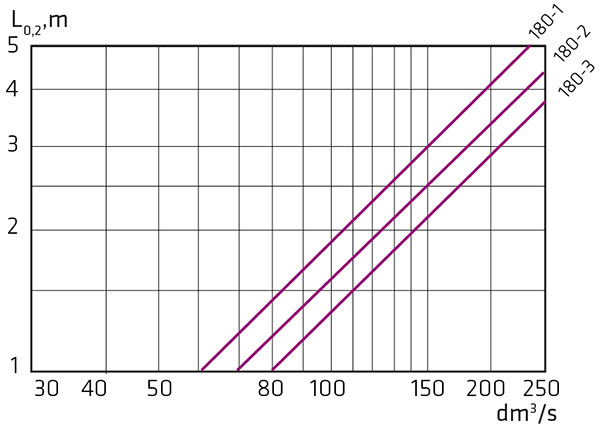

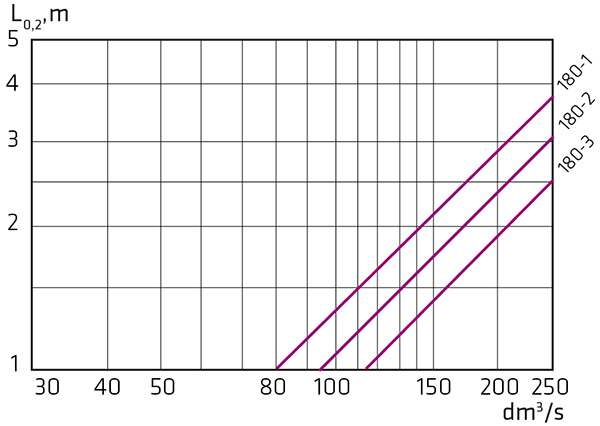

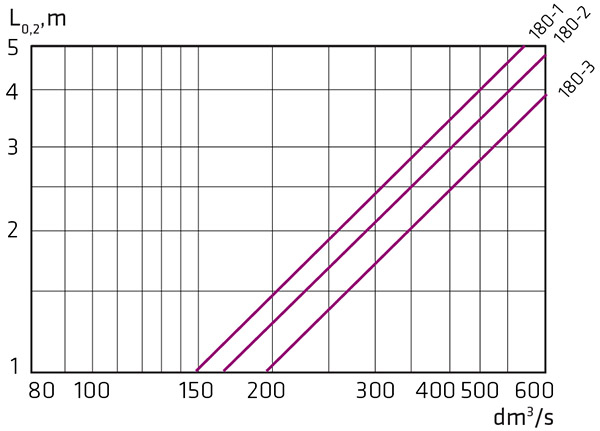

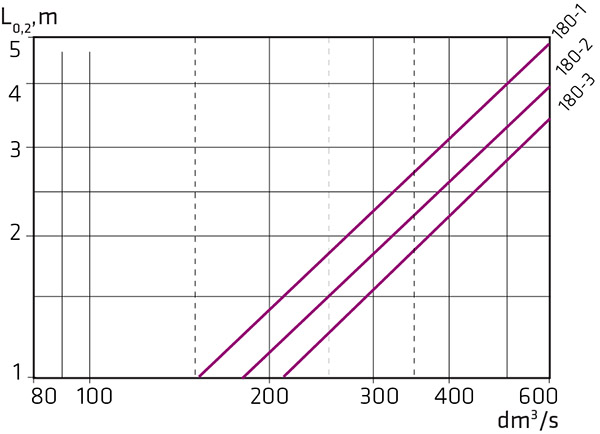

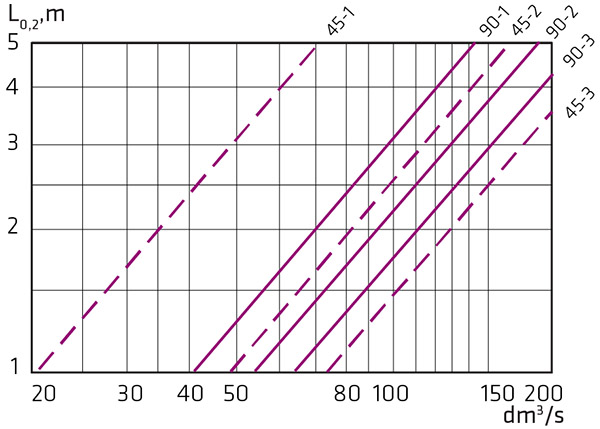

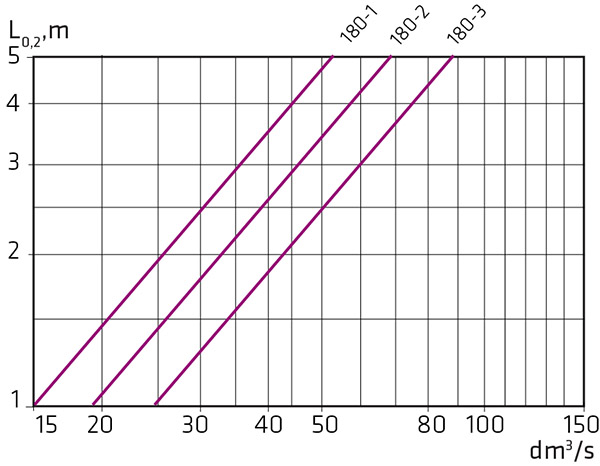

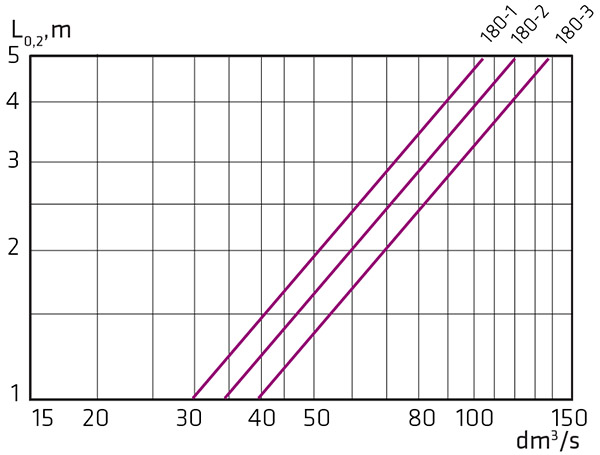

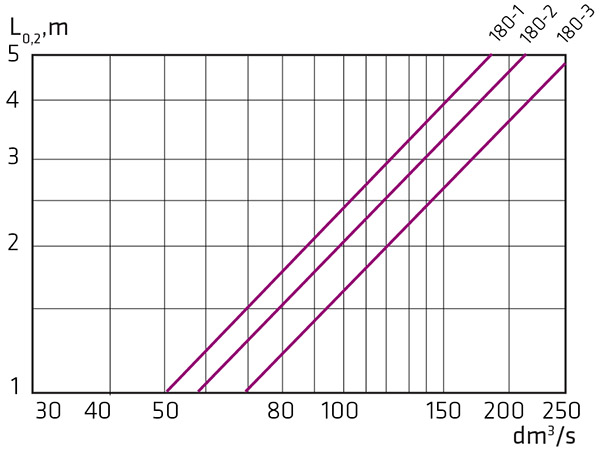

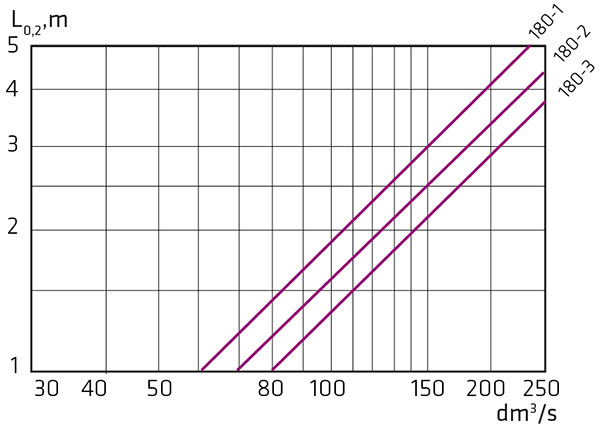

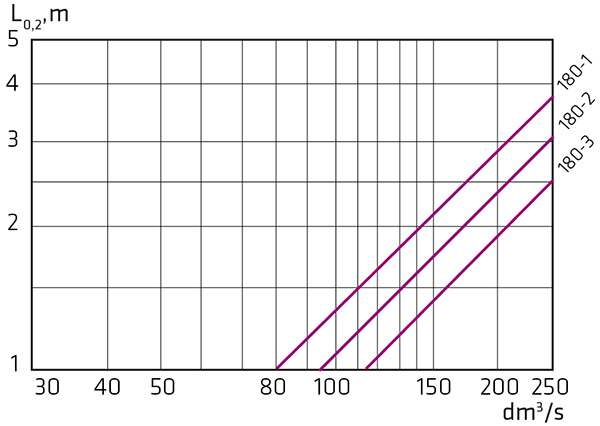

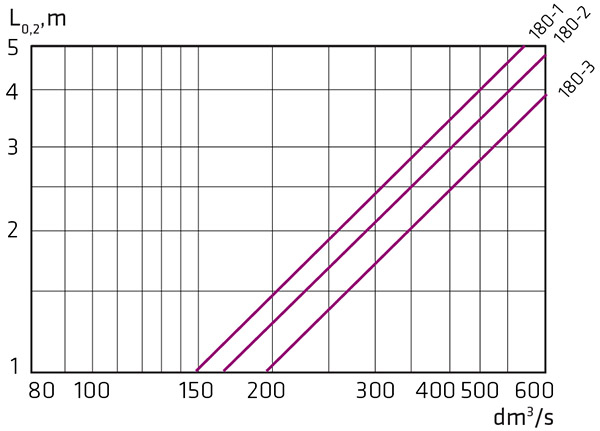

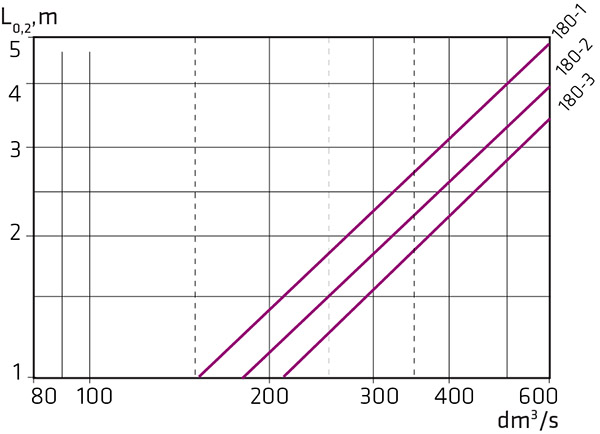

