Beschreibung

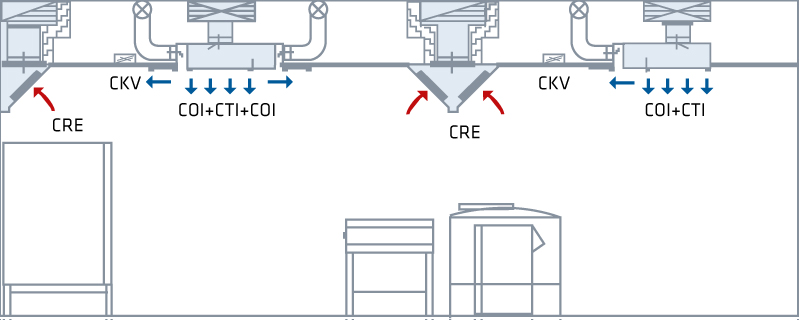

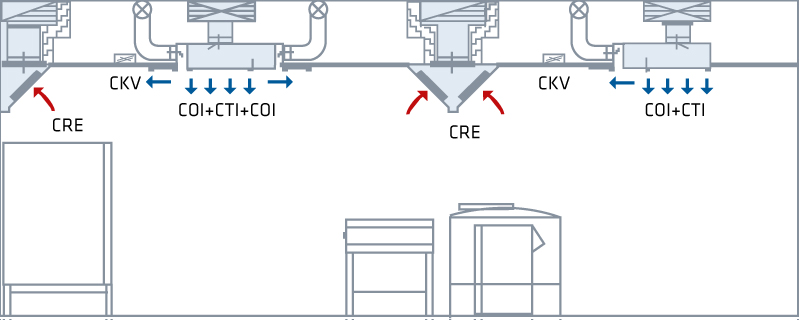

Die Lüftungsdeckenlösungen von Climecon umfassen eine große Auswahl an verschiedenen Lüftungseiheiten für Zuluft, Lufterfassungsstrom und Abluft, sowie Luftschleier, die die Ausbreitung verschmutzter Luft außerhalb der Frittierstationen verhindern. Lüftungsdeckenlösungen können mit Dämpfungselementen ausgestattet werden, die Geräusche effizient dämpfen und die Arbeitsbedingungen verbessern.

Durch die Kombination verschiedener Komponenten lässt sich das Lüftungssystem der Küche individuell an die jeweiligen Bedürfnisse anpassen.

Die Wahl ist CleanMaster

CleanMaster-Abzugshauben sind ein Meisterwerk der Ingenieurskunst und verfügen über fortschrittliche Fettabscheideleistung und herausragende Funktionen für eine einfache und sichere Bedienung, sowie ein besonders hohes Niveau beim Thema Brandschutz.

Seit über drei Jahrzehnten wird CleanMaster kontinuierlich weiterentwickelt, um den Anforderungen selbst anspruchsvollster Nutzer in den anspruchsvollsten Profiküchen noch besser gerecht zu werden. CleanMaster ist die Wahl echter Profis – von Michelin-Sternerestaurants bis hin zu Gastronomiebetrieben, öffentlichen Einrichtungen und Geschäftsräumen.

Fortschrittliche vierstufige Reinigungstechnologie

CleanMaster nutzt die fortschrittlichste vierstufige Reinigungstechnologie für saubere Fettkammern und Kanäle. CleanMaster verfügt über geprüfte und UV-zertifizierte Fettfilter.

Mechanische Abscheidung/Aufprallabscheidung

Die mechanische Abscheidung filtert effizient große Fettpartikel resultierend aus dem Kochprozess heraus. Die schweren Partikel werden aus der Abluft durch einen Filter ausgesiebt.

UV-C

UV-C ist eine weit verbreitete, konventionelle keimtötende Reinigungstechnologie. Sie wirkt gegen Mikroorganismen, Schimmel, Pilze und Bakterien.

Vakuum UV

Vakuum-UV löst hocheffizient kleine Fettpartikel in natürliche Verbindungen wie Sauerstoff, Kohlendioxid und Wasser auf. Zusätzlich zur herkömmlichen UV-Technologie bietet Vakuum-UV eine noch höhere Abluftreinigungsleistung.

Ozon

Ozon oxidiert effektiv die letzten Fettpartikel und desodoriert die Luft.

