Beschreibung

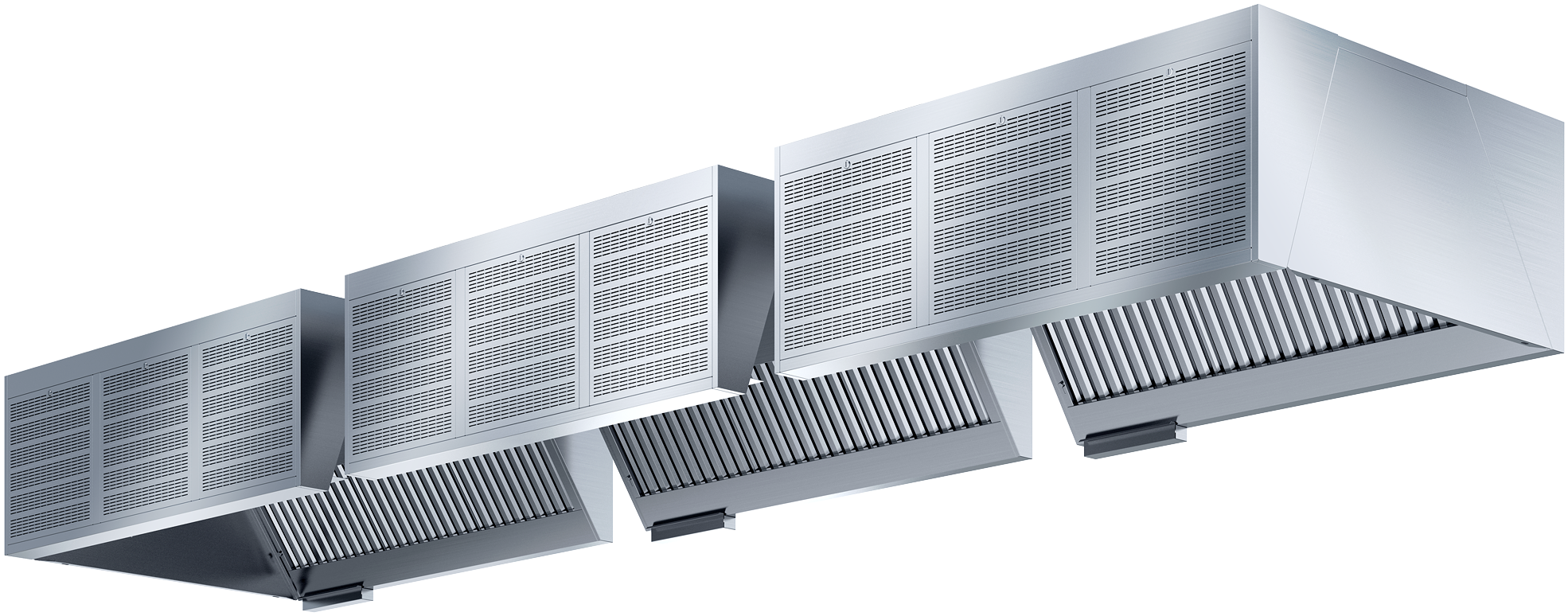

CleanMaster-Abzugshauben sind ein Meisterwerk der Ingenieurskunst und verfügen über fortschrittliche Fettabscheideleistung und herausragende Funktionen für eine einfache und sichere Bedienung, sowie ein besonders hohes Niveau beim Thema Brandschutz.

Seit über drei Jahrzehnten wird CleanMaster kontinuierlich weiterentwickelt, um den Anforderungen selbst anspruchsvollster Nutzer in den anspruchsvollsten Profiküchen noch besser gerecht zu werden. CleanMaster ist die Wahl echter Profis – von Michelin-Sternerestaurants bis hin zu Gastronomiebetrieben, öffentlichen Einrichtungen und Geschäftsräumen.

Wenn ein hoher Abscheidegrad, niedrige Wartungskosten und verlässlicher Brandschutz gefragt sind, ist CleanMaster die richtige Wahl.

Fortschrittliche vierstufige Reinigungstechnologie

CleanMaster nutzt die fortschrittlichste vierstufige Reinigungstechnologie für saubere Fettkammern und Kanäle. CleanMaster verfügt über geprüfte und UV-zertifizierte Fettfilter.

Mechanische Abscheidung/Aufprallabscheidung

Die mechanische Abscheidung filtert effizient große Fettpartikel resultierend aus dem Kochprozess heraus. Die schweren Partikel werden aus der Abluft durch einen Filter ausgesiebt.

UV-C

UV-C ist eine weit verbreitete, konventionelle keimtötende Reinigungstechnologie. Sie wirkt gegen Mikroorganismen, Schimmel, Pilze und Bakterien.

Vakuum UV

Vakuum-UV löst hocheffizient kleine Fettpartikel in natürliche Verbindungen wie Sauerstoff, Kohlendioxid und Wasser auf. Zusätzlich zur herkömmlichen UV-Technologie bietet Vakuum-UV eine noch höhere Abluftreinigungsleistung.

Ozon

Ozon oxidiert effektiv die letzten Fettpartikel und desodoriert die Luft.

Getestete Filter

Die Schalldaten, der Druckverlust, der Flammschutz und die Abscheidegrade der Abzugshaubenfilter sind von Eurofins Expert Services/VTT Expert Services/DAkkS/UL zertifiziert (EUFI29-21002238-T1, EUFI29-21002238-T2, VTT-S-7826, VTT-CR-04456, DAkkS_23368, UL-R39744).

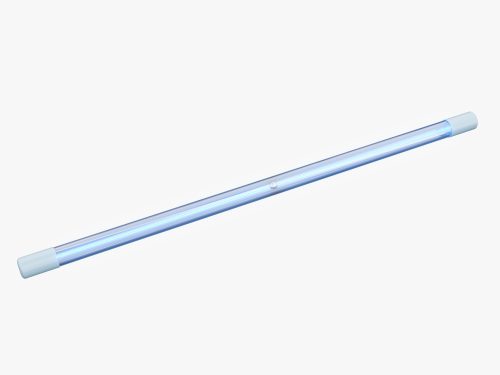

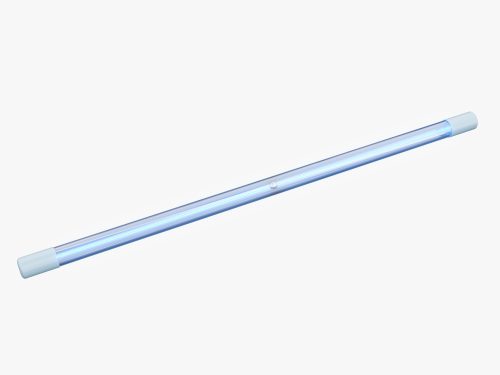

Dual UV Kitchen Pro

Kernstück der Nutzung des Reinigungspotenzials zweier verschiedener UV-Wellenlängen sind die technisch überlegenen DualWave KitchenPro-Lampen. Die UV-Lampen bieten leistungsstarke Desinfektion, Oxidation und photochemische Fettlösung.

Die DualWave KitchenPro-Technologie bietet eine besonders hohe UV-Intensität und eine lange Lebensdauer. Dadurch müssen Sie seltener reinigen oder die Lampen wechseln, was insbesondere langfristig zu geringeren Wartungskosten führt.

OptiLumo Profi-Küchenleuchte

Climecon OptiLumo Leuchten wurden speziell für den professionellen Kücheneinsatz entwickelt. Sie tragen maßgeblich zur Arbeitssicherheit und zu den Arbeitsbedingungen des Küchenpersonals bei. Die ausgeklügelte Optik sorgt für gleichmäßig verteiltes Licht am Arbeitsplatz ohne die Augen zu blenden. Küchenprofis loben die Beleuchtungsstärke, Lichtleistung und Farbwiedergabe von OptiLumo und geben an, dass selbst ein langer Arbeitstag die Augen nicht belastet.

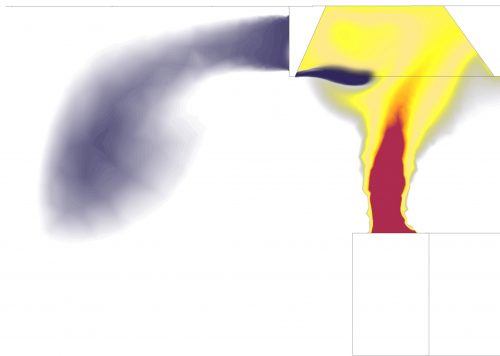

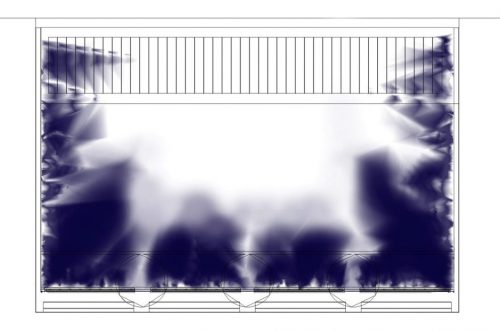

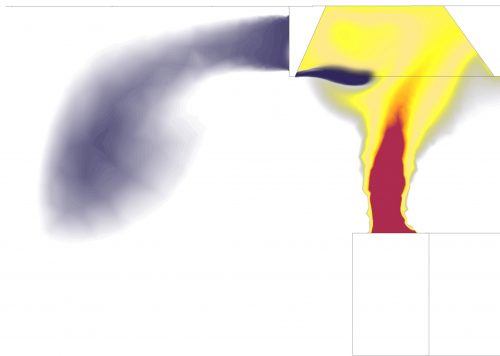

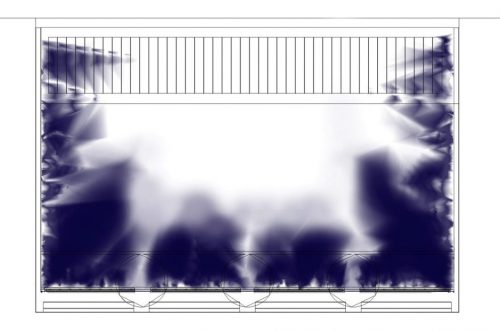

AirBoost Lufterfassungsstrom

Climecon-Hauben sind mit einer effizienten AirBoost-Lufterfassungsfunktion ausgestattet. Sie leitet Fettdämpfe effizient in die Abluftkammer und verbessert die Leistung der Hauben auch unter anspruchsvollen Bedingungen.

Die Abluft von der Kochstelle wird von der Vorderseite und den Seiten der Haube in den Abluftbereich geleitet. AirBoost verhindert effizient einen Luftüberlauf.