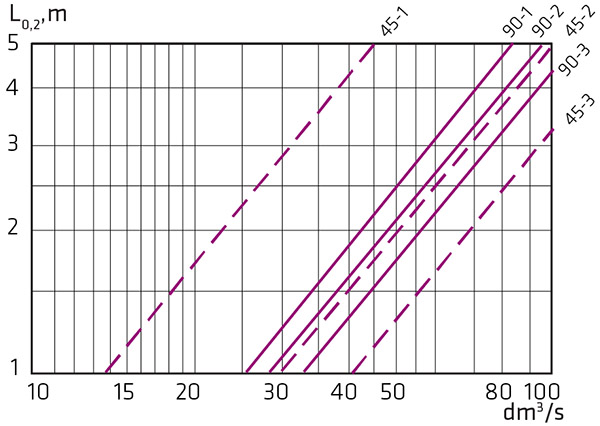

ROL nozzle duct throw length in 2 directions 180°

ROL-125/180°-x

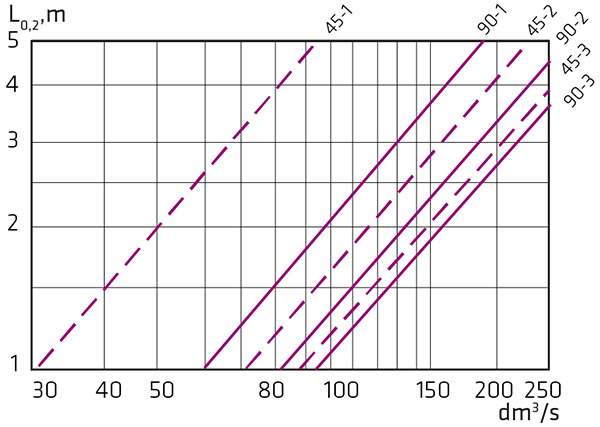

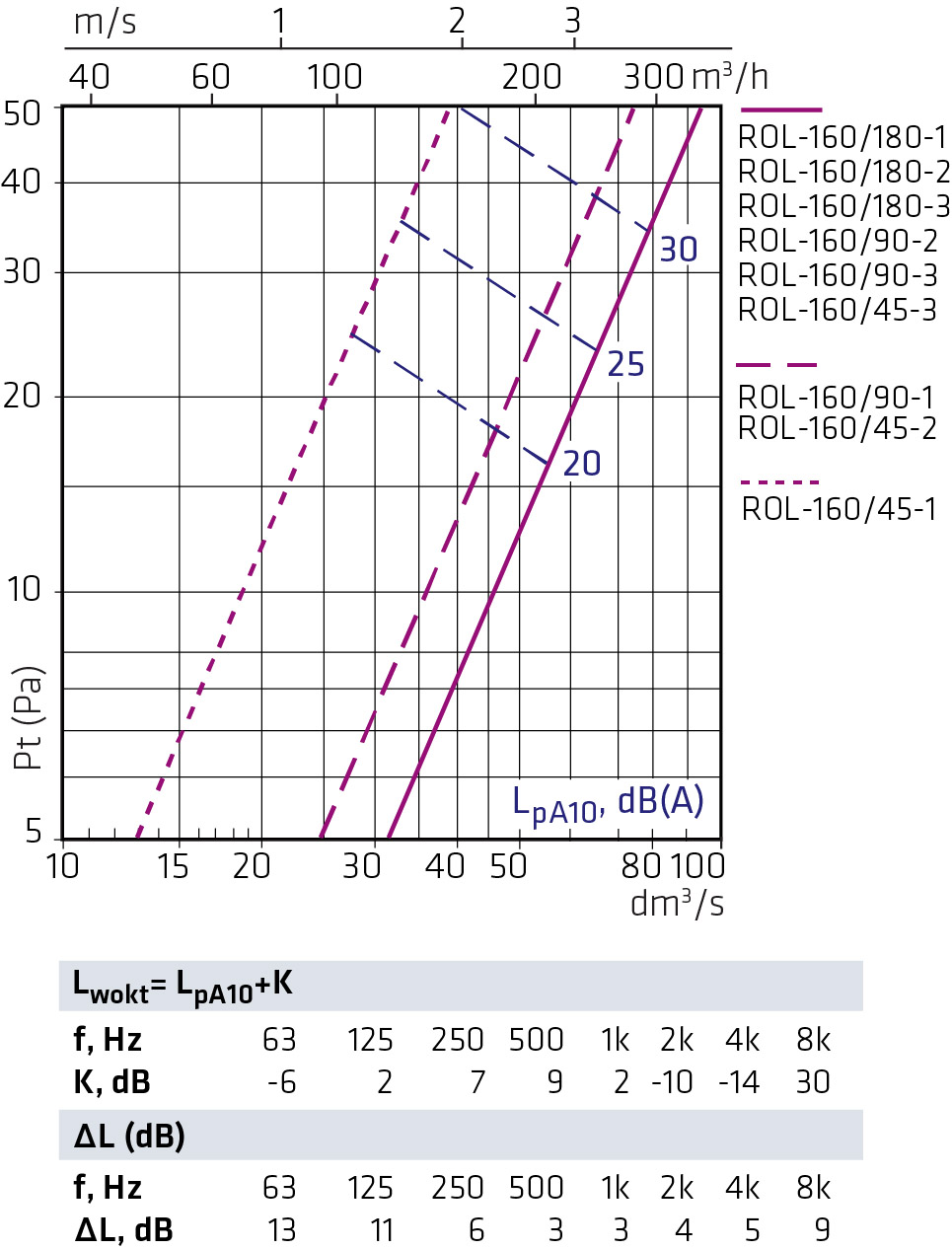

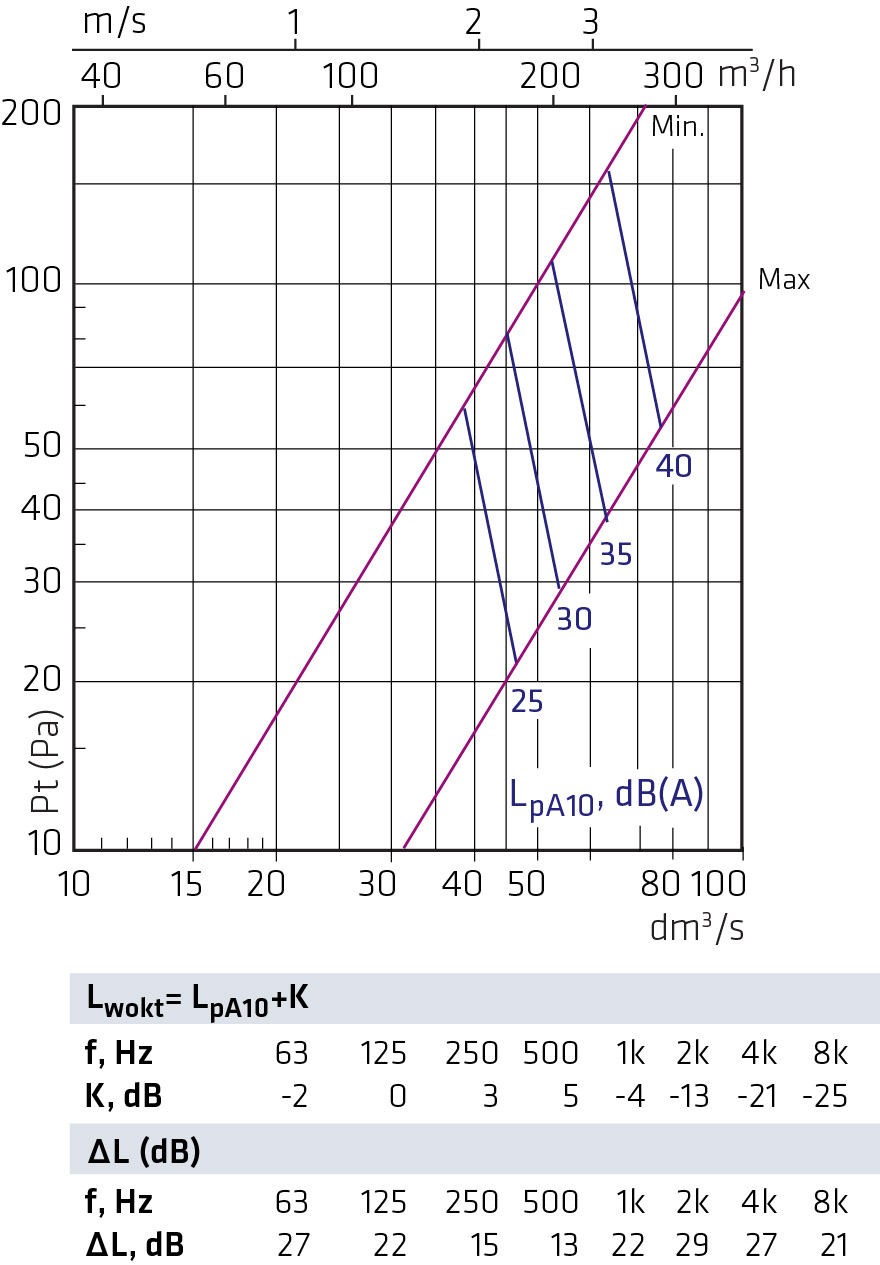

ROL-160/180°-x

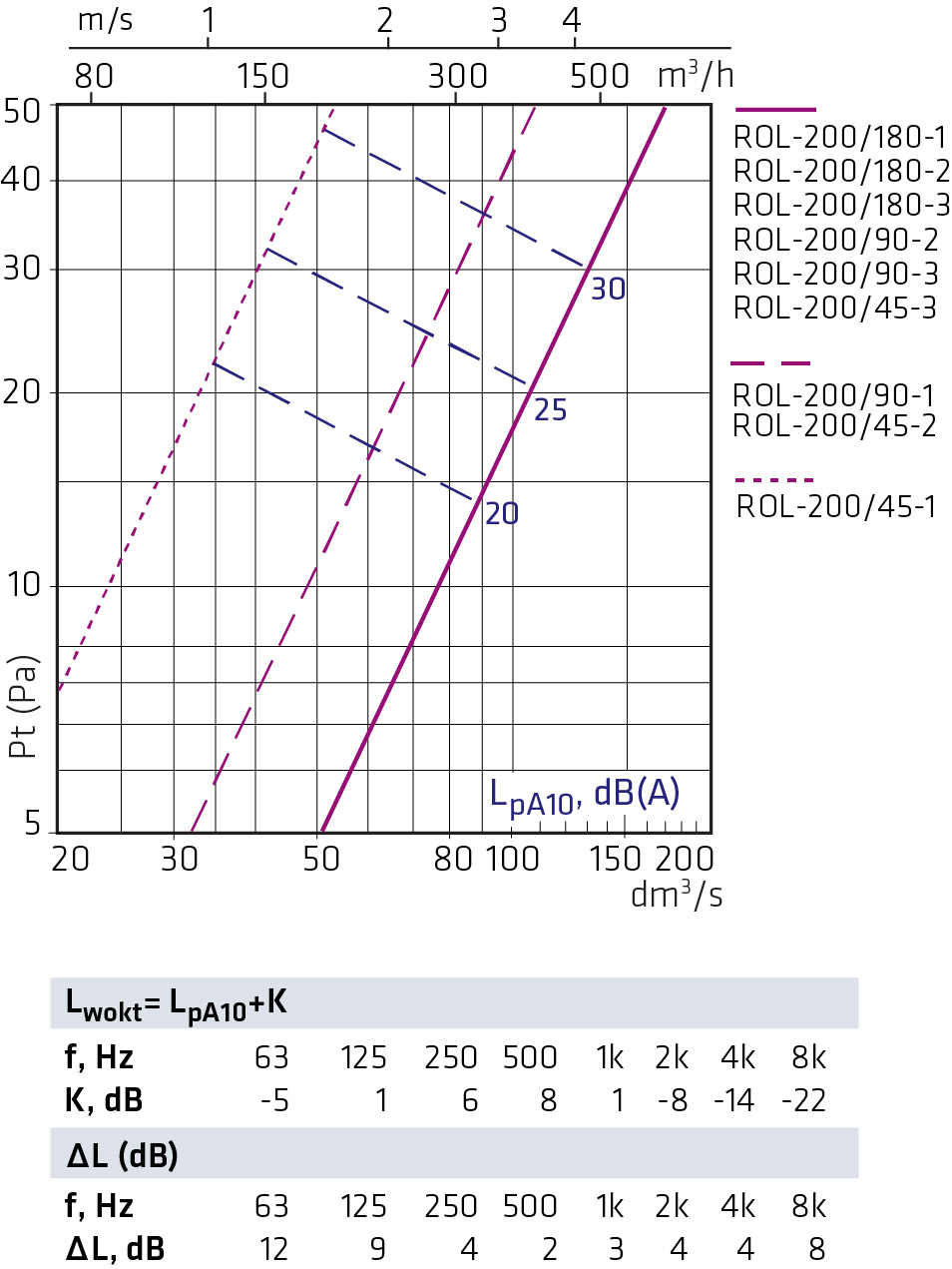

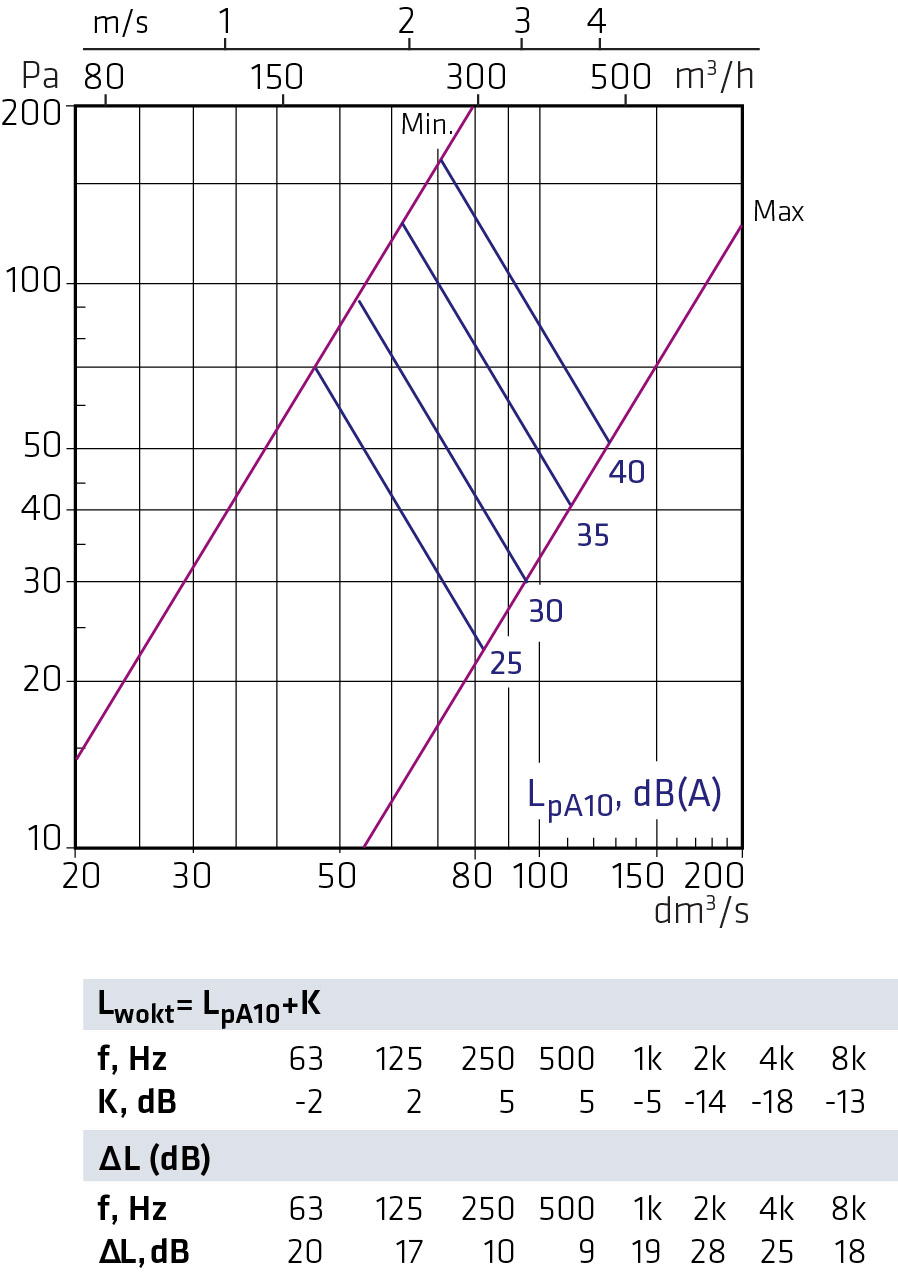

ROL-200/180-x

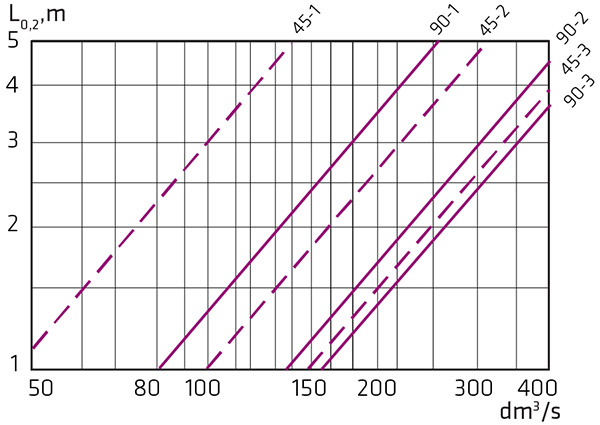

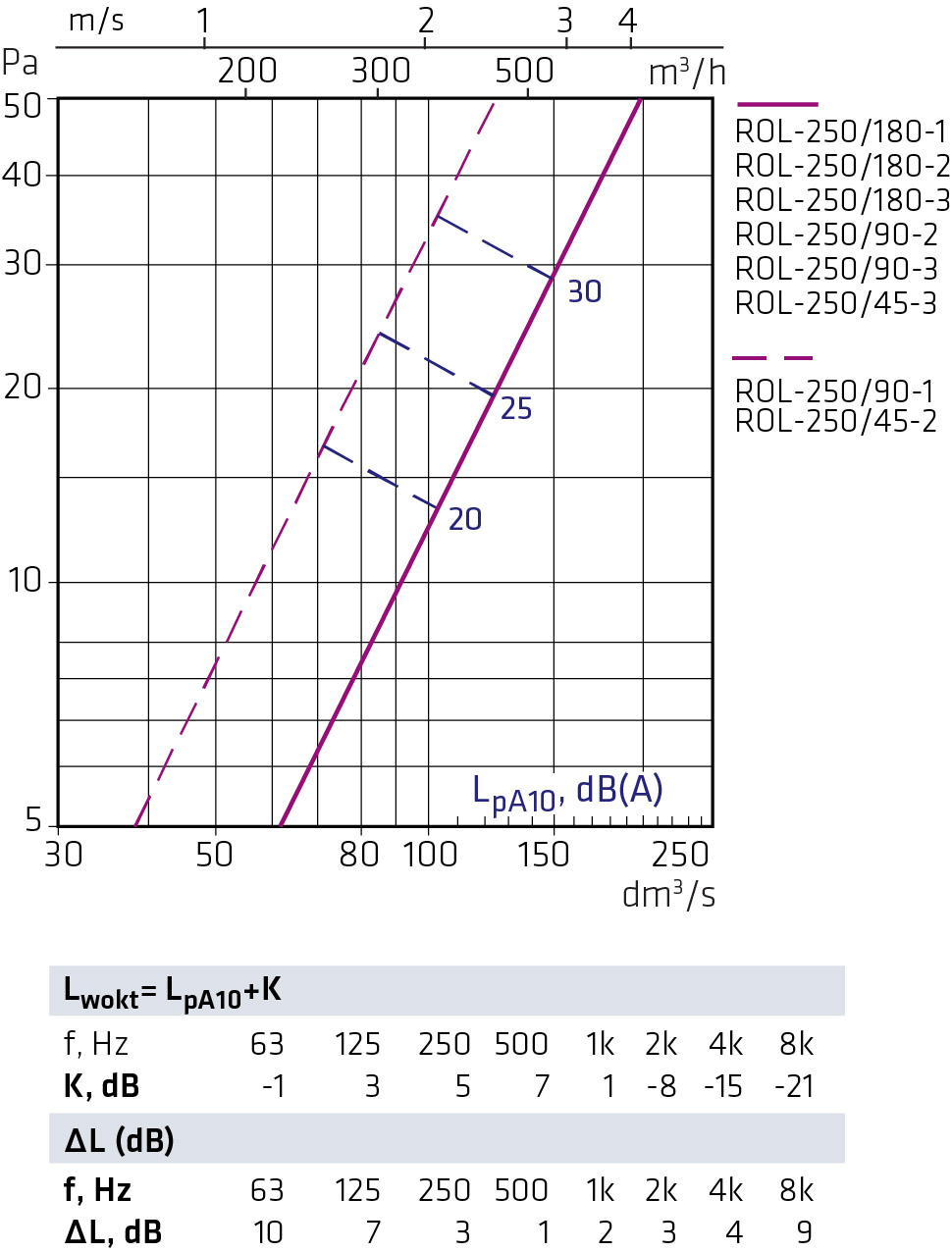

ROL-250/180-x

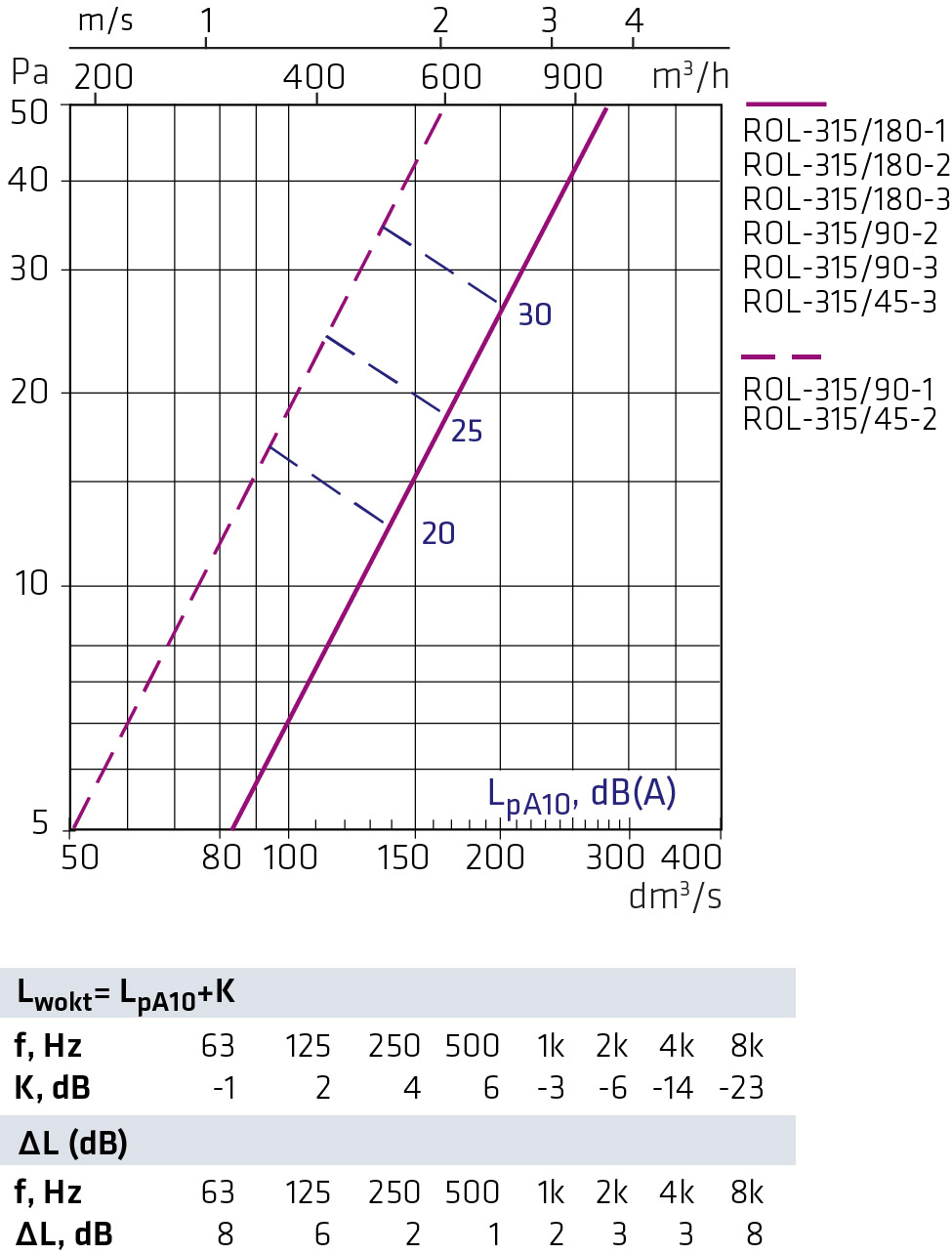

ROL-315/180-x

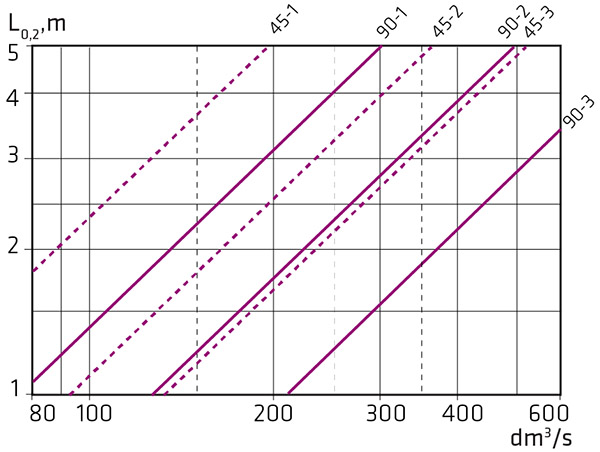