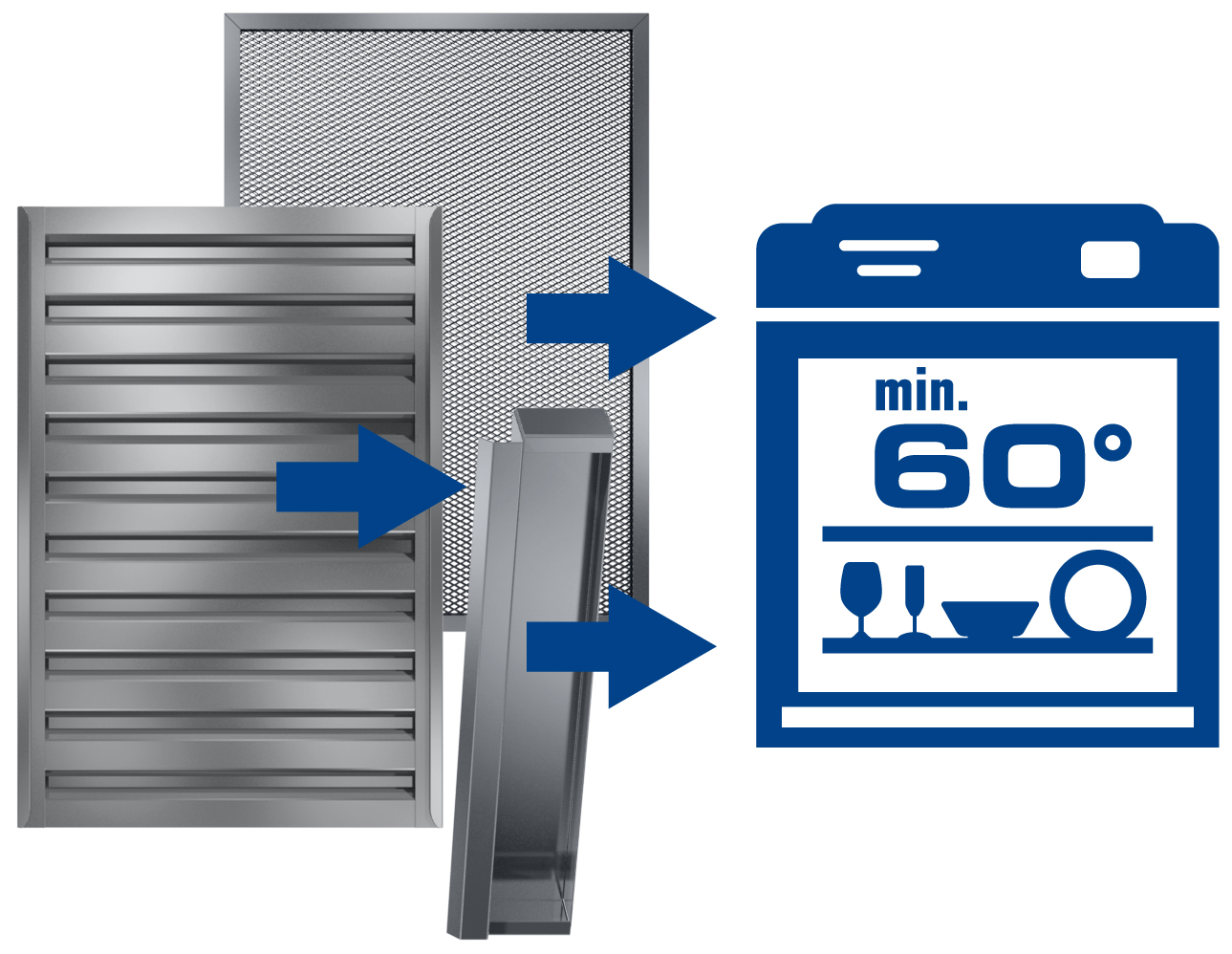

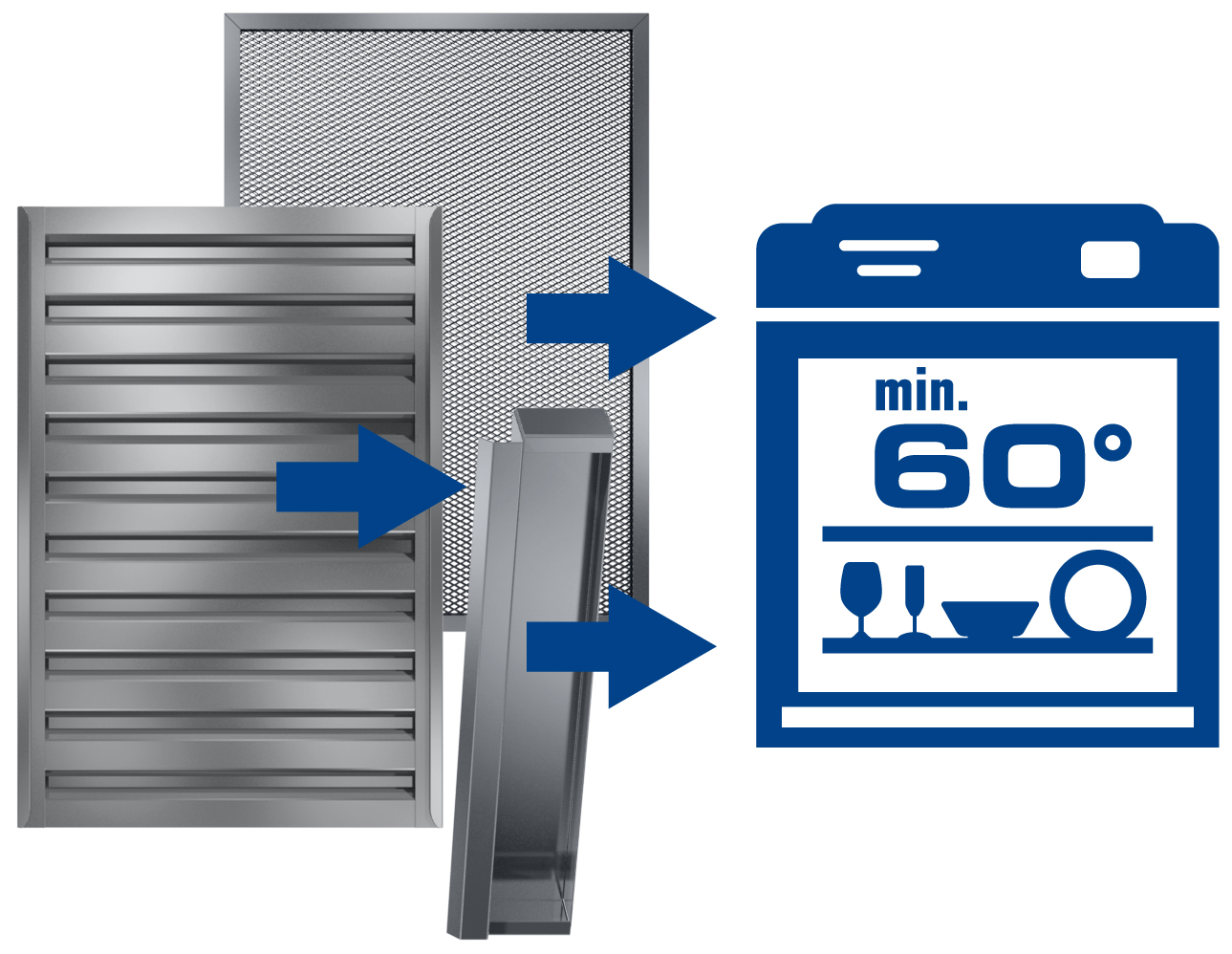

EasyCare Konzept

Die Eigenschaften des EasyCare-Konzepts gewährleisten ein hohes Maß an Hygiene. Einfache Wartung sorgt dafür, dass die Lösungen in gutem Zustand bleiben und ihre volle Leistung erbringen. Dank der leicht abnehmbaren und maschinenwaschbaren Teile führt die mühelose und schnelle Reinigung zu weniger Ausfallzeiten und geringeren Wartungskosten.

- Die Reinigung der Kanäle kann über Zu- und Ablufteinheiten erfolgen

- Die Oberflächen sind frei von unnötigen Einbuchtungen und somit leicht zu reinigen

- Fettfilter, Fettauffangschalen und Zuluftmodule sind maschinenwaschbar

Die Reinigung der Kanäle kann über Zu- und Ablufteinheiten erfolgen.