CO2-Fußabdruck

EPD-geprüfte Lösungen für Profi-Küchen

Der CO2-Fußabdruck von Abzugshauben für professionelle Küchen, wurde im Rahmen der Anforderungen der EPD-Umwelterklärung der Building Information Foundation, berechnet.

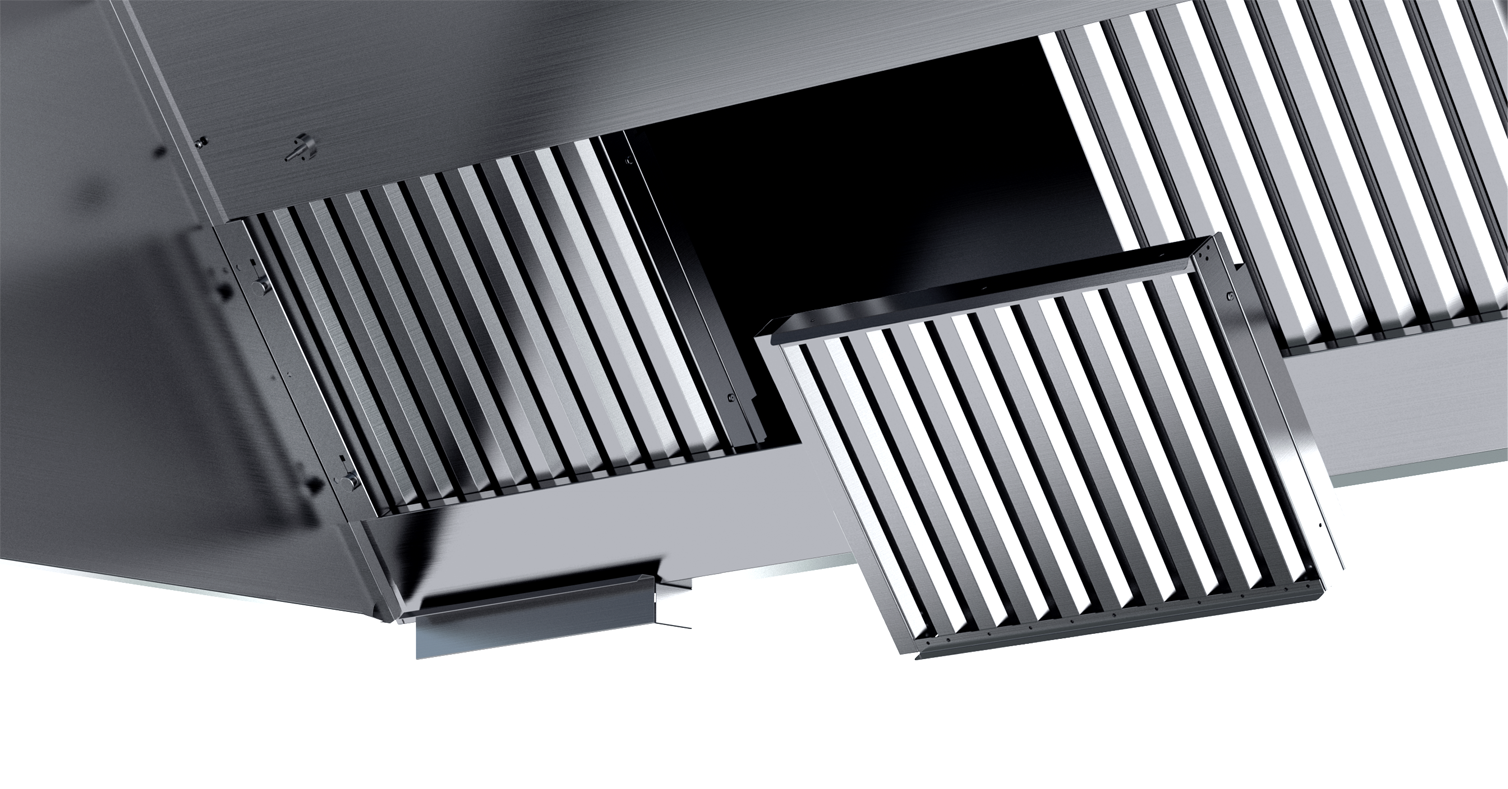

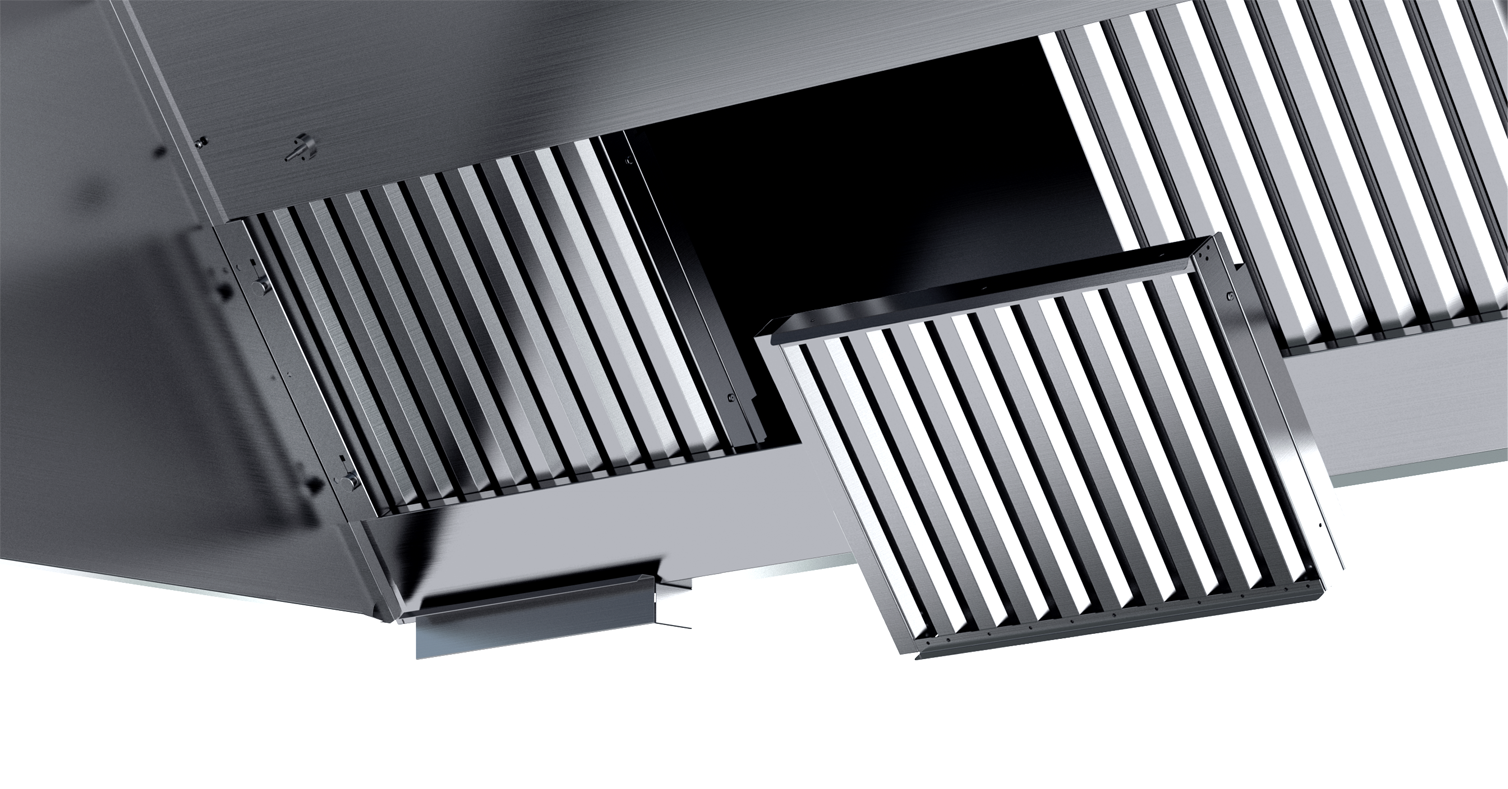

Innovative Eigenschaften

Die Merkmale des EasyCare-Konzepts gewährleisten ein hohes Maß an Hygiene. Einfache Wartung sorgt dafür, dass die Lösungen in gutem Zustand bleiben und ihre volle Leistung erbringen. Dank der leicht abnehmbaren und maschinenwaschbaren Teile führt die mühelose und schnelle Reinigung zu weniger Ausfallzeiten und geringeren Wartungskosten.

- Die Kanäle lassen sich leicht über Zu- und Ablufteinheiten reinigen

- Die Oberflächen sind frei von unnötigen Einbuchtungen und somit leicht zu reinigen