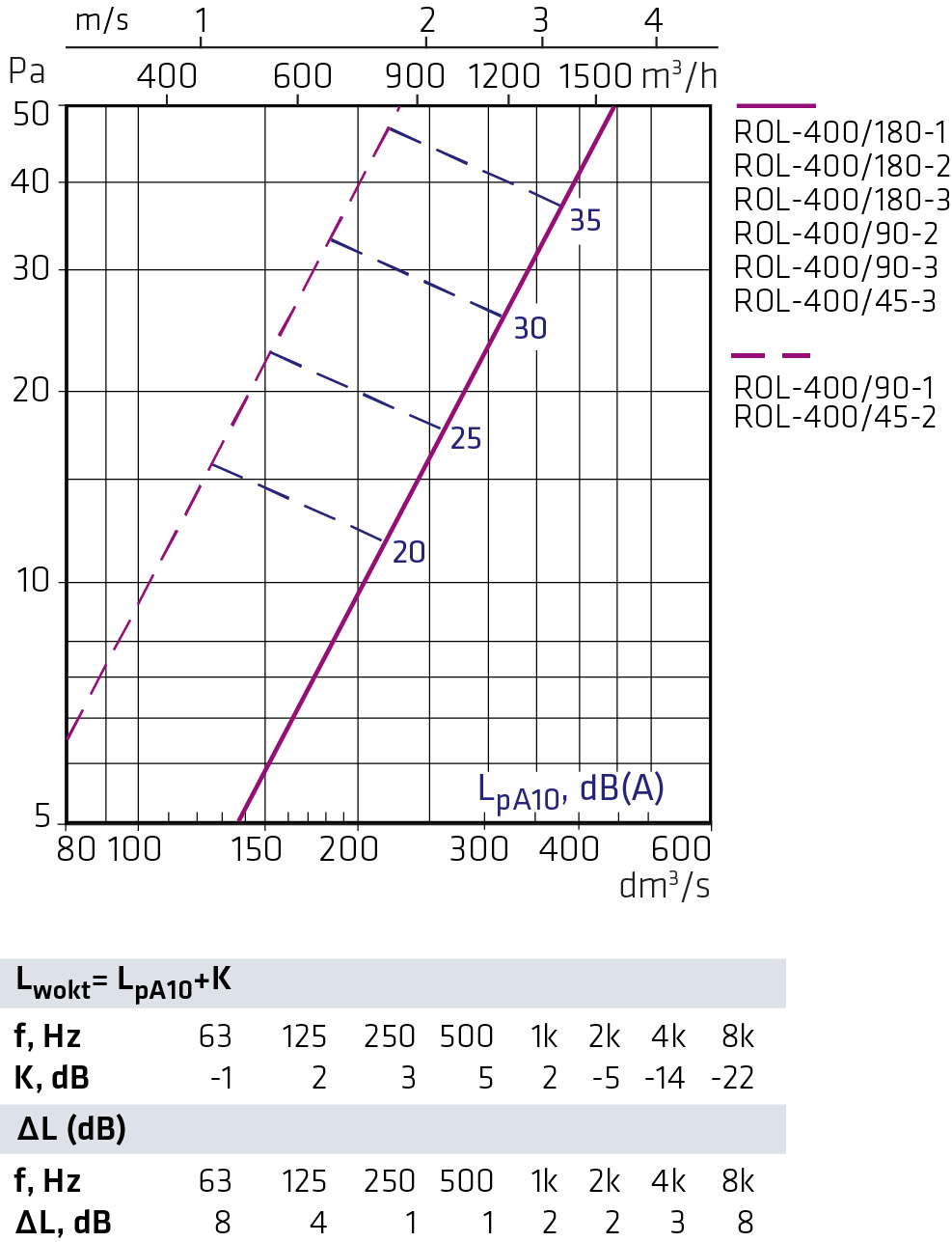

ROL-400/180-x

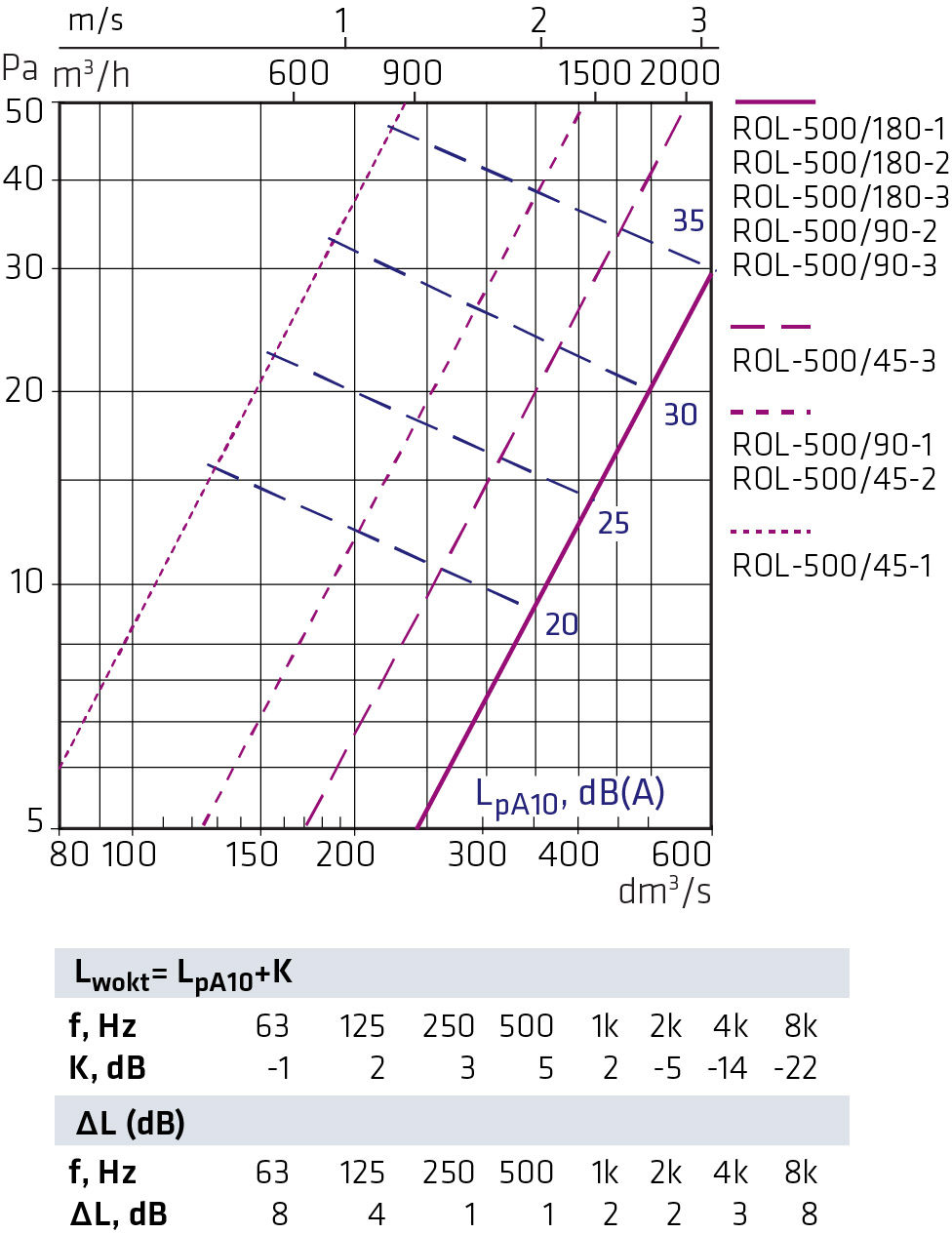

ROL-500/180-x

x: length 1, 2 or 3 = the number of modules

1=1500

2=3000

3=4500

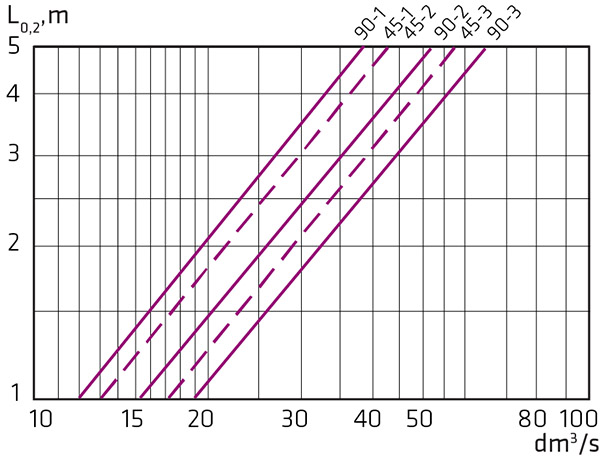

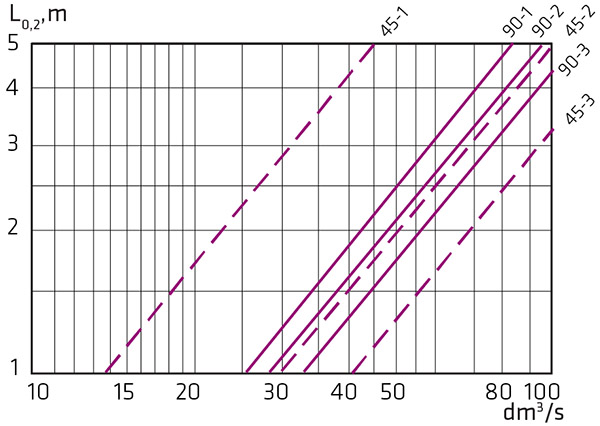

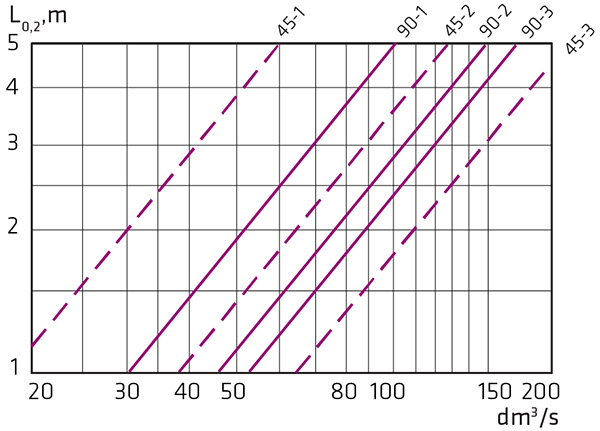

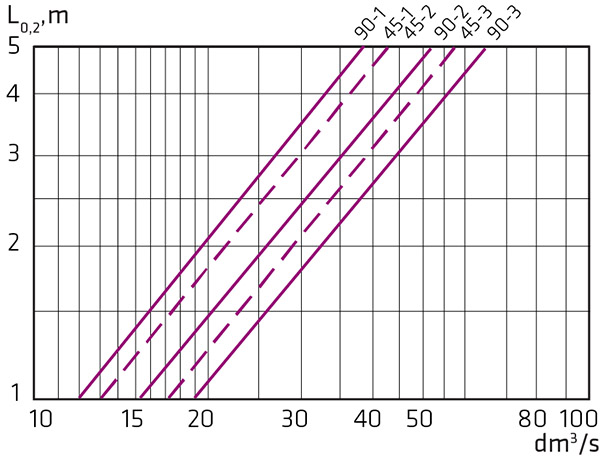

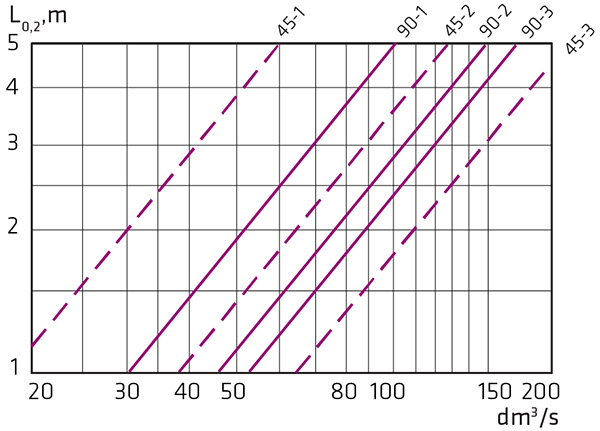

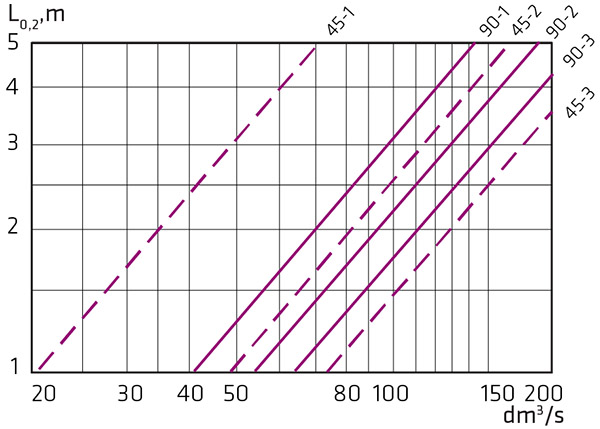

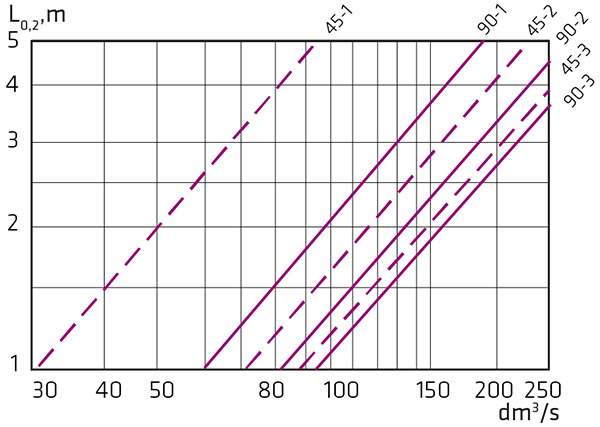

ROL nozzle duct throw length in one direction 90° or 45°

ROL-125/90-x, ROL-125/45-x

ROL-160/90-x, ROL-160/45-x

ROL-200/90-x, ROL-200/45-x

ROL-250/90-x, ROL-250/45-x

ROL-315/90-x, ROL-315/45-x

ROL-400/90-x, ROL-400/45-x

ROL-500/90-x, ROL-500/45-x

x: length 1, 2 or 3 = number of modules

1=1500

2=3000

3=4500

ROL-S adjustment and damper unit

ROL-S adjustment unit based on the static pressure difference measurement enables highly accurate air flow measurement and control. The adjustment unit allows a precise adjustment of airflow (± 5%) even at low airflows and duct speeds. ROL-S forms an openable clean-out hatch.

ROL-S is easy to adjust

1. The pressure difference is measured from the measuring socket of the control unit.

2. This adjustment can be made by a screwdriver. The adjustment is done by rotating the control dial with the tool. The control dial readings correspond to separate k-values that can be found on the side of the adjustment unit.

3. The adjustment position can be locked with a screw.

The adjustment unit can be opened:

