NOT supply air diffuser

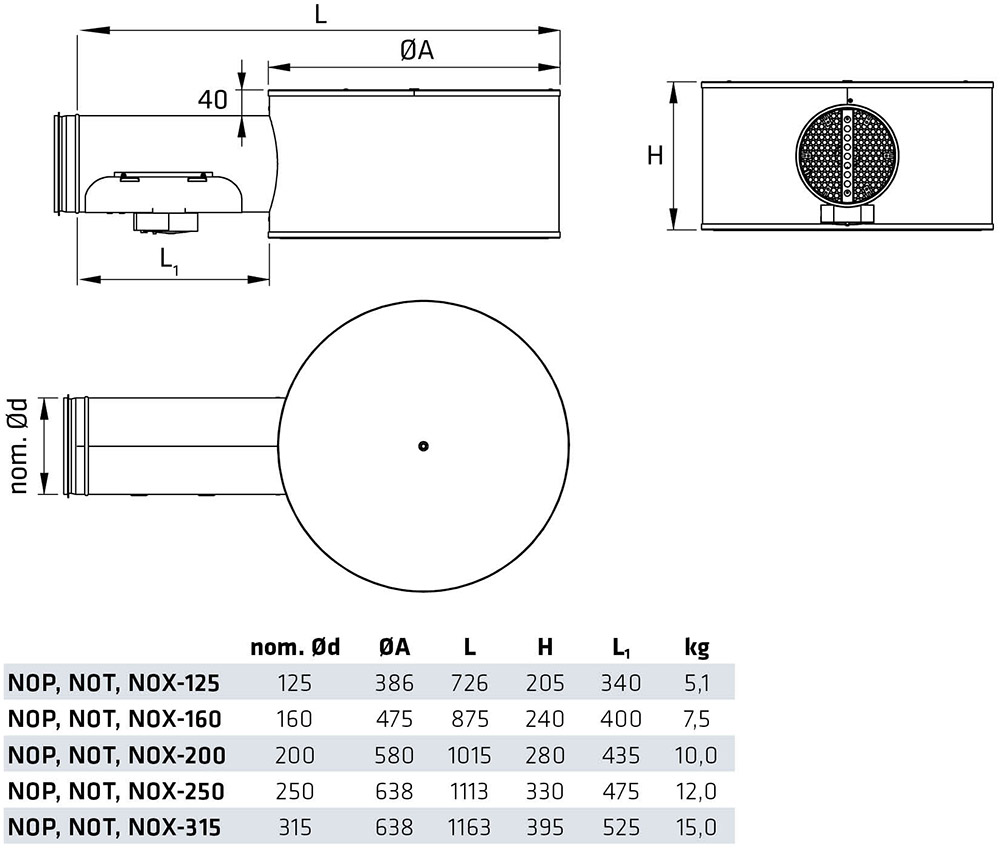

NOT supply air diffuserNOT supply air diffuser for free installation is extremely flexible in use. Whenever the layout or use of the space changes, the throw pattern may always be redirected to achieve the best possible, draught-free air distribution. Air flow range20-205 dm³/s, 72-738 m³/h Duct sizesØ 125-315 mm Sustainable productBiocomposite nozzles, CO2 footprint calculated, EPD calculated Color optionsRAL 9016 white (matte), RAL 9005 black (matte) DescriptionThe diffuser part may be changed afterwards. The product’s features can be changed to be more suitable for either cooling or heating, if the use of the rooms changes during the product’s lifecycle. NOT is especially suited for isothermal and low temperature air. NOX is particularly designed for handling overtemperature air. A unique characteristic of NOX is the possibility to turn the vertical throw pattern 30 degrees to the side. This is a huge advantage if the throw pattern becomes obstructed, for example due to changes in the room’s layout. NOT is a part of the new OptiFlow® product family!OptiFlow® products adapt to changes in the life cycle of the space due to an optimized and adaptable throw pattern. Features:

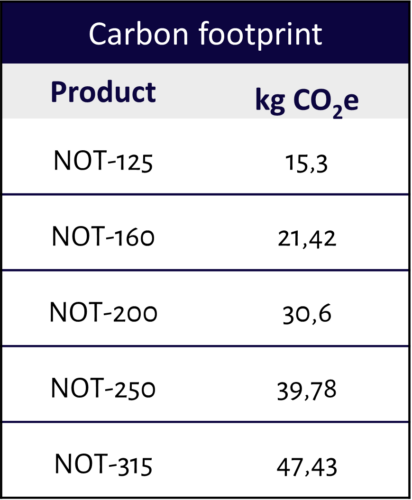

Carbon footprintThe carbon footprint of the products has been calculated as part of the requirements of the Building Information Foundation’s EPD environmental report.