|

|

|

| Alle Haubenoberflächen können sauber gewischt werden. |

|

Fettfilter, Fettauffangschalen und Zuluftmodule sind maschinenwaschbar. |

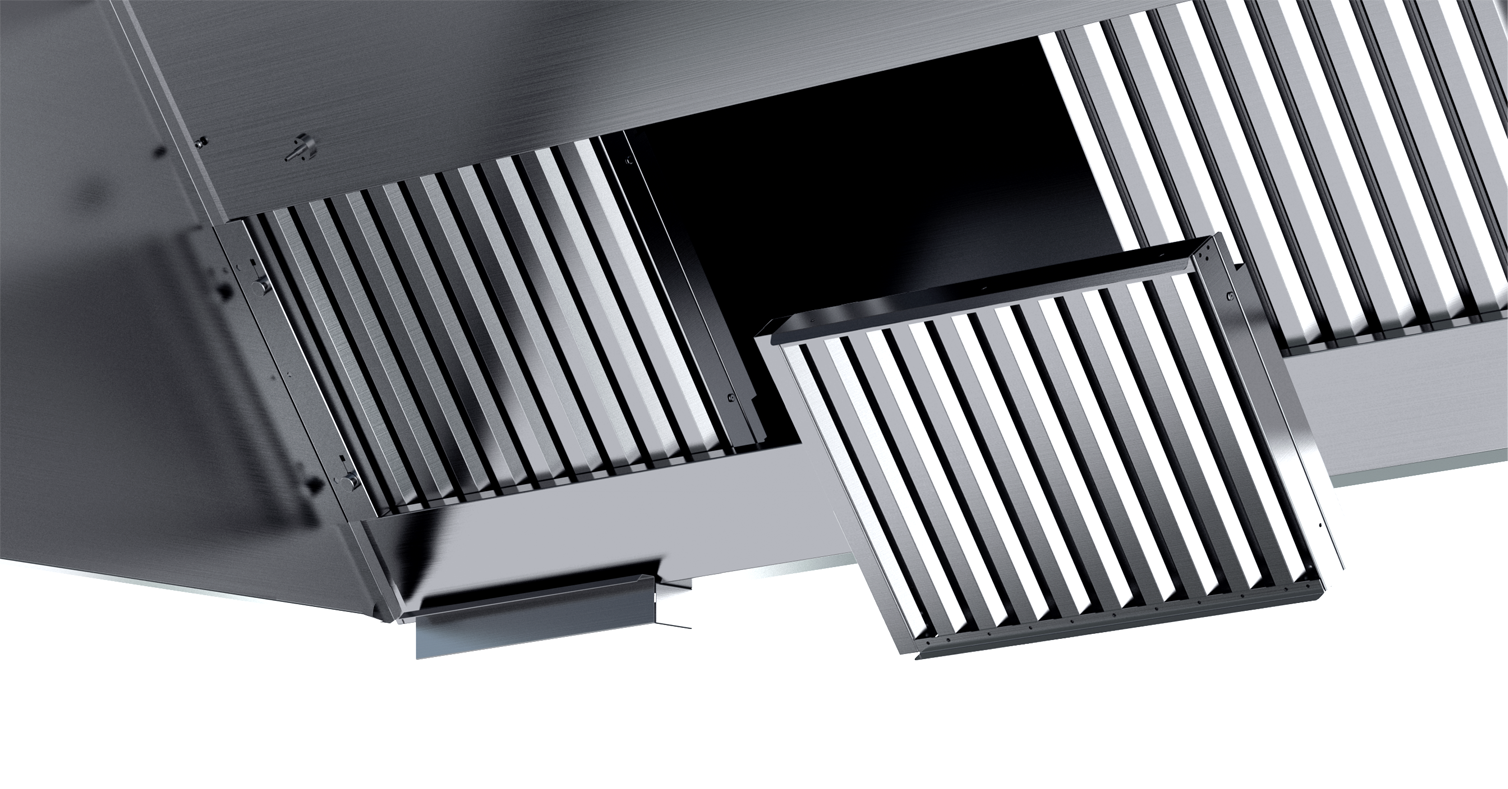

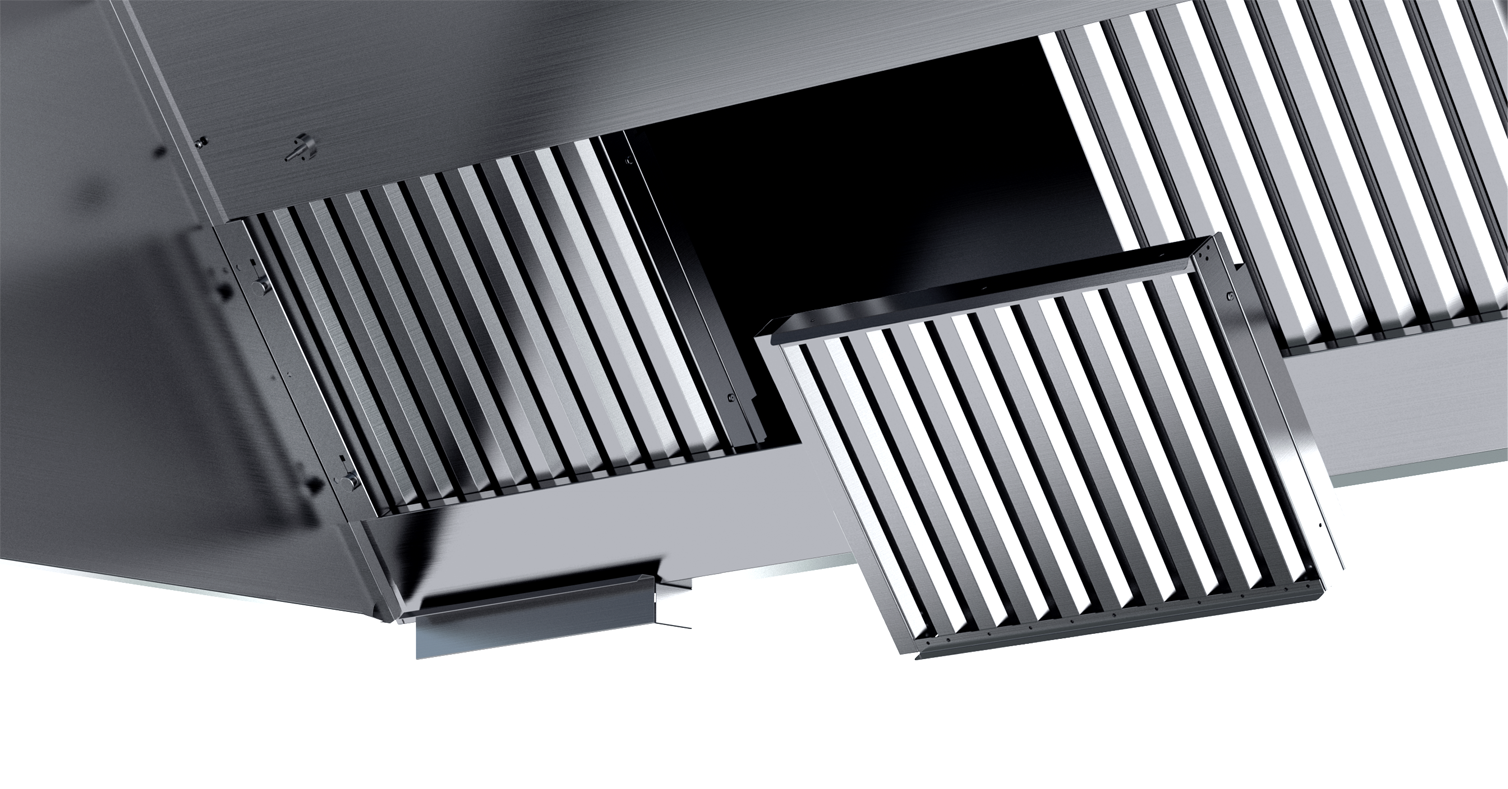

Design und Funktionsweise

Die Lüftungsdeckensysteme von Climecon zeichnen sich durch ein besonderes Design aus. Modernes Design in Kombination mit niedriger Bauweise verleiht der Küche architektonisch wertvolle Großzügigkeit.

Alle Komponenten der Deckenlüftungslösung sind aus Edelstahl gefertigt. Zur Produktpalette gehören auch Zu- und Abluftdurchlässe für andere Räumlichkeiten, die in der gewünschten Farbe lackiert werden können.

Design Service

Der Planungsservice von Climecon stellt sicher, dass die Lüftungssysteme unter Berücksichtigung der individuellen Bedürfnisse jeder Profiküche richtig dimensioniert und konzipiert werden.

Funktionale Lüftungsdeckenlösungen umfassen:

- Effiziente und richtig platzierte Ablufteinheiten

- Richtig platzierte Zulufteinheiten, die eine gleichmäßige und zugfreie Verteilung der Zuluft in der Küche gewährleisten

- Richtige Platzierung von Begrenzungsluftstromeinheiten und Luftschleiern

- Richtige Platzierung der Beleuchtung, die zusätzlich die Arbeitsbedingungen verbessert

- Dämpfungsplatten, die zusätzlich die Akustik und die Arbeitsbedingungen in der Küche verbessern

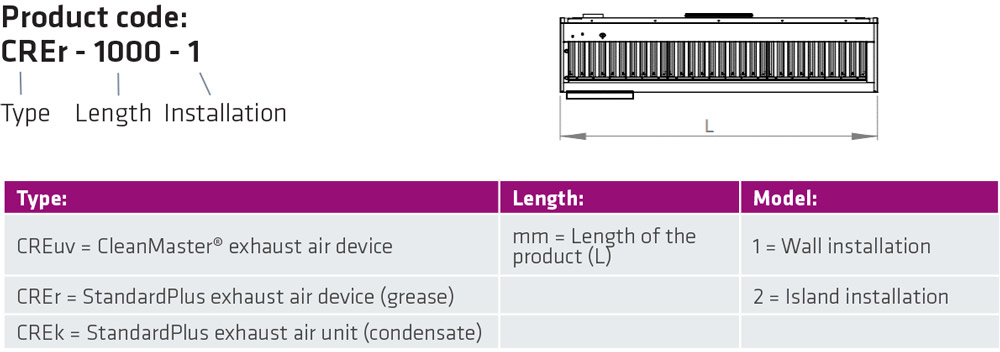

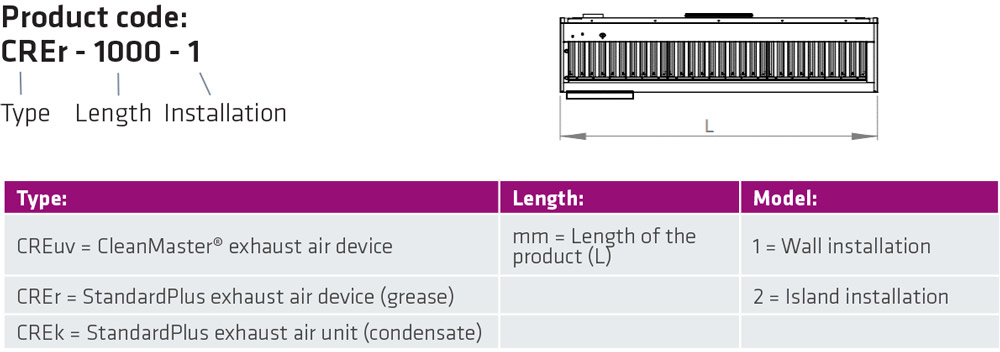

CRE Ablufteinheit

Die CRE-Ablufteinheit dient zum Abführen des aus den Frittierstationen austretenden Fettdampfes.