- free access to the duct from the cleaning hatch complying with regulations

- the adjustment unit is easy to clean and maintein

- ROL-S can be cleaned reliably also from the inside

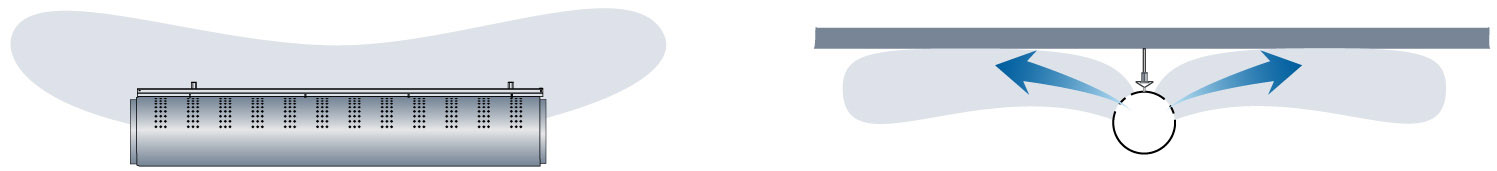

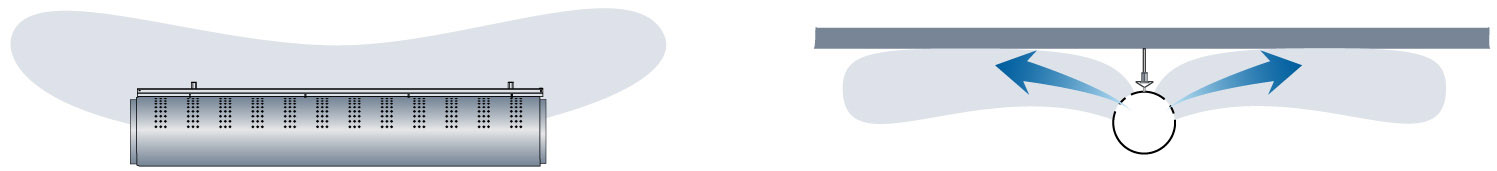

How the nozzle duct ROL works

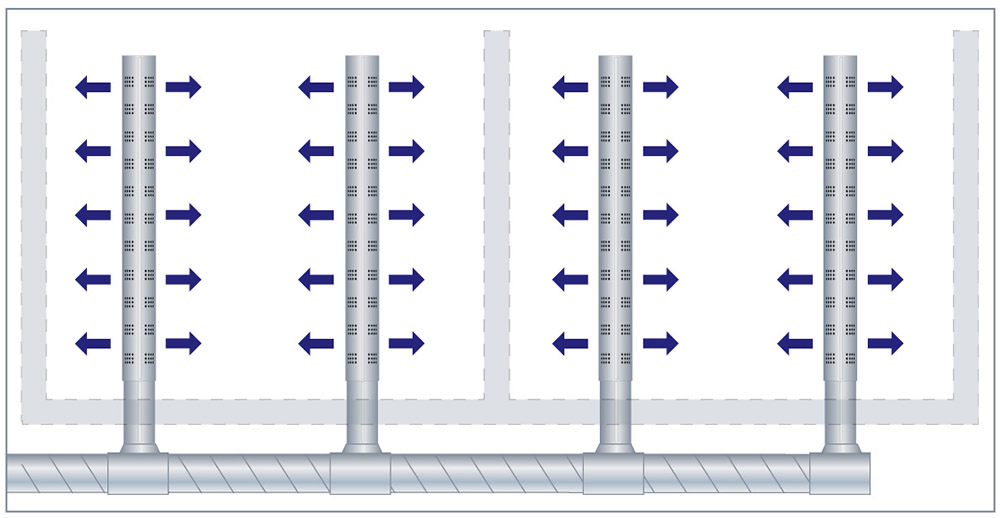

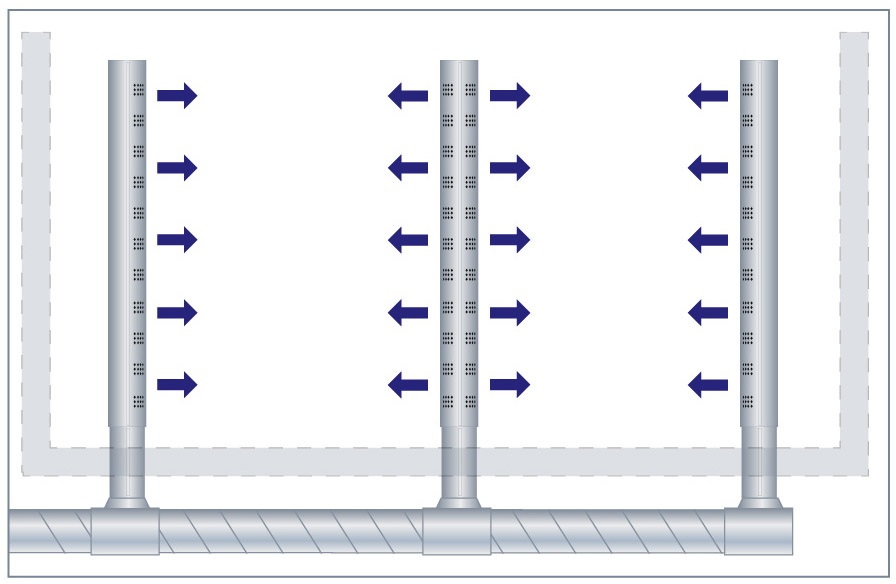

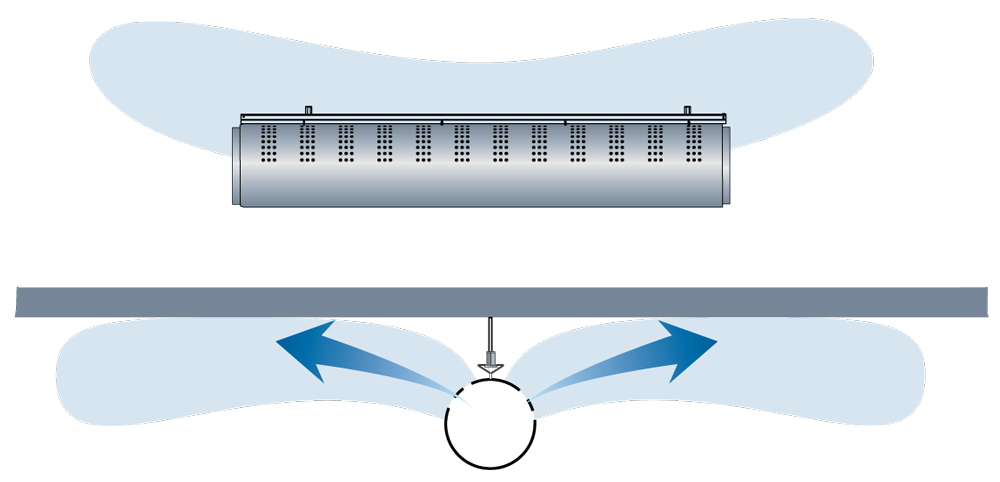

ROL’s even perforation pattern creates an even, wide air distribution with a good mixing ratio.

For the best results, ROL nozzle duct comes in four different supply air sector options. This guarantees an optimal throw direction in all circumstances.

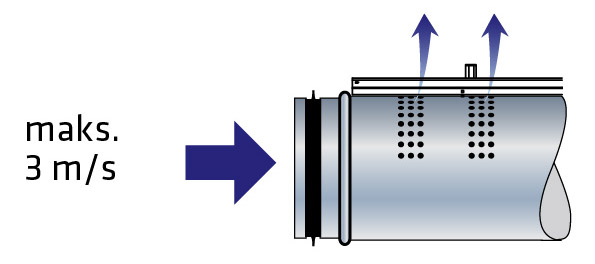

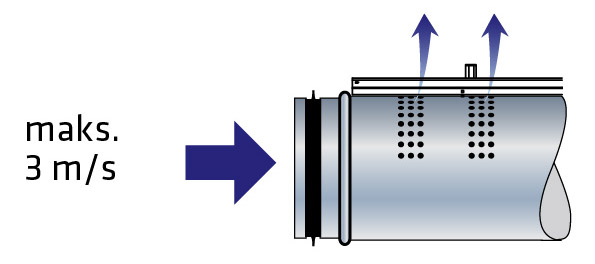

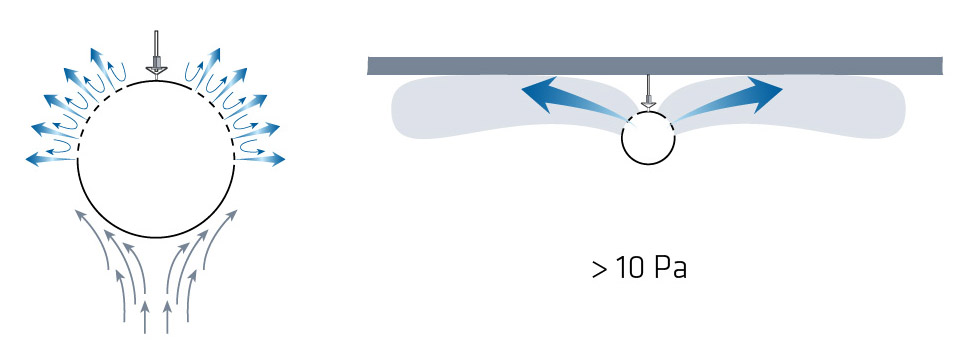

The airflow in ROL is determined by its diameter. The larger the air volume required, the larger diameter or the more ducts should be chosen. Controlled air velocity and a sufficient terminal resistance or pressure drop are required for perfect operation. The recommended minimum pressure drop is 10 Pa, providing good control over the throw pattern and reliable adjustment for the entire system.

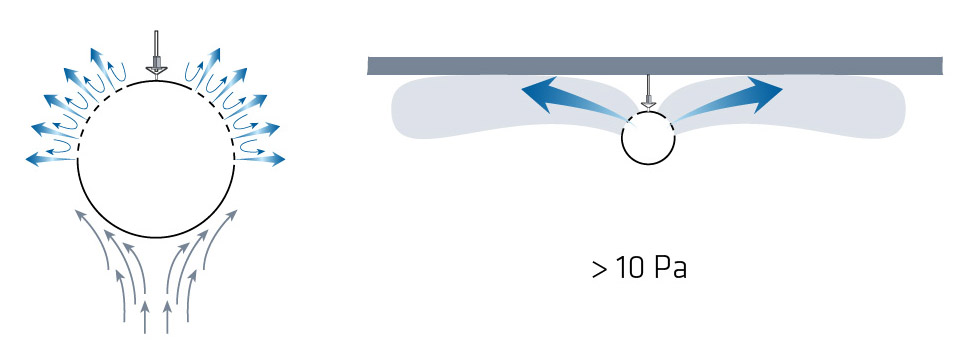

Draught-free indoor climate and high mixing ratio through sufficient pressure difference

A sufficient pressure drop creates the coanda effect, guaranteeing an evenly distributed and well mixed supply airflow. The nozzle duct will then function as designed even with low temperature air.

A low pressure drop will not create the coanda effect, which results in a low mixing ratio. The low-temperature supply air flows down creating a feeling of draught.

NOTE! This concerns all nozzle ducts.

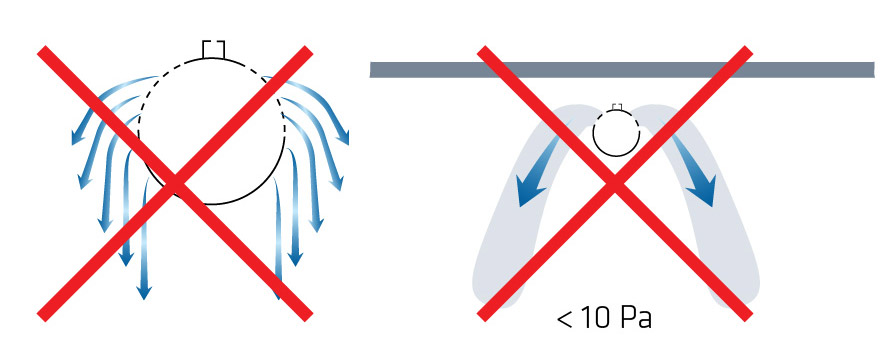

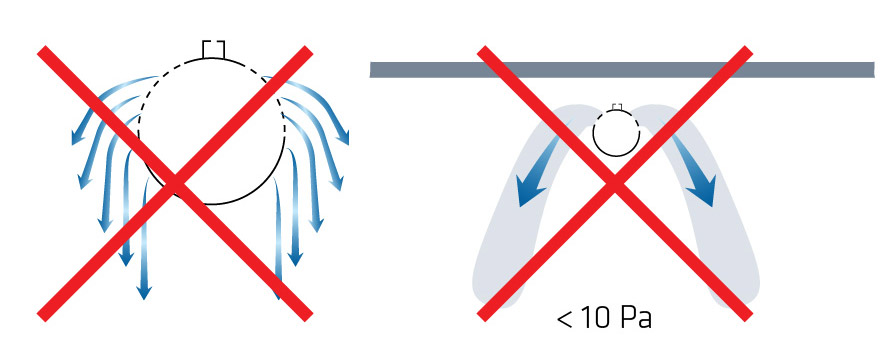

Dimensions

ROL main dimensions + ROL-0 + ROL-S

On request ROL may also be made as a 4 module unit the length of which is 6015 mm in sizes Ø125-400 and 5715 mm in size Ø500.

NOTE! The supply air area (number of perforations) is standard regardless of section length. Thus the pressure drop is not decreased or flow velocity increased as the duct length increases, which improves measurement and adjustment while at the same time ensuring a controlled throw pattern along the entire duct length.