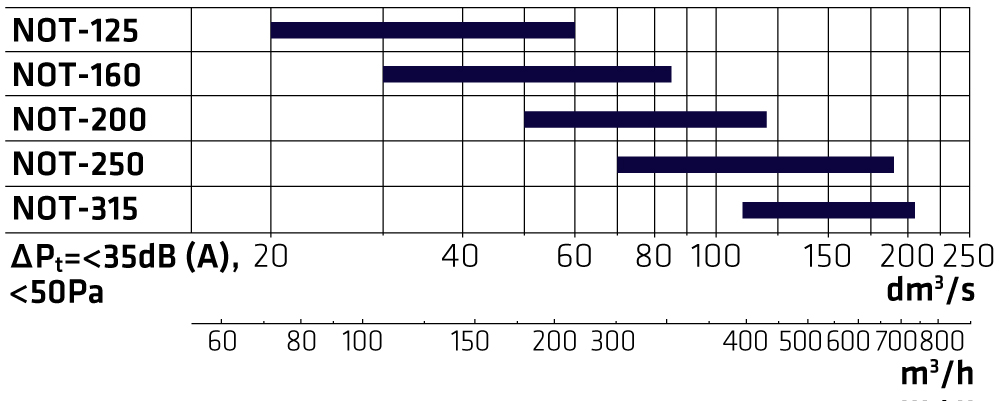

Quick selection guide

Sound level lower than 35 dB(A) at 50 Pa total pressure. NOTE! The S models achieve low sound levels even at significantly higher total pressure Pa values! NOT dimensions