- Fettabscheidegrad geprüft im Technischen Forschungszentrum VTT in Helsinki

- UV-zertifizierte Fettfilter gemäß Norm

DIN 18869-7:2006-06

- Leicht herausnehmbare und maschinenwaschbare

Fettfilter

|

|

|

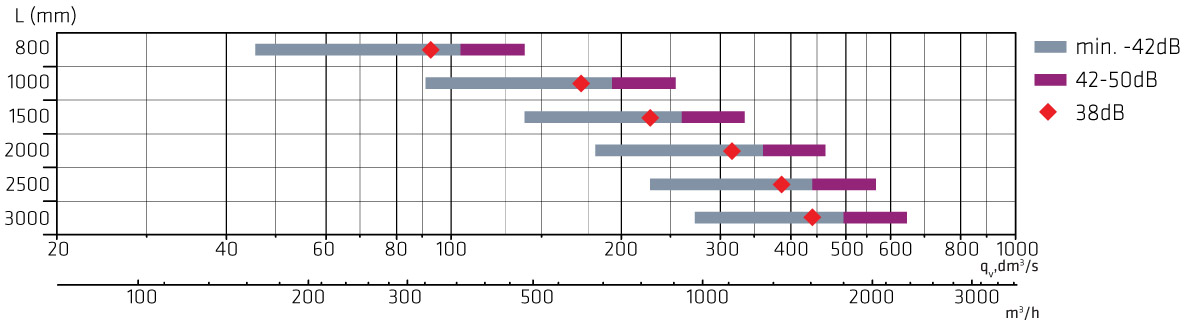

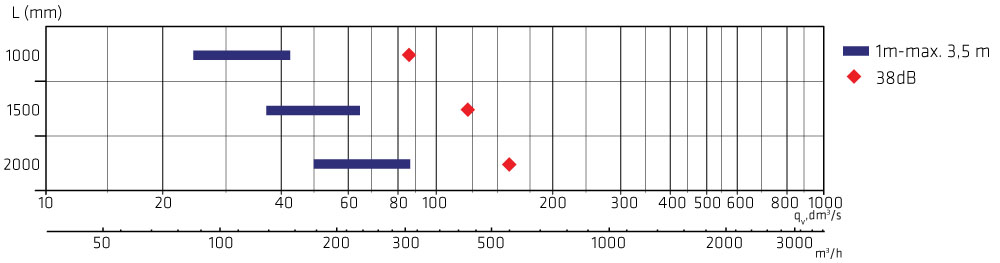

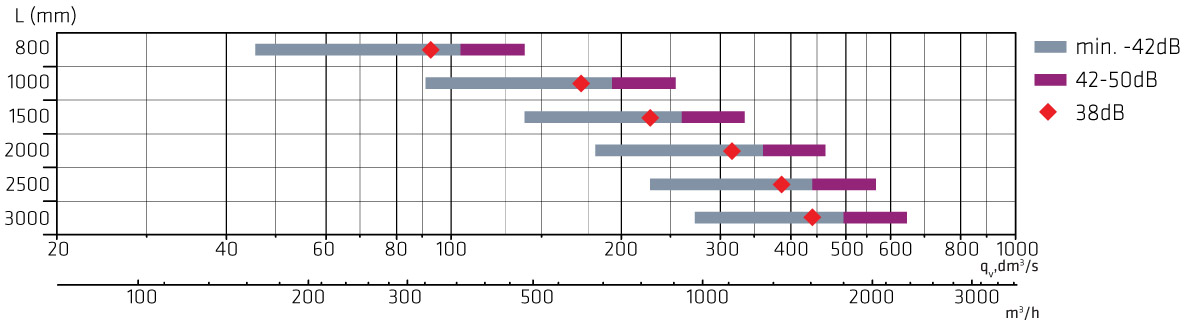

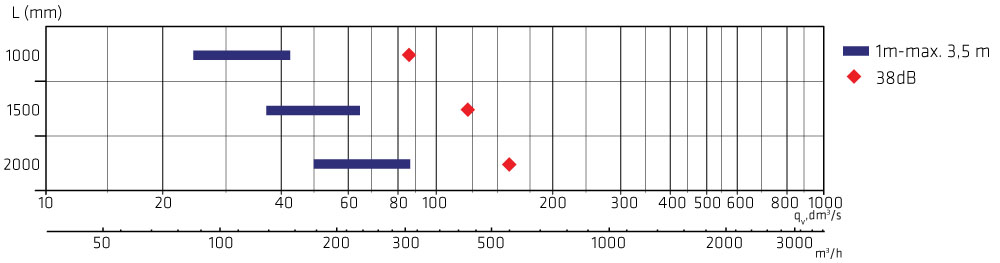

Schnellauswahl, Wandinstallation

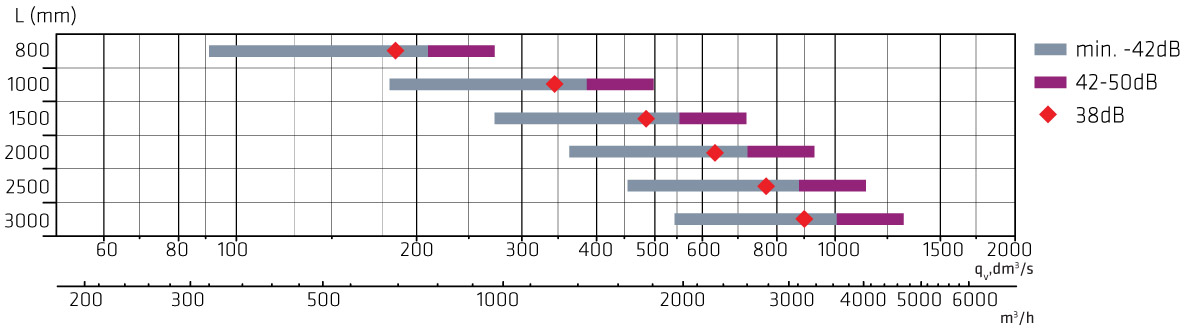

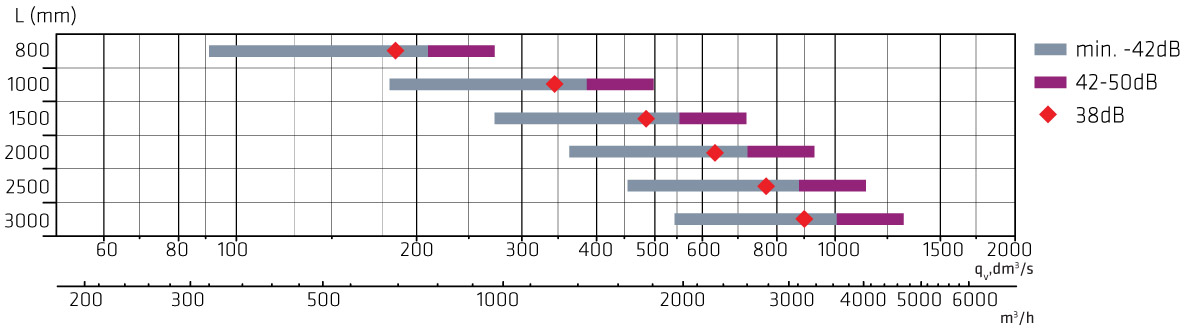

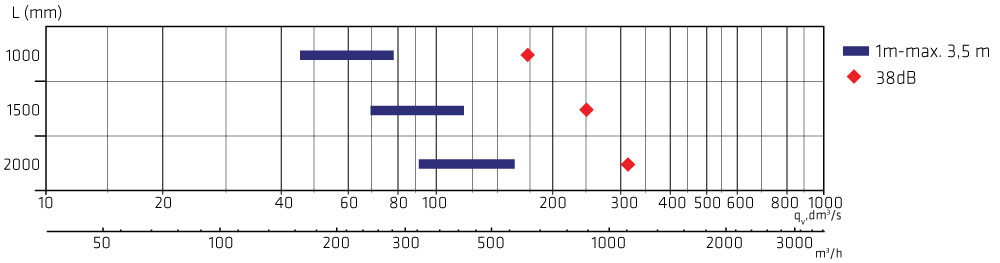

Schnellauswahl, Inselinstallation

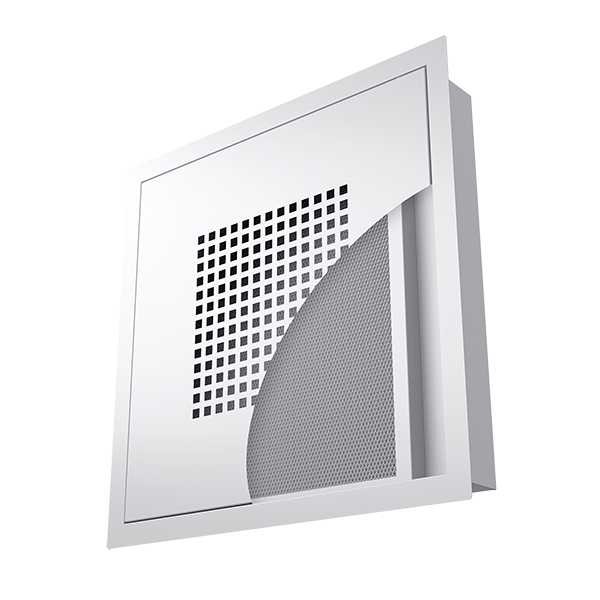

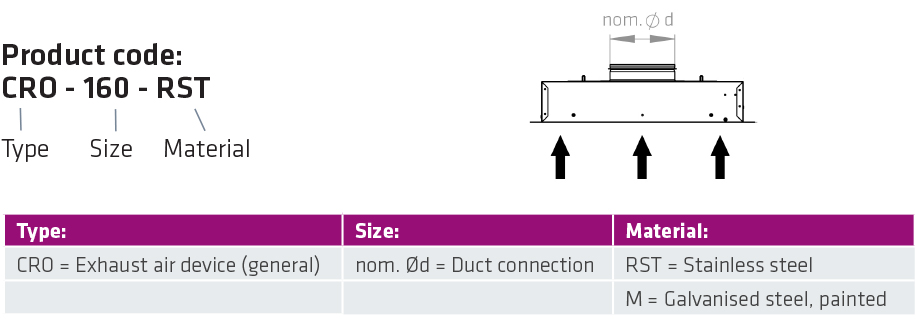

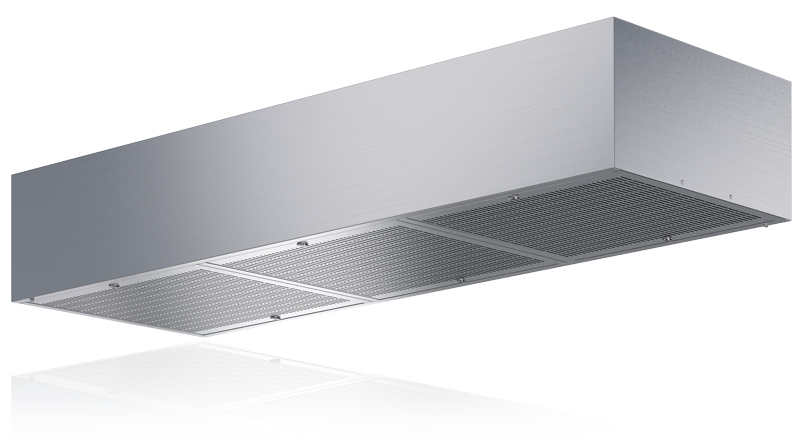

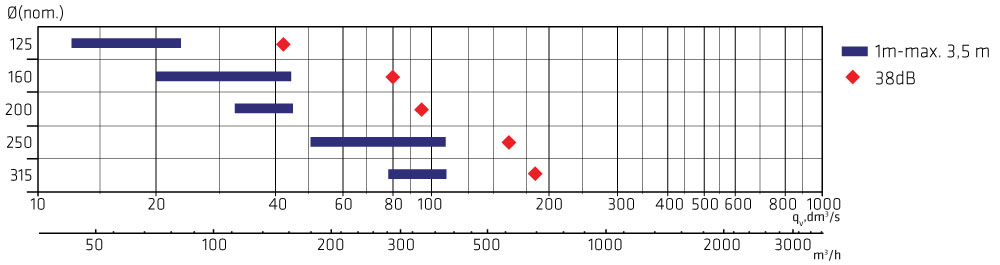

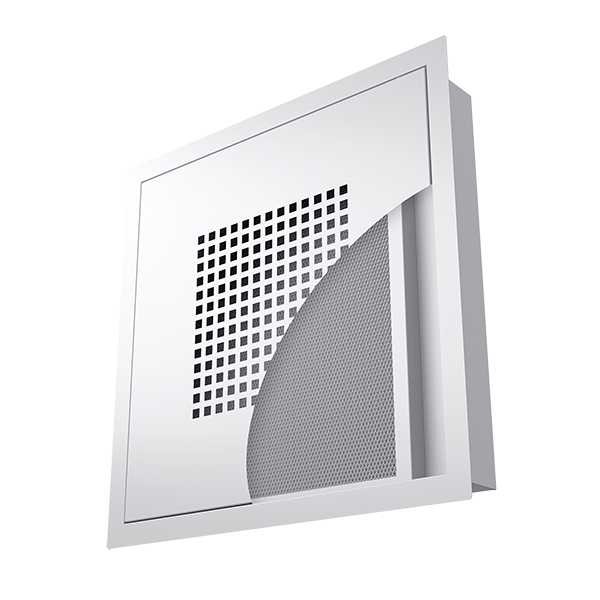