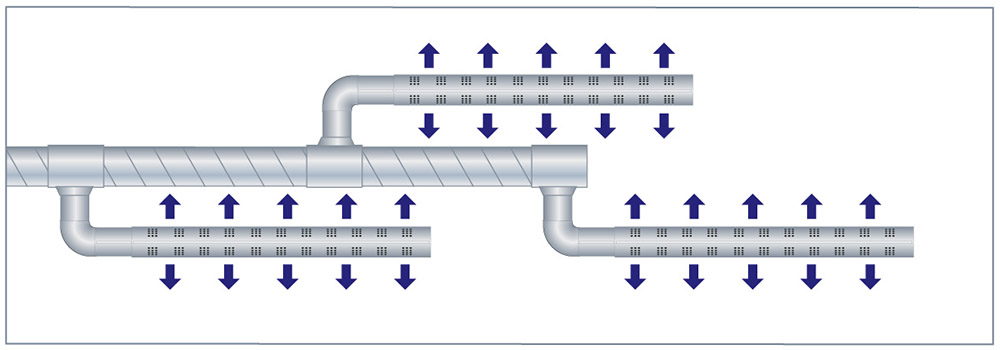

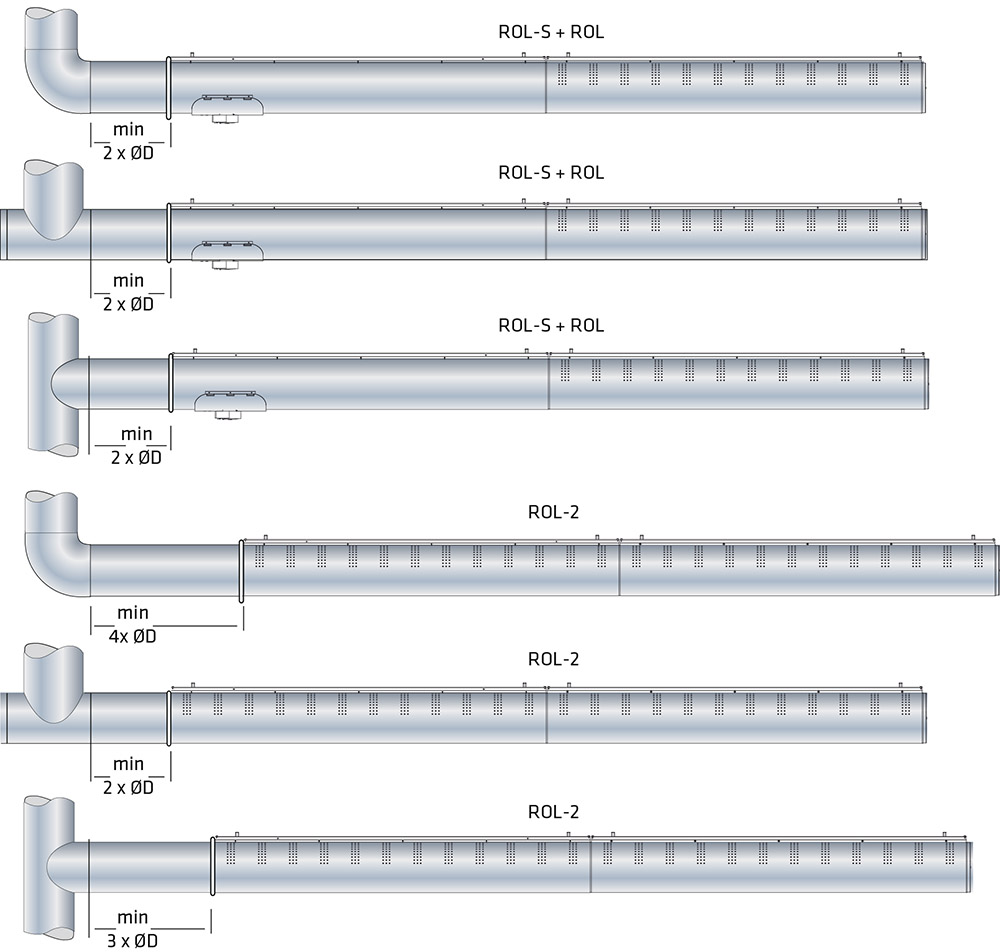

ROL installation examples

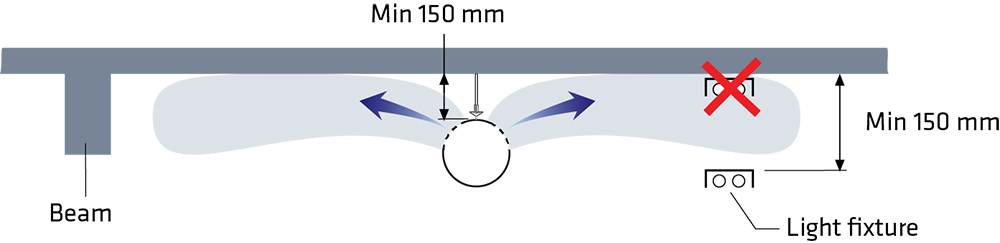

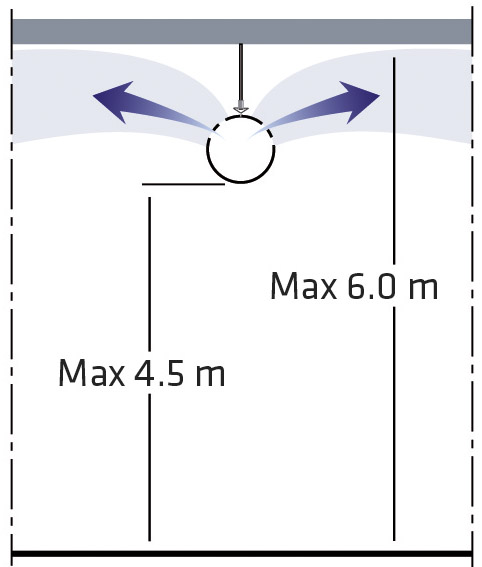

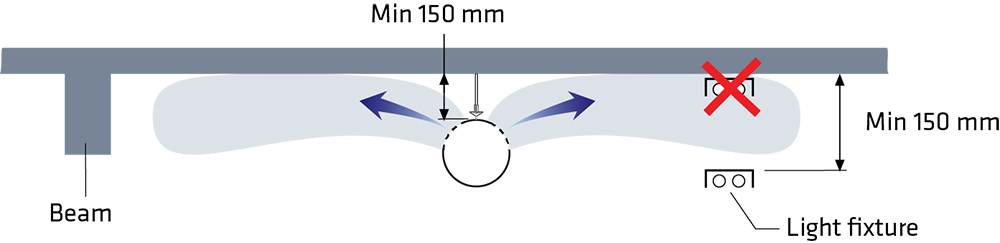

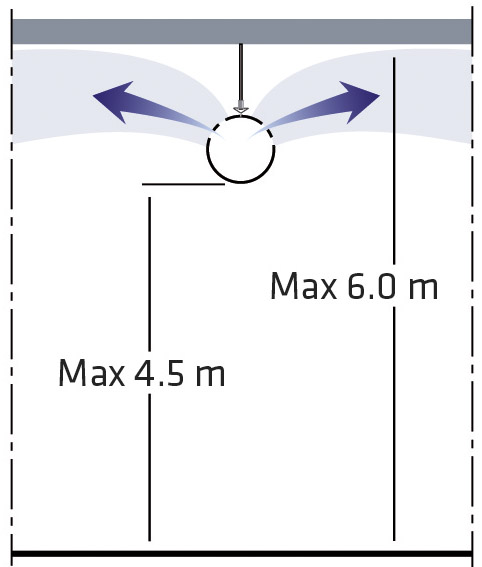

The recommended installation distance of the ROL nozzle duct from the ceiling is min 150 mm. Obstacles to the airflow, such as beams or surface-mounted light fixtures, should be avoided.

If beams are located close to one another, it is recommended that ROL is installed next to the beam with a single-directional throw.

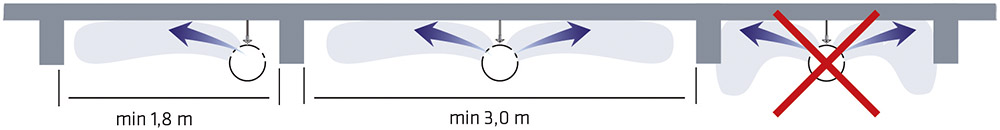

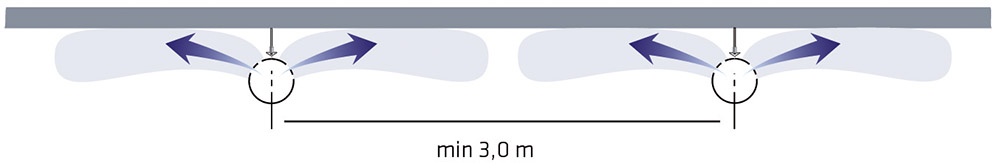

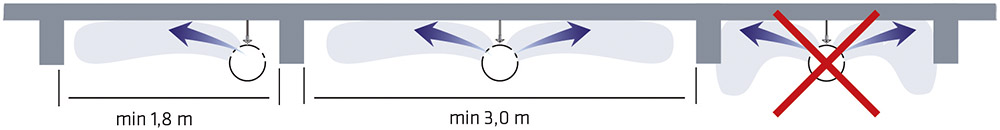

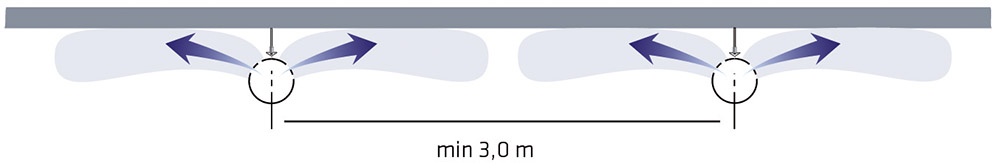

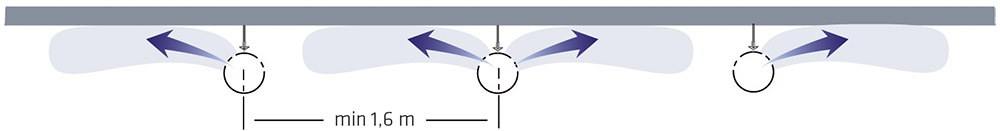

The minimum distance between two nozzle ducts should be 3 metres.

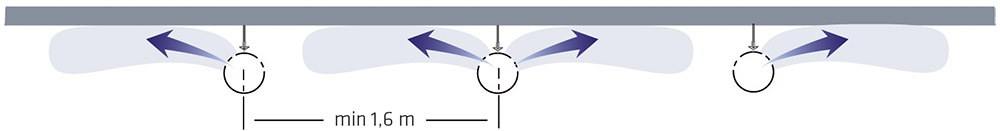

Alternative installation when nozzle ducts are less than 3 metres from each other.