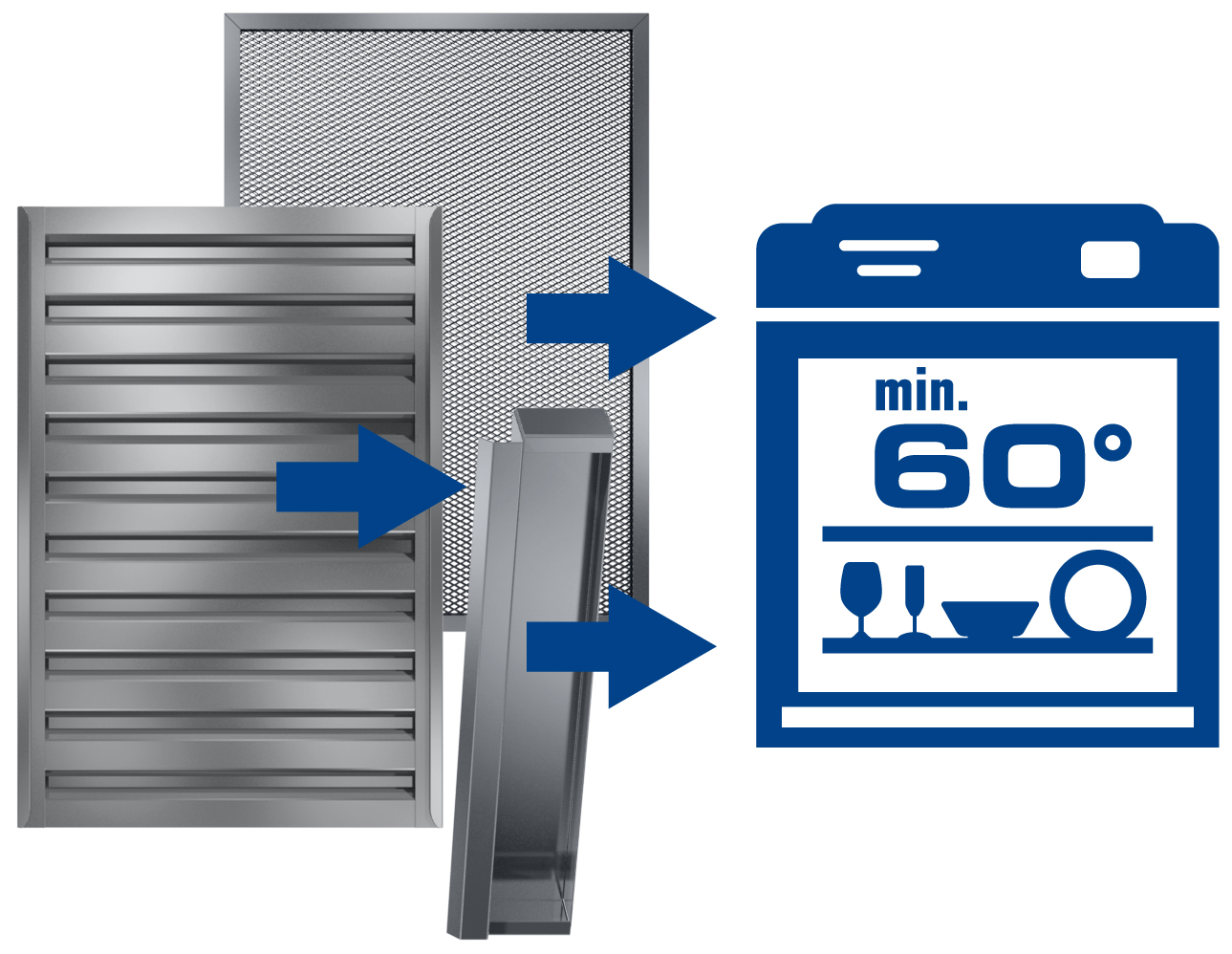

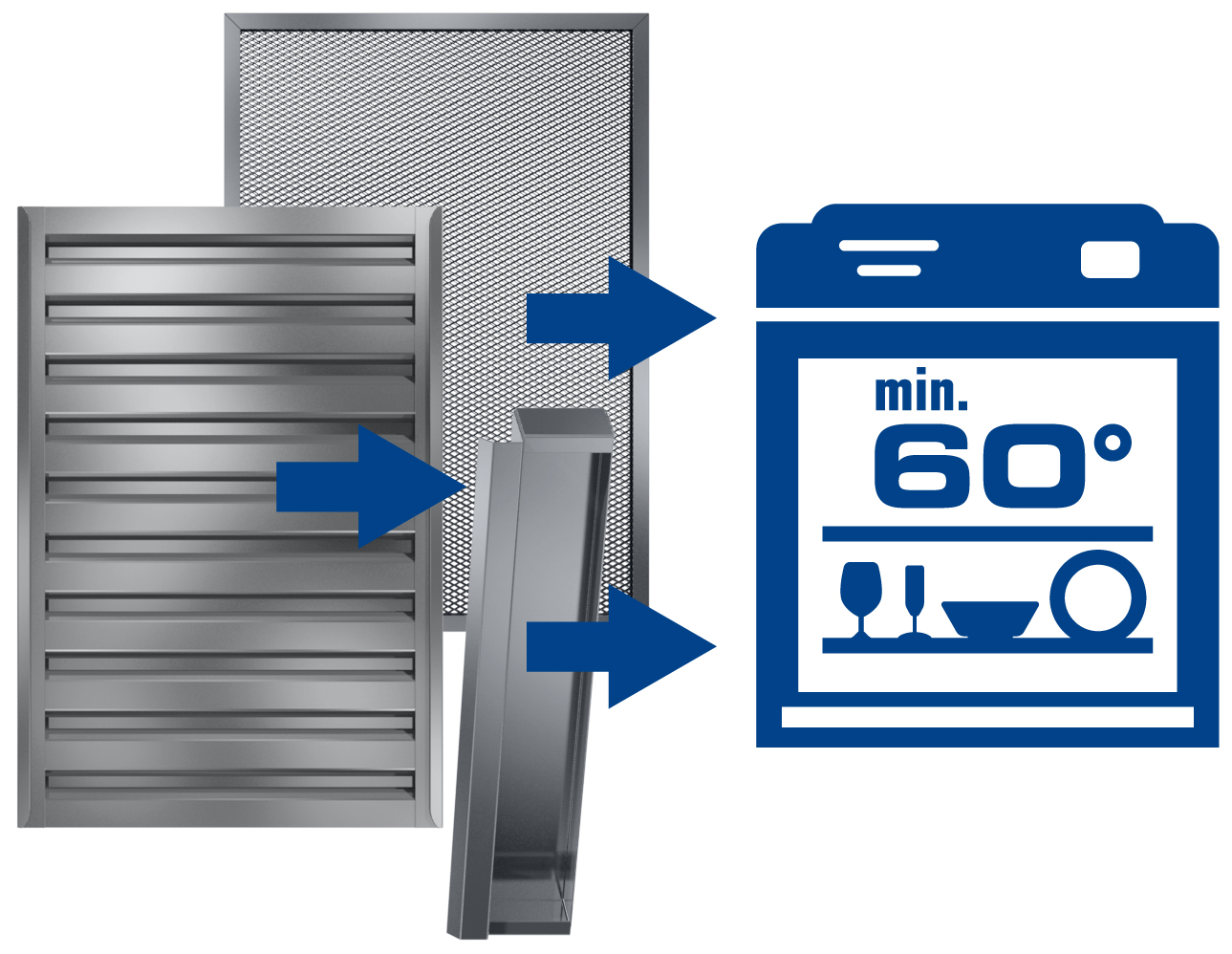

- Fettfilter, Fettauffangschalen und Zuluftmodule sind maschinenwaschbar

Die Reinigung der Kanäle kann über Zu- und Ablufteinheiten erfolgen.

|

|

|

| Alle Haubenoberflächen können sauber gewischt werden. |

|

Fettfilter, Fettauffangwannen und Zuluftmodule sind maschinenwaschbar. |

Plug n Play – Schnelle Inbetriebnahme

Die Plug-and-Play-Funktion ist in den CleanMaster-Hauben integriert und vereinfacht die Inbetriebnahme. Eine separate Steuerung ist nicht erforderlich, was die Planung und Installation vereinfacht. Schalten Sie die Haube ein, und sie ist einsatzbereit.

SlideSafe für sichere Handhabung der UV-Leuchten während der Wartung

Die patentierte SlideSafe-Technologie gewährleistet die sichere Handhabung von UV-Hauben während Installation und Wartung. Diese Funktion ist Standard in allen CleanMaster-Hauben und Lüftungsdecken.

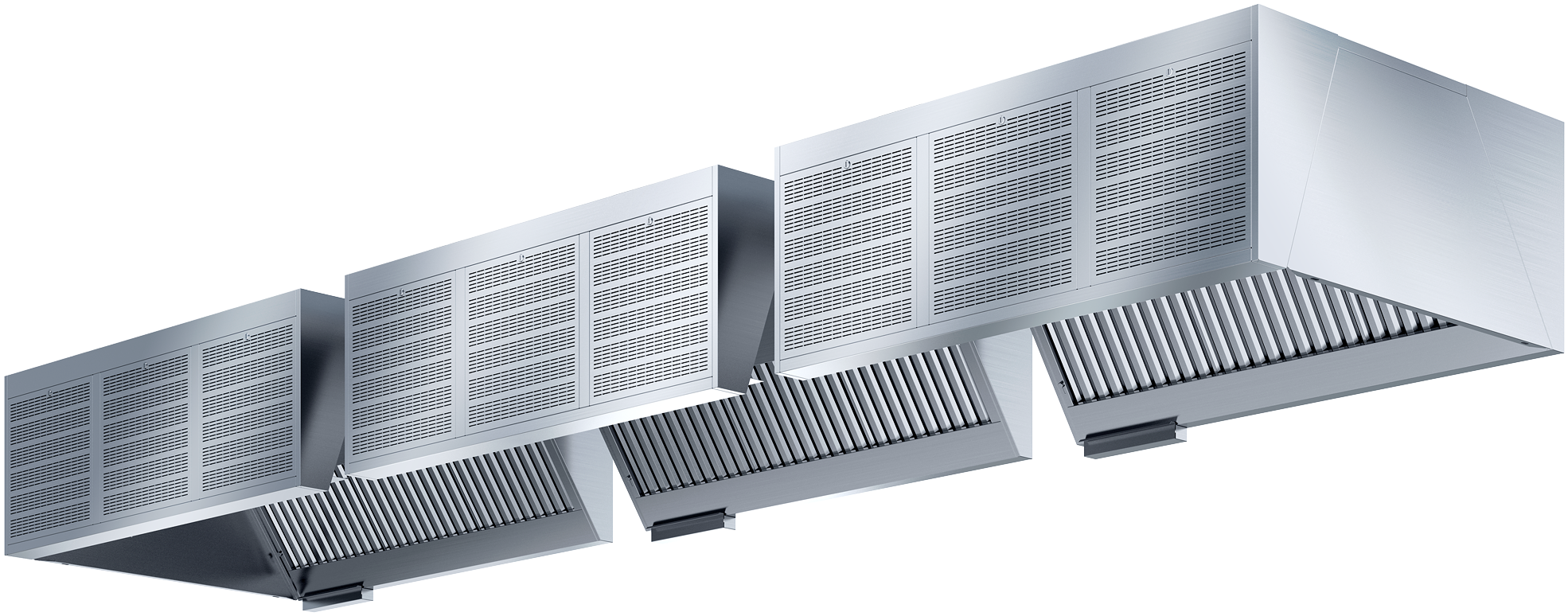

Design und Funktionsweise

Alle Climecon-Hauben in Standardgrößen und mit allen Reinigungstechnologien lassen sich nahtlos und funktional zu einer Einheit verbinden. Die Verbindung erfolgt ohne Zwischenwände und die Trennwände können auch nachträglich entfernt werden.