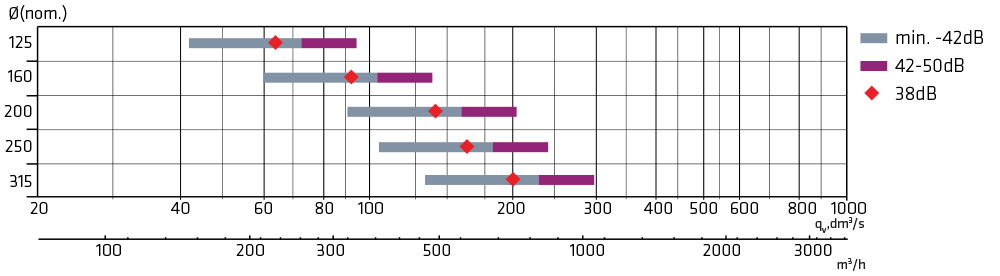

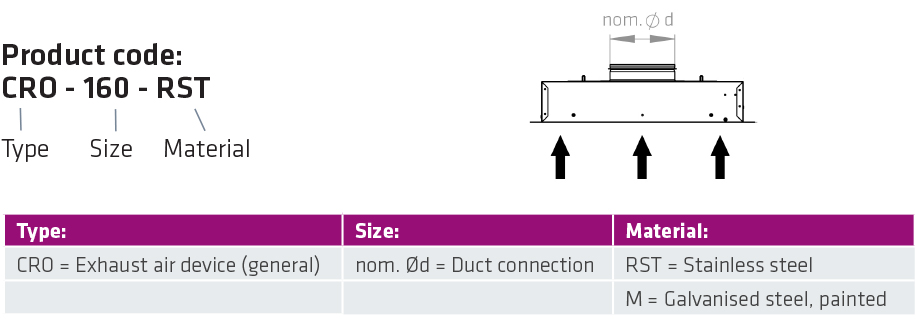

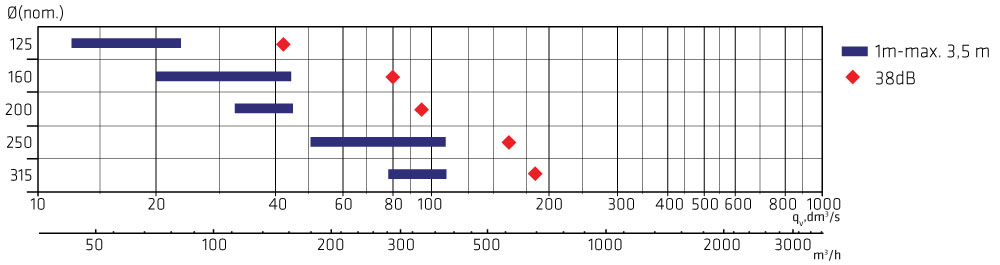

CRO Abluftdurchlass

Der CRO-Abluftdurchlass ist für die allgemeine Abfuhr der Luft konzipiert.

- Ausgestattet mit abnehmbarem und maschinenwaschbarem Filter

- Montage in abgehängter Decke

- Material: Edelstahl, optional auch in RAL 9016 lackiert erhältlich

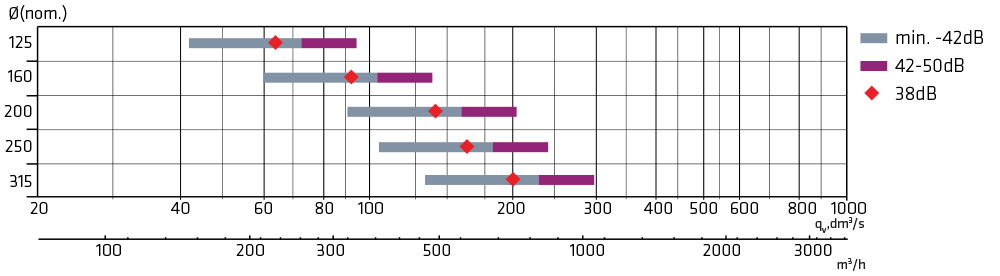

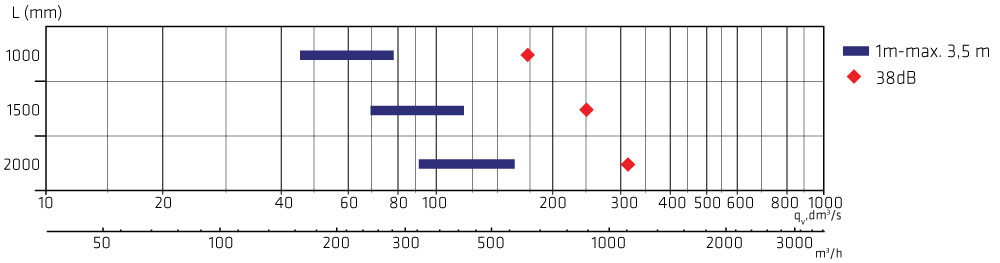

Schnellauswahl CRO

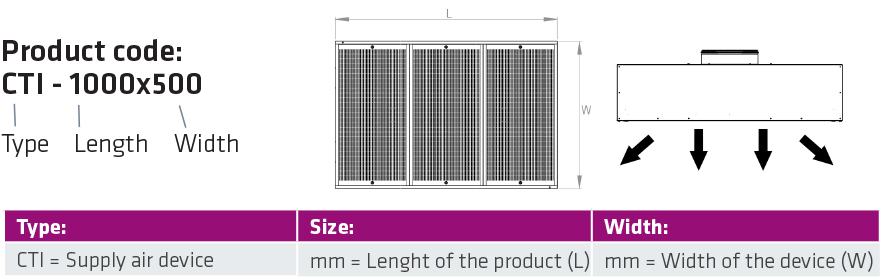

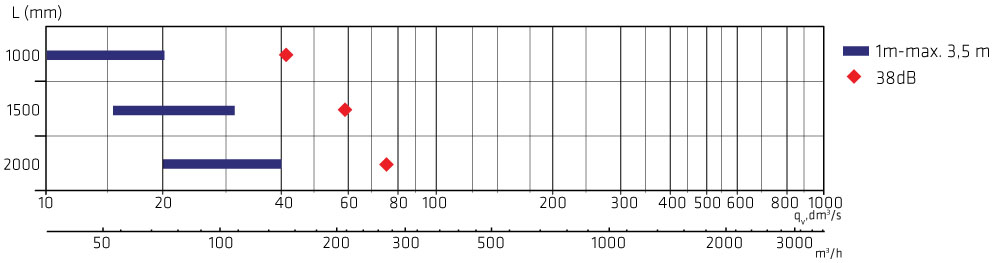

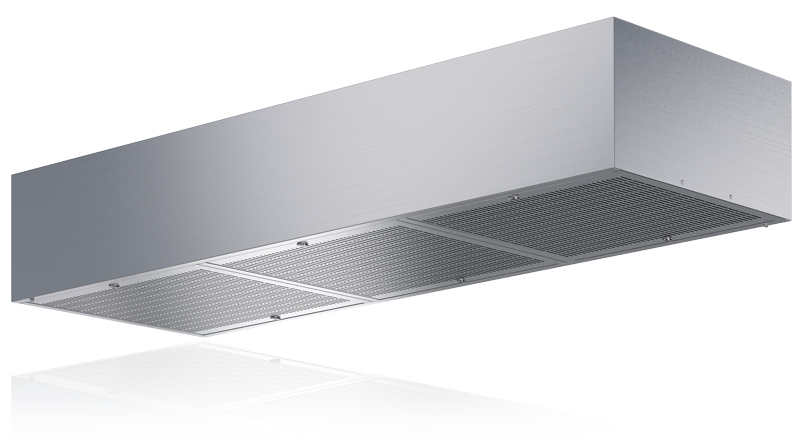

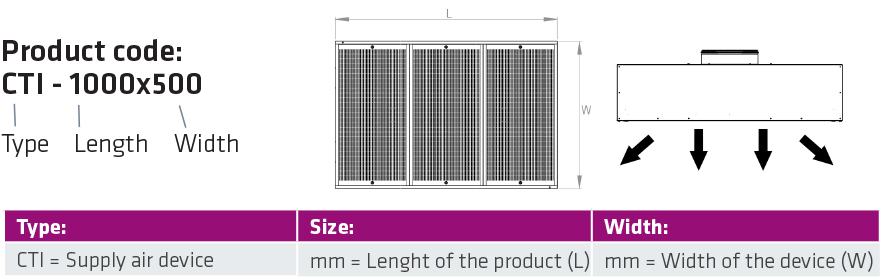

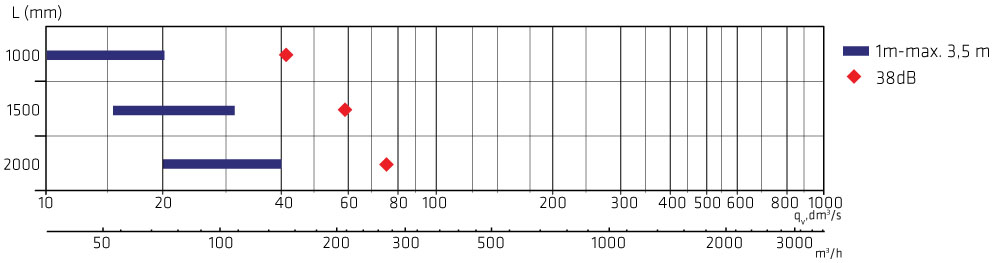

CTI Zulufteinheit

CTI-Zulufteinheit gewährleistet eine gleichmäßige und zugfreie Luftverteilung in der Profiküche.