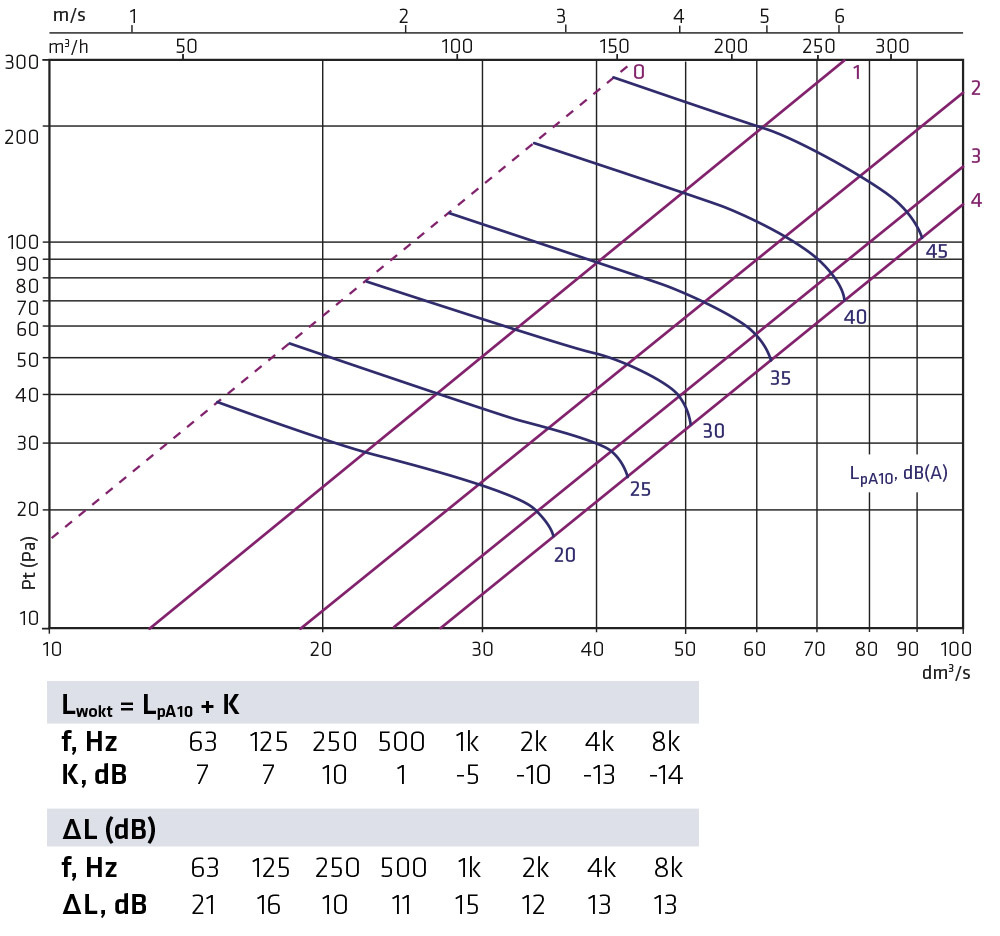

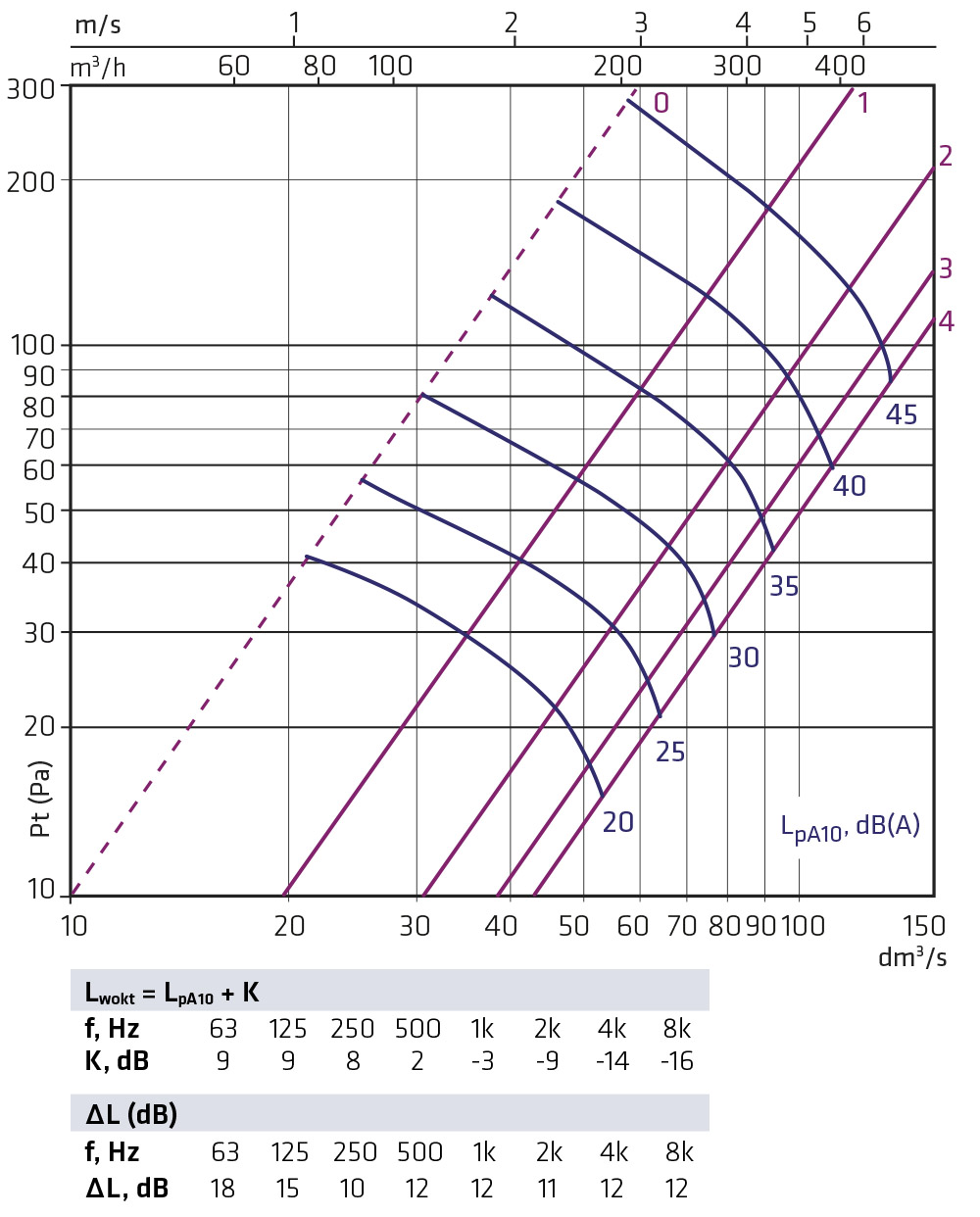

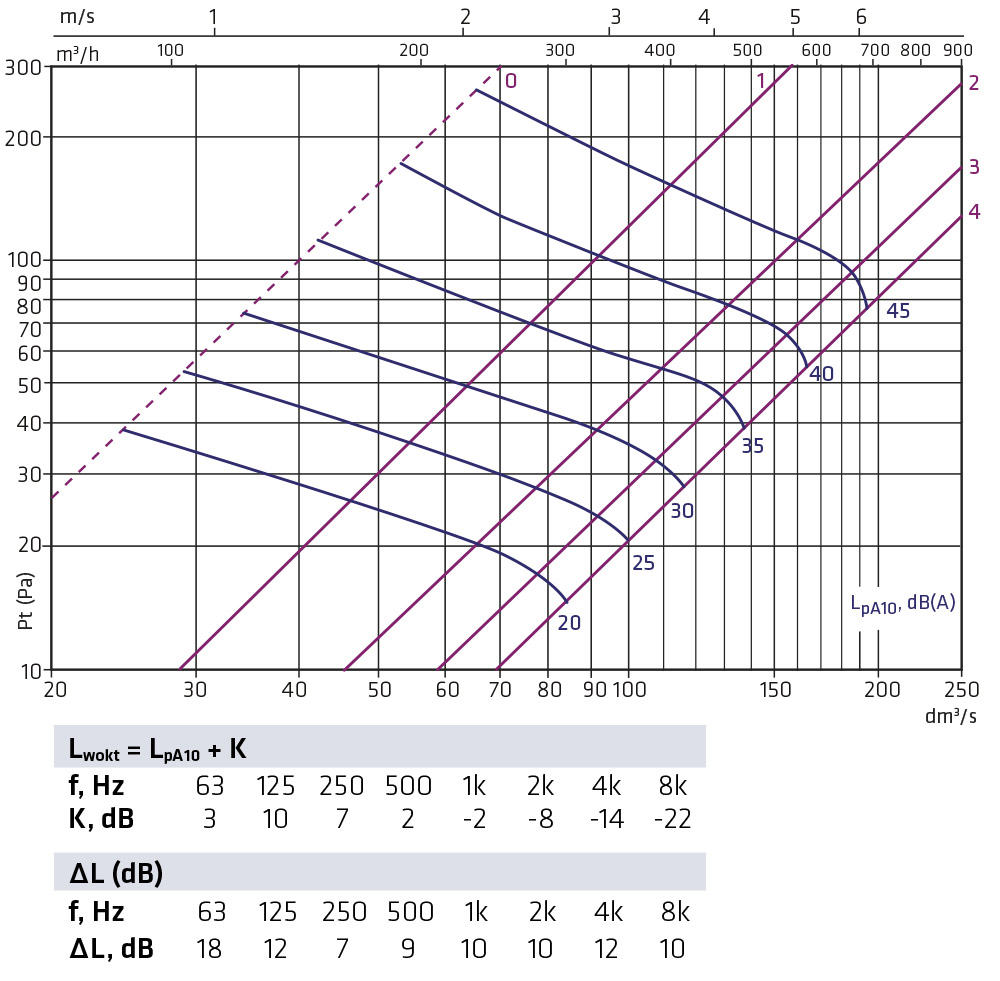

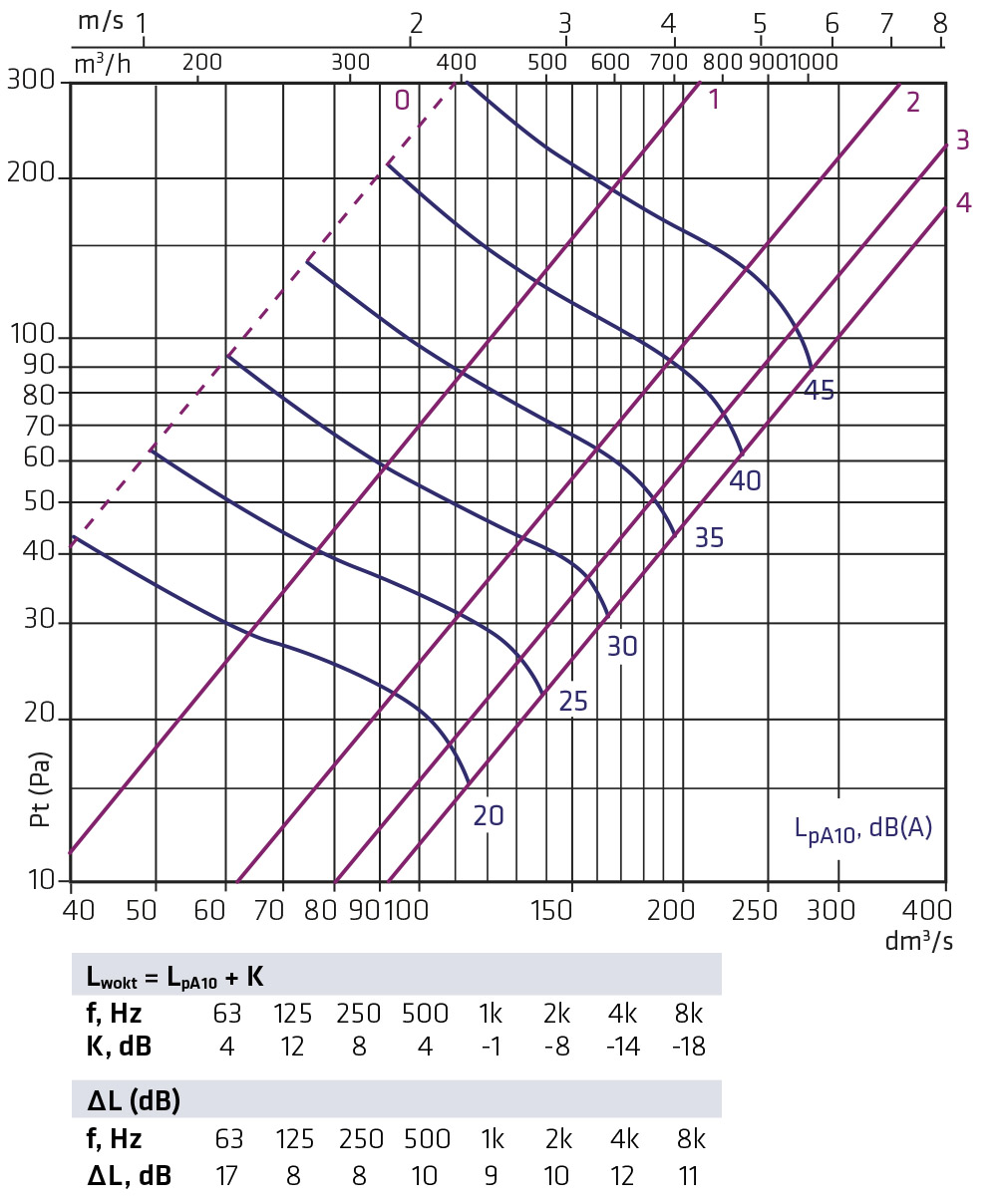

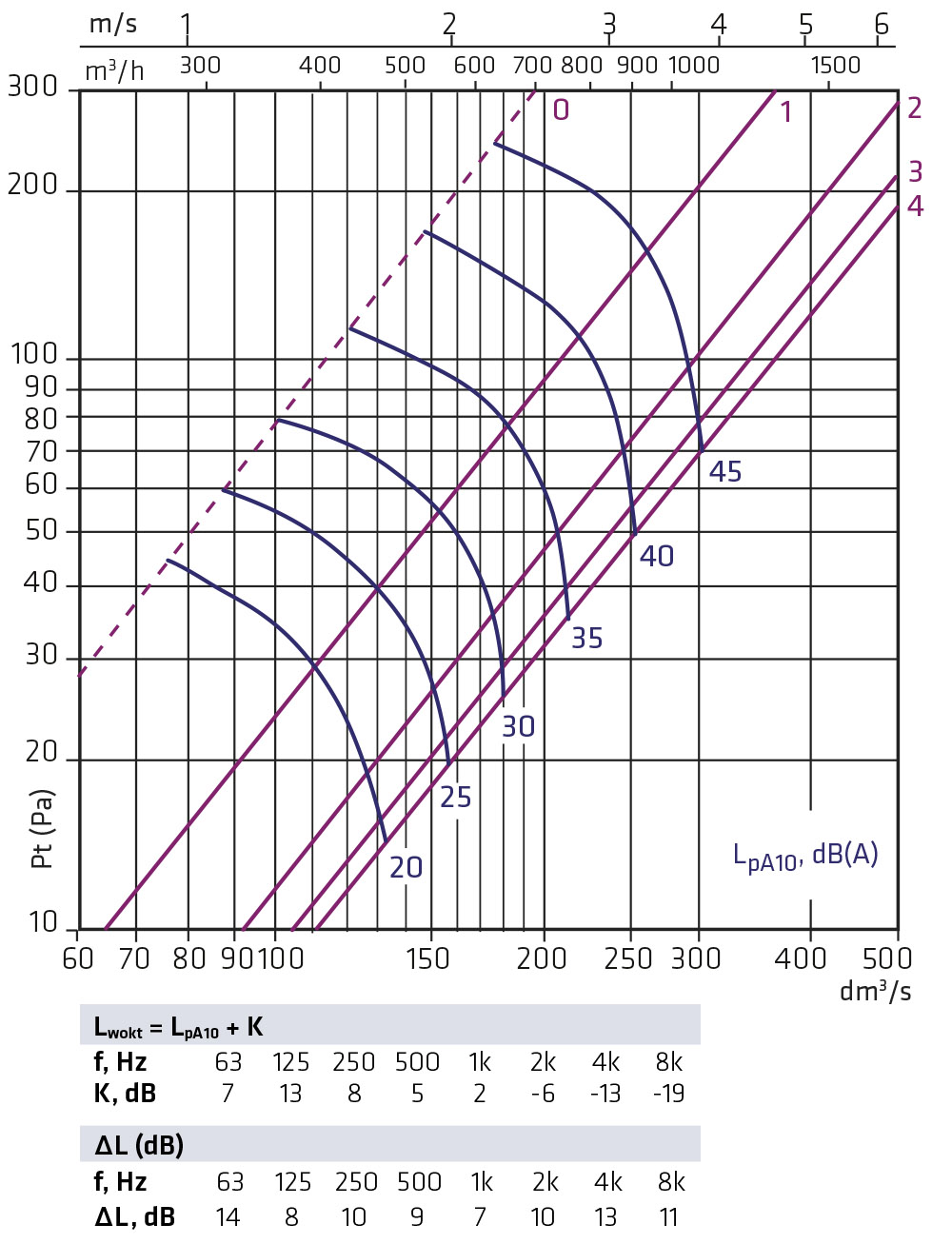

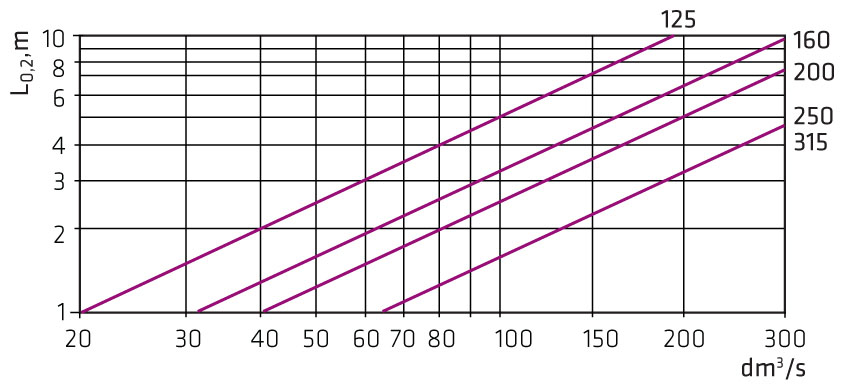

Selection diagramsThe graphs are not intended for adjustment. NOT-125