Die Leistung der Hauben lässt sich direkt über ein integriertes Bedienfeld steuern und überwachen. An großen Standorten können die Hauben gruppiert oder direkt über die Gebäudeautomation gesteuert werden.

|

CleanMaster® Hauben sind Modbus-kompatibel. |

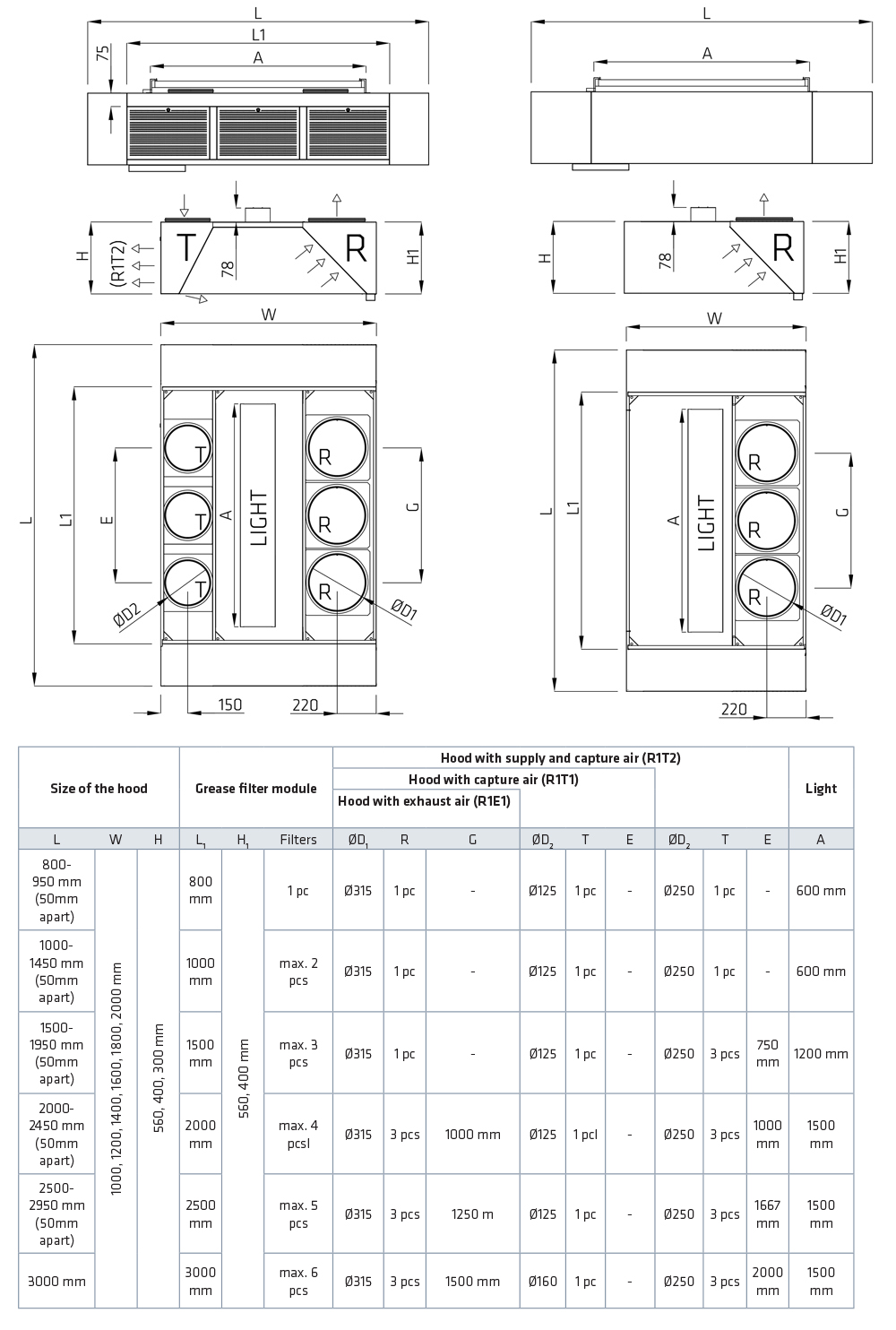

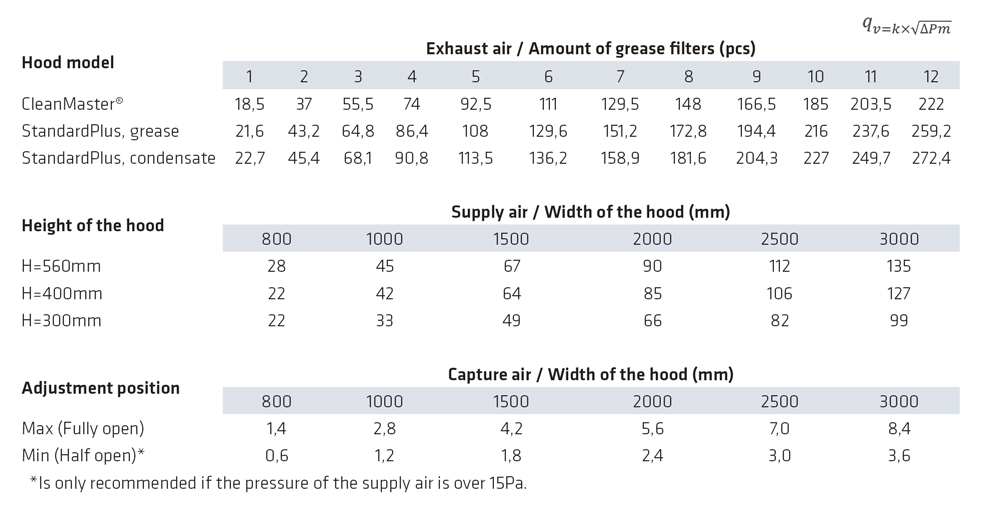

Schnellauswahl

Abluft

Zuluft und Lufterfassungsstrom

Die in der Kurzanleitung angegebene Höhe der Haube beträgt h=560. Bei Verwendung anderer Modelle ist der Luftstrom wie folgt zu messen:

- Haube h=400, Luftstrom x 0,95

- Haube h=300, Luftstrom x 0,70

Bitte prüfen Sie die spezifischen Luftströme mit dem Hood.X – Auswahltool.