- Ausrichtbares Verteilmuster

- Abnehmbare und maschinenwaschbare Zuluftmodule

|

|

|

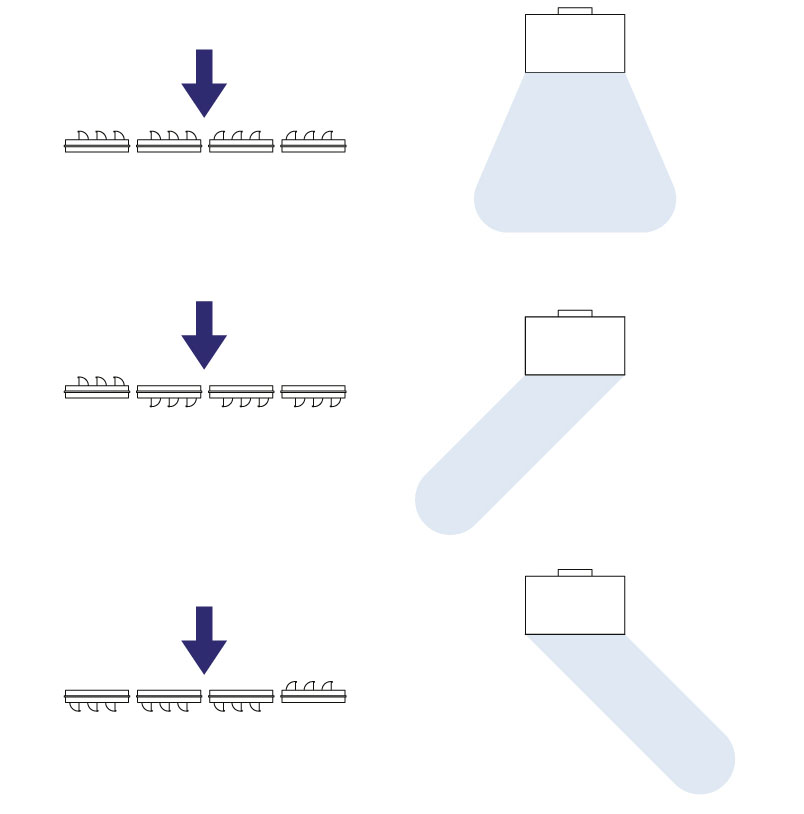

Verteilmuster

Das Verteilmuster von CTI lässt sich leicht lenken.

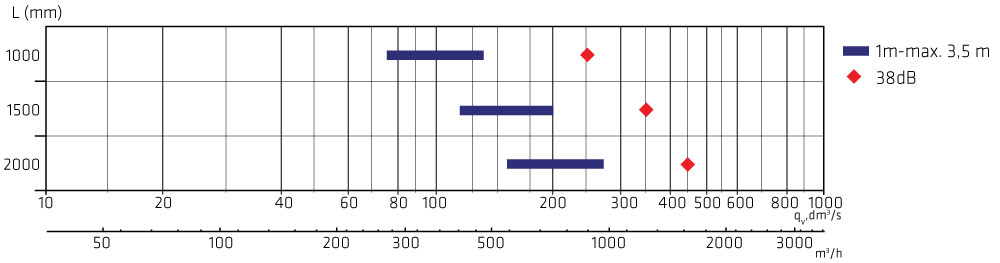

Schnellauswahl CTI W300

Schnellauswahl CTI W500

Schnellauswahl CTI W800

Schnellauswahl CTI W1000

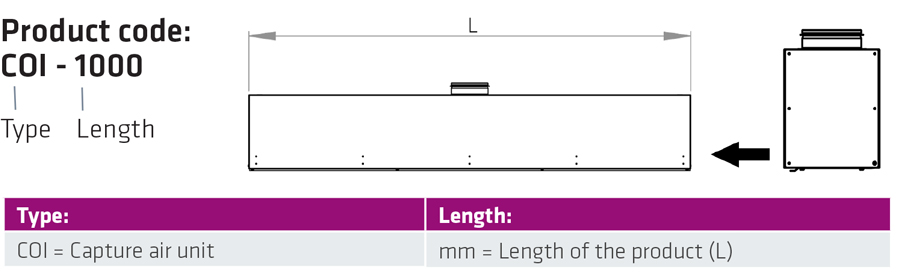

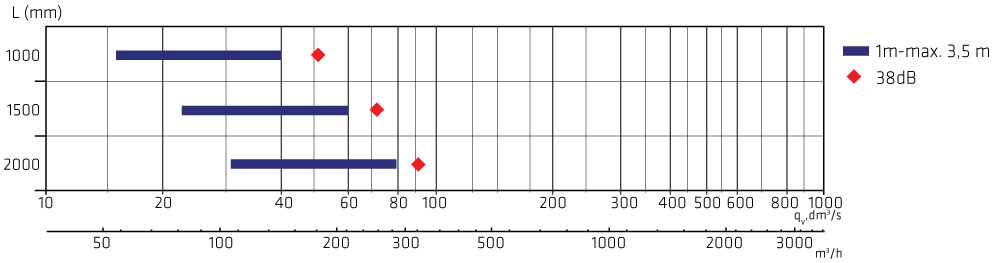

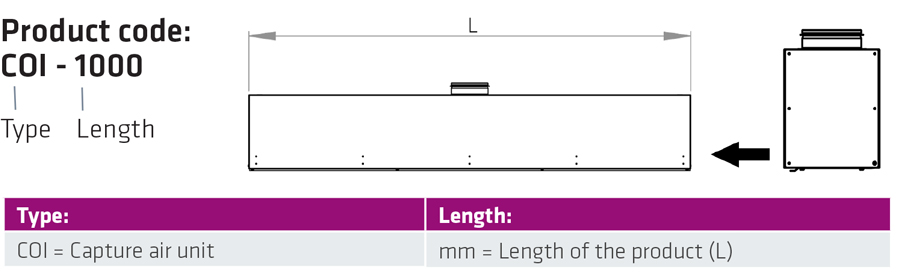

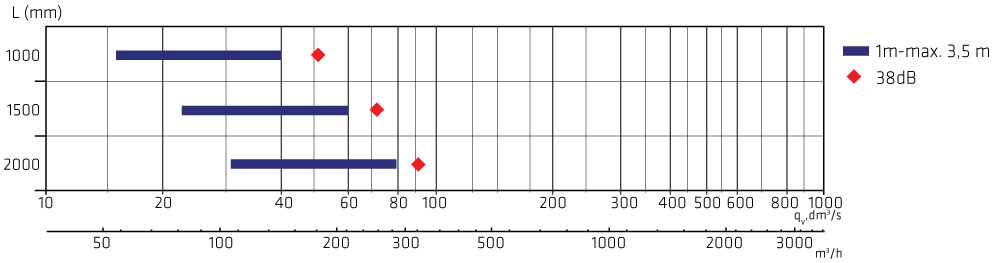

COI Lufterfassungseinheit

COI Lufterfassungseinheit leitet die Fettdämpfe effizient zu den Fettfiltern.