Recommended mounting height is 2.5-4.5 meters.

Recommended room height is 6 meters max.

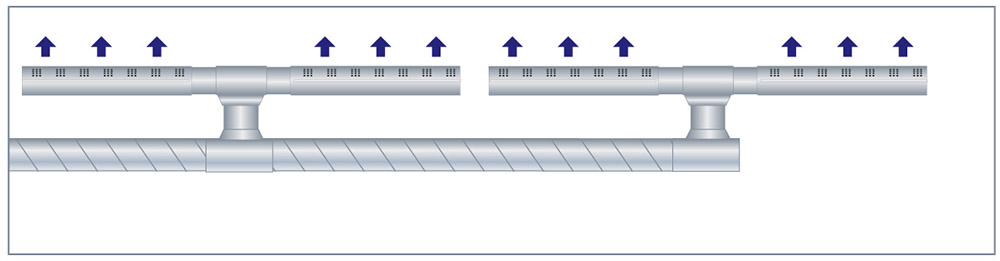

ROL installation

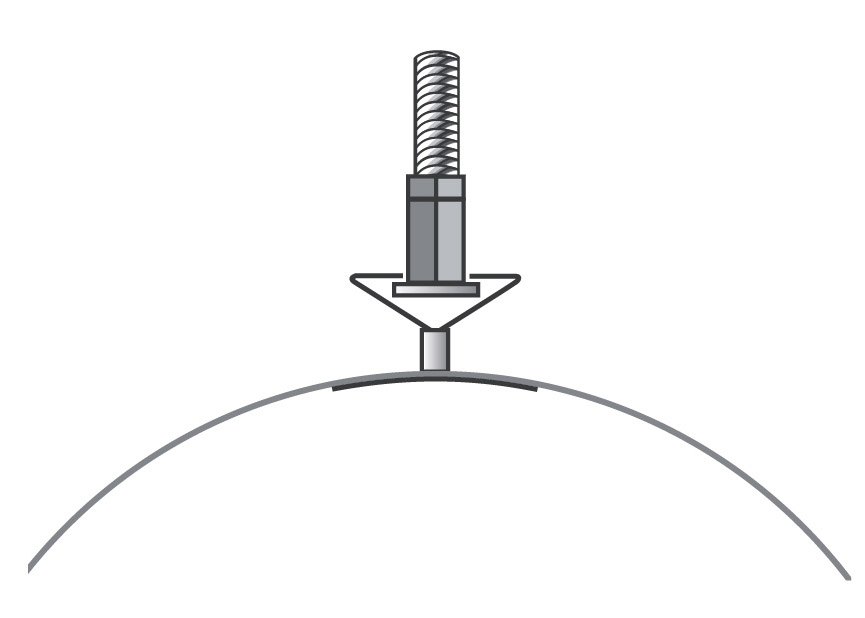

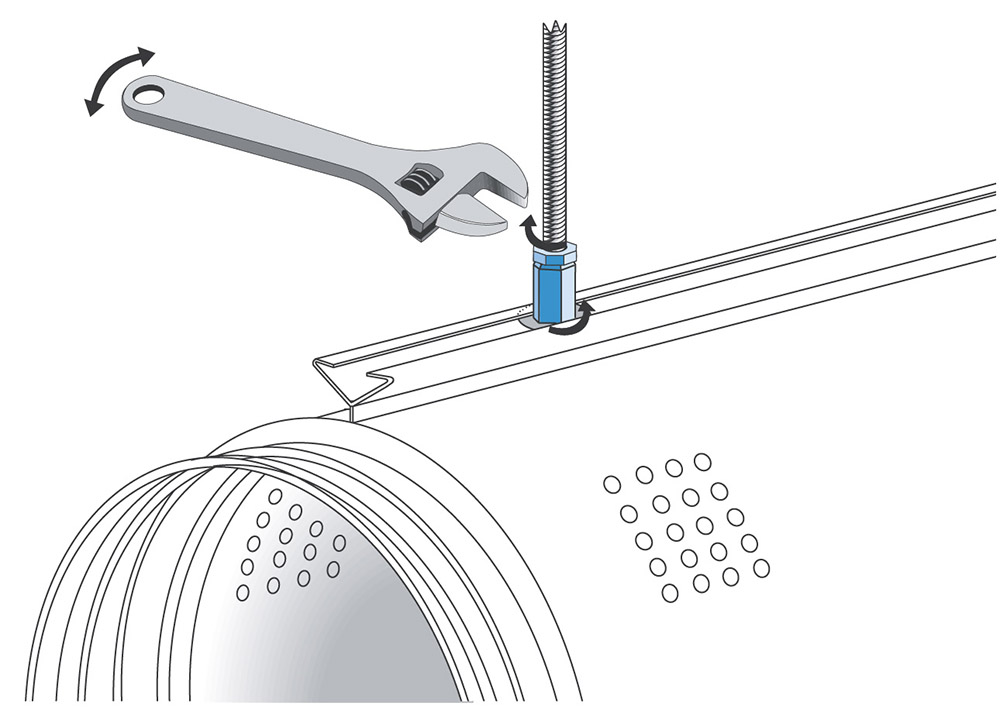

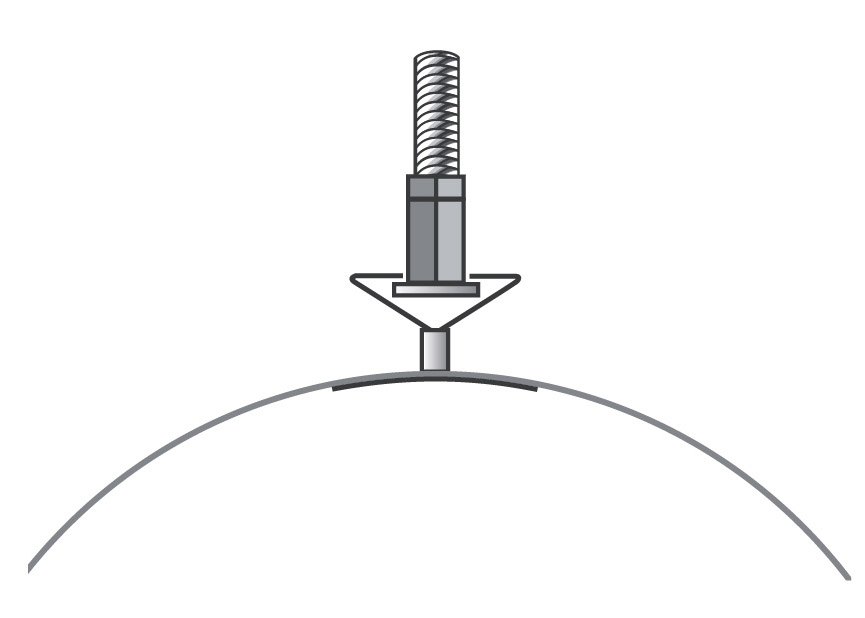

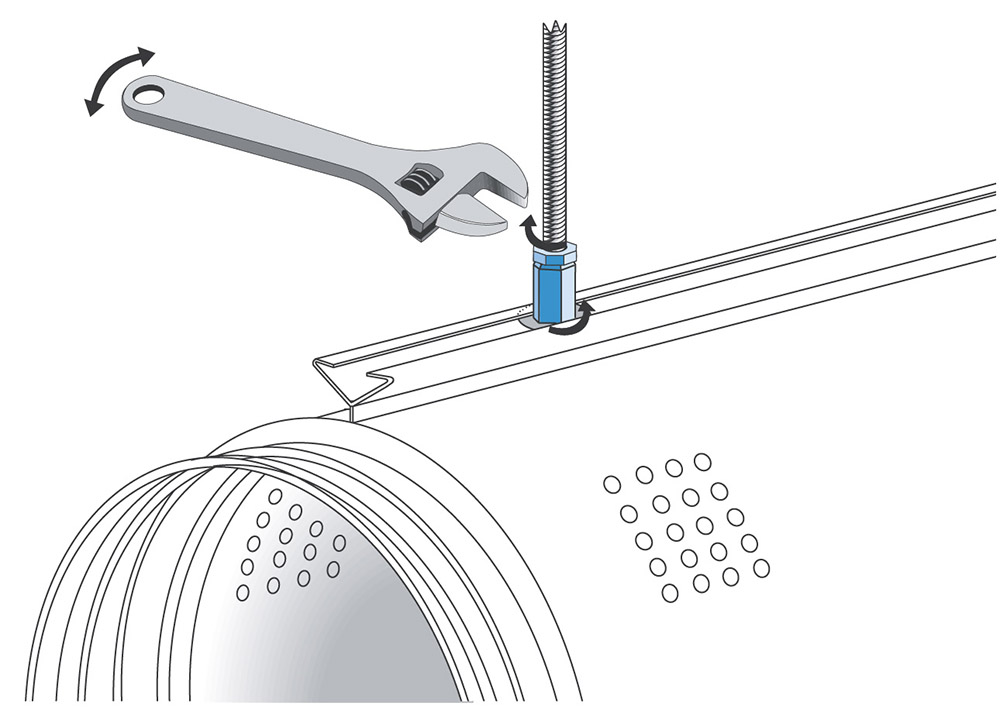

The hanging rail allows quick installation!

The rotating rivets with left-hand thread in the hanging rail move freely, allowing the longitudinal hanging points to be chosen freely.

The rotating rivets make fastening extremely simple and quick, while allowing exact fine-tuning of the height.

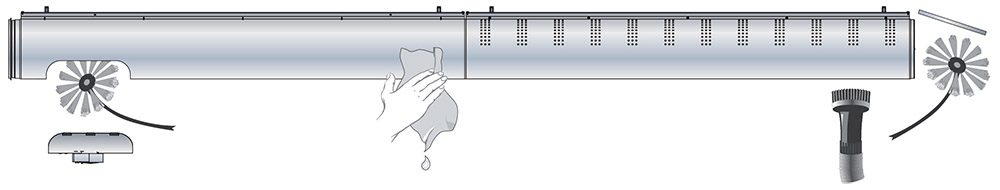

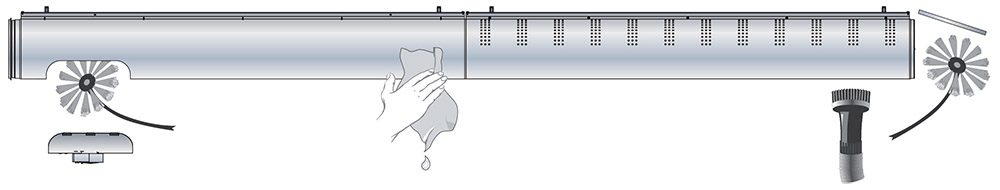

Maintenance and cleaning

The smooth surface of ROL is easy to keep clean!

The end cap can be opened, allowing easy mechanical sweeping of the inside. The ROL-S adjustment unit can be easily removed and it operates as a cleaning hatch from which the duct can be swept clean. The adjustment unit can thus be cleaned separately.