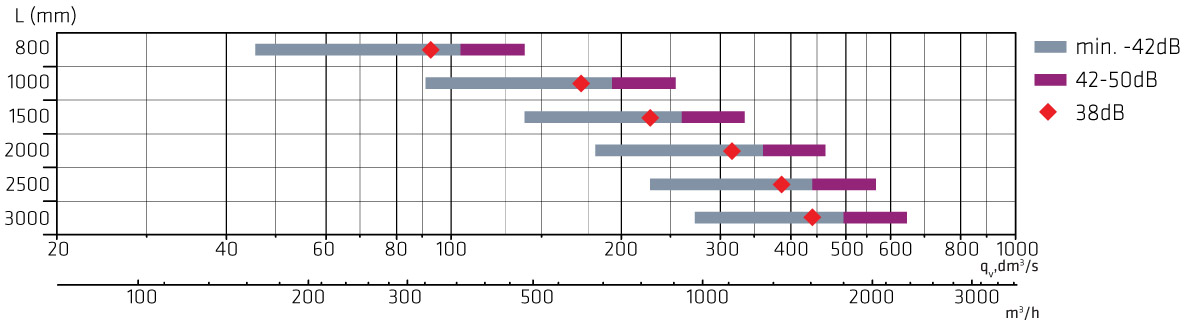

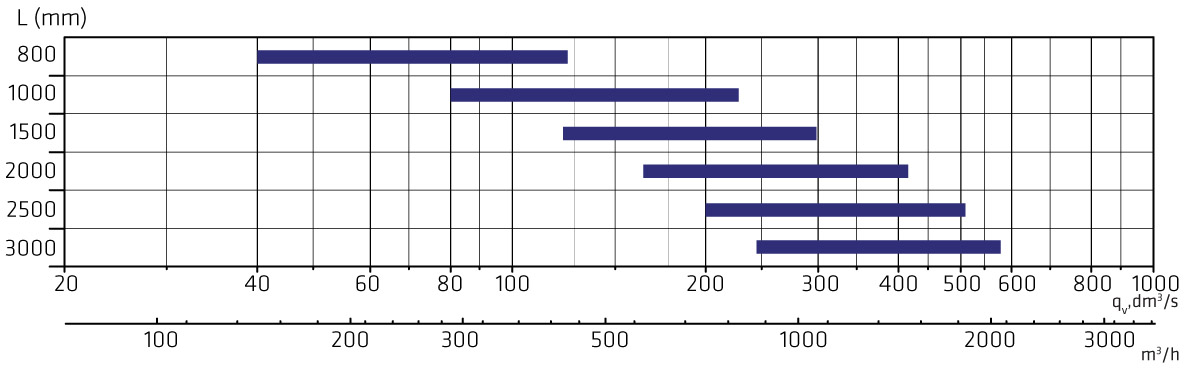

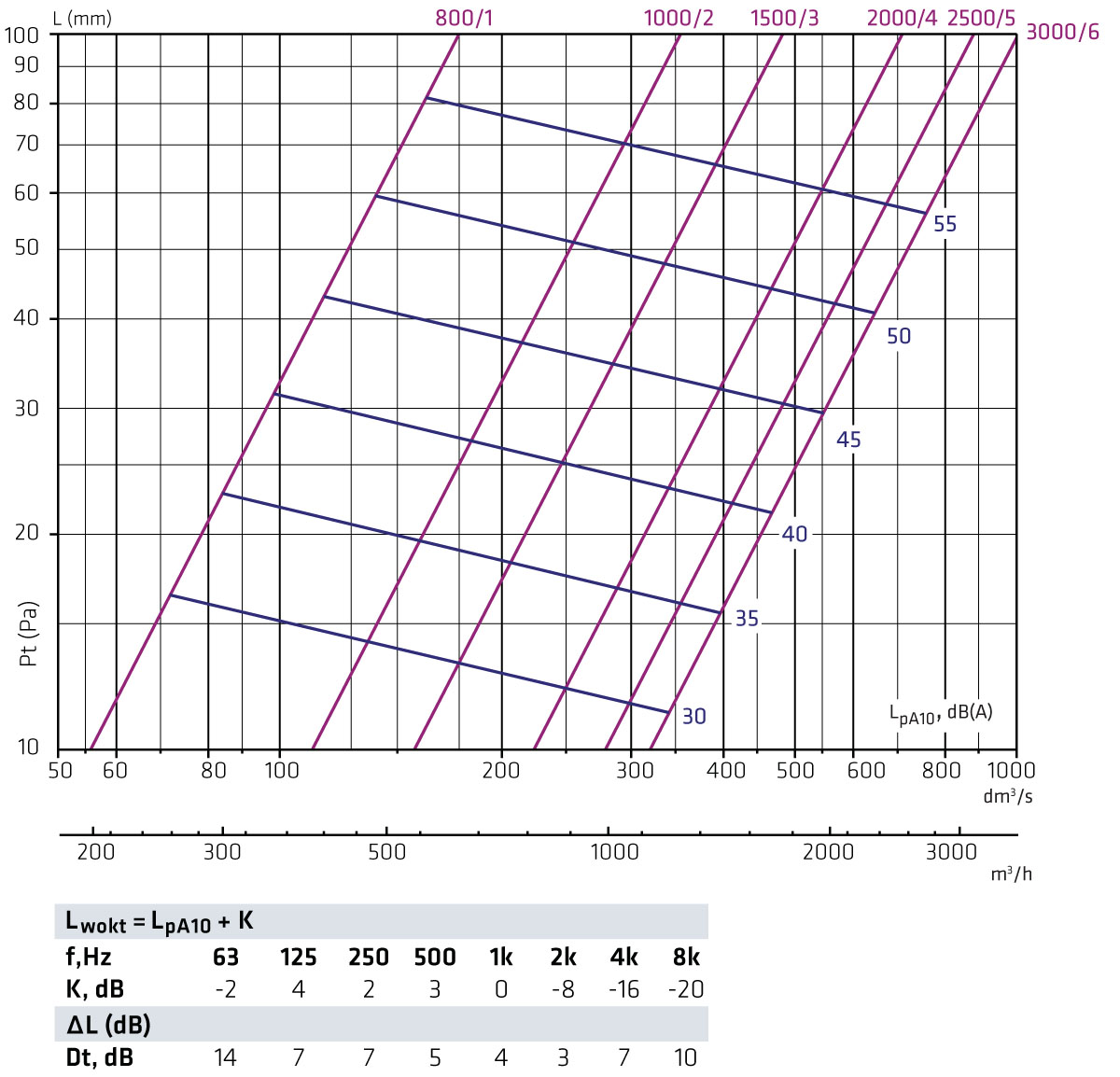

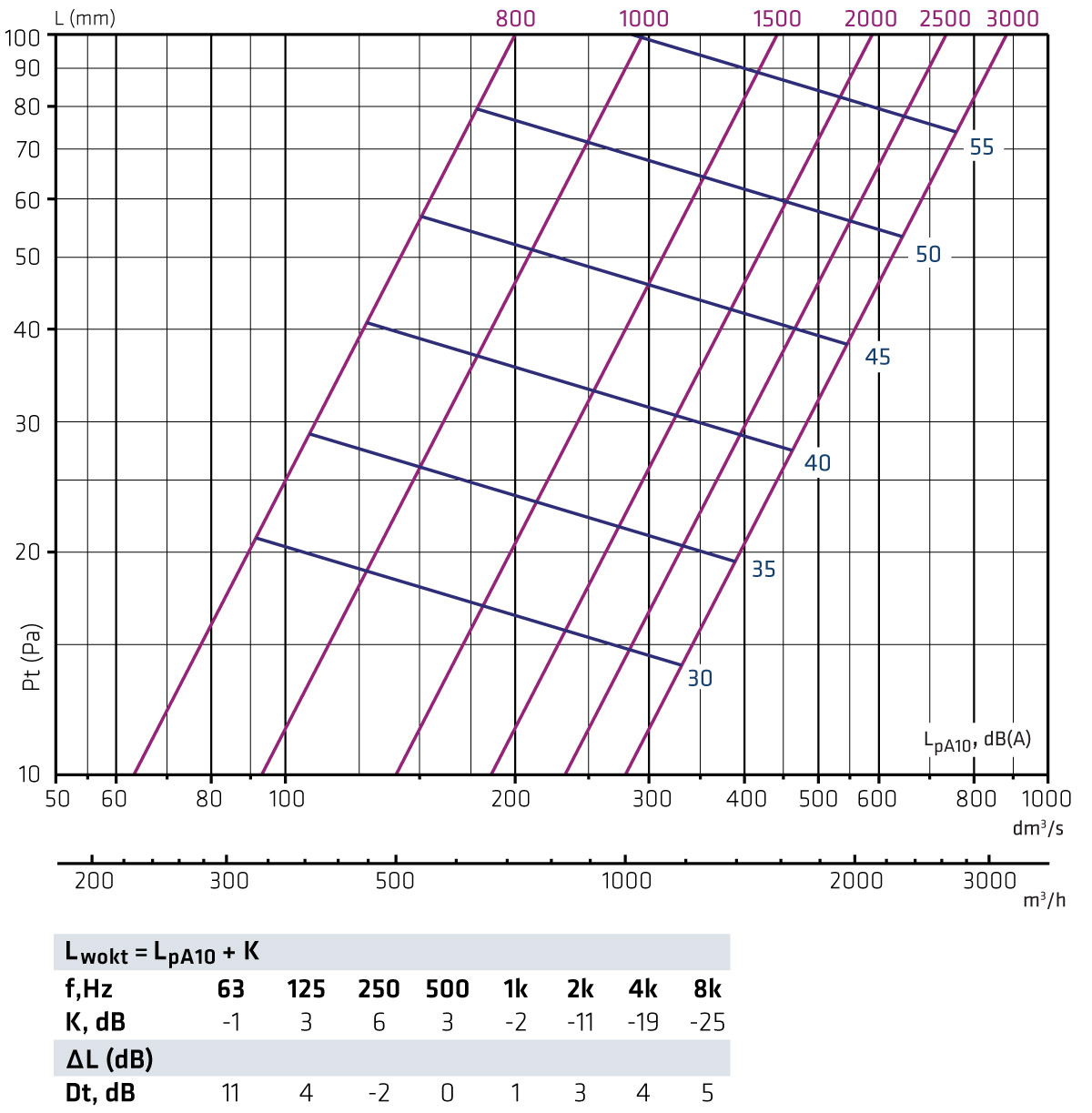

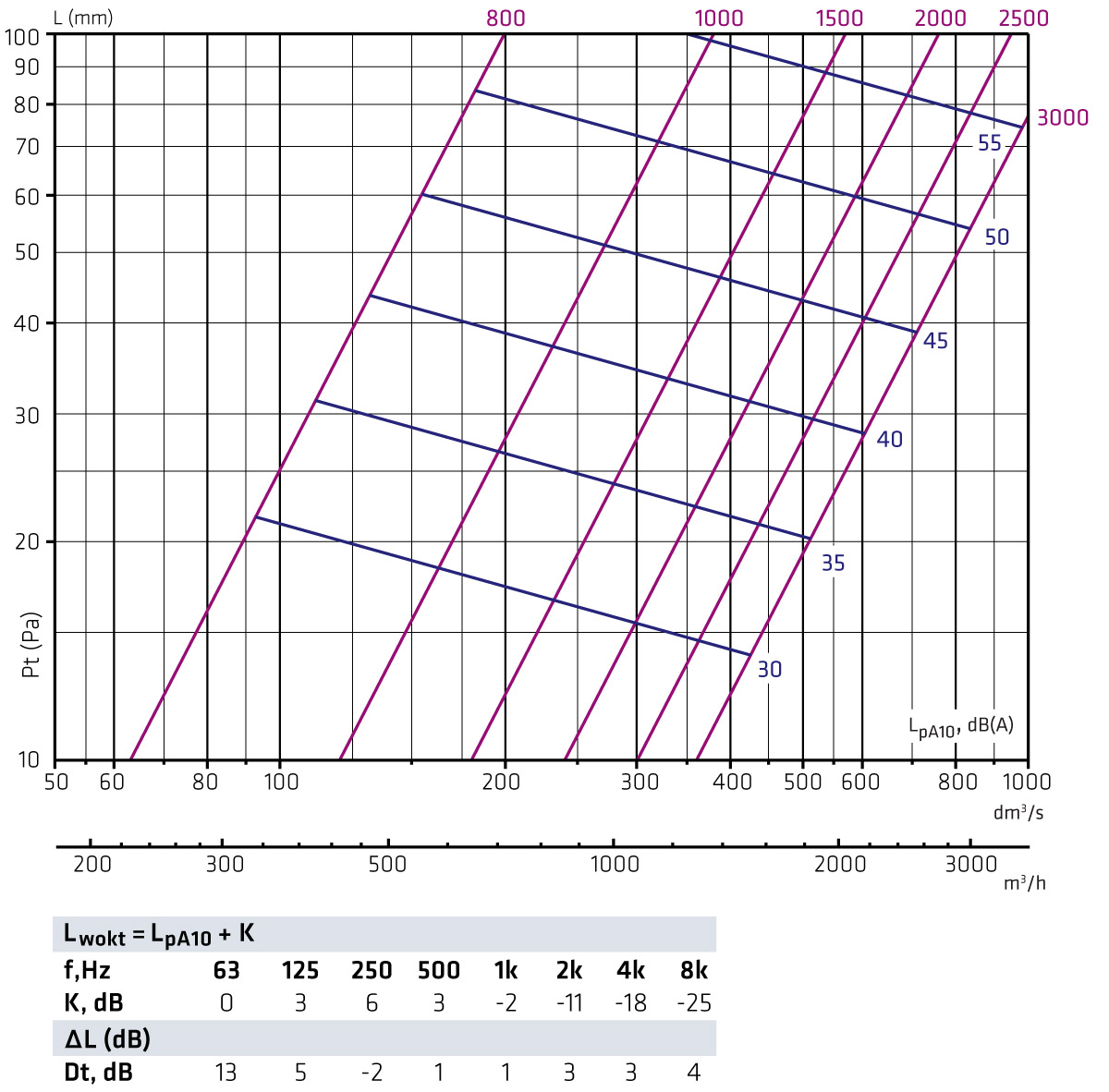

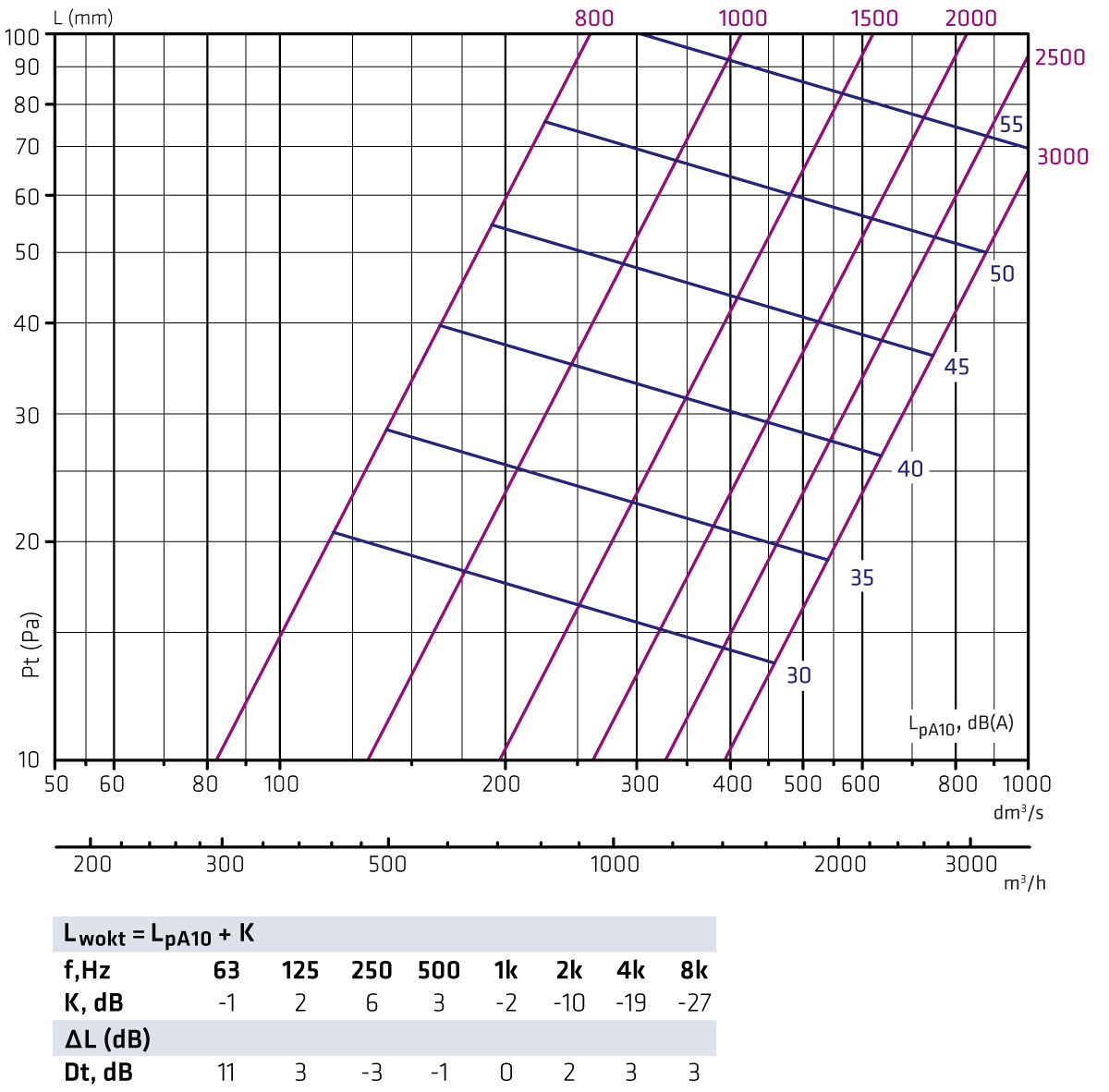

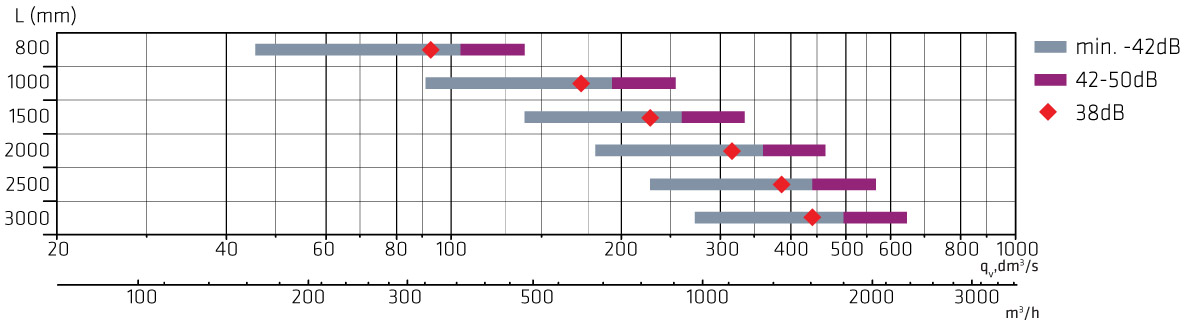

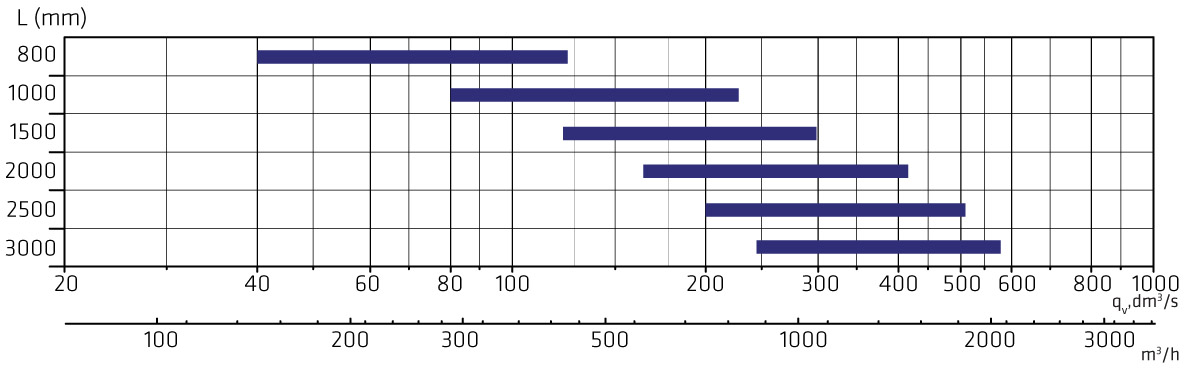

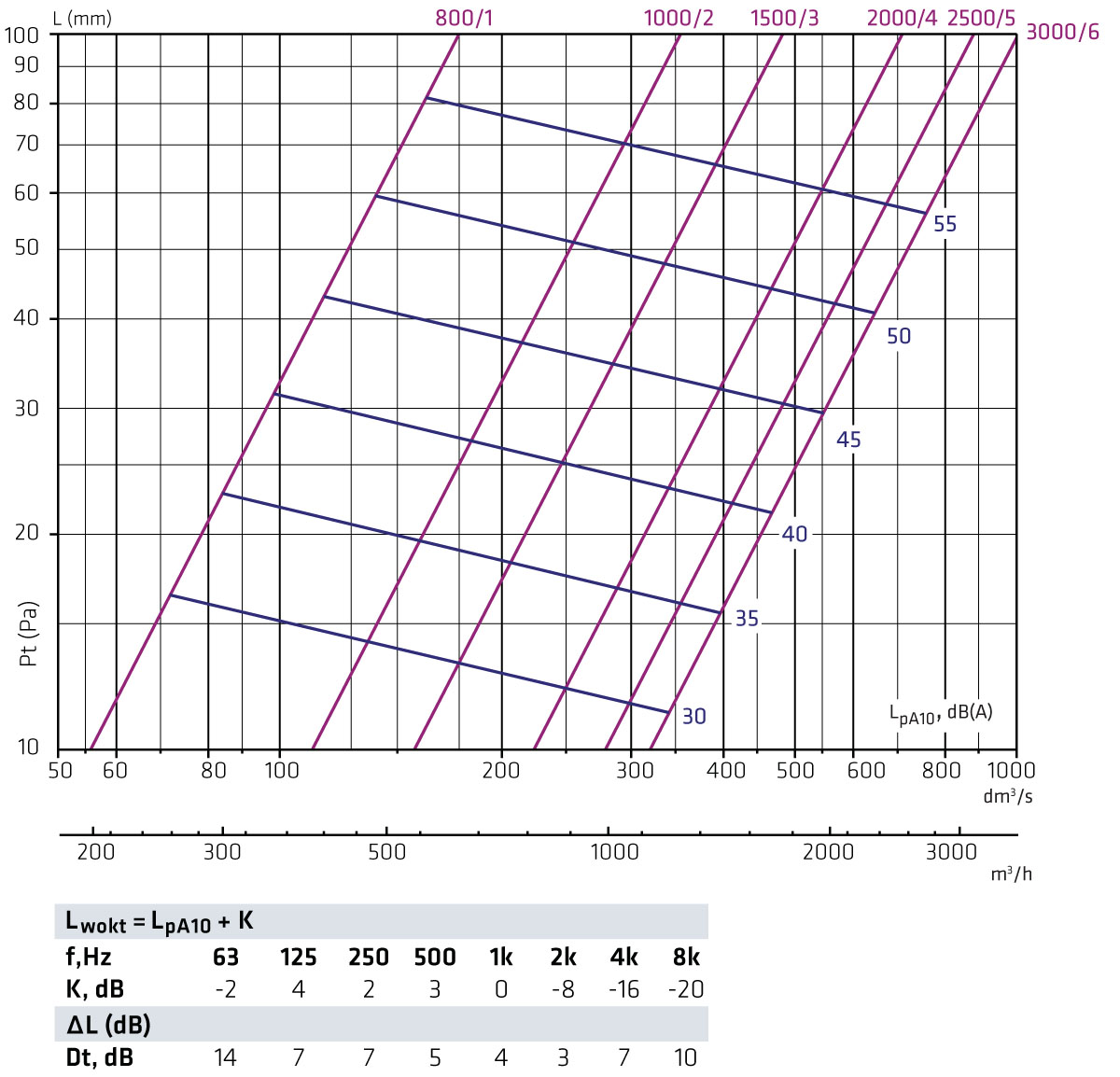

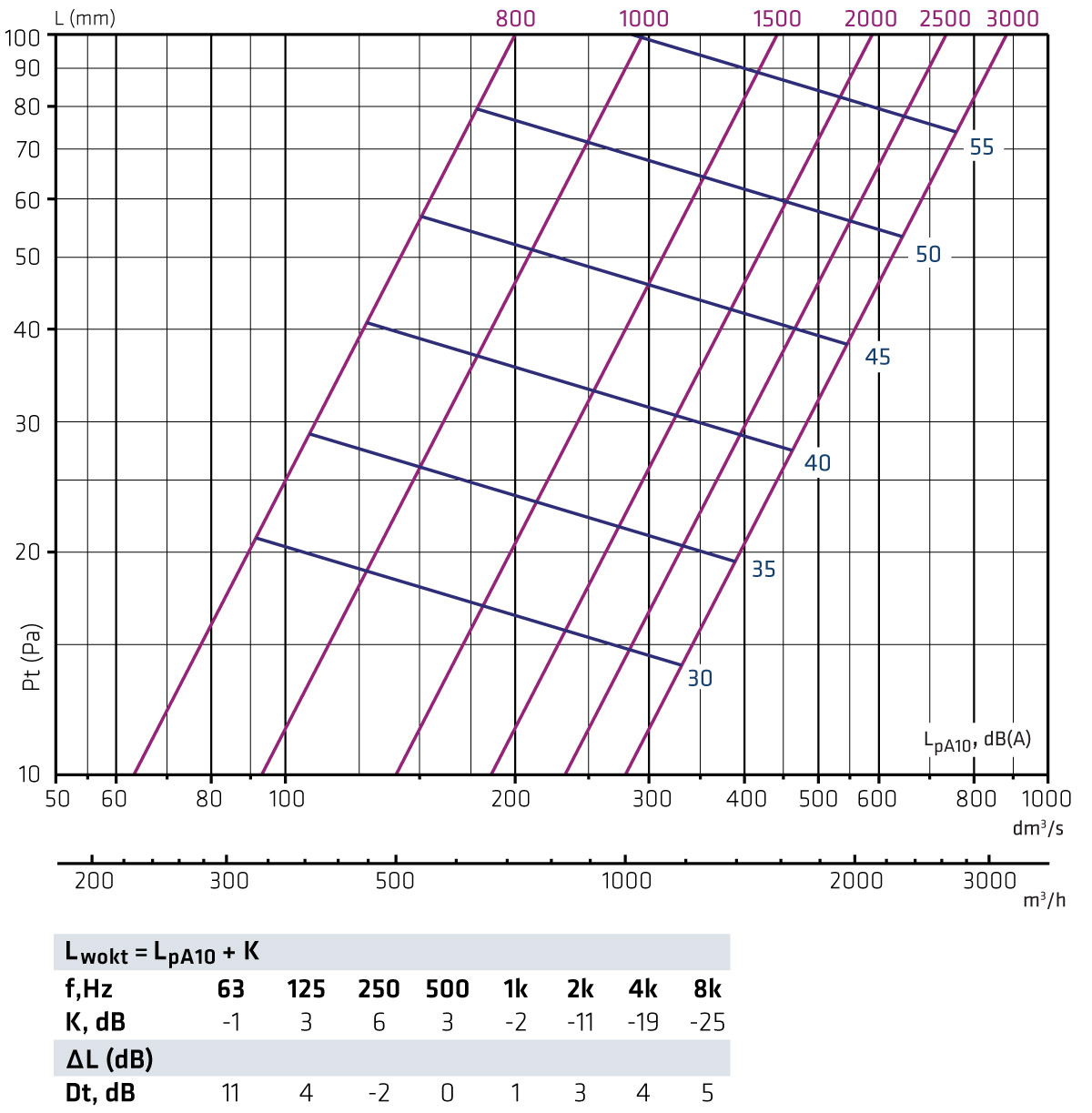

Auswahldiagramme