- Steigert die Leistung der Ablufteinheiten

|

|

|

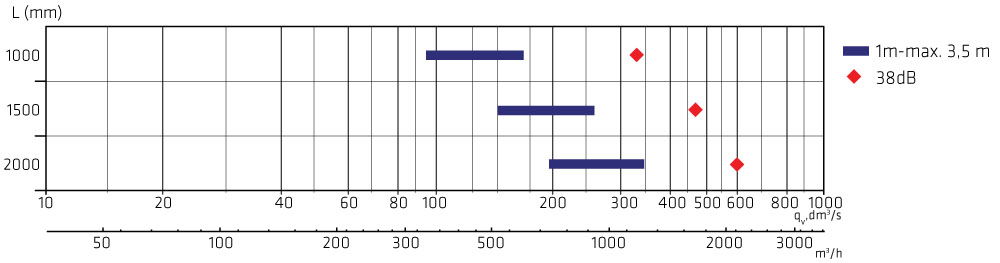

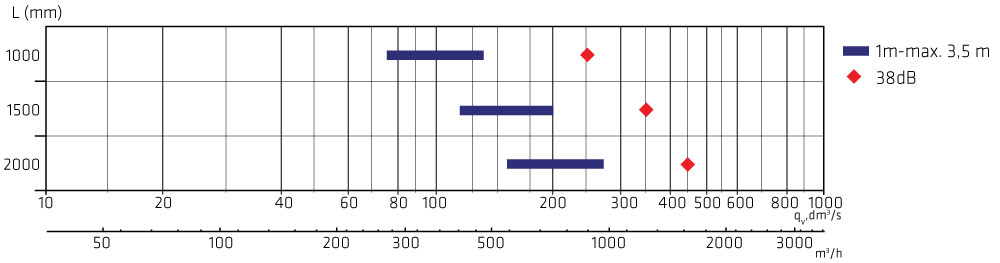

Schnellauswahl COI

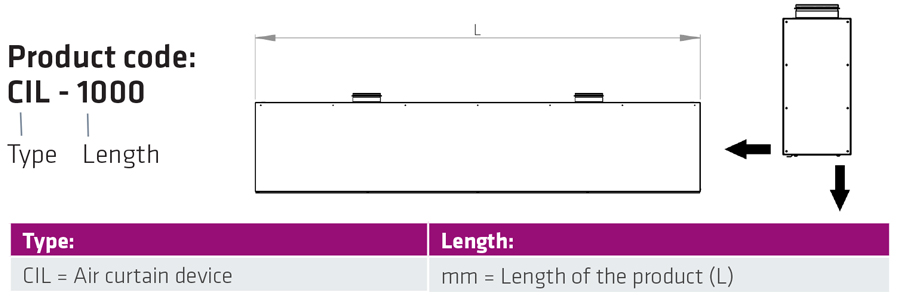

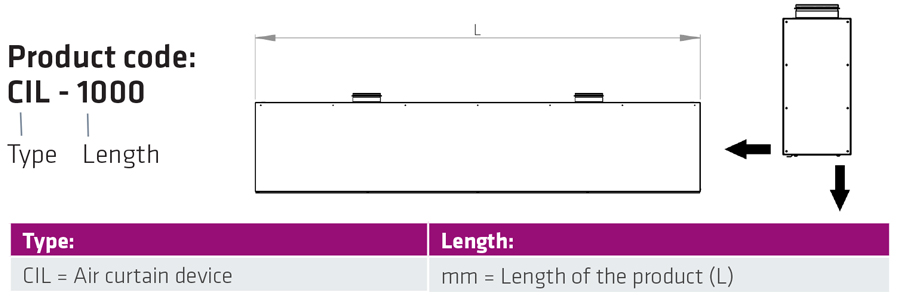

CIL Luftschleier

CIL-Luftschleier verhindern, dass Fettdämpfe aus dem Küchenbereich austreten.

- Werden in den Seitenbereichen der Küche eingesetzt

- Passen gut in offene Küchen

|

|

|

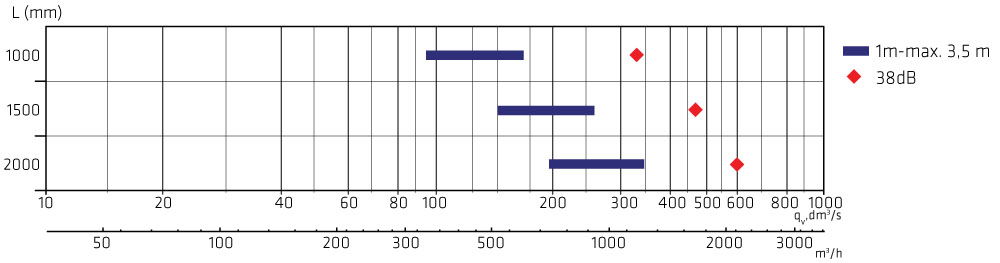

Schnellauswahl CIL

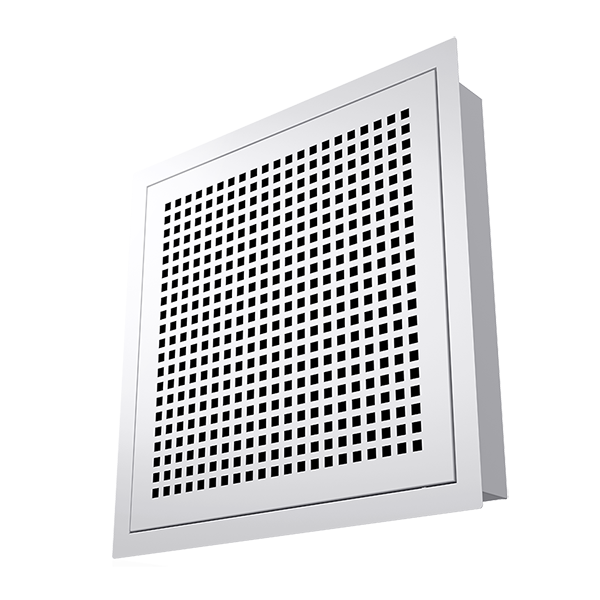

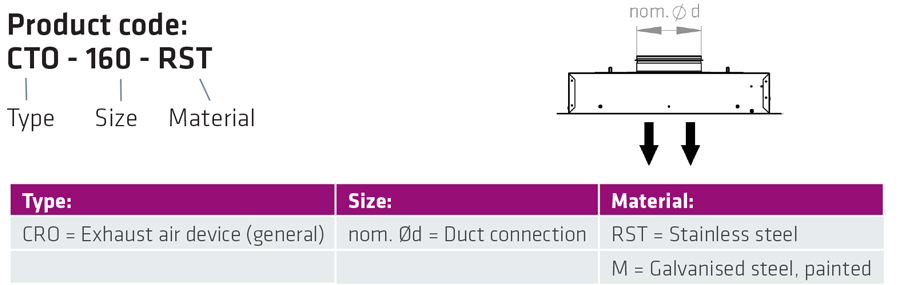

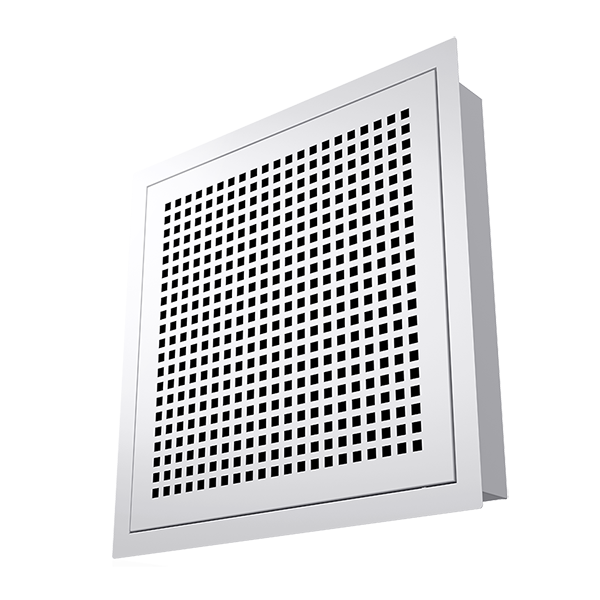

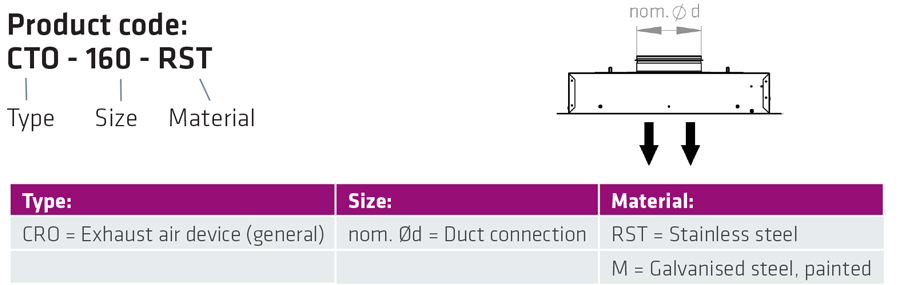

CTO Zuluftauslass

Die CTO-Zuluftauslass ist für die allgemeine Luftversorgung konzipiert.

- Einbau in abgehängte Decke

- Material: Edelstahl, aber auch weiß lackiert (RAL 9016) erhältlich

Schnellauswahl CTO

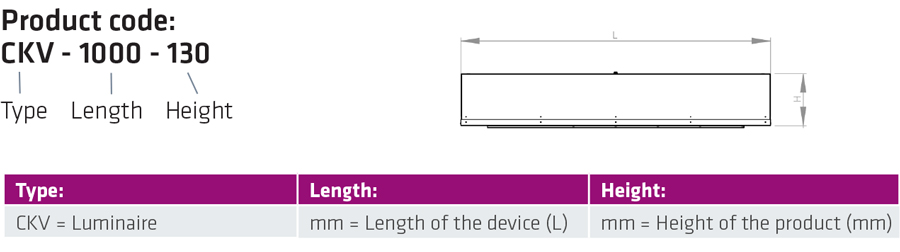

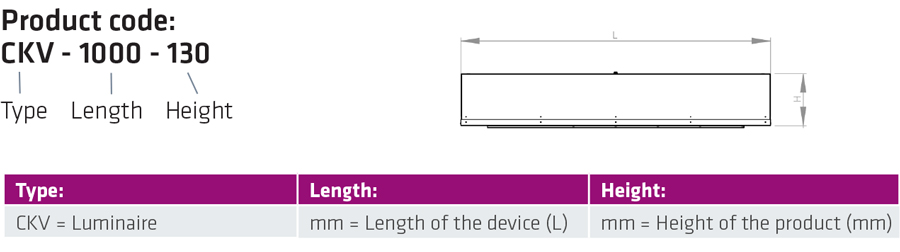

CKV Leuchte

CKV-Leuchten sorgen für eine angemessene und gleichmäßige Beleuchtung der Arbeitsplätze.