NOT-160

NOT-200

NOT-250

NOT-315

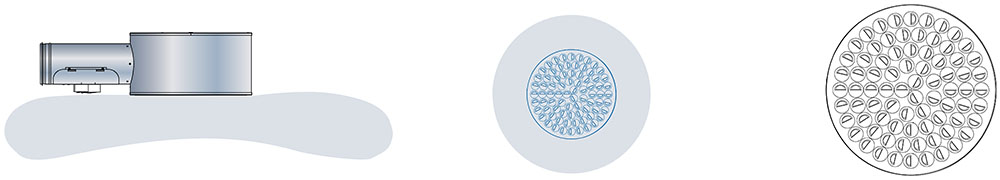

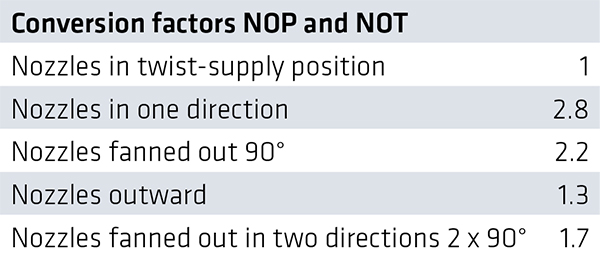

Throw patterns and throw lengthNOT and NOP throw patternsNozzles in twist-supply position

NOT and NOP alternative throw patternsNozzles in one direction