Die Diagramme sind nicht zur Einregulierung geeignet!

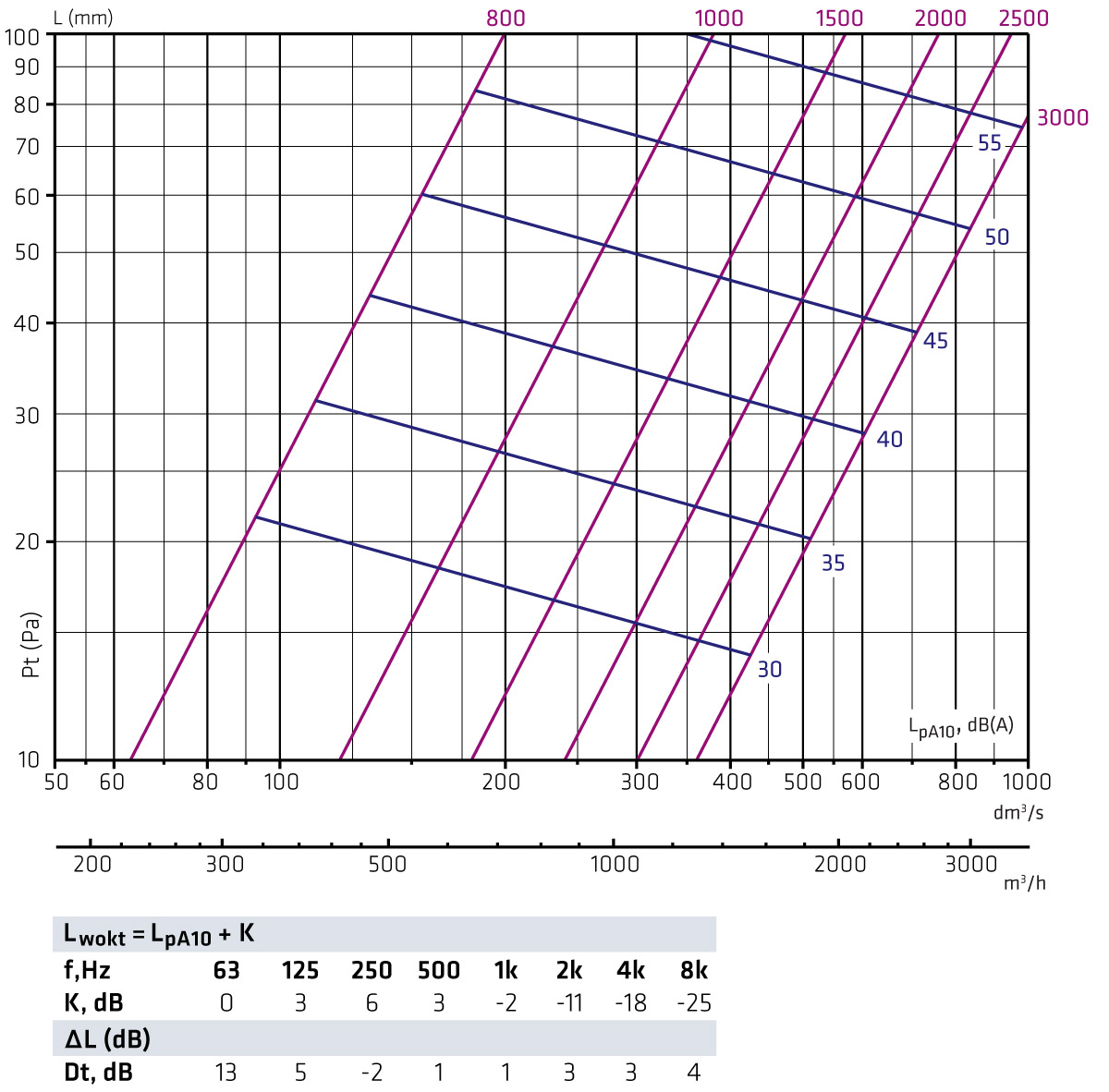

Druckverlust- und Geräuschangaben für die Abluft

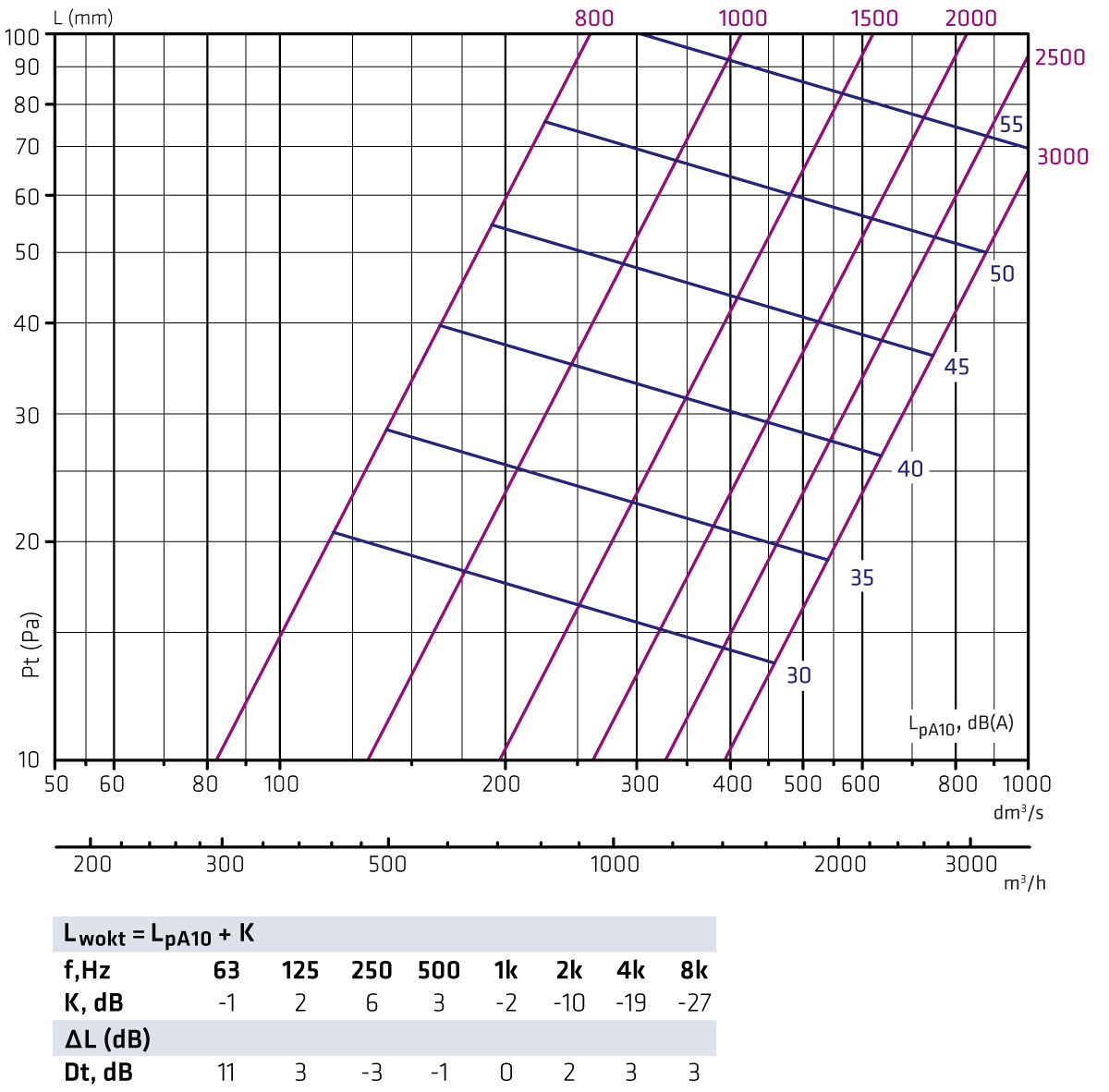

Druckverlust- und Geräuschangaben für Lufterfassungsstrom und Zuluft, Zulufteinheithöhe 300 mm

Druckverlust- und Geräuschdaten werden nur für eine Zulufteinheit gemessen. Bei Modellen mit Installation als Insel gibt es zwei Zulufteinheiten.

Druckverlust- und Geräuschangaben für Lufterfassungsstrom und Zuluft, Zulufteinheithöhe 400 mm

Druckverlust- und Geräuschdaten werden nur für eine Zulufteinheit gemessen. Bei Modellen mit Installation als Insel gibt es zwei Zulufteinheiten.

Druckverlust- und Geräuschangaben für Lufterfassungsstrom und Zuluft, Zulufteinheithöhe 560 mm

Druckverlust- und Geräuschdaten werden nur für eine Zulufteinheit gemessen. Bei Modellen mit Installation als Insel gibt es zwei Zulufteinheiten.