- Erhältlich mit T5-Leuchtstofflampe oder LED-Lampe

- Dampfdichte Konstruktion

|

|

|

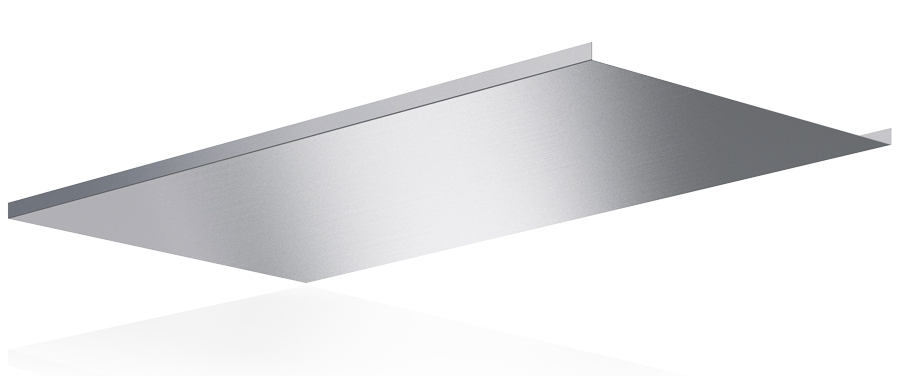

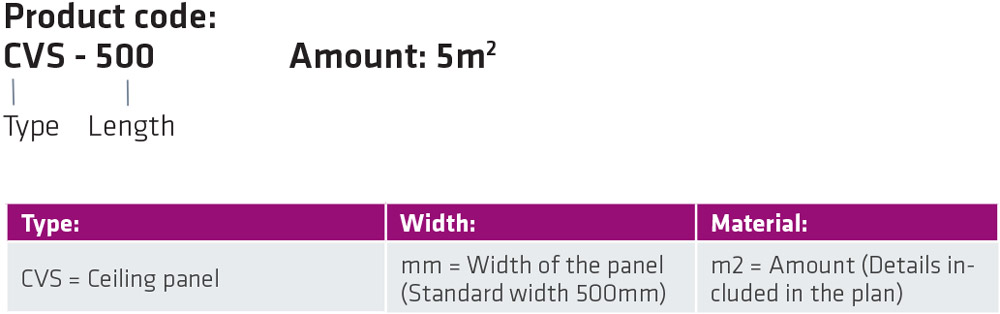

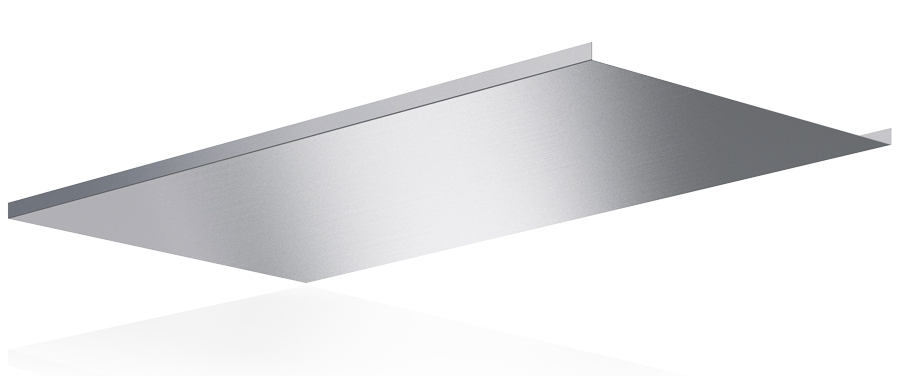

CVS Deckenplatte

Das stilvolle CVS-Deckenplatte besteht aus Edelstahl.

- Die Befestigung der Deckenplatten an den umliegenden Elementen erfolgt über die im Lieferumfang enthaltenen L- und T-Leisten

|

|

|

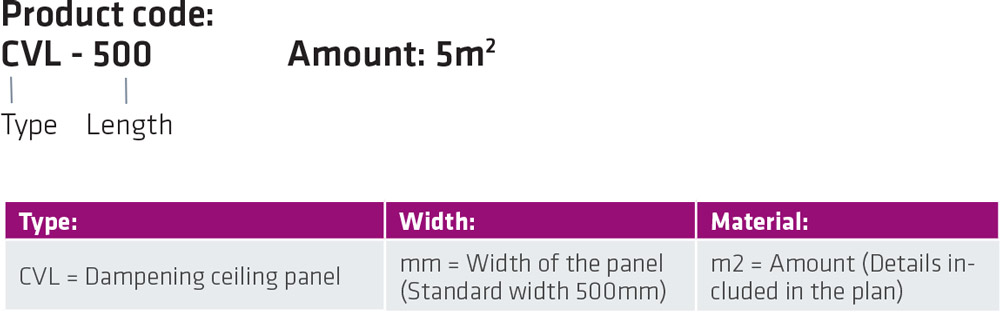

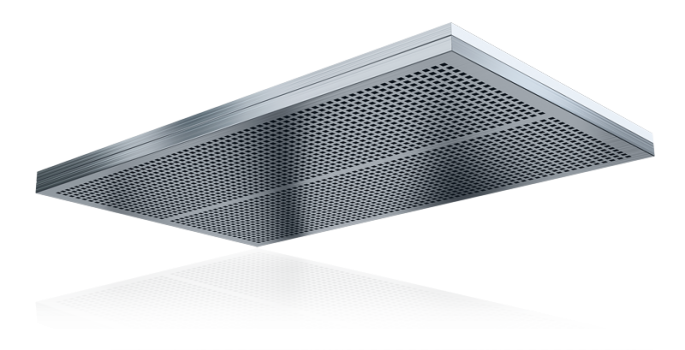

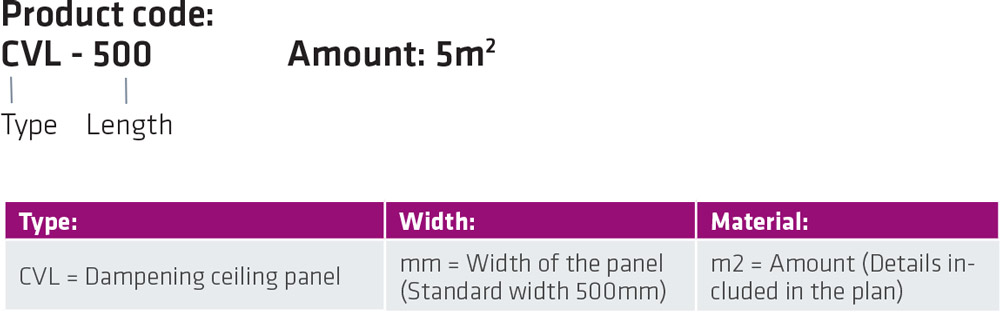

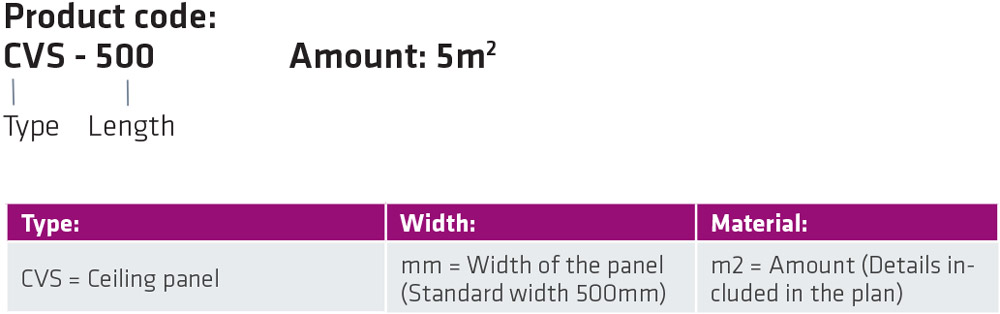

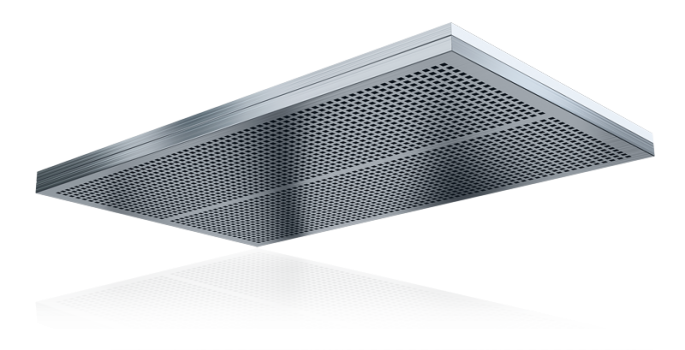

CVL Dämpfungsplatte

CVL-Dämpfungsplatten reduzieren Hintergrundgeräusche und verbessern die Arbeitsumgebung.

- Die in den Paneelen enthaltene Akustikplatte erfüllt die Hygieneanforderungen

- Schallabsorptionsgrad ist D

|

|

|