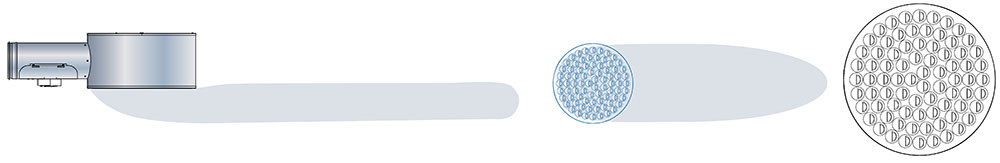

Nozzles fanned out 90°

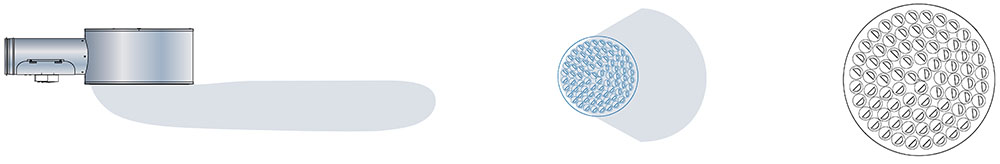

Nozzles outward

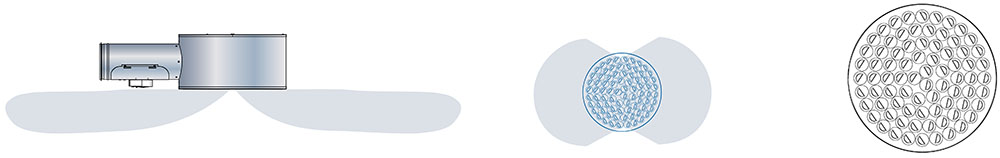

Nozzles fanned out in two directions 2 x 90°

Throw length

NOT adjustment unitNOT adjustment unit based on the static pressure difference measurement enables highly accurate air flow measurement and control. The adjustment unit allows a precise adjustment of airflow (± 5%) even at low airflows and duct speeds. NOT is easy to adjust

1. The pressure difference is measured from the measuring socket of the control unit.

2. This adjustment can be made by a screwdriver. The adjustment is done by rotating the control dial with the tool. The control dial readings correspond to separate k-values that can be found on the side of the adjustment unit. 3. The adjustment position can be locked with a screw. |