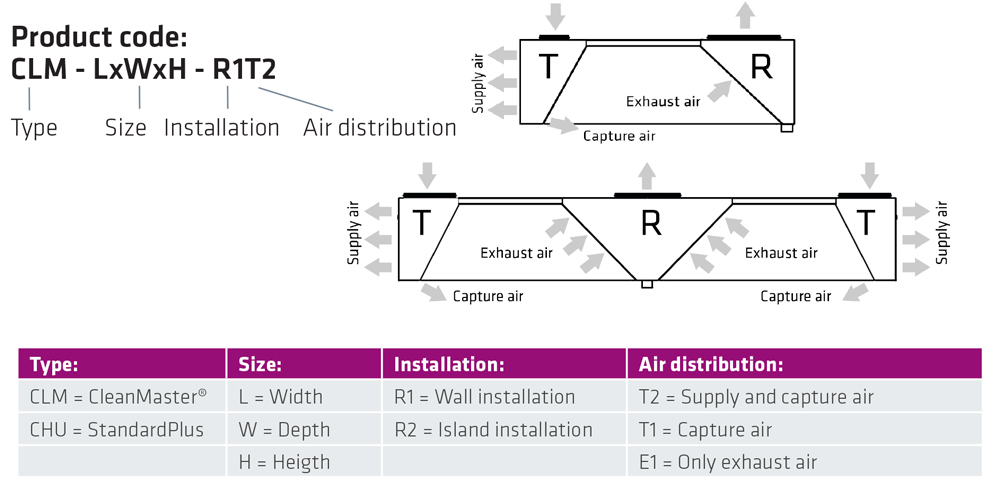

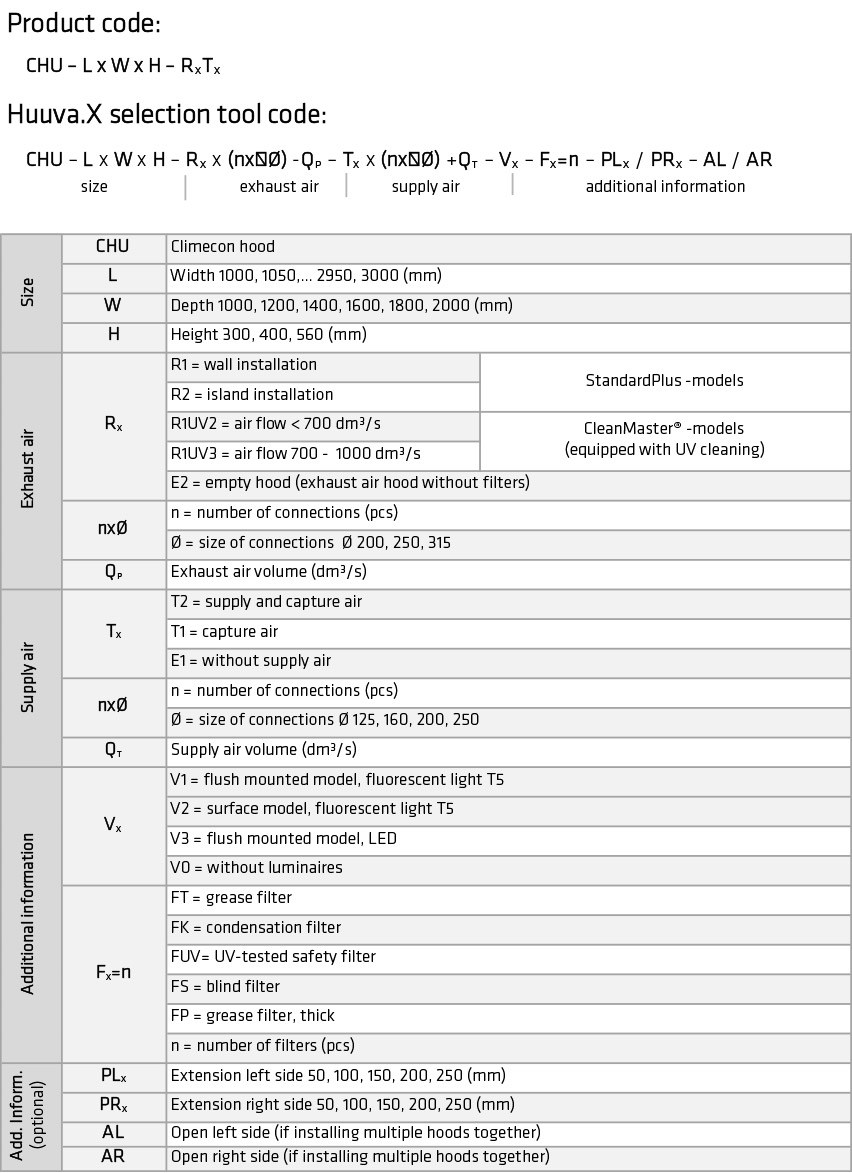

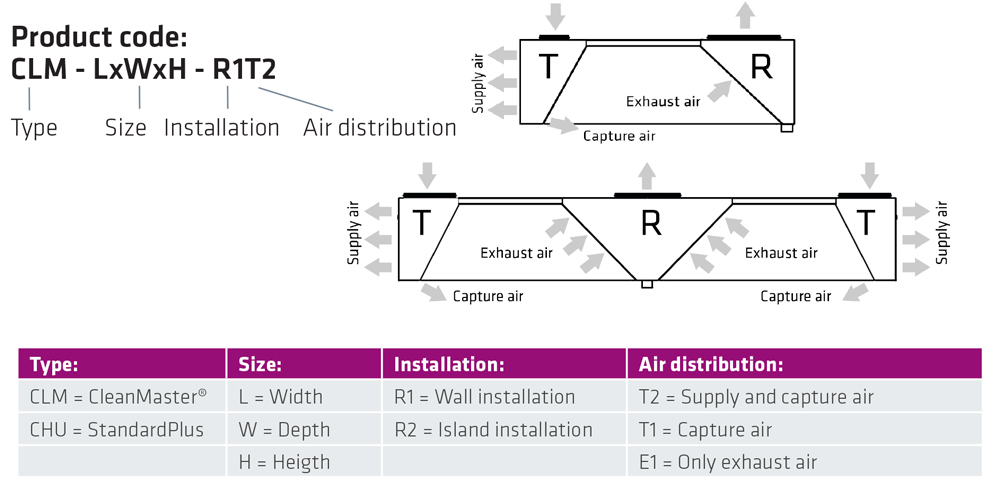

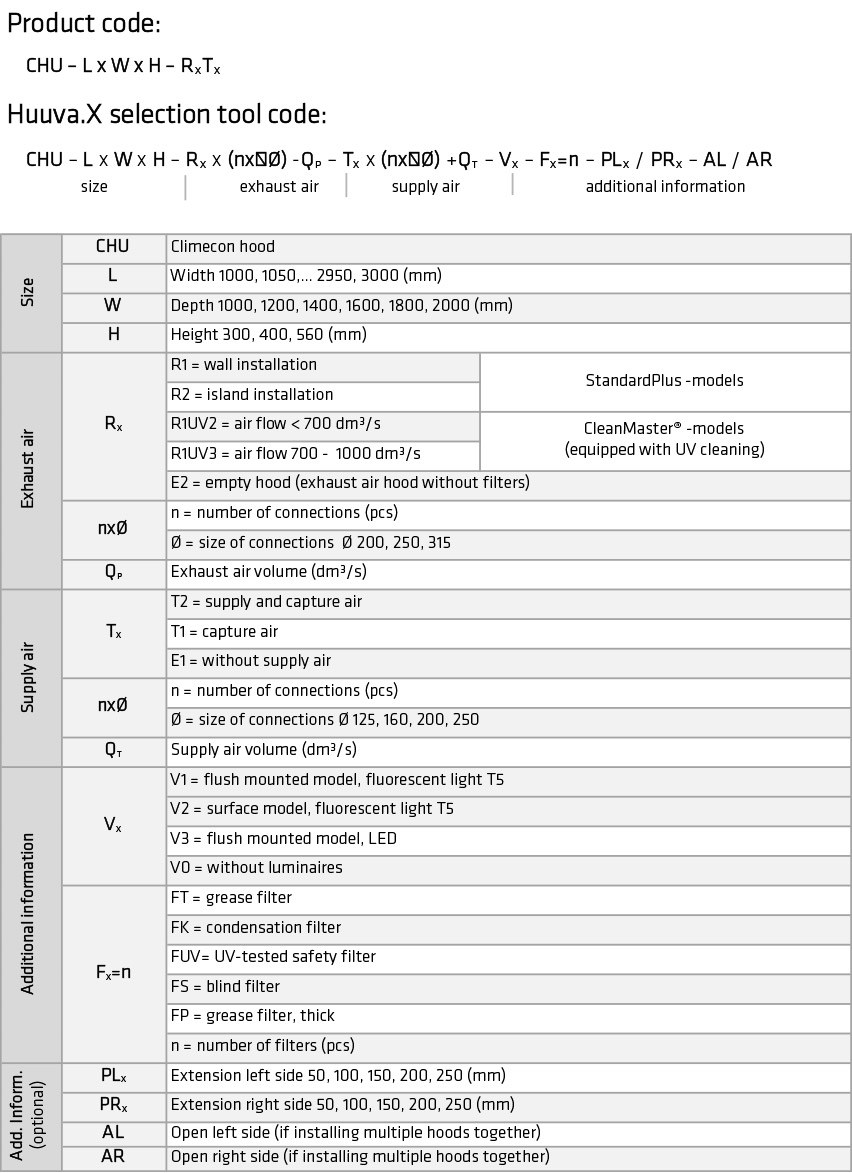

Produktcode

Die Standardmodelle der Abzugshauben sind mit Zuluft und Lufterfassungsstrom ausgestattet, um eine ausgewogene und gleichmäßige Abluft bei niedriger Geschwindigkeit in der Küche zu gewährleisten. Die Hauben sind auch nur mit Abluft erhältlich.

- Wandhaube mit Abluft, Zuluft und Begrenzungsluftstrom R1-T1/T2

- Wandhaube mit Abluft R1-E1

- Haube zur Inselinstallation mit Abluft, Zuluft und Begrenzungsluftstrom R2-T1/T2

- Haube zur Inselinstallation mit Abluft R2-E1

CleanMaster®-Hauben können mit zwei verschiedenen Produktcodes bestellt werden. Der erste Produktcode umfasst die Hauben, die aufgrund der Küchenausstattung ausgewählt wurden.

Nach der Auswahl der Hauben folgt der zweite Produktcode, der die Auswahl der richtigen CCM-Steuerung beinhaltet. Die CCM-Steuerung steuert die Hauben in der Küche und wird je nach Anzahl der Hauben ausgewählt. Beispiel: Für drei CleanMaster®-Hauben ist die CCM 3-Steuerung die beste Wahl.