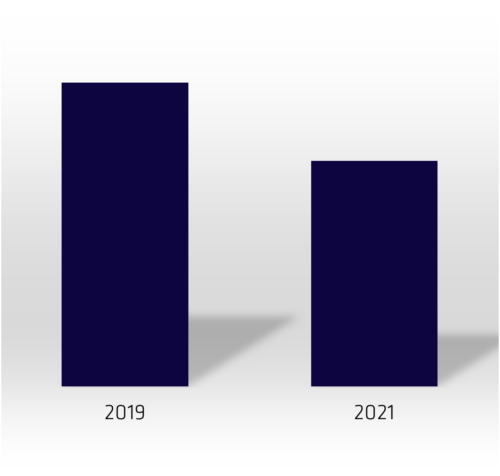

Our emission savings correspond to approximately 1,000 tons of carbon dioxide per year. The large number equals about 6 million kilometers of driving or 2,072 people’s round-trip flight between Helsinki and Munich – annually. Such a large decrease in carbon dioxide emissions is also significant in the sense that it has not come at the expense of turnover, but on the contrary, the volume of our business has increased.

Our CEO Tommi Uksila, who has an uncompromising approach to issues of responsibility, comments on the following, “A quarter of emissions reduction in a company like ours is a lot, and the work to further reduce emissions is still ongoing. In addition, we develop our own portfolio towards a smaller carbon footprint. In this way, the carbon footprint of the entire built environment is affected.”

Success from systematic work and determination

We started the emissions analysis well in advance, back in 2019 and we achieved carbon neutrality in the spring of 2020. The part of the emissions that has not yet been eliminated will be compensated for increasing the global carbon sinks. The work has been systematic. For instance, we have invested in the renewal of machinery and fixed assets. Over the course of three years, the decrease in carbon dioxide emissions has been achieved, among other things, by switching into green electricity and geothermal heat. In addition, part of our factory’s energy is produced with an own solar power plant.

“Plenty of effort has been put into analyzing and calculating emissions. We have actively talked about our responsibility and carbon neutrality work, because in addition to informing our own stakeholders, we aim to inspire other actors towards their own responsibility and carbon neutrality goals,” Uksila